Documente Academic

Documente Profesional

Documente Cultură

Procedures Rev 2 English Vers.

Încărcat de

Benjamin Enmanuel Mango DDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Procedures Rev 2 English Vers.

Încărcat de

Benjamin Enmanuel Mango DDrepturi de autor:

Formate disponibile

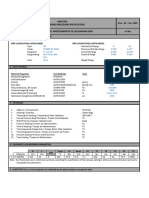

QUALITY MANAGEMENT PLAN

PP0089-13

"SYSTEM IMPROVEMENT TREAT. SEWAGE WASTEWATER"

PROJECT

WORK PROCEDURES

SURFACE PREPARATION AND COATING APPLICATION

PAGE

1 de 15

DATE

03/07/13

OVERVIEW

STRUCTURES, TANKS INTERIOR AND EXTERIOR

COATING PROCEDURES

OWNER

: SOCIEDAD MINERA CERRO VERDE S.A.A.

CUSTOMER

: ACCUAPRODUCT S.A.C

CONTRACTOR : PENTATECH CONSTRUCCIN S.A.C.

ITEM

DIRECTED

TO

REVIEWED

BY

WRITTEN BY

NAME

TITLE

SIGNATURE

Ing. Renzo Vargas

PENTATECH CONSTRUCCIN SAC

QUALITY CONTROL AND

ASSURANCE CHIEF

Ricardo Martnez

Sherwin Williams Per

Plant & Technical Dept.

Sub-Manager

03/07/13

Ing. Didiana Huaigua

Sherwin Williams Per

Commercial Tech Councelor

03/07/13

CONTROLLED COPY N

DATE

03/07/13

Effective Date::

ISSUE

DATE

CHANGES

REV 1

04/07/2013

NAME PROJECT CHANGED

01

QUALITY MANAGEMENT PLAN

"SYSTEM IMPROVEMENT TREAT. SEWAGE WASTEWATER"

PROJECT

WORK PROCEDURES

SURFACE PREPARATION AND COATING APPLICATION

TABLE OF CONTENTS

1. OBJECTIVE

2. SCOPE

3. STANDARDS AND REFERENCE DOCUMENTS

4. DEFINITIONS

5. COATING SYSTEM SPECIFIED

6. SURFACE PREPARATION AND APPLICATION

7. RESPONSABILITIES

8. INSPECTION

9. HEALTH, SAFETY AND ENVIRONMENT

10. APPENDICES

a. COVERAGE

b. WET FILM THICKNESS (WFT)

c. APPLICATION LOSS

d. TOUCH-UP PROCEDURE

PP0089-13

PAGE

2 de 15

DATE

03/07/13

OVERVIEW

01

QUALITY MANAGEMENT PLAN

"SYSTEM IMPROVEMENT TREAT. SEWAGE WASTEWATER"

PROJECT

WORK PROCEDURES

SURFACE PREPARATION AND COATING APPLICATION

PP0089-13

PAGE

3 de 15

DATE

03/07/13

OVERVIEW

1. OBJECTIVE

The current document will establish the procedures for: surface preparation, coating application for

interior and exterior tanks structures.

2. SCOPE

This procedure is applicable for coatings application of interior and exterior tank structures, new armed

tanks and for coated tanks beginning its preventive maintenance.

3. STANDARDS REFERENCE

Especificacin o contrato.

Norma NTP ISO 9001:2001, Quality Management Systems

SSPC : Society for Protective Coatings

ASTM : American Society for Testing and Materials

Organization

Standard

Description

SSPC

SP1

Solvent Cleaning

SSPC

SP11

Power Tool Cleaning to Bare Metal

SSPC

SP6/NACE N3

Commercial Blast Cleaning

SSPC

SP5/NACE N1

White Metal Blast Cleaning

SSPC

SP10/NACE N2

Near-White Metal Blast Cleaning

SSPC

AB1

SSPC

AB2

SSPC

AB3

SSPC

Vis1

SSPC

Guide 15

SSPC

PA1

Shop, Field, and Maintenance Painting of Steel

SSPC

PA2

Measurement of Dry Coating Thickness With Magnetic Gages

NACE

SP0188

ASTM

D 4285

ASTM

D 4417

ASTM

E 337

Abrasive specification/Mineral and Slag Abrasives

Abrasive specification/Cleanliness of Recycled Ferrous

Metallic Abrasives

Abrasive specification/Newly Manufactured or ReManufactured Steel Abrasives

Guide and Reference Photographs for Steel Surfaces

Prepared by Dry Abrasive Blast Cleaning

Field Methods for Retrieval and Analysis of Soluble Salts on

Steel and Other Nonporo.

Discontinuity (Holiday) Testing of New Protective Coatings

on Conductive Substrates

Standard Test Method for Indicating Oil or Water in

Compressed Air

Field Measurement of Surface Profile of Blast Cleaned Steel

Measuring Humidity with a Psychrometer

01

QUALITY MANAGEMENT PLAN

PP0089-13

"SYSTEM IMPROVEMENT TREAT. SEWAGE WASTEWATER"

PROJECT

WORK PROCEDURES

SURFACE PREPARATION AND COATING APPLICATION

ASTM

D 4414

ASTM

D 4541

ASTM

D5162

ISO

8502-3

PAGE

4 de 15

DATE

03/07/13

OVERVIEW

Measurement of Wet Film Thickness by Notch Gages

Standard Test Method for Pull-Off Strength of Coatings Using

Portable Adhesion Testers

Standard Practice for Discontinuity (Holiday) Testing of

Nonconductive Protective Coating on Metallic Substrates

Loose particulate present on a steel surface prepared for

painting arising from blast cleaning

4. DEFINITIONS

4.1. Specificaction

Referred to the cautions taken on the surface coating, considering all possible factors for the protection

to be lasting. Each project has a specification prevaling for surface preparation and application, coating

and inspections to be carried out on the coated structures.

4.2. Coating Systems

Referred to the Type and total number of coats to be applied on the substrate, under predetermined

order.

4.3. Contractor

Organization responsible before the coating application owner.

4.4. Register

Document which provides objective evidence of the performed activities or obtained results.

4.5. Quality Records

Are the support, on paper, microfilm or digital file which reflects and copy the results of variable

nature, which are direct or indirect consequence of the activities performed related to the applied

quality during coating application.

4.6. Filing

Physic or digital media (folder, portfolio or similar) where are kept and mantained the Records and/or

documents resulting of the Quality Management Plan.

5. COATING SYSTEM SPECIFIED

5.1 Surface Preparation

5.1.1.

Structures and Tank Exterior (System 2)

Type

Commercial Blast Cleaning

Standard

SSPC-SP6/NACE N3

Roughness Profile 2.0 mils

5.1.2.

Interior de Tanque (Sistema 4)

Type

Near-White Metal Blast Cleaning

Roughness Profile 2.0 mils

Standard

SSPC-SP10/NACE N2

01

QUALITY MANAGEMENT PLAN

PP0089-13

"SYSTEM IMPROVEMENT TREAT. SEWAGE WASTEWATER"

PROJECT

WORK PROCEDURES

SURFACE PREPARATION AND COATING APPLICATION

PAGE

5 de 15

DATE

03/07/13

OVERVIEW

5.2 Coating System (Structures and Tank Exterior)

Coat

Paint

EPS (mils)

Base

ZINC CLAD 60

2.5

Finishing

MACROPOXY 850

5.0

EPS TOTAL (mils)

7.5

5.3 Coating System (Interior)

Coat

Paint

EPS (mils)

Base

Macropoxy 850

6.0

Finishing

Macropoxy 850

6.0

EPS TOTAL (mils)

12.0

6. SURFACE PREPARATION AND COATING APPLICATION

Before starting with coating, the contractor representatives must meet with the owner and the

technical consultant of Sherwin Williams to unite concepts, coating acceptance criteria and

standards which will determine the linings for coating application.

6.1. Surface Preparation

Type

Solvent Cleaning

SSPC-SP1

Near-White Metal Blast Cleaning

Commercial Blast Cleaning

SSPC-SP10 / NACE N2

SSPC-SP6 / NACE N3

6.1.1.

Standard

Prior Cleaning

Remove by mechanical tools: scum and welding burr, all sharp or jagged edges must be done

smooth.

If steel surfaces are found contaminated with grease and/or oil, must be washed with water and

industrial detergent and then be rinsed with fresh water according to Standard SSPC-SP1.

SSPC-SP1: Solvent Cleaning: Remove all visible grease, oils, cutting compounds and other soluble

contaminants from steel surfaces using some of the following methods: cleaned brushes or wipers

soaked in solvent, solvent spraying chlorine, alkaline detergents, etc. It is intended that solvent

cleaning be used prior to the application of paint and in conjunction with surface preparation

methods specified for the removal of rust, mill scale, or paint.

01

QUALITY MANAGEMENT PLAN

"SYSTEM IMPROVEMENT TREAT. SEWAGE WASTEWATER"

PROJECT

WORK PROCEDURES

SURFACE PREPARATION AND COATING APPLICATION

6.1.2.

PP0089-13

PAGE

6 de 15

DATE

03/07/13

OVERVIEW

Abrasive Blasting Cleaning

SSPC-SP6 Commercial Blast Cleaning: When viewed without magnification, the surface shall be free of

all visible oil, grease, dust, dirt, mill scale, rust, coating, oxides, corrosion products and other foreign

matter of at least 66-2/3% of unit area, which shall be a square 3 in. x 3 in. (9 sq. in.). Light shadows,

slight streaks, or minor discolorations caused by stains of rust, stains of mill scale, or stains of previously

applied coating in less than 33-1/3% of the unit area is acceptable

SSPC-SP10 Near-White Blast Cleaning: This joint standard covers the requirements for near-white blast

cleaning of unpainted or painted steel surfaces by the use of abrasives. These requirements include the

end condition of the surface and materials and procedures necessary to achieve and verify the end

condition. A near-white metal blast cleaned surface, when viewed without magnification, shall be free of

all visible oil, grease, dust, dirt, mill scale, rust, coating, oxides, corrosion products, and other foreign

matter, except for staining as noted. Random staining shall be limited to no more than 5 percent of each

unit area of surface as defined, and may consist of light shadows, slight streaks, or minor discolorations

caused by stains of rust, stains of mill scale, or stains of previously applied coating.

6.1.3.

Requirements and general aspects for abrasive blasting

Before abrasive blasting must be evaluated the compressed air to the standard ASTM D4285.

For abrasive quality testing, if mineral or slag) must be performed Chloride Analysis, for exposed

surfaces to weather is recommended that the abrasive has a chloride concentration less than 100

ppm and for inmersed surfaces less than 40ppm.

Testing on Non Metallic Abrasives (mineral and slag) according to the SSPC - AB1.

Testing on Metallic Abrasives (shot) according to the SSPC - AB2 and SSPC - AB3.

Check nozzle diameter and outlet pressure from nozzle. For best results pressure must be between

90 to 100 psi.

Surface Preparation by Abrasive-blasting to fulfill the specified standards for each coating system

The roughness profile recommended for this project is from 1.5 to 2.0 mils.

We recommend that people who do this work have leather gloves to avoid contamination by

sweating.

At the end of the abrasive blasting, must be cleaned by compressed air and if necessary to

supplement with nylon brush, to remove all traces of the abrasive surface preparation. Take the

pictorial references corresponding to the qualification of residual dust quantity on surfaces before

coating in classes of 0 to 5 according to ISO 8502-3, may be taken as acceptance criteria rating

classes from 0 to 2.

In the case of surfaces treated with non metallic abrasives (mineral and slag), must verify the

concentration of remaining salts in the surface according to SSPC Guide 15 standard. The

admisible values are: for inmersed and buried surfaces < 3 ppm, for exposed surfaces to weather < 7

ppm (reference SSPC SP12).

In structures areas where joints are welded with another one, we recommend taping borders with

Masking tape (2 inch), to minimize damage to the applied coat.

01

QUALITY MANAGEMENT PLAN

"SYSTEM IMPROVEMENT TREAT. SEWAGE WASTEWATER"

PROJECT

WORK PROCEDURES

SURFACE PREPARATION AND COATING APPLICATION

PP0089-13

PAGE

7 de 15

DATE

03/07/13

OVERVIEW

6.2. Coating Application

6.2.1.

Coating Equipments

Contractor Coating equipment must be in good conditions in order to perform an application without

any problems and achieve best coverage and application time Consider the following:

Choose the application method according to coating type.

Have the necessary gauges for application pressure display (in case of using equipments)

Airless Equipments): A good selection of tip and proper pressure of the equipment will help to

obtain better performance and quality.

Conventional Equipments: It is important to consider a pressure equipment with a good selection

of nozzles, valves and needle depending on coating type to be applied. To obtain best coverage

with these equipments is necessary to make major dilution than airless equipment.

Suction equipment (Siphon feed gun) can also be used only for touch up as these equipments

tend to spray more as they work with major dilution.

Brushes and Rollers: Must be resistant and adequate to solvent based coating for finishing

application coats. These devices are used for touch up in specific areas, although the finishing will

not be the same as to applied with equipments.

6.2.2.

Weather Conditions

Consider the following weather conditions for coating:

% Relative Humidity < 85.0

Surface T < 45.0 C

Surface T T dew point 3.0 C

Wind Speed no less than a 8 Km/h

Weather conditions must be considered for all coating application, by applying under unsuitable

weather conditions can bring consequences such as peeling of multiple coats or a different

finishing than expected.

6.2.3.

Coating Preparation and Application

Once the surface is prepared, cleaned and dried, proceed to mix the coat following these

recomendations.

La preparacin de pintura debe realizarse en recipientes totalmente limpios. Se debe homogenizar

Coating preparation must be done in clean containers. Must homogenize the coating separately

both part A (resin) as part B (hardener)

Add part B to part A and homogenize with electric agitator or pneumatic type Jiffy, for a maximum

of 3 minutes until the mixture takes uniform appearance, add thinner only after the mix of both

components is completed. Filter to another container with mesh of 30 to 60 or Nylon fabrics.

01

QUALITY MANAGEMENT PLAN

PP0089-13

"SYSTEM IMPROVEMENT TREAT. SEWAGE WASTEWATER"

PROJECT

WORK PROCEDURES

SURFACE PREPARATION AND COATING APPLICATION

PAGE

8 de 15

DATE

03/07/13

OVERVIEW

Each pass of the spray gun shall overlap by 50% to avoid holidays, bare areas and pinholes. If

required, cross spray at right angles to first pass. The gun must always be perpendicular to the

surface at a distance of 25 cm for a conventional equipment and 30 cm for an airless equipment.

It is better for the coating to be applied with natural light, in case of requiring use of artificial

lighting area lighting shall be more than 530 lumen /m2, white light of preference.

When exceeding pot life of the coating brings a variation of viscosity losing moisture and levelling

properties so it should be discarded.

Cure is accomplished at 7 days at 25 C and will also depend on the area temperature.

6.2.4.

First Coat Application (Structures and Tank Exterior)

Zinc Clad 60 BR, is an inorganic zinc primer, ethyl silicate type supplied in two parts, liquid base and zinc

dust. It gives an outstanding and longlasting galvanic protection to carbon steel and prevents the corrosive

progression under the film in case of damage of the paint system.

The mixture requires constant agitation during use and application, otherwise, the zinc dust will settle

quickly.

When the environment relative humidity is below to te stated, the film must be water sprayed two

hours after the application , every 3 hours to assure its cure.

Due to fast dry of this product the wet film thickness measure is not possible, therefore the measure is

through its coverage.

El zinc Clad 60 is not repaintable to itself, which means if for any reason occurs a low thickness could not

be repaint with the same product. If found zones with low thinckness, this lacking thickness will be

recovered by an organical zinc paint application.

Prior to the following coat application should be done a mist coat, consisting on the application of a coat

from 1.5 to 2 mils diluted to 40%.

After mist coat application wait a lapsing time before general application of the next coat.

El Zinc Clad 60 has a relation to weight, though is not practical to prepare 1/4 or 1/8 gallon, but using a

scale to measure Zinc dust.

PRODUCT

Solvent

Zinc Clad 60

P30

Application

Airless Equipment

Conventional Equipment

Brush or Roller

%Volume

Solids

Mix

Proportion

Pot life at

o

25 C

612

Resin Kit and

filler Zinc

Clad 60 (1

gallon)

4 hours

Repainted at 25 C

min

mx

10 hours

No

restriction

% vol. dilution

Nozzle

Spraying Pressure (psi)

Up to 15%

0.017 - 0.019

1800 - 2500

FF o FX 704.

50

---

---

Up to 10%

---

01

QUALITY MANAGEMENT PLAN

PP0089-13

"SYSTEM IMPROVEMENT TREAT. SEWAGE WASTEWATER"

PROJECT

WORK PROCEDURES

SURFACE PREPARATION AND COATING APPLICATION

6.2.5.

9 de 15

DATE

03/07/13

OVERVIEW

Mist Coat

Is a thin film coat with ideal characteristis applied to seal an absorbent dry film as shown in

inorganic paints based Ethyl Silicate as Zinc Clad 60, during its cure process where organic vapors

produced on the formulation leaves empty spaces (air) that must be filled properly letting a

continous film of low thickness dry film which removes the air captured on these spaces.

Mist Coat Application is a thin coat diluted between 40 50 %, in this case of Macropoxy 850, this

thin coat must assure proper seal, which will depend on the technique and expertise of the paintor,

can be applied with nozzles of 0.013 or 0.015 (Airless).

After Mist Coat application, wait an time lapse of 60 to 90 minutes before general application of full

coat (Macropoxy 850) reaching the specified thinckness.

6.2.6.

PAGE

Stripe coat

After applying the first coat, all welds, edges, corners and hard to reach areas shall be striped

with brush or roller as these areas are critical points of premature failure of the coating system.

A reinforcement on each edge, living angle and weld bead is commonly specified since liquid

coatings tend to flow out of these places. This is a result of weathering during curing. If occurs, the

film close to edges will be thinner than the rest of the surface and the result can lead to premature

corrosion in those areas. This situation can become critical when coating fails to nuts, edges, flanges

and weld because these are those that hold the pieces together.

Stripe Coat shall be applied after the first coat and before the second or top coat of paint for any

application system, with the product of the next coat.

6.2.7.

Second Coat Aplication (Structures, Tank Exterior)

Macropoxy 850.- is a product based on polyamide epoxy of high thickness and fast drying, designed for

protecting steel and concrete exposed to industrial environments. Ideal for the finish of industrial

machinery and equipment. Its high solid content assures a proper protection to edges, corners and

welded areas. This product may be applied directly to barely prepare steel surfaces

PRODUCT

Macropoxy 850

Solvent

P33

Application

%Volume

Solids

Mix

Proportion

Pot life at

o

25 C

852

1A : 1B

4 hours

Repainted at 25 C

min

mx

10 hours

3 months

% vol. dilution

Nozzle

Spraying Pressure (psi)

Airless Equipment

Up to 15%

0.017 - 0.023

3000-3800

Conventional Equipment

Up to 20%

E-704

60-65

Brush or Roller

Up to 20%

---

---

01

QUALITY MANAGEMENT PLAN

PP0089-13

"SYSTEM IMPROVEMENT TREAT. SEWAGE WASTEWATER"

PROJECT

WORK PROCEDURES

SURFACE PREPARATION AND COATING APPLICATION

6.2.7

PAGE

10 de 15

DATE

03/07/13

OVERVIEW

First and Second Coat Application (Tanks Interior)

Macropoxy 850.- is a product based on polyamide epoxy of high thickness and fast drying, designed for

protecting steel and concrete exposed to industrial environments. Ideal for the finish of industrial

machinery and equipment. Its high solid content assures a proper protection to edges, corners and

welded areas. This product may be applied directly to barely prepare steel surfaces.

PRODUCT

Macropoxy 850

Solvent

P33

Application

Mix

Proportion

Pot life at

o

25 C

852

1A : 1B

4 hours

Repainted at 25 C

min

mx

10 hours

3 months

% vol. dilution

Nozzle

Spraying Pressure (psi)

Airless Equipment

Up to 15%

0.017 - 0.023

3000-3800

Conventional Equipment

Up to 20%

E-704

60-65

Brush or Roller

Up to 20%

---

---

6.2.8.

6.

%Volume

Solids

Stripe coat

After applying the first coat, all welds, edges, corners and hard to reach areas shall be striped

with brush or roller as these areas are critical points of premature failure of the coating system.

A reinforcement on each edge, living angle and weld bead is commonly specified since liquid

coatings tend to flow out of these places. This is a result of weathering during curing. If occurs, the

film close to edges will be thinner than the rest of the surface and the result can lead to premature

corrosion in those areas. This situation can become critical when coating fails to nuts, edges, flanges

and weld because these are those that hold the pieces together.

Stripe Coat shall be applied after the first coat and before the second or top coat of paint for any

application system, with the product of the next coat.

RESPONSIBILITIES

The contractor must have technical personnel qualified in preparation of surface and application as

well as calibrated inspection equipments and in optimal conditions, as minimum: psychrometer,

surface thermometer, wet and dry film thickness gauge.

The contractor is responsible for compliance with this procedure and the General conditions of the

project.

The contractor is responsible for the coating application and quality controls of the applied coatings.

The supplier is responsible for advising proper use of provided coatings for the project.

The supplier will provide ongoing advice on the project and carry out periodic visits to the workshop

or works where coatings are being applied.

The supplier will provide their equipments for special tests such as: adhesion, Holiday detector, etc.

01

QUALITY MANAGEMENT PLAN

"SYSTEM IMPROVEMENT TREAT. SEWAGE WASTEWATER"

PROJECT

WORK PROCEDURES

SURFACE PREPARATION AND COATING APPLICATION

7.

PP0089-13

PAGE

11 de 15

DATE

03/07/13

OVERVIEW

INSPECTION

Inspection Equipments and Technical Standards:

Psychrometer Bacharach Type.

Surface Thermometer.

Digital Dry film Detector (mils and microns).

Adhesive Tape Rugosity Profile Detector press-o-film

Tester Adhesion Pull off.

Low voltage Holiday dectector.

For control and quality evaluation of the preparation phase the following standards will be used:

ASTM D 4285: Oil and Water determination on Air compressed

ASTM D 4417: Rugosity Profile Grade

ASTM E 337 : Weather Conditions Measure

For control and quality evaluation of the applied painting system the following standards will be used:

8.

ASTM D 4414: Measurement of Wet Film Thickness by Notch Gages.

SSPC-PA-2 : Measurement of Dry Coating Thickness With Magnetic Gages.

ASTM D 3359: Adhesion Test Determined by cut.

ASTM D 4541: Adhesion grade Measure through pull off equipments.

NACE ST0188-99: Discontinuity (Holiday) Testing of New Protective Coatings on Conductive

Substrates.

HEALTH, SAFETY AND ENVIRONMENT

Personnel who perform coating must follow the work procedures established by the security department

that indicates guidelines, patterns, and the acceptable minimum requirements allowing the worker to work

in safe conditions, preserving their health and integrity.

Recommendations to follow:

8.1. Storage of Materials

Coatings and solvents, will be stored in proper places and will only be maintained the necessary

materials in sufficient quantities for a days work, storage of coatings remainings or solvents is not

allowed.

For proper coating control should have a register of daily consumption and stock.

Electrical equipment in these places and their closeness, shall be of approved, in order to eliminate

the risks of fire and explosion.

Coating should be stored indoors at temperature range of 10 40 C, and away from any source

of ignition.

Store should have good ventilation. No flames or sparks in this area. Any equipment must be

grounded.

Each product safety data sheets (MSDS) must visibly stored, indications of safety and first aid are

stated in this MSDS.

01

QUALITY MANAGEMENT PLAN

"SYSTEM IMPROVEMENT TREAT. SEWAGE WASTEWATER"

PROJECT

WORK PROCEDURES

SURFACE PREPARATION AND COATING APPLICATION

PP0089-13

PAGE

12 de 15

DATE

03/07/13

OVERVIEW

8.2. Coating Area

It is recommended that the painting area to be indoors, with adequate ventilation.

Works flooring must be firm to avoid pollution problem affecting application, drying and curing of

the coating system.

Structures to be painted should be supported on trestles with brackets with a minimum height of

80 cm and distributed properly with spaces that allow free movement for coating applicator.

8.3. Coating Preparation

Refer to procedures established for Coating Preparation and Application.

Minimum PPE use is required, work clothes and their maintenance must be verified by security

responsible. For coating manipulation neoprene gloves and masks should use filters against organic

vapors and lenses.

Consider Personal protective equipment if required as well as the recommendations made in the

safety sheet (MSDS) of products to be applied.

To prevent spills on the floor is recommended to use spill trays in the paint preparation area or

cover with plastic.

For coating mixing is recommended to use a pneumatic agitator type Jiffy.

Follow the instructions of the Application Procedures of Product Technical Data Sheet.

8.4. Coating Application

9.

Coating by spraying and brush, will be carry out in places equipped with good ventilation and/or

extraction proper for gases and powdered particles.

Electrical equipment in these places and their proximities shall be approved in order to eliminate

the risks of fire and explosion.

Workers must be trained for this type of work and will use appropriate minimum required personal

protective equipment (PPE).

Since many of the equipments used for surfaces preparation by abrasive blasting and coating

application use compressed air, workers should be aware that the noise may cause a risk and must

use ear protectors when working with compressed air- tools.

Should encourage employees to take breaks every so often.

Workers must know the security related by working with high pressure guns during coating

application. For this reason must have qualified and experienced personnel in handling pressure

guns.

To facilitate used containers disposal is recommended to remove all coating content during its

preparation.

APPENDICES

9.1. COVERAGE

Theoretical and practical coverage as follows:

01

QUALITY MANAGEMENT PLAN

PP0089-13

"SYSTEM IMPROVEMENT TREAT. SEWAGE WASTEWATER"

PROJECT

WORK PROCEDURES

SURFACE PREPARATION AND COATING APPLICATION

Theoretical Coverage

Rt =

Practical Coverage

Rp =

149.02 x % SV

EPS

PAGE

13 de 15

DATE

03/07/13

OVERVIEW

m2/gallon

Coated Area

consumed gallons

m2/gallon

9.2. WET FILM THICKNESS : (WFT)

Wet Film thickness to be applied is linked to specified dry film thickness, used dilution and volume solids

percentage, according to the following formule:

EPS (1+%d)

WFT

%SV

WFT = Wet Film Thickness

DFT = Dry Film Thickness

% d = Dilution

% VS = Volume Solids

9.3. APPLICATION LOSS BY ROUGHNESS

Roughness of the surface

A rough and an abrasive surface will require a major amount of coating than a smooth surface. In this

case is very important the particle size of the material used in abrasive blasting. An abrasive grain thick

and hard, leaves a cutting profile much more crude and harsh than one of more fine and soft grain.

The roughness causes a considerable increase in the actual surface respecting the projected surface. This

aspect should necessarily be considered in order to not make mistakes in the calculations.

Is here where definition of bottle dead, known as the amount of coating to be used for covering the

increased area caused by roughness profile achieved during surface preparation.

The calculation is done taking into account the ratio of bottle dead depending on profile roughness:

01

QUALITY MANAGEMENT PLAN

PP0089-13

"SYSTEM IMPROVEMENT TREAT. SEWAGE WASTEWATER"

PROJECT

WORK PROCEDURES

SURFACE PREPARATION AND COATING APPLICATION

Coating Volume (liters) =

:

:

Bottle Dead/m2

14 de 15

DATE

03/07/13

OVERVIEW

CVM

SV

Base Coat Solids Volume :

Average Roughness Profile

Bottle Dead Coefficient

PAGE

72 %

2 mils

50.8 microns

or

3.5

=

=

0.0492 liters/m2

0.0130 gallons/m2

or

*VS : Volume solids

* BDV: Bottle Dead Volume Coefficient

9.4. TOUCH UP PROCEDURE

Touch up procedures are ellaborated according to the application type of damage or defect in

existing structures.

a)

Transport and Setup Mechanical Damages Zones

These damages occur when elements are transported from one place to another and stacking them,

also during the setup lifting structures. All the elements having these mechanical damages by

transport and setup most in edges and borders should be repaired. The case is more critical in areas

where damage has got the metal.

b)

Welded Joints

All the elements that have weld joints and those that by timing shows uniform corrosion, as damage

in adjacent welded joints by burns (flame cutting and joints welding).

9.4.1. Surface Preparation.

a)

Remove by mechanical tools: slag and welding spatter, as are found sharp edges must be rounded.

b) If steel surfaces are contaminated with welding fumes, grease and/or oil, should be washed with

water and industrial detergent and then rinse with drinking water according to standard SPC-SP1.

c)

Best cleaning method will be according to standard SSPC-SP-11, otherwise apply standard SSPC-SP3

SSPC-SP11: Mechanical or Pneumatic Cleaning to Bare Metal: When viewed without magnification, the

surface shall be free of all visible oil, grease, dirt, dust, mill scale, rust, paint, oxides, corrosion products,

and other foreign matter. Slight residues of rust and paint may be left in the lower portion of pits if the

original surface is pitted. The surface profile shall not be less than 1 mil (25 microns). Remainings of rust

and paint can be slightly on the bottom of the pits if the original surface had these pits. Before surface

preparation with power tool, remove visible deposits of oil or grease by any of the methods set out in

the SSPC-SP1, cleaning solvents, or other established methods.

01

QUALITY MANAGEMENT PLAN

"SYSTEM IMPROVEMENT TREAT. SEWAGE WASTEWATER"

PROJECT

WORK PROCEDURES

SURFACE PREPARATION AND COATING APPLICATION

PP0089-13

PAGE

15 de 15

DATE

03/07/13

OVERVIEW

SSPC-SP3: Power Tool Cleaning: Removes all loose mill scale, loose rust, loose paint, and other loose

detrimental foreign matter by power wire brushing, power sanding, power grinding, power tool

chipping, and power tool descaling. In this type of cleaning you should take care of not polishing the

metal surface in order to achieve a good adhesion of paint to the base.

Where the damage gets the metal, is weakened around these areas so all loose paint or poorly added,

must be removed with spatulas and then must use a motive equipment (power Sander) to eliminate the

reliefs, leaving the repairing area with the appearance of chamfer or down Beach. This procedure is

important and avoids pulling up the edges of old coating by effect of the solvent on the new coat in

these areas by applying the touch up.

9.4.2.

Coating System for Repainting zones

In repaiting zones must be applied the same coating system according to the specification or technical

recommendation and to stated thickness.

Damaged area and/or

Rust

Prepared Area through

Manual Cleaning /

mechanical

Primer Application

Finishing Application

01

S-ar putea să vă placă și

- Páginas desdeC-CS-50-005 HDPE - REV0 PDFDocument1 paginăPáginas desdeC-CS-50-005 HDPE - REV0 PDFBenjamin Enmanuel Mango DÎncă nu există evaluări

- Hdpe Bps Sab355Document1 paginăHdpe Bps Sab355Benjamin Enmanuel Mango DÎncă nu există evaluări

- Páginas Desdec Cs 50 005 Hdpe - Rev0 2Document1 paginăPáginas Desdec Cs 50 005 Hdpe - Rev0 2Benjamin Enmanuel Mango DÎncă nu există evaluări

- Páginas Desdec Cs 50 005 Hdpe - Rev0Document1 paginăPáginas Desdec Cs 50 005 Hdpe - Rev0Benjamin Enmanuel Mango DÎncă nu există evaluări

- Iron-Iron Carbide Phase Diagram ExampleDocument3 paginiIron-Iron Carbide Phase Diagram ExampleBenjamin Enmanuel Mango DÎncă nu există evaluări

- GSK 3-1 Engineered Gasketing Cat ColorDocument60 paginiGSK 3-1 Engineered Gasketing Cat ColorBenjamin Enmanuel Mango DÎncă nu există evaluări

- MBG - 533-09 Welding Standards For Fabrication of Steel Stainless Steel and Aluminium Bar GratingDocument19 paginiMBG - 533-09 Welding Standards For Fabrication of Steel Stainless Steel and Aluminium Bar GratingCarlo Monsalve100% (1)

- Astm D610 PDFDocument6 paginiAstm D610 PDFAmbarÎncă nu există evaluări

- Bsi 5352-1981Document32 paginiBsi 5352-1981Benjamin Enmanuel Mango DÎncă nu există evaluări

- Asme b1.20.1 NPT ThreadsDocument1 paginăAsme b1.20.1 NPT ThreadsGabriel Arghiriade100% (1)

- Ems 1001 B 01 102Document1 paginăEms 1001 B 01 102Benjamin Enmanuel Mango DÎncă nu există evaluări

- MSS-SP-006 Standard Finishes For Contact Faces of Pipe Flanges 1996Document6 paginiMSS-SP-006 Standard Finishes For Contact Faces of Pipe Flanges 1996quack1111Încă nu există evaluări

- Evaluación InspectorDocument13 paginiEvaluación InspectorBenjamin Enmanuel Mango DÎncă nu există evaluări

- QC Matrix - EstructurasDocument8 paginiQC Matrix - EstructurasBenjamin Enmanuel Mango DÎncă nu există evaluări

- Asme b1.20.1 NPT ThreadsDocument1 paginăAsme b1.20.1 NPT ThreadsGabriel Arghiriade100% (1)

- Tangram Quality ManualDocument10 paginiTangram Quality ManualBenjamin Enmanuel Mango DÎncă nu există evaluări

- Bsi 1868-1975Document25 paginiBsi 1868-1975Benjamin Enmanuel Mango DÎncă nu există evaluări

- AWS D1-1 PQR-WPS Yes Pre QualifiedDocument2 paginiAWS D1-1 PQR-WPS Yes Pre QualifiedJRodengineerÎncă nu există evaluări

- H 99 Sec 8 D 1 App 1Document9 paginiH 99 Sec 8 D 1 App 1Benjamin Enmanuel Mango DÎncă nu există evaluări

- ASME B16.5 Flanges PDFDocument50 paginiASME B16.5 Flanges PDFPedro De Mesquita Soares CamposÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Engineering Data: Heat Pump Outdoor UnitDocument10 paginiEngineering Data: Heat Pump Outdoor UnitAflredo FloresÎncă nu există evaluări

- DBH Global Freight Co ProfileDocument17 paginiDBH Global Freight Co ProfileMohd Afif SukriÎncă nu există evaluări

- List Ebook BKKMTKI Daerah IIDocument26 paginiList Ebook BKKMTKI Daerah IIIrvan Arfian MaulanaÎncă nu există evaluări

- Green June Alcoa Portland TSL Furnace 2002Document20 paginiGreen June Alcoa Portland TSL Furnace 2002Bernard MosserÎncă nu există evaluări

- Supply ChainDocument38 paginiSupply ChainMk YapÎncă nu există evaluări

- Scm5 - MM - Sol Sap - PDF Catalogue2Document21 paginiScm5 - MM - Sol Sap - PDF Catalogue2陳厚宇Încă nu există evaluări

- MEC 532 Composite MaterialsDocument2 paginiMEC 532 Composite MaterialsSumit SharmaÎncă nu există evaluări

- Chapter 6 Inputs and Production FunctionsDocument3 paginiChapter 6 Inputs and Production FunctionsHeap Ke XinÎncă nu există evaluări

- APQP Training MaterialDocument13 paginiAPQP Training Materialsuresh kumar100% (1)

- WPS, PQR & WQT According To ASME Section IX - 2019Document50 paginiWPS, PQR & WQT According To ASME Section IX - 2019Anon YmousÎncă nu există evaluări

- Mil Q 9858 - ADocument9 paginiMil Q 9858 - A09132014398Încă nu există evaluări

- Electrical Solutions For Motors and Generators MersenDocument7 paginiElectrical Solutions For Motors and Generators Mersendbasak5043Încă nu există evaluări

- Flat Products Made of Steel BS EN10028 - 2Document26 paginiFlat Products Made of Steel BS EN10028 - 2Javier OrnaÎncă nu există evaluări

- Peer-Graded Assignment: Transportation Assignment (Supply Chain Logistics-Week 01)Document5 paginiPeer-Graded Assignment: Transportation Assignment (Supply Chain Logistics-Week 01)subhash chandra100% (1)

- NX Sheet MetalDocument2 paginiNX Sheet MetalSathish KumarÎncă nu există evaluări

- Excel Perhitungan Tugas Besar SCM - Kelompok-7 - TI4207Document49 paginiExcel Perhitungan Tugas Besar SCM - Kelompok-7 - TI4207FADILLA ZARA LARASHATIÎncă nu există evaluări

- Indian Steel Market ScanDocument8 paginiIndian Steel Market Scanminushastri33Încă nu există evaluări

- Kanban SystemDocument23 paginiKanban SystemSlamet Dwi HaryantoÎncă nu există evaluări

- Hea Steel Desities s275 GradeDocument3 paginiHea Steel Desities s275 GradeSunday PaulÎncă nu există evaluări

- ProductionDocument12 paginiProductionhelloÎncă nu există evaluări

- Managing The Supply ChainDocument26 paginiManaging The Supply ChainiltdfÎncă nu există evaluări

- Supply Chain Strategy Study For Marks and SpencerDocument9 paginiSupply Chain Strategy Study For Marks and SpencerSiva Kumar ArumughamÎncă nu există evaluări

- ContiTech Select Catalog 2018 enDocument92 paginiContiTech Select Catalog 2018 enJuan Altamirano Rojas JarÎncă nu există evaluări

- Spirit 19 En-WebDocument19 paginiSpirit 19 En-Webevillalobos000Încă nu există evaluări

- Stainless Steel CatalogDocument114 paginiStainless Steel CatalogSiva KumarÎncă nu există evaluări

- Training Report On BSPDocument14 paginiTraining Report On BSPsanchay3090Încă nu există evaluări

- Railway Steel Grade PDFDocument4 paginiRailway Steel Grade PDFv4lkr3yÎncă nu există evaluări

- Writing Activity: My Skill Is WeldingDocument3 paginiWriting Activity: My Skill Is Weldingkevin araujoÎncă nu există evaluări

- Vizag-Chennai Industrial Corridor - Full ReportDocument388 paginiVizag-Chennai Industrial Corridor - Full ReportPrasad GogineniÎncă nu există evaluări

- ENSYN RTP Description (2011)Document25 paginiENSYN RTP Description (2011)iboukis100% (1)