Documente Academic

Documente Profesional

Documente Cultură

Project Execution Risks and Mitigation

Încărcat de

Adaghara0 evaluări0% au considerat acest document util (0 voturi)

160 vizualizări3 paginiThe key risks to the MIPS Pipeline Project are summarized along with proposed mitigations. Risks include inadequate design work, late changes, delays in equipment or fabrication, carry over work between phases, and issues with the marine spread or community disturbances. Mitigation strategies include early verification, freezing designs, tight schedules, contingency planning, expediting, and proactive community management to help ensure the project is delivered on time and on budget.

Descriere originală:

This project Mitigation plan can stand as guide to develop a comprehensive one for complex projects.

Titlu original

Project Execution Risk and Mitigation Plan

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThe key risks to the MIPS Pipeline Project are summarized along with proposed mitigations. Risks include inadequate design work, late changes, delays in equipment or fabrication, carry over work between phases, and issues with the marine spread or community disturbances. Mitigation strategies include early verification, freezing designs, tight schedules, contingency planning, expediting, and proactive community management to help ensure the project is delivered on time and on budget.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

160 vizualizări3 paginiProject Execution Risks and Mitigation

Încărcat de

AdagharaThe key risks to the MIPS Pipeline Project are summarized along with proposed mitigations. Risks include inadequate design work, late changes, delays in equipment or fabrication, carry over work between phases, and issues with the marine spread or community disturbances. Mitigation strategies include early verification, freezing designs, tight schedules, contingency planning, expediting, and proactive community management to help ensure the project is delivered on time and on budget.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 3

Project Execution Risk

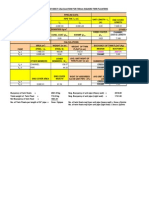

PROJECT RISKS AND MITIGATION PLAN

The key cost, schedule and execution risks associated with the MIPS Pipeline Project and the

proposed mitigation are summarized in the table below.

Phase / Risk

Detail Design Phase

Inadequate FEED

Site verification

Late changes to overall

execution plan

Fabrication phase

Late design changes

Consequence

Mitigation

Scope increase

Scope increase

Schedule delay

Feed review

Early site verification

Early approval of execution

plan

Schedule and cost effect

Freeze design as early as

possible and achieve AFC

documents status prior to subcontracting.

Early presentation of

personnel and milestone

target for COMPANY approval

Late approval of

CONTRACTORs personnel

for key positions, fabrication

documents and schedules

Delay in equipment delivery

Delayed fabrication

Start-up

Equipment not meeting

MPN specs

Delayed installation

Incomplete work or Change

Orders at time of Load Out.

Carry Over work to

Installation / Hook-up phase

Schedule and cost effect.

Install. & Hook-up Phase

Carry Over work from

fabricators.

Schedule and cost effect

Extended Hook-Up phase.

Schedule- and cost effect

Specific plans to be developed

for all critical path equipment.

Ensure design allows

equipment to be lifted or

skidded into topsides after

erection of decks. Strong

expediting of equipment.

Ensure FAT is completed in

time.

Ensure manufacturer

surveillance, QC inspections,

and FAT attendance. Verify

compliance through MC

check-sheets and reporting

Ensure tight compliance with

Mechanical Completion

procedure. Accelerate by

request extended shifts.

Increase manpower.

Reschedule to minimize

consequences.

Close follow up of fabricator

performance.

Late design changes

Changes in operational

criteria of marine spread

operations

Increase installation lift

weight of piping spools /

deck modifications

Mechanical breakdown of

marine Spread

Schedule- and cost effect of

Hook-up phase

Marine spread stand by.

Schedule and cost effect

Tight control of engineering

and operational changes.

Tight control of engineering

and operational changes.

Cost effect. Larger spread/

lift capacity.

Tight control of installed

weights. Weight contingency.

Schedule effect

Pre-verification of ships,

barges etc. and HAZOP of

marine operations.

Commissioning & Start-Up

Late approval of operability Delayed Commissioning

and maintenance

and subsequent Start up

documents.

and delivery

Time-consuming internal

approval process of

commissioned systems and

handover

Other factors

Community disturbance at

work sites

Delayed Start up process

and Handover to Customer

Delayed schedule and

delivery time and safety risk

to personnel

Early start of operability and

maintenance procedures.

Define milestone completion

time for document and training

completion.

Clearly define acceptance

criteria and have customer

personnel available offshore,

authorized to sign acceptance

Proactive management will be

put in place to anticipate and

resolve issues with host

communities.

S-ar putea să vă placă și

- Notes For PrimaveraDocument11 paginiNotes For PrimaveraSmart FunboyÎncă nu există evaluări

- Materials Management in Project PlanningDocument8 paginiMaterials Management in Project PlanningAbhiruchi SinghÎncă nu există evaluări

- Estimating Project Times and Costs: Mcgraw-Hill/Irwin ReservedDocument23 paginiEstimating Project Times and Costs: Mcgraw-Hill/Irwin ReservedAbdullah TalibÎncă nu există evaluări

- How To Get Resource Loading Histogram-S CurveDocument7 paginiHow To Get Resource Loading Histogram-S CurveAbhishekKumarÎncă nu există evaluări

- Al Khorayef LSTPP Project Execution PlanDocument26 paginiAl Khorayef LSTPP Project Execution PlanLeon PeterÎncă nu există evaluări

- Fatty Acid PlantDocument11 paginiFatty Acid PlantNurulSyahibah Che ManÎncă nu există evaluări

- Weekly Project Status ReportDocument2 paginiWeekly Project Status ReportRobi Maulana100% (1)

- Project Execution Plan For TankDocument3 paginiProject Execution Plan For TankiwansalmaÎncă nu există evaluări

- FGP WPMP OverviewDocument15 paginiFGP WPMP OverviewyazardÎncă nu există evaluări

- Cash Flow (S-CURVE) : Monthly Cashout Monthly Cashin Cum Cashout Cum CashinDocument6 paginiCash Flow (S-CURVE) : Monthly Cashout Monthly Cashin Cum Cashout Cum CashinZahra NoorÎncă nu există evaluări

- PEDMS User Guide - v5 - 8 1Document1 paginăPEDMS User Guide - v5 - 8 1fandi_othmanÎncă nu există evaluări

- Pakistan 2005 Earthquake: Prepared by Asian Development Bank and World Bank Islamabad, Pakistan November 12, 2005Document26 paginiPakistan 2005 Earthquake: Prepared by Asian Development Bank and World Bank Islamabad, Pakistan November 12, 2005Aslam KyonÎncă nu există evaluări

- Engineering Consultancy ServicesDocument2 paginiEngineering Consultancy ServicesJohnÎncă nu există evaluări

- Structural Inspection Checklist For FactoryDocument1 paginăStructural Inspection Checklist For FactoryAnonymous FD64zqL6S100% (1)

- Marketing Plan For Cold Bitumen in India - School of Petroleum Management - GandhinagarDocument25 paginiMarketing Plan For Cold Bitumen in India - School of Petroleum Management - GandhinagarAbhik Tushar DasÎncă nu există evaluări

- Jitendra Joshi Resume - 2020Document4 paginiJitendra Joshi Resume - 20200000000000000000Încă nu există evaluări

- ASSAI Booklet Ver2Document2 paginiASSAI Booklet Ver2mohammadazraiÎncă nu există evaluări

- Manual de Vaporizadores AmbientalesDocument9 paginiManual de Vaporizadores AmbientalesJose Luis Tadeo SabinoÎncă nu există evaluări

- Operations ManualDocument19 paginiOperations ManuallogesniceÎncă nu există evaluări

- Industrial TrainingDocument59 paginiIndustrial TrainingSatnam SinghÎncă nu există evaluări

- Primavera P6 TutorialDocument23 paginiPrimavera P6 Tutorialedla3710100% (1)

- Install Primavera Risk AnalysisDocument6 paginiInstall Primavera Risk AnalysisRic S. MalongaÎncă nu există evaluări

- Plant Layout ProblemDocument52 paginiPlant Layout Problemtony_njÎncă nu există evaluări

- AFSS-Commissioning & Testing..Document4 paginiAFSS-Commissioning & Testing..sanchezdreiÎncă nu există evaluări

- Cause and Effect AnalysisDocument13 paginiCause and Effect AnalysisAadi KhanÎncă nu există evaluări

- Pipeline Stress Analysis With Caesar IIDocument16 paginiPipeline Stress Analysis With Caesar IIank_mehra100% (1)

- Aspen Capital Cost Estimator User Certification Exam ACU-ACCE01Document3 paginiAspen Capital Cost Estimator User Certification Exam ACU-ACCE01Osama El-ShafieyÎncă nu există evaluări

- PVU Chapter 5 Costs in Petroleum E&PDocument26 paginiPVU Chapter 5 Costs in Petroleum E&Psmile100% (1)

- Change Control Plan TemplateDocument9 paginiChange Control Plan TemplateNagaraj MuniyandiÎncă nu există evaluări

- P6 Training AberdeenDocument3 paginiP6 Training AberdeenNnamdiÎncă nu există evaluări

- An Optimal Preventive Maintenance Model For Natural Gas Transmission PipelinesDocument10 paginiAn Optimal Preventive Maintenance Model For Natural Gas Transmission PipelinessidÎncă nu există evaluări

- YmcaDocument39 paginiYmcaViraj DuaÎncă nu există evaluări

- Engineering Management Course Code: EMG: Instructor: Engr. Cesar Amante TingDocument63 paginiEngineering Management Course Code: EMG: Instructor: Engr. Cesar Amante TingCesar Amante TingÎncă nu există evaluări

- EOI Final PreviousDocument24 paginiEOI Final PreviousSaniSah100% (1)

- Manpower List - Aims HCMLDocument5 paginiManpower List - Aims HCMLJuliyanto STÎncă nu există evaluări

- Project Proposal TemplateDocument7 paginiProject Proposal Templatekumelachewbirre22Încă nu există evaluări

- Terra Construction Plan Rev0Document44 paginiTerra Construction Plan Rev0hasan_676489616Încă nu există evaluări

- ADL 16 Total Quality Management V4ADocument8 paginiADL 16 Total Quality Management V4Asolvedcare0% (2)

- Dr. Nawar Khan - Continuous Improvement in Quality & Productivity Through Integral Lean ManagementDocument25 paginiDr. Nawar Khan - Continuous Improvement in Quality & Productivity Through Integral Lean ManagementaalwajhkÎncă nu există evaluări

- Slide Email MemoDocument41 paginiSlide Email MemoAndina KusumawardaniÎncă nu există evaluări

- TENTATIVE COMMISSIONING SEQUENCEDocument3 paginiTENTATIVE COMMISSIONING SEQUENCEMahadevan MahalingamÎncă nu există evaluări

- Chapter One: Background To The Project Management Tools and TechniquesDocument34 paginiChapter One: Background To The Project Management Tools and TechniquesNalyanyaÎncă nu există evaluări

- Interface Engineer Job ResponsibilitiesDocument1 paginăInterface Engineer Job ResponsibilitiesAnonymous ygQUvDKÎncă nu există evaluări

- DB32 Vessel Flysheets 24M062018H 4Document2 paginiDB32 Vessel Flysheets 24M062018H 4jhonnyÎncă nu există evaluări

- AspenCapitalCostEstimatorV9 0 UserGuideDocument682 paginiAspenCapitalCostEstimatorV9 0 UserGuideRoudaina Benzeguir100% (1)

- Project Execution and Control Best PracticesDocument0 paginiProject Execution and Control Best PracticesMahnooranjumÎncă nu există evaluări

- Aspen-Getting Started Building and Running Process ModelDocument101 paginiAspen-Getting Started Building and Running Process ModelSurya Budi WidagdoÎncă nu există evaluări

- How To Cost Load A ScheduleDocument3 paginiHow To Cost Load A ScheduleInaam Ullah MughalÎncă nu există evaluări

- Syllabus: Primavera-P6: Er. Praveen Chaudhary Hydropower ExpertDocument5 paginiSyllabus: Primavera-P6: Er. Praveen Chaudhary Hydropower ExpertPRAVEEN CHAUDHARY0% (1)

- Opercom Course For Trainees by TRDDocument14 paginiOpercom Course For Trainees by TRDMohammad MohseniÎncă nu există evaluări

- Technical Proposal GuidelinesDocument2 paginiTechnical Proposal GuidelinesashleesuchiÎncă nu există evaluări

- Construction Phase Progress: Progrees Status Report As of 28Th January 2018Document2 paginiConstruction Phase Progress: Progrees Status Report As of 28Th January 2018Athambawa RameesÎncă nu există evaluări

- Service FormatDocument1 paginăService FormatMadhan MohanÎncă nu există evaluări

- Maintenance management system for oil and gas upstream operationsDocument7 paginiMaintenance management system for oil and gas upstream operationslucas ronaldo coronel mendozaÎncă nu există evaluări

- Mitigation Plans A Complete Guide - 2019 EditionDe la EverandMitigation Plans A Complete Guide - 2019 EditionÎncă nu există evaluări

- IBM Maximo Asset Configuration Manager A Complete Guide - 2020 EditionDe la EverandIBM Maximo Asset Configuration Manager A Complete Guide - 2020 EditionÎncă nu există evaluări

- Value Of Work Done A Complete Guide - 2020 EditionDe la EverandValue Of Work Done A Complete Guide - 2020 EditionÎncă nu există evaluări

- Advanced Process Control A Complete Guide - 2020 EditionDe la EverandAdvanced Process Control A Complete Guide - 2020 EditionÎncă nu există evaluări

- Well Completion PlanningDocument13 paginiWell Completion Planningreborn2100% (1)

- Oil & Gas Project Management Seeking Senior AssignmentsDocument4 paginiOil & Gas Project Management Seeking Senior AssignmentsrashidÎncă nu există evaluări

- Offshore Platform InstallationDocument189 paginiOffshore Platform InstallationAdaghara100% (2)

- Rules For Classification and Construction IV Industrial ServicesDocument38 paginiRules For Classification and Construction IV Industrial ServicessreenathsÎncă nu există evaluări

- Irjet V5i1155 PDFDocument8 paginiIrjet V5i1155 PDFNguyễn Quốc PhượngÎncă nu există evaluări

- Revision Philosophy NotesDocument5 paginiRevision Philosophy NotesAdagharaÎncă nu există evaluări

- Buoyancy Calculator: Thus, Flotation Thus, FlotationDocument4 paginiBuoyancy Calculator: Thus, Flotation Thus, FlotationAdaghara100% (1)

- METHOD STATEMENT - Marsh DitchingDocument6 paginiMETHOD STATEMENT - Marsh DitchingAdagharaÎncă nu există evaluări

- Pull Study Calculation SheetDocument2 paginiPull Study Calculation SheetAdagharaÎncă nu există evaluări

- Pipeline Stability and Weight Coating CalculationDocument4 paginiPipeline Stability and Weight Coating CalculationAdaghara67% (3)

- Pipe Bend RadiusDocument8 paginiPipe Bend RadiusAdagharaÎncă nu există evaluări

- JHA For Vehicular MovementDocument3 paginiJHA For Vehicular MovementAdagharaÎncă nu există evaluări

- Method Statement - Crane Barge Tie-InsDocument6 paginiMethod Statement - Crane Barge Tie-InsAdaghara100% (1)

- Valve Selection GuideDocument3 paginiValve Selection Guideandy131078Încă nu există evaluări

- General Piping DesignDocument32 paginiGeneral Piping DesignS_hassan_16Încă nu există evaluări

- Drying and Nitrogen ProcedureDocument5 paginiDrying and Nitrogen ProcedureAdaghara67% (3)

- Valve SelectionDocument8 paginiValve SelectionShreya Sahajpal KaushalÎncă nu există evaluări

- MEDEVAC flow chart guides medical emergenciesDocument2 paginiMEDEVAC flow chart guides medical emergenciesAdaghara100% (1)

- CraneDocument71 paginiCraneAdagharaÎncă nu există evaluări

- Lift and DragDocument2 paginiLift and DragAdagharaÎncă nu există evaluări

- 24in Pipeline Buoyancy CalculationDocument1 pagină24in Pipeline Buoyancy CalculationAdaghara67% (3)

- Pipelay Procedure RevisedDocument31 paginiPipelay Procedure RevisedAdaghara83% (6)

- Load-Out and Sea-Fastening ProcedureDocument17 paginiLoad-Out and Sea-Fastening ProcedureAdaghara100% (2)

- 18in Floater Design and Install Calc. WorksheetDocument3 pagini18in Floater Design and Install Calc. WorksheetAdagharaÎncă nu există evaluări

- Calculation Sheet For 700mm SQ Metal FloatersDocument3 paginiCalculation Sheet For 700mm SQ Metal FloatersAdagharaÎncă nu există evaluări

- Barangay SindalanDocument1 paginăBarangay SindalanAna GÎncă nu există evaluări

- In - Gov.uidai ADHARDocument1 paginăIn - Gov.uidai ADHARvamsiÎncă nu există evaluări

- InterContinental Global Etiquette Compendium FO backTVDocument12 paginiInterContinental Global Etiquette Compendium FO backTVGian SyailendraÎncă nu există evaluări

- Taste of IndiaDocument8 paginiTaste of IndiaDiki RasaptaÎncă nu există evaluări

- US Multifamily Specialist Opens First Regional Office in HKDocument1 paginăUS Multifamily Specialist Opens First Regional Office in HKNichole SimblanteÎncă nu există evaluări

- 3rd Yr 2nd Sem Business Plan Preparation Quiz 1 MidtermDocument14 pagini3rd Yr 2nd Sem Business Plan Preparation Quiz 1 MidtermAlfie Jaicten SyÎncă nu există evaluări

- Fundamentals of Accountancy, Business and Management 1 (FABM1)Document9 paginiFundamentals of Accountancy, Business and Management 1 (FABM1)A.Încă nu există evaluări

- SSS LAwDocument14 paginiSSS LAwbebs CachoÎncă nu există evaluări

- 2015 Scholarship ApplicationDocument3 pagini2015 Scholarship Applicationapi-280767644Încă nu există evaluări

- Promoting a school walkathon for weight lossDocument3 paginiPromoting a school walkathon for weight lossDamon HelthÎncă nu există evaluări

- Poetry and PoliticsDocument21 paginiPoetry and Politicshotrdp5483Încă nu există evaluări

- New Venture Creation IdeasDocument6 paginiNew Venture Creation IdeasDaoud HamadnehÎncă nu există evaluări

- CoA Judgment - Kwan Ngen Wah V Julita Binti TinggalDocument25 paginiCoA Judgment - Kwan Ngen Wah V Julita Binti TinggalSerzan HassnarÎncă nu există evaluări

- Questions of ValueDocument2 paginiQuestions of ValueRockyÎncă nu există evaluări

- Tritium - Radioactive isotope of hydrogenDocument13 paginiTritium - Radioactive isotope of hydrogenParva KhareÎncă nu există evaluări

- SAMPLE Information On RapeDocument2 paginiSAMPLE Information On RapeMay May100% (2)

- Chapter 2 - Part 1 - Measures of Central Tendency - Practice ProblemsDocument8 paginiChapter 2 - Part 1 - Measures of Central Tendency - Practice ProblemsTejas Joshi0% (3)

- Medicina Musica Amistad y Prejuicios BrahmsDocument3 paginiMedicina Musica Amistad y Prejuicios BrahmsBreen MisiÎncă nu există evaluări

- Deportation of Jews of IoanninaDocument7 paginiDeportation of Jews of IoanninajaboninÎncă nu există evaluări

- Greek Avant Garde Poetry MovementDocument176 paginiGreek Avant Garde Poetry MovementRapha JoseÎncă nu există evaluări

- Who Gsap 2017Document56 paginiWho Gsap 2017Mirzania Mahya FathiaÎncă nu există evaluări

- Boscastle Family Book SeriesDocument4 paginiBoscastle Family Book SeriesChingirl89100% (1)

- Expedite Unclaimed Cargo AuctionsDocument4 paginiExpedite Unclaimed Cargo AuctionsDinesh ChakravartyÎncă nu există evaluări

- Receivable Financing Pledge Assignment ADocument34 paginiReceivable Financing Pledge Assignment AJoy UyÎncă nu există evaluări

- Web Design Wordpress - Hosting Services ListDocument1 paginăWeb Design Wordpress - Hosting Services ListMotivatioNetÎncă nu există evaluări

- English FinalDocument6 paginiEnglish FinalAPRIL LYN D. GETI-AYONÎncă nu există evaluări

- Rules For SopeDocument21 paginiRules For Sopearif zamanÎncă nu există evaluări

- Harnessing The Heat Beneath Our Feet GE - Feb 22 224Document1 paginăHarnessing The Heat Beneath Our Feet GE - Feb 22 224ShhhhhhhhyeahÎncă nu există evaluări

- Fondazione Prada - January 2019Document6 paginiFondazione Prada - January 2019ArtdataÎncă nu există evaluări

- The Powers To Lead Joseph S. Nye Jr.Document18 paginiThe Powers To Lead Joseph S. Nye Jr.George ForcoșÎncă nu există evaluări