Documente Academic

Documente Profesional

Documente Cultură

Qcs 2010 Section 11 Part 2.3.05 She Procedures - Powered Work Equipme

Încărcat de

bryanpastor106Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Qcs 2010 Section 11 Part 2.3.05 She Procedures - Powered Work Equipme

Încărcat de

bryanpastor106Drepturi de autor:

Formate disponibile

QCS 2010

Section 11

Part 2

SAMAS

Page 1

SAFETY

AND

ACCIDENT

PREVENTION

MANAGEMENT

/

ADMINISTRATION SYSTEM (SAMAS) ......................................................1

2.3

SAFETY, HEALTH AND ENVIRONEMNT PROCEDURES ............................. 1

2.3.5

POWERED WORK EQUIPMENT PROCEDURE ............................................. 1

2.3.5.1 Responsibilities ................................................................................................ 4

2.3.5.2 Definitions ........................................................................................................ 5

2.3.5.3 Action Required to Implement this Procedure ................................................. 6

2.3.5.4 Guidance To This Procedure ........................................................................... 7

2.3.5.5 Appendices .................................................................................................... 10

2.3.5.6 Reference Documents ................................................................................... 12

2.3.5.7 Author ............................................................................................................ 12

2.3.5.8 Approvals....................................................................................................... 12

QCS 2010

QCS 2010

Section 11

Part 2

SAMAS

Page 2

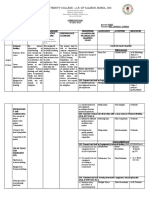

PROCESS MAP

Estimator/

Bid

Manager

Project

Site

Manager

Plant

Coordinator

Supervisors

Procurement

Quantity

Surveyor

Identify PWE

requirements

and produce

PWE schedule

3.1

Operator

Contractor

Regional

Training

Coordinator

SHE Team

Provide proof

of

competence

Review PWE

schedule and

maintain during

the project

3.7

3.2

Monitor use

of PWE

including

inspection

and

maintenance

3.4

Appoint a plant

Co-ordinator

Operate,

inspect and

maintain plant

as required

3.7

3.2

Develop and

revise PW

Schedule

3.3

Ensure

relevant

Certification is

available for

PWE on site

3.3

Monitor use,

inspection

and

maintenance

of PWE on

3.3

site

Key:

Activity

Guidance

QCS 2010

Assist and

advise on

plant

requirements

use and

maintain as

necessary

3.8

Report

defects as

identified

3.4

Advise

Subcontracto

r

Management

of PWE

requirement

at pre-start

Report

defects as

identified

3.5, 3.6

3.7

Identify PWE

equipment

and provide

a copy to

COMPANY

Plant Coordinator

3.8

Arrange

training as

requested

by Project

Team

3.9

QCS 2010

Section 11

Part 2

SAMAS

Page 3

PURPOSE

1

The purpose of this procedure is to assign responsibilities and establish a system for the control

and safe use of powered work equipment.

SCOPE

1

This procedure covers all COMPANY Projects and locations under the control of COMPANY. A

COMPANY is defined as the organization with responsibility for management of safety at a

construction site.

QCS 2010

QCS 2010

Section 11

Part 2

SAMAS

Page 4

2.3.5.1 Responsibilities

SHE DIRECTOR

1

Authorises this procedure

ESTIMATOR/TENDER TEAM

Ensures that information provided by designers is utilised at tender stage for inclusion of resource

to allow compliance by others with this procedure.

PROJECT/SITE MANAGER

Ensures this procedure is established on Projects under his control. For the purposes of this

procedure, Project/Site Manager may also mean Office Manager.

PLANT CO-ORDINATOR

Applies the requirements of this procedure.

Note: The person appointed must be site based and competent to carry out their duties.

PROCUREMENT/BUYER/QS

Supports the Plant Co-ordinator in the application of this procedure.

SUPERVISOR

Supports the plant co-ordinator in the application of this procedure.

OPERATOR

Operates Plant in accordance with the requirements of this procedure.

SHE ADVISER

Provides advice and guidance in support of this procedure and monitors the effectiveness of

its application.

CONTRACTOR

10

Ensures

only

competent

personnel

are

dedicated/owned/hired plant and equipment.

authorised

11

Ensures maintenance is completed and recorded as appropriate.

REGIONAL TRAINING CO-ORDINATOR

12

Processes formal training requests from the Project/Site Manager.

QCS 2010

to

operate

specifically

QCS 2010

Section 11

Part 2

SAMAS

Page 5

2.3.5.2 Definitions

POWER

1

The Provision and Use of Work Equipment.

POWERED WORK EQUIPMENT (PWE)

Powered Work Equipment as referred to in PUWER.

NB. The Requirements for the use of Lifting Equipment are contained in SHEPRO-010

SUITABILITY OF PWE

Defines the equipment as fit for its intended use within its design and operational parameters.

USE

For the purposes of this procedure, use includes all activities involving PWE such as starting,

operating and stopping the equipment, plus any setting, repair, modification, maintenance,

servicing, transportation and cleaning.

CONTRACTOR

Contractor means any work package contractor or their sub-contractor and include any PWE

supplier.

COMPETENCE

The individuals demonstrated capacity to perform, i.e., the possession of knowledge, experience,

training, skills and personal characteristics needed to satisfy the special demands or requirements

of a particular situation.

PWE SCHEDULE

A control/management document displayed within the project office to be updated regularly by the

Plant Co-ordinator. SHE-FRM-5-001.

PWE CHECKLIST

An aide memoir and control document to be completed by the Plant Coordinator (COMPANY and

Contractor) or nominated person for any equipment received onto site and filed within the SHE

Register. SHE-FRM-5-02.

PLANNED PREVENTIVE MAINTENANCE (PPM)

10

Involves replacing parts and consumables or making necessary adjustments at preset intervals

so that risks do not occur as a result of the deterioration or failure of the equipment.

CONDITION-BASED MAINTENANCE

11

Involves monitoring the condition of safety-critical parts and carrying out maintenance whenever

necessary to avoid hazards which could otherwise occur.

QCS 2010

QCS 2010

Section 11

Part 2

SAMAS

Page 6

BREAKDOWN MAINTENANCE

12

Involves carrying out maintenance only after faults or failures have occurred. It is appropriate only

if the failure does not present an immediate risk and can be corrected before risk occurs, It is

unlikely that this system of maintenance would be acceptable for the PWE covered by this

procedure.

2.3.5.3 Action Required to Implement this Procedure

ESTIMATOR/TENDER TEAM

1

Identify the PWE requirements for the project and complete the initial PWE schedule (Appendix

1) Allow resource for any equipment in the bid and include details and information relative to the

same in the handover process between the pre-construction and construction teams.

PROJECT/SITE MANAGER

Review the initial PWE schedule (Appendix 1) and amend / maintain as required throughout the

Project duration.

Where appropriate, appoint a Plant Co-ordinator or retain the duties of that appointment.

Arrange training for Directly employed persons through the Regional Training Co-ordinator as

necessary to ensure the competence of appointees.

Monitor PWE use on site to ensure the effectiveness of controls.

PLANT CO-ORDINATOR

Take control of, review and develop the PWE Schedule as the project progresses.

Enter all details of PWE received on site into the PWE Schedule (SHE-FRM-5-01).

Act as the focal point for all PWE used on site and assist other management/supervision in the

selection and control of the PWE used.

Must ensure either a certificate of thorough inspection not more than 12 months old (6 Months

where lifting persons) for any lifting equipment received on site is attached to the site register and

the next inspection date is logged on the PWE Schedule (SHE-FRM-5-001).

10

Arrange/Complete all pre-use checks as detailed on SHE-FRM-5-002.

11

Record operators/users of each PWE on the PWE Schedule.

12

Complete or ensure the completion of all regular inspections and maintenance of PWE in the

appropriate Project SHE Register or the equivalent subcontractor control document.

13

Ensure arrangements are made for the safe-keeping and issue of all ignition and security keys

and for smaller PWE for its safe storage and controlled issue.

14

Confirm a system of PPM or Condition Based Maintenance is applied by all sub-contractors on

any PWE used on site.

15

Implement a system of PPM or Condition Based Maintenance on any PWE purchased for use on

site based on manufacturers guidelines and completed by competent people (externally

contracted as necessary).

QCS 2010

QCS 2010

Section 11

Part 2

SAMAS

Page 7

SUPERVISORS

16

Complete all duties as appointed and authorised by the Plant Co-ordinator.

17

Monitor PWE use on site to ensure the effectiveness of controls, maintenance and servicing.

PROCUREMENT/BUYERS

18

Advise sub-contractor management at pre-start of requirements regarding PWE (see

Contractor actions below).

QS

19

Advise sub-contractor management at pre-start of requirements regarding PWE (see

Contractor actions below) and issue copy of Appendices 1 & 2 where no sub-contractor internal

control documents/system exists.

OPERATOR

20

Provides proof of competence.

21

Operates plant and equipment when authorised to do so, in approved areas, subject to site

or ordered limitations and in compliance with training and manufacturers guidelines.

22

Ensures maintenance is completed in accordance with training, employers Risk Assessment

and manufacturers guidance.

23

Ensures defects are promptly reported to the plant co-ordinator and where necessary secures

unsafe equipment in a safe location/state.

CONTRACTOR

24

Identify the PWE requirements for the project and complete an initial PWE schedule (Appendix

1) or similar in-house control document. Provide copy to COMPANY Project Manager/Plant

Co-ordinator.

25

Monitor PWE use on site to ensure the effectiveness of controls, maintenance and servicing.

REGIONAL TRAINING CO-ORDINATOR

26

Deliver or arrange to be delivered any training formally requested by the Project Team to

ensure the competence of Directly employed appointees.

SHE ADVISER

27

2.3.5.4

Assist pre-construction and construction teams as requested in application of this procedure.

Guidance To This Procedure

This procedure and guidance is intended to ensure compliance with statutory requirements for all

COMPANY projects regarding PWE.

Although POWER covers all work equipment, this procedure and guidance is only intended to

provide direction on the control of Powered Work Equipment (PWE) which would include but is

not limited to the following:

(a)

Drills - cable fed, hydraulic and petrol driven (it is not intended that sites include low risk

QCS 2010

QCS 2010

Section 11

Part 2

SAMAS

Page 8

battery drills etc within the scheduled part of this procedure however this does not remove

the needs to monitor the use of such equipment to ensure it is fit for purpose and used

correctly).

(b)

Saws circular, reciprocating, bench and rip

(c)

Breakers/Hammers/Chisels/Tampers All

(d)

Electric/petrol/diesel/gas Powered Plant All

(e)

Self Propelled Work Equipment Dumpers, Dozers, Rollers, Excavators etc

(f)

Cartridge Operated Fixing Tools - All

(g)

Lifting Equipment - FLTs, Hoists, HIABs, MEWPs

(h)

n.b. Other than inclusion on the PWE Schedule, all Crane Lifting Operations controls and

requirements are covered in SHE-PRO-010.

RISK ASSESSMENT

3

Where the specific controls required for the use of PWE have not been considered under the

general Risk Assessment for work, a specific Risk Assessment is required prior to its use. The

Plant Co-ordinator or Contractor (in the case of sub-contractor equipment) is responsible for its

completion. See SHE-PRO-001.

SELECTION AND SUITABILITY

The equipment ordered must be suitable to the work intended and the operating environment,

e.g.

(a)

Telehandler consider: loads, reach, site height/width/ground restrictions, operator

competence/ability and delivery restrictions etc.

(b)

Breaker consider: Individual capability, material to be broken, access, technological

developments (noise/vibration suppression), tool outputs etc.

Experience coupled with Risk Assessment should allow the selection of the correct equipment,

however, if doubt exists consult your local SHE Adviser.

PRE-USE/RECEIPT INSPECTION

To ensure serviceability, all equipment received on site (COMPANY and Sub-contractor) must be

subject to a pre-use inspection using either the COMPANY PWE Checklist (SHE-FRM-5-002) or

manufacturers guidance as appropriate.

REGISTRATION AND AUTHORISATION

To assist in ensuring only competent and authorised personnel use PWE on site, all operators

shall be recorded on the PWE Schedule (SHE-FRM-5-001).

COMPETENCE

Where a recognised industry standard exists i.e. certificate of training achievement, to show

competence for the operation of particular equipment, the operator shall possess that appropriate

certification, the details of which shall be entered on the PWE Schedule.

Where there is no recognised industry standard/certificate of training achievement, the operator

shall possess evidence of training on that particular equipment or his employer shall provide

written confirmation of training on that particular equipment.

QCS 2010

QCS 2010

Section 11

Part 2

SAMAS

Page 9

REGULAR INSPECTION

10

The purpose of an inspection is to identify whether the equipment can be operated, adjusted and

maintained safely and that any deterioration (for example defect, damage, wear) can be detected

and remedied before it results in unacceptable risks. Inspection should include, where

appropriate, visual checks, functional checks and testing. Regular inspections in this context

should be completed by the nominated competent person (usually the operator) and conform to the

requirements of the Risk Assessment taking into account, training requirements, manufacturers

guidelines and equipment specifications.

11

All PWE in use on COMPANY sites will subject to a regime of regular recorded inspection. The

maximum period between inspections shall be 7 days and these inspections shall be recorded in

the site SHE Register.

12

The above does not include any pre-use checks required of the operator, the occurrence of which

should be included in the monitoring checks.

THOROUGH INSPECTION (LIFTING EQUIPMENT)

13

In line with current statutory requirements, all lifting equipment must be subject to thorough

inspection:

(a)

Before being put into service for the first time unless either ;

(i)

the lifting equipment has not been used before; and

(ii)

in the case of lifting equipment, the employer has received such a declaration made

not more than 12 months before the lifting equipment is put into service or if it is

obtained from the undertaking of another person, it is accompanied by physical

evidence of thorough inspection

(iii)

Where the safety of the lifting equipment is dependent on the installation conditions

14

Where it is exposed to conditions causing deterioration which is liable to result in dangerous

situations

15

As a maximum the thorough inspection should be completed at 12 monthly intervals, where the

equipment is used for the lifting of persons, the period is reduced to 6 months.

MAINTENANCE

16

It should be remembered that different maintenance management techniques have different

benefits:

17

Where safety-critical parts could fail and cause the equipment, guards or other protection devices

to fail and lead to immediate or hidden potential risks, a formal system of PPM or Conditioned

Based Maintenance is likely to be required.

RECORDS

18

The following records shall be maintained throughout the use of any PWE on site:

(a)

PWE Schedule - Completed on receipt of any PWE and maintained with all relevant detail

until the PWE is removed from site. Any PWE merely Off-Hired shall be subject to the

same controls as other in-use equipment.

(b)

Maintenance A record of all maintenance completed shall be kept in the site SHE

Register.

(c)

Regular Inspection All regular inspections shall be recorded in the site SHE Register.

(d)

Thorough Inspection A record of all thorough inspections completed prior to or during the

PWE time on site shall be maintained in the site SHE Register.

QCS 2010

QCS 2010

Section 11

Part 2

SAMAS

Page 10

2.3.5.5 Appendices

APPENDIX 1 PWE SCHEDULE

Owner

COMPANY

Works

Package/ Subcontractor

QCS 2010

Equipment Registration/

Date

Checklist

Type

Fleet/

Received Completed

Serial

on

By

Number

Site

Date of Last

Thorough

Inspection

Date of

Next

Thorough

Inspection

Authorised

User(s)

By Name

Competence

Details

Risk

Assessment

Completed and

Communicated

By

Competent

Inspector

Date

Removed

From

Site

QCS 2010

Section 11

Part 2

SAMAS

Page 11

Appendix 2 PWE Checklist

PLANT/WORK EQUIPMENT DETAILS

Contract:

Location:

Type of plant/Equipment:

Equipment Fleet or Serial No:

Supplier:

Order No:

Received by:

Date:

User (COMPANY or Sub-Contractor):

CHECKLIST

WORK EQUIPMENT

Yes

1. Is the item of plant/work equipment as ordered or a suitable alternative?

2. Is the item of plant/work equipment in good condition? Are there any noticeable

defects i.e. oil leaks, damaged panels, tyres, guards missing, etc?

3. Has plant/equipment been supplied with the necessary;

Operating instructions

Manufacturers Handbook

Completed maintenance Checklist (PPM/Service Record)

Warning Notices/Signs/Safety Equipment (locking bars/pins etc.) attached

Appropriate Drip Trays/Spill Response Kit

Is all information in English

4. Has a current certificate of thorough examination (or EU Declaration of

Conformity) been supplied/provided with the equipment (Lifting Equipment only)

5. Where equipment has been assembled on site, has a written confirmation been

provided as to its fitness for use?

Defects/Comments/Actions:

Signature:

Date:

Notes:

1: Where a suitable alternative has been provided, the person completing the checklist must revisit the Risk Assessment and amend controls as necessary.

2: Where lifting equipment is supplied for the lifting of persons, the thorough inspection/EU

Declaration must be within 6 months of issue date.

COMPLETED FORM TO BE FILED IN PROJECT SHE REGISTER

QCS 2010

No

QCS 2010

Section 11

Part 2

SAMAS

Page 12

2.3.5.6 Reference Documents

PROCEDURES

1

SHE PRO 001 SHE Risk Management and Written Safe Systems of Work

SHE PRO 010 The Safe Use of Cranes and other Lifting Appliances

REFERENCE DOCUMENTS

Qatar Regulatory Document (Construction) RD1.4

2.3.5.7 Author

SECTION

NAME

POSITION IN

COMPANY

CONTACT DETAILS

SHE Manager

2.3.5.8 Approvals

NAME

Approved by:

QCS 2010

POSITION IN

COMPANY

SHEQ Director

SIGNATURE & DATE

QCS 2010

Section 11

Part 2

SAMAS

Page 13

PLANT/WORK EQUIPMENT DETAILS

Contract:

Location:

Type of plant/Equipment:

o

Equipment Fleet or Serial N :

o

Supplier:

Order N :

Received by:

Date:

User (COMPANY or Sub-Contractor):

CHECKLIST

WORK EQUIPMENT

Yes

No

1. Is the item of plant/work equipment as ordered or a suitable alternative?

2. Is the item of plant/work equipment in good condition? Are there any

noticeable defects i.e. oil leaks, damaged panels, tyres, guards missing, etc?

3. Has plant/equipment been supplied with the necessary;

Operating instructions

Manufacturers Handbook

Completed maintenance Checklist (PPM/Service Record)

Warning Notices/Signs/Safety Equipment (locking bars/pins etc.)

attached

Appropriate Drip Trays/Spill Response Kit

Is all information in English

4. Has a current certificate of thorough examination (or EU Declaration of

Conformity) been supplied/provided with the equipment (Lifting Equipment

only)

5. Where equipment has been assembled on site, has a written confirmation

been provided as to its fitness for use?

Defects/Comments/Actions:

Signature:

Date:

Notes:

1: Where a suitable alternative has been provided, the person completing the checklist must revisit the Risk Assessment and amend controls as necessary.

2: Where lifting equipment is supplied for the lifting of persons, the thorough inspection/EU

Declaration must be within 6 months of issue date.

COMPLETED FORM TO BE FILED IN PROJECT SHE REGISTER

QCS 2010

QCS 2010

Section 11

Part 2

GENERAL REQUIREMENTS

1 Suitable for its purpose

SAMAS

SPECIFIC REQUIREMENTS

1 Satisfactory guards provided for

dangerous parts of machinery?

2 Suitable for its location

2 Other hazards minimised?

3 In a good order

a) Ejection/falling of anything

4 Restricted to use by authorised

personnel (if necessary)

b) Disintegration/collapse of equipment

5 Provided with instruction for use

and maintenance (in Arabic &

English)

c) Fire or overheating

6 Have operators been trained?

e) Hot/cold surfaces

7 Have supervisors been trained?

3 Controls satisfactory?

8 Is a maintenance log kept (plant

and machinery only)

a) Stop/start

d) Explosion of equipment or contents

b) Emergency (over-rides others)

9 Is log kept up to date (plant and

machinery only

10 Are maintenance arrangement

satisfactory

c) Run controls

d) Audible/visual warnings

e) Clearly indicated, visible, safely

positioned

f) Fail safe

g) Isolation arrangements

4 Is equipment stable?

5 Is lighting adequate?

6 Have the safety of maintenance

personnel been considered?

7 Is safety information marked on the

equipment

8 Are necessary warnings/warning

devices on equipment?

9 If warnings not marked and necessary

is there a written system of

work/permit?

QCS 2010

Page 14

S-ar putea să vă placă și

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Qcs 2010 Section 13 Part 2 Mortar and GroutDocument6 paginiQcs 2010 Section 13 Part 2 Mortar and Groutbryanpastor106Încă nu există evaluări

- Qcs 2010 Section 25 Part 3 WorkmanshipDocument4 paginiQcs 2010 Section 25 Part 3 Workmanshipbryanpastor106Încă nu există evaluări

- QCS 2010 Section 25 Part 2 Glass PDFDocument5 paginiQCS 2010 Section 25 Part 2 Glass PDFbryanpastor1060% (1)

- QCS 2010 Section 25 Part 4 Glazed Curtain WallDocument10 paginiQCS 2010 Section 25 Part 4 Glazed Curtain Wallbryanpastor106100% (1)

- Qcs 2010 Section 25 Part 1 General PDFDocument3 paginiQcs 2010 Section 25 Part 1 General PDFbryanpastor106Încă nu există evaluări

- Qcs 2010 Section 13 Part 1 GeneralDocument4 paginiQcs 2010 Section 13 Part 1 Generalbryanpastor106Încă nu există evaluări

- Qcs 2010 Section 13 Part 3 Accessories PDFDocument3 paginiQcs 2010 Section 13 Part 3 Accessories PDFbryanpastor106Încă nu există evaluări

- Qcs 2010 Section 13 Part 5 Masonry Laying PDFDocument11 paginiQcs 2010 Section 13 Part 5 Masonry Laying PDFbryanpastor106Încă nu există evaluări

- Qcs 2010 Section 13 Part 4 Unit Masonry PDFDocument12 paginiQcs 2010 Section 13 Part 4 Unit Masonry PDFbryanpastor106100% (1)

- Qcs 2010 Section 11 Part 2.3.11 She Procedures - Permit To Work SysteDocument20 paginiQcs 2010 Section 11 Part 2.3.11 She Procedures - Permit To Work Systebryanpastor106Încă nu există evaluări

- Qcs 2010 Section 12 Part 3 Filling PDFDocument4 paginiQcs 2010 Section 12 Part 3 Filling PDFbryanpastor106100% (1)

- Qcs 2010 Section 12 Part 2 Excavation PDFDocument4 paginiQcs 2010 Section 12 Part 2 Excavation PDFbryanpastor106100% (1)

- Qcs 2010 Section 12 Part 1 General PDFDocument4 paginiQcs 2010 Section 12 Part 1 General PDFbryanpastor106Încă nu există evaluări

- QCS 2010 Section 11 Part 2.3.07 She Procedures - Contractors InitialDocument15 paginiQCS 2010 Section 11 Part 2.3.07 She Procedures - Contractors Initialbryanpastor106Încă nu există evaluări

- Qcs 2010 Section 11 Part 2.3.09 SHE Procedures - PERSONAL PROTECTIVE PDFDocument12 paginiQcs 2010 Section 11 Part 2.3.09 SHE Procedures - PERSONAL PROTECTIVE PDFbryanpastor106Încă nu există evaluări

- Qcs 2010 Section 11 Part 2.3.08 She Procedures - The Report and InvesDocument39 paginiQcs 2010 Section 11 Part 2.3.08 She Procedures - The Report and Invesbryanpastor106Încă nu există evaluări

- Qcs 2010 Section 11 Part 2.3.10 She Procedures - The Safe Use of CranDocument26 paginiQcs 2010 Section 11 Part 2.3.10 She Procedures - The Safe Use of Cranbryanpastor106100% (7)

- Qcs 2010 Section 11 Part 1.7 Regulatory Document - FIRE and FLAMMABLEDocument75 paginiQcs 2010 Section 11 Part 1.7 Regulatory Document - FIRE and FLAMMABLEbryanpastor106100% (1)

- Qcs 2010 Section 11 Part 2.3.12 She Procedures - Control of Working ADocument9 paginiQcs 2010 Section 11 Part 2.3.12 She Procedures - Control of Working Abryanpastor106Încă nu există evaluări

- Qcs 2010 Section 11 Part 2.3.14 SHE Procedures - ASBESTOSDocument17 paginiQcs 2010 Section 11 Part 2.3.14 SHE Procedures - ASBESTOSbryanpastor106Încă nu există evaluări

- Qcs 2010 Section 11 Part 2.3.13 She Procedures - Fire Precautions DurDocument10 paginiQcs 2010 Section 11 Part 2.3.13 She Procedures - Fire Precautions Durbryanpastor106Încă nu există evaluări

- Qcs 2010 Section 11 Part 2.3.01 She Procedures - Risk IdentificationDocument31 paginiQcs 2010 Section 11 Part 2.3.01 She Procedures - Risk Identificationbryanpastor106Încă nu există evaluări

- Qcs 2010 Section 11 Part 2.4 Risk Assessment GuidesDocument84 paginiQcs 2010 Section 11 Part 2.4 Risk Assessment Guidesbryanpastor106100% (1)

- Qcs 2010 Section 11 Part 2.3.15 She Procedures - Environmental ProtecDocument43 paginiQcs 2010 Section 11 Part 2.3.15 She Procedures - Environmental Protecbryanpastor106Încă nu există evaluări

- Qcs 2010 Section 11 Part 2.1 Safety, Health and Environment (She) ManDocument30 paginiQcs 2010 Section 11 Part 2.1 Safety, Health and Environment (She) Manbryanpastor10675% (8)

- Qcs 2010 Section 11 Part 1.6 Regulatory Documents - HUMAN FACTORS PDFDocument74 paginiQcs 2010 Section 11 Part 1.6 Regulatory Documents - HUMAN FACTORS PDFbryanpastor106Încă nu există evaluări

- Qcs 2010 Section 11 Part 2.3.16 She Procedures - Learning Event ReporDocument9 paginiQcs 2010 Section 11 Part 2.3.16 She Procedures - Learning Event Reporbryanpastor106Încă nu există evaluări

- Qcs 2010 Section 11 Part 1.5 Regulatory Document - OTHER HAZARDOUS A PDFDocument124 paginiQcs 2010 Section 11 Part 1.5 Regulatory Document - OTHER HAZARDOUS A PDFbryanpastor106100% (1)

- Qcs 2010 Section 11 Part 1.3 Regulatory Document - WORKING at HEIGHTSDocument145 paginiQcs 2010 Section 11 Part 1.3 Regulatory Document - WORKING at HEIGHTSbryanpastor106100% (5)

- Qcs 2010 Section 11 Part 1.4 Regulatory Document - SAFE USE OF PLANT PDFDocument130 paginiQcs 2010 Section 11 Part 1.4 Regulatory Document - SAFE USE OF PLANT PDFbryanpastor106Încă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Risk Matrix For Risk ManagersDocument18 paginiRisk Matrix For Risk ManagersTunas Andiranto100% (2)

- JOB SAFETY ANALYSIS DikonversiDocument4 paginiJOB SAFETY ANALYSIS DikonversiAgung Tri SugihartoÎncă nu există evaluări

- Material Safety Data Sheet for Aqua Soft CIDocument3 paginiMaterial Safety Data Sheet for Aqua Soft CIJaleel AhmedÎncă nu există evaluări

- RAMS For Installation of MDB DB SMDBDocument22 paginiRAMS For Installation of MDB DB SMDBAnandu AshokanÎncă nu există evaluări

- Construction Safety and Health ProgramDocument19 paginiConstruction Safety and Health Programjoel.paz.vitugÎncă nu există evaluări

- NFPA Hazard Diamond ExplainedDocument2 paginiNFPA Hazard Diamond ExplainedMuhammad UzairÎncă nu există evaluări

- Rmdjv-pj74-Hiradc-subc 04 (Site Clearing & Earthwork)Document2 paginiRmdjv-pj74-Hiradc-subc 04 (Site Clearing & Earthwork)myn maliQueÎncă nu există evaluări

- Astm F770-18Document4 paginiAstm F770-18Martin Tapankov100% (1)

- Manual Safety Relays 3SK2 en-USDocument352 paginiManual Safety Relays 3SK2 en-USKarina Ospina100% (3)

- Road Safety PresentationDocument22 paginiRoad Safety PresentationMahesh Ramteke100% (4)

- Kavo in Exam 3510 Digital X-Ray - User ManualDocument68 paginiKavo in Exam 3510 Digital X-Ray - User ManualJuancarlosÎncă nu există evaluări

- Ipsg 6 Patient SafetyDocument12 paginiIpsg 6 Patient SafetyJamilaturRasyidahEfendiÎncă nu există evaluări

- Sample Commissioning PlanDocument36 paginiSample Commissioning Planvan81% (16)

- MAN LIFT ML-001 TB42manual-OperatorDocument68 paginiMAN LIFT ML-001 TB42manual-OperatorRoxana Elizabeth Valencia NavarrteÎncă nu există evaluări

- Policy EditedDocument57 paginiPolicy EditedJoann SacolÎncă nu există evaluări

- Chapter 19 - Value Analysis Table of ContentsDocument36 paginiChapter 19 - Value Analysis Table of ContentsaouadibelgacemÎncă nu există evaluări

- Curriculum Map TLE8Document11 paginiCurriculum Map TLE8Leonisa GurreaÎncă nu există evaluări

- Disaster ManagementDocument39 paginiDisaster ManagementmujeebtalibÎncă nu există evaluări

- Risk Assessment FormDocument8 paginiRisk Assessment FormRochdi BahiriÎncă nu există evaluări

- LS CS M 069 Defender Press Brake Guarding System Operation Manual 1.04Document55 paginiLS CS M 069 Defender Press Brake Guarding System Operation Manual 1.04gustavo gonzalezÎncă nu există evaluări

- HAZOP Study Guide for Process SafetyDocument137 paginiHAZOP Study Guide for Process SafetyPutri Saidatina100% (1)

- Cross Hole Sonic Integrity Tests - Khulna - 15.11.2014Document6 paginiCross Hole Sonic Integrity Tests - Khulna - 15.11.2014Probal ProsoilÎncă nu există evaluări

- Safety Data Sheet: Section 6. Accidental Release MeasuresDocument2 paginiSafety Data Sheet: Section 6. Accidental Release Measurespkegulf pkegulfÎncă nu există evaluări

- Philippine National Standards For Drinking Water PNSDW 2007 PDFDocument40 paginiPhilippine National Standards For Drinking Water PNSDW 2007 PDFJenny Dawn Valdez100% (1)

- Computer Systems Servicing NC II: Unit of Competency 1Document7 paginiComputer Systems Servicing NC II: Unit of Competency 1Mitchyku Zapanta DiamolaÎncă nu există evaluări

- Develop WHS Plan and Implement: Submission DetailsDocument19 paginiDevelop WHS Plan and Implement: Submission DetailsTawan Prayord100% (2)

- Planned Job Observation For OHC DONEDocument4 paginiPlanned Job Observation For OHC DONEWelma JohnsonÎncă nu există evaluări

- Abb Substation Instr.Document8 paginiAbb Substation Instr.Ramesh RakhadeÎncă nu există evaluări

- Preventive and Corrective Action For Safety and Health HazardsDocument2 paginiPreventive and Corrective Action For Safety and Health HazardsTHOMASÎncă nu există evaluări

- g7 Safety Regulations Household ServicesDocument36 paginig7 Safety Regulations Household ServicesTalim Pt NhsÎncă nu există evaluări