Documente Academic

Documente Profesional

Documente Cultură

DIN 82-1973-Eng-Knurls PDF

Încărcat de

mrccrmmrcDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

DIN 82-1973-Eng-Knurls PDF

Încărcat de

mrccrmmrcDrepturi de autor:

Formate disponibile

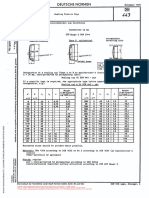

DEUTSCHE NORMEN

UDC 681.945

(www.freebz.net)

January 1973

EN

Knurls

82

Rndel

Dimensions i n mm

Manufacturing methods using

h u r l i n g r o l l s according t o DIN 403

Denomination and representation

Detail

i

--IA

t

c

Workpie

Section

A-A

0

o

Knurling r o l l AA

Knur? RAA

drkpiece

lorkpie

Knur? RAA

Workpiec

I

Knurling r o l l BL

s w i v e l l e d 30,

Left-hand h u r l

Section

Knurling roll^

e w i v e l l e d 30'

B-6

Workpie

.-E

c

Knurling r l l BR

.-cm

Knurl& r o l l AA

s w i v e l l e d 30

Workpiece

2

3

2

Knurl RBR

n

BR

dorkp

KnurlingI roll BL

Knurling r o l l AA

s w i v e l l e d 30

Continued on pages 2 to 4

Explanations on page 4

Alleinverkauf der Normbltter durch Beuth VerlagGmbH, Berlin 30 und Kln

(www.freebz.net)

DIB 82 engl. Preisgr.

--`,,,,``,,`,`,,,`,`,```````,``-`-`,,`,,`,`,,`---

Knurl RAA

Knurl with grooves p a r a l l e l t o axia

(www.freebz.net)

PaEe 2

DIN 82

Manufacturing methode using

b u r l i n g r o l l e according t o DIN 40:

Denomination arid repreeentation

h u r l , pointe raised' )

Leit-hand/rigt-hand

0-0

Section

RGE

oripie ce

Knurling roll 81

hurling roll11

swivelled 30'

hurl, pointe indented*)

Leit-hand/right-hand

Section

F-F

section

Detail

Knurl RGV

G-G

RGU

Workpi

burling roll GE

Yorkpiec.

--`,,,,``,,`,`,,,`,`,```````,``-`-`,,`,,`,`,,`---

-4G

Croes-knurl, points raised

H-H

Section

Knurl RKE

/

tKE

Detail

Sec tion

J-J

hurling r o l l KV

Uorkp iec e

--i

'1 Previous denomination "Diamond hurling"

2 , Previous denomination "Negative diamond hurling"

(www.freebz.net)

(www.freebz.net)

D I N 82

Manufacturing methods using

h u r l i n g r o l l s accordingtoDIN 405

Denomination and representation

Cross-knurl,

Page 3

p o i n t s indented

Section K- K

Knurl RKV

Section L-L

Workpi

/

Knurling r o l l KE

knurl, p o i n t s r a i s e d (Type RGE) with p i t c h t

Knml RGE 08 DIN 82

Designation of a left-hand/right-hand

(08):

2. Dimensions

2.1. P r o f i l e an&

P r o f i l e angle a

-----------_---

0.8 mm

90.

I f necessary, knurls can a l s o be made with p r o f i l e angle a

105O. i n t h i s case, t h e designat i o n reads, e.

f o r a left-hand/rlght-hand

knurl, pointe r a i s e d (Type RGE) with p i t c h

t = 0.8 mm (087 and p r o f i l e angle a

105O (105):

Knurl RGE O8

105 D I N 82

.,

'Po minimize t h e number of lmurling r o l l e required f o r making t h e knurls, t h e

are l i m i t e d t o t h e nominal values

0.5

0.6

0.8

knurl p i t c h e s t

1.6 m.

1.2

The nominal diameter d l s t a t e d i n t h e workshop drawing i s the outside diameter of t h e finished knurl; t h i s dimension i s a function of the design.

2.4. I n i t i a l diameter d2

The i n i t i a l diameter d of t h e workpiece p r i o r t o h u r l i n g muet be smaller than the nominal

diameter d l , because t i e i n i t i a l diameter undergoes enlargement through displacement of t h e

m a t e r i a l during the h u r l i n g operation.

The i n i t i a l diameter d2 for h u r l e with p r o f i l e angle a = 90 can be c a l c u l a t e d from t h e f o r mulae i n t h e Table below, depending on t h e type of knurl and t h e s i a e of pitch.

The f a c t o r s i n the fonuulae, however, do n o t take i n t o account t h e rounding of t h e grooves

r e s u l t i n g from t h e h u r l i n g operation or t h e s p e c i f i c p r o p e r t i e s of the materiale t o be

knurled.

---------------------

Type of k n u r l

I n i t i a l diameter

RAA Knurl v i t h grooves parallel t o axis

RBL Left-hand k n u r l

RBR Right-hand k n u r l

d l -0,5 t

RGE Left-hand/right-hand knurl, p o i n t s

d l -0.67 t

RGV Left-hand/right-hand knurl, p o i n t s

indented

dl -0.33 t

RKE Cross-knurl, p o i n t s r a i s e d

d l -0,67 t

raised

d2-

RKV Cross-knurl, p o i n t s indented

--`,,,,``,,`,`,,,`,`,```````,``-`-`,,`,,`,`,,`---

(www.freebz.net)

d l -0.33 t

(www.freebz.net)

Page 4 DIB 82

References to further etandards

DIB 403 h u r l i n g rolls

DIB 8583 Sheet 5 Production method compression foming; inipreeaing, c l a s s i f i c a t i o n , definitions

Explanations

Compared with t h e January 1940 issue of DIN 82, t h e standard denomination "knurl" has been adopted f o r

a l l types, s i n c e t h e previous denominations "diamond knurling" and "negative diamond knurlng" vere not

used c o n a i a t e n t l y , and hence d i f f i c u l t i e a a r o s e i n t h e choice of toola. Some type8 of knurl have been

given b r i e f e r denominations, auch ea left-hand h u r l , right-hand k n u r l , left-hand/right-hand b u r l .

The type l e t t e r symbols assigned t o t h e various types provido both for b e t t e r d i f f e r e n t i a t i o n and a l s o

y i e l d a code deaienation f o r use in e l e c t r o n i c d a t a processing. The l e t t e r R d i f f e r e n t i a t e s t h e b u r l a

Zrom t h e h u r l i n g r o l l e (aee DIN 403). t h e second l e t t e r (A, E, (i and K) d e s i g n a t e s t h e b a s i c type.

v h i l e t t h e t h i r d l e t t e r (A

p a r a l l e l t o axia, L

left-hand, E

right-hand, E

raised, Y

indented)

marks t h e d i r e c t i o n and form of t h e groovea.

standard value of .

'03

The p r o f i l e an&e is

The h e l i x cingle o f Types BB, BL. GE and QV is f i x e d a t

n o m a l l y a = 90, but, I f necessary, knurls with a p r o f i l e a = 10.50 giving a s h a l l o u e r depth

can

be made. This s p e c i a l c a s e must be s t a t e d in t h e designation.

2 m has been discontinued becauBe it is s c a r c e l y uaed in p r a c t i c e . S i m i l a r l y , no attempt

The p i t c h t

haa been made t o c o r r e l a t e p i t c h v i t h uorkpiece diameter, s i n c e recommendations made e a r l i e r have n o t

proved s u i t a b l e i n a11 f i e l d s of a p p l i c a t i o n and hence t h s i r adoption in a c t u a l p r a c t i c e has been l i m ited.

Formulae f o r c a l c u l a t i n g t h e i n i t i a l diameter of t h e workpiece a s a function of t h e type of k n u r l and

of t h e o u t s i d e diameter of t h e f i n i s h e d h u r l , which counts as t h e nominal diameter, a r e given. The res u l t s obtained a r e only r e f e r e n c e values. however, s i n c e t h e s p e c i f i c p r o p e r t i e s of t h e m a t e r i a l s hare

not been taken i n t o account.

To f a c i l i t a t e t h e ChOOBing of h u r l i n g r o l l e aCCOrdin& t o DIN 403, t h e manufacturing methods s u i t a b l e

f o r each type of b u r l are indicated.

--`,,,,``,,`,`,,,`,`,```````,``-`-`,,`,,`,`,,`---

(www.freebz.net)

S-ar putea să vă placă și

- Din 8062-3 2009 PDFDocument10 paginiDin 8062-3 2009 PDFkoalaboi33% (3)

- Iso 7380Document8 paginiIso 7380pradelles100% (1)

- Din 443 PDFDocument1 paginăDin 443 PDFLuciano Fontes100% (1)

- Din 13-1Document4 paginiDin 13-1Sankha Dasgupta100% (3)

- DIN 76-1 - (2004) - Thread Run-Outs and Thread Undercuts For ISO Metric Threads As in DIN 13-1 PDFDocument5 paginiDIN 76-1 - (2004) - Thread Run-Outs and Thread Undercuts For ISO Metric Threads As in DIN 13-1 PDFnoraafshin100% (2)

- Iso 4156 1 2005 en PDFDocument11 paginiIso 4156 1 2005 en PDFDavide FregniÎncă nu există evaluări

- Din 5480-15Document2 paginiDin 5480-15Bajrang Gears67% (3)

- Din 3963 PDFDocument18 paginiDin 3963 PDFLuciano Fontes0% (1)

- DT40 PDFDocument34 paginiDT40 PDFFrancisco Carlos TelesÎncă nu există evaluări

- Knurling Profiles DIN 82Document3 paginiKnurling Profiles DIN 82mirzasinanovic100% (1)

- Din 475Document4 paginiDin 475Sinan Chen100% (1)

- 6935 2011Document13 pagini6935 2011Tufan Ünal100% (4)

- Din 8140-1 PDFDocument13 paginiDin 8140-1 PDFOSCAR VALENCIAÎncă nu există evaluări

- Splines: Side Splines For Soft Holes in Fittings-Sae J499aDocument4 paginiSplines: Side Splines For Soft Holes in Fittings-Sae J499aSanjay C BhattÎncă nu există evaluări

- Din en Iso 9013Document8 paginiDin en Iso 9013Cemal NergizÎncă nu există evaluări

- DEXT 085 DIN 928 Porca Solda QuadradaDocument10 paginiDEXT 085 DIN 928 Porca Solda Quadradatestesada100% (2)

- Sae J1102M 2001 (En)Document5 paginiSae J1102M 2001 (En)Oh No PotatoÎncă nu există evaluări

- BS 57 (1951)Document23 paginiBS 57 (1951)dapsiduÎncă nu există evaluări

- Din 938 - StudsDocument5 paginiDin 938 - StudsRicky WCKÎncă nu există evaluări

- Ford Worldwide Fastener Standard: Printed Copies Are UncontrolledDocument7 paginiFord Worldwide Fastener Standard: Printed Copies Are Uncontrolledferhat aydoganÎncă nu există evaluări

- Cold Bending DIN 6935 (Eng)Document4 paginiCold Bending DIN 6935 (Eng)maik angelo0% (2)

- ISO 8062 3 2007 Casting Tolerance PDFDocument1 paginăISO 8062 3 2007 Casting Tolerance PDFPankajMakwanaÎncă nu există evaluări

- Din 267 - 27Document18 paginiDin 267 - 27Ricardo Vitoriano100% (1)

- Iso 8062Document1 paginăIso 8062Asrar Ahmed100% (2)

- Douglas UFO DocsDocument275 paginiDouglas UFO DocsAndrew JohnsonÎncă nu există evaluări

- 8×8 LED Matrix MAX7219 With Scrolling Text & Android Control Via BluetoothDocument15 pagini8×8 LED Matrix MAX7219 With Scrolling Text & Android Control Via BluetoothakashlogicÎncă nu există evaluări

- TYBTech Syllabus MechanicalDocument49 paginiTYBTech Syllabus MechanicalswapnillkÎncă nu există evaluări

- Av36d303 SchematicDocument30 paginiAv36d303 SchematicLuis MorenoÎncă nu există evaluări

- Din 8140-1Document5 paginiDin 8140-1main46prairieÎncă nu există evaluări

- Din 472 1981-09 PDFDocument12 paginiDin 472 1981-09 PDFSenthil Kumar GanesanÎncă nu există evaluări

- Din 5480Document27 paginiDin 5480MiguelÎncă nu există evaluări

- Keyway DIN 6885 - Parallel Metric Keys and Keyway DimensionsDocument2 paginiKeyway DIN 6885 - Parallel Metric Keys and Keyway DimensionsHenrique MarquesÎncă nu există evaluări

- Din 76-1Document5 paginiDin 76-1mesa142Încă nu există evaluări

- DIN 7349 - Arruela Plana PDFDocument1 paginăDIN 7349 - Arruela Plana PDFpierocarnelociÎncă nu există evaluări

- DIN 5480-2.PDF - Engineering Tolerance - GearDocument25 paginiDIN 5480-2.PDF - Engineering Tolerance - GearDeniz Tuncbilek0% (2)

- Din 434Document1 paginăDin 434RaduZapciroiuÎncă nu există evaluări

- Iso 7379Document2 paginiIso 7379Ahmed ElsafouryÎncă nu există evaluări

- DIN 5480 Nazubljena OsovinaDocument27 paginiDIN 5480 Nazubljena OsovinaNikola MilojevicÎncă nu există evaluări

- Din 6885Document1 paginăDin 6885Riadini Anis Hade50% (2)

- Din76 2 84Document3 paginiDin76 2 84Luis TestaÎncă nu există evaluări

- Din en Iso 7090Document8 paginiDin en Iso 7090Jennifer Owens100% (2)

- Din en 1663-EnDocument9 paginiDin en 1663-EnThiago GoncalvesÎncă nu există evaluări

- Metric DIN 137 SpecDocument5 paginiMetric DIN 137 Specpradipbhosale81Încă nu există evaluări

- Din 1705Document2 paginiDin 1705Anurag Jain50% (2)

- Din 470 PDFDocument6 paginiDin 470 PDFLuciano FontesÎncă nu există evaluări

- Cross Recessed Cheese Head Screws: UDC 621 882 215.3.091 2 July 1986Document5 paginiCross Recessed Cheese Head Screws: UDC 621 882 215.3.091 2 July 1986Charmaine DrafkeÎncă nu există evaluări

- Din Iso 965-1Document21 paginiDin Iso 965-1Memo Gonzalez Aleman100% (1)

- DIN 137 Type A, Spring Washers, CurvedDocument2 paginiDIN 137 Type A, Spring Washers, CurvedSteve1108Încă nu există evaluări

- Iso 7380Document1 paginăIso 7380Nisa_nisheÎncă nu există evaluări

- Cutting With BroachDocument5 paginiCutting With BroachJori Kristian RidayatÎncă nu există evaluări

- Din 929 - 01-00Document5 paginiDin 929 - 01-00qualidade1fameqÎncă nu există evaluări

- Din 7977Document1 paginăDin 7977zorghi1Încă nu există evaluări

- Din 13-51Document1 paginăDin 13-51anks_raÎncă nu există evaluări

- Artigo Stave de Ferro Fundido 1976Document14 paginiArtigo Stave de Ferro Fundido 1976Gabriel MáximoÎncă nu există evaluări

- Lammeren W P A.Wageningen B-Screw S.1969.TRANS PDFDocument49 paginiLammeren W P A.Wageningen B-Screw S.1969.TRANS PDFStefanoÎncă nu există evaluări

- A Simple Method For The Selection of Axial Fan Blade ProfilesDocument7 paginiA Simple Method For The Selection of Axial Fan Blade ProfilesVigiiÎncă nu există evaluări

- Tonar Katalog 0-11sDocument10 paginiTonar Katalog 0-11schampionÎncă nu există evaluări

- Sulzer 6rlb76 Me Diesel Engines SulzerDocument300 paginiSulzer 6rlb76 Me Diesel Engines SulzerJoseph AbrahamÎncă nu există evaluări

- Deburring Catalog 2011Document30 paginiDeburring Catalog 2011WVPÎncă nu există evaluări

- Investigations On Partial Penetration Welded NozzleDocument15 paginiInvestigations On Partial Penetration Welded NozzleAndres_Pastor1987Încă nu există evaluări

- Imi022 David Brown Technical Service Bulletins & Parts Bulletins Part 1Document151 paginiImi022 David Brown Technical Service Bulletins & Parts Bulletins Part 1Mauro SantanaÎncă nu există evaluări

- UT Rotary Tube TestingDocument4 paginiUT Rotary Tube Testingach soÎncă nu există evaluări

- 110 Semiconductor Projects for the Home ConstructorDe la Everand110 Semiconductor Projects for the Home ConstructorEvaluare: 4 din 5 stele4/5 (1)

- Planning For Procurement of Construction ContractsDocument41 paginiPlanning For Procurement of Construction ContractsJoel AlcantaraÎncă nu există evaluări

- 2 TensionDocument28 pagini2 TensionRICKY IVANÎncă nu există evaluări

- Statistical Process Control & Cost of QualityDocument114 paginiStatistical Process Control & Cost of QualityAshraf S. Youssef100% (2)

- Wanyiri S K - Traffic Congestion in Nairobi CBDDocument65 paginiWanyiri S K - Traffic Congestion in Nairobi CBD1man1bookÎncă nu există evaluări

- SW11Document6 paginiSW11Adam GordonÎncă nu există evaluări

- Olefins-All Product CatalogDocument28 paginiOlefins-All Product Catalogayon_hossen242Încă nu există evaluări

- Case Study - RESCOMDocument43 paginiCase Study - RESCOMMahima PriyadarshiniÎncă nu există evaluări

- Glass & Glazing WorkDocument34 paginiGlass & Glazing WorkPratik ThakkarÎncă nu există evaluări

- Department: First Year Name of Subject: Engg. Mechanics Unit Number: 04 (Analysis of Structure)Document2 paginiDepartment: First Year Name of Subject: Engg. Mechanics Unit Number: 04 (Analysis of Structure)JayÎncă nu există evaluări

- Comb - Chemkin - Format PDFDocument5 paginiComb - Chemkin - Format PDFMUHAMMAD FAREEZ IZWAN BIN ABDUL JALILÎncă nu există evaluări

- Assignment 1 Low Temperature and SuperconductivityDocument3 paginiAssignment 1 Low Temperature and SuperconductivityNadhrah MuradÎncă nu există evaluări

- Modeling and Control of Side Face Beam Cracking - FroschDocument10 paginiModeling and Control of Side Face Beam Cracking - FroschphamminhquangÎncă nu există evaluări

- Mobile Network LayerDocument25 paginiMobile Network LayerAmrendra Kumar Mishra100% (2)

- SuperOrca ManualDocument22 paginiSuperOrca Manualarm usaÎncă nu există evaluări

- SS-7 May Refer To:: RFC 2719 RFC 2719Document15 paginiSS-7 May Refer To:: RFC 2719 RFC 2719William GentryÎncă nu există evaluări

- A Review On Water ElectrolysisDocument18 paginiA Review On Water ElectrolysisSilvester KolicÎncă nu există evaluări

- Remote Log-In, Electronic Mail and File Transfer: Solutions To Odd-Numbered Review Questions and ExercisesDocument2 paginiRemote Log-In, Electronic Mail and File Transfer: Solutions To Odd-Numbered Review Questions and ExercisesAnurag UpadhyayÎncă nu există evaluări

- Stanley 46 InstructionsDocument2 paginiStanley 46 Instructionsj_abendstern4688Încă nu există evaluări

- Day 1 Borehole Geophysics WDocument21 paginiDay 1 Borehole Geophysics Waliy2k4uÎncă nu există evaluări

- Wireman, Terry - Training Programs For Maintenance Organizations - Maintenance Strategy Series (2013, Reliabilityweb Com)Document221 paginiWireman, Terry - Training Programs For Maintenance Organizations - Maintenance Strategy Series (2013, Reliabilityweb Com)Faiza TariqÎncă nu există evaluări

- Swimming Pool Pump & Filter SystemDocument8 paginiSwimming Pool Pump & Filter SystemDedy KristiantoÎncă nu există evaluări

- ProeDocument160 paginiProejohn100% (1)

- Excel To C I For Positive in PutDocument23 paginiExcel To C I For Positive in PuthimanshuÎncă nu există evaluări

- XMT 350 Vs PDFDocument36 paginiXMT 350 Vs PDFgerman gualavisiÎncă nu există evaluări

- Interfaces KelloggDocument16 paginiInterfaces KelloggUrrÎncă nu există evaluări

- Asymmetric Cycler Time Relay: Instruction ManualDocument2 paginiAsymmetric Cycler Time Relay: Instruction ManualRamius HamdaniÎncă nu există evaluări

- SA-6 Press KitDocument53 paginiSA-6 Press KitBob Andrepont100% (1)