Documente Academic

Documente Profesional

Documente Cultură

Casos de Estudio

Încărcat de

psycopaulDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Casos de Estudio

Încărcat de

psycopaulDrepturi de autor:

Formate disponibile

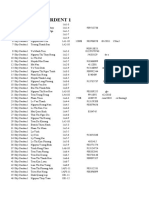

Product Area:

Aspen Plus

Dow

Applying Solids Modeling in Aspen Plus

Dow significantly improved their understanding a process where a key reactant was a solid, particularly particle

growth mechanisms and how particle size affected batch size downstream.

Liquid Light

Commercialization of Green Chemical & Fuel Technologies

Liquid Light used Aspen Plus and Aspen Properties to design and scale up a new process for the conversion of

CO2 into chemicals and fuel.

CTBE

Virtual Sugarcane Biorefinery

CTBE used Aspen Plus to investigate 1st and 2nd generation sugarcane ethanol plants with and without sorghum

and butanol production while also assessing economic, social, and environmental factors.

Product Area:

Aspen Plus (continued)

Cansolv

Model Development for CO2 Capture using Aspen Plus

Cansolv developed scaled up commercial designs of CO2 capture plants based on Aspen properties and

validated with pilot data.

Pan Pacific Technologies

Algal Bioprocess Modeling

Pan Pacific Technologies gained important process constraint, scale-up and lifecycle cost insights through

using Aspen Plus to model a difficult bioprocesses.

Arithmetek

aspenONE for a Flexible Business Model

Arithmetek used aspenONE engineering desktop to maintain flexibility in the cyclically behaiving metals

and mining industry.

Product Area:

Aspen HYSYS

Repsol and Inprocess

Validating Dynamic Models to Reproduce Plant Dynamics

Inundated condensers thought to be functional were discovered and repaired improving

plant controllability.

Petrofac

Rigorous modeling for gas plant debottlenecking

The capacity of a gas plant was increased 20% with equipment modification and

replacement. Petrofac avoided overdesign, thus saving capital costs and producing a solution

that saw a return in less than a month.

Sipchem

Modeling Methanol Plant for Revamp Pre-Feasibility Study

Improvements in the efficiency of a methanol plant were investigated in-house rather than

outsourced, saving $300-400K and 4-6 weeks of time.

Product Area:

Aspen HYSYS (continued)

Dow

Complex Flow Overpressure Analysis

Using HYSYS Dynamics, Dow was able to better understand the system surrounding a

failed drying tower and how the incident occurred, allowing them to investigate and

prevent further emergency scenarios.

Petrofac

Steam System Modeling with Aspen HYSYS

Petrofac found that even with a SRU train trip, the Acid Gas Removal Unit of their stream

system could remain online, preventing Petrofac from overdesigning the system and thus

saving capital costs.

Canmet Energy

Process Model Development and Simulation of an Integrated Oxy-fuel Power

Generation System with CO2 Capture

Using Aspen HYSYS, Canmet developed a robust integrated process model to find sources of

exergy destruction and improve efficiencies for a oxy-fuel power generation system.

Product Area:

Exchanger Design & Rating

Kuwait National Petroleum Company: KNPC Shuaiba

Refinery Energy Management Study

KNPC used Aspen HYSYS Petroleum Refining, Aspen EDR, and Aspen Utilities Planner to reduce energy use and save a

projected $15MM/year.

TUV NEL

Impact of R&D on the Accuracy of Exchanger Design

By exploring the newest versions of EDR (V7.3 and V8), NEL discovered four improvements

that reinforce their confidence in the software.

Petrofac

Rigorous modeling for gas plant debottlenecking

The capacity of a gas plant was increased 20% with equipment modification and

replacement. Petrofac avoided overdesign, thus saving capital costs and producing a solution

that saw a return in less than a month.

Product Area:

Exchanger Design & Rating (continued)

Fives Cryogenie

Why Integrate Plate Fin Exchangers into Aspen HYSYS

Simulations

Fives Cryogenie holistically optimized the cold section of the ethylene plant and reduced the amount of time required

to finalize the Plate Fin HX design by using HYSYS and EDR.

Perstorp

Finding Appropriate Design Margins for Heat Exchangers

Perstop utilized Aspen EDRs unique design optimization algorithm to reduce over design while minimizing cost or area

of the exchanger rather than just minimizing the heat transfer area.

Saudi Aramco & Inprocess

Monitoring and Cleaning Sequence Scheduling Tool for a

Refinery Pre-heat Train

Saudi Aramco and Inprocess developed a schedule for cleaning the fouling in heat exchangers to enhance process

performance while the avoiding costs associated with over cleaning.

Product Area:

Aspen Economic Evaluation Suite

PEMEX

New Refinery Cost Estimation

PEMEX estimated the cost of a new refinery by using Aspen HYSYS & Aspen Economic

Evaluation Suite to conduct feasibility studies, size equipment, and evaluate project scope.

Linde

Relocation of a 200MMSCFD Facility

An estimating team used Aspen Capital Cost Estimator to relocate a proposed 200MMSCFD gas

processing plant, which involved changes in plot, geography, labor indexes, climate, and power and

control distribution.

SABIC

Chemicals to Hydrocarbons- A Conceptual Approach with Aspen

Engineering Suite

SABIC developed a model covering a range of process conditions and optimized the process for waste

and material consumption minimization as well as economic benefit.

.

S-ar putea să vă placă și

- CDU Webinar Presentation 6-27Document30 paginiCDU Webinar Presentation 6-27psycopaul100% (1)

- Vibration Integrity PrimerDocument2 paginiVibration Integrity PrimerJose BijoyÎncă nu există evaluări

- AIV and FIV in Pipelines Plants and Facilities - IPC2016-64651 PDFDocument5 paginiAIV and FIV in Pipelines Plants and Facilities - IPC2016-64651 PDFpsycopaulÎncă nu există evaluări

- Guidelines For The Avoidance of Vibration Induced Fatigue Failure in Process PDocument236 paginiGuidelines For The Avoidance of Vibration Induced Fatigue Failure in Process PSoodamany Ponnu Pandian93% (14)

- Flow and Accoustically Induced Vibrations A Real Problem For LNG Facilities PDFDocument12 paginiFlow and Accoustically Induced Vibrations A Real Problem For LNG Facilities PDFSargunam SankaravadivelÎncă nu există evaluări

- Centrifugal Compressor Case StudyDocument13 paginiCentrifugal Compressor Case Studysqualljavier612Încă nu există evaluări

- Cyclone Performance and DesignDocument23 paginiCyclone Performance and DesignpsycopaulÎncă nu există evaluări

- Overfill White PaperDocument48 paginiOverfill White PaperpsycopaulÎncă nu există evaluări

- Ansys Advantage Digital Exploration Aa V11 I2Document60 paginiAnsys Advantage Digital Exploration Aa V11 I2david_valdez_83Încă nu există evaluări

- BLOWDOWN Webinar Presentation PDFDocument47 paginiBLOWDOWN Webinar Presentation PDFpsycopaulÎncă nu există evaluări

- Mastering EES Chapter1Document98 paginiMastering EES Chapter1psycopaulÎncă nu există evaluări

- Natural Gas Sampling Case Study v2.1Document2 paginiNatural Gas Sampling Case Study v2.1psycopaulÎncă nu există evaluări

- About Fieldwire: Company Fact SheetDocument2 paginiAbout Fieldwire: Company Fact SheetpsycopaulÎncă nu există evaluări

- Hydrocarboom ProcessingDocument145 paginiHydrocarboom ProcessingpsycopaulÎncă nu există evaluări

- Overfill White PaperDocument48 paginiOverfill White PaperpsycopaulÎncă nu există evaluări

- 57-241 Signal To Noise White PaperDocument4 pagini57-241 Signal To Noise White PaperpsycopaulÎncă nu există evaluări

- A Neural Conversation Model PDFDocument7 paginiA Neural Conversation Model PDFCarlangaslangasÎncă nu există evaluări

- Zwick Whitepaper 2 PDFDocument9 paginiZwick Whitepaper 2 PDFpsycopaulÎncă nu există evaluări

- Chemical Engineering April 2015Document86 paginiChemical Engineering April 2015XuanTung0% (1)

- C Level WhitePaper Reducing Risk USDocument8 paginiC Level WhitePaper Reducing Risk USLUQMAN HAKIMÎncă nu există evaluări

- Zwick Whitepaper 2 PDFDocument9 paginiZwick Whitepaper 2 PDFpsycopaulÎncă nu există evaluări

- WhitePaper SE LIO SimSci UnifiedLifecycleSimulation 05 17Document10 paginiWhitePaper SE LIO SimSci UnifiedLifecycleSimulation 05 17psycopaulÎncă nu există evaluări

- Overfill White PaperDocument48 paginiOverfill White PaperpsycopaulÎncă nu există evaluări

- Understanding Equipment Certification Programs For Potientaially Eplisive EnviromentDocument5 paginiUnderstanding Equipment Certification Programs For Potientaially Eplisive EnviromentpsycopaulÎncă nu există evaluări

- Informe de Produccion de Biodiesel en CHEMCADDocument7 paginiInforme de Produccion de Biodiesel en CHEMCADGustavo BarciaÎncă nu există evaluări

- Effect o Flow Velocity and Inhibitors On Formation of Methane Hudrates in High Pressure PipelineDocument6 paginiEffect o Flow Velocity and Inhibitors On Formation of Methane Hudrates in High Pressure PipelinepsycopaulÎncă nu există evaluări

- Handbook PentairDocument233 paginiHandbook PentairpsycopaulÎncă nu există evaluări

- A Neural Conversation Model PDFDocument7 paginiA Neural Conversation Model PDFCarlangaslangasÎncă nu există evaluări

- Simulation Ebook 45 Tips and Tricks To Build and Manage Process SimulationDocument21 paginiSimulation Ebook 45 Tips and Tricks To Build and Manage Process SimulationpsycopaulÎncă nu există evaluări

- Techical Emerson - PCV SizingDocument21 paginiTechical Emerson - PCV SizingpsycopaulÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- New Micra BrochureDocument14 paginiNew Micra BrochureGlobalGroupOfDealersÎncă nu există evaluări

- Special Power of AttorneyDocument1 paginăSpecial Power of Attorneywecans izza100% (1)

- 10 Me 42 BDocument144 pagini10 Me 42 BdineshÎncă nu există evaluări

- L8 Logistics ManagementDocument41 paginiL8 Logistics ManagementShahmien SevenÎncă nu există evaluări

- Aga 11Document7 paginiAga 11elijbbÎncă nu există evaluări

- F110 Payment Run - CheckDocument29 paginiF110 Payment Run - Checktawfikmohamed213Încă nu există evaluări

- k90mcc6 PDFDocument381 paginik90mcc6 PDFTammy JohnsonÎncă nu există evaluări

- 2008 Almocera vs. OngDocument11 pagini2008 Almocera vs. OngErika C. DizonÎncă nu există evaluări

- File 1379580604 PDFDocument9 paginiFile 1379580604 PDFMuhammad Salik TaimuriÎncă nu există evaluări

- MEMORIAL ON BEHALF OF APPELLANTS DocsDocument29 paginiMEMORIAL ON BEHALF OF APPELLANTS DocsPrashant KumarÎncă nu există evaluări

- Fax Cross ReferenceDocument32 paginiFax Cross ReferenceBranga CorneliuÎncă nu există evaluări

- Privatization of ExtensionDocument49 paginiPrivatization of ExtensionLiam Tesat67% (3)

- AWS Certified Cloud Practitioner Practice Tests Dumps 2021Document10 paginiAWS Certified Cloud Practitioner Practice Tests Dumps 2021Aaron Clifton100% (1)

- United States v. Hollis, 4th Cir. (2001)Document3 paginiUnited States v. Hollis, 4th Cir. (2001)Scribd Government DocsÎncă nu există evaluări

- MBridgeDocument50 paginiMBridgeTsila SimpleÎncă nu există evaluări

- in The Matter of The Estate of Remigia SaguinsinDocument3 paginiin The Matter of The Estate of Remigia SaguinsinAila AmpieÎncă nu există evaluări

- 4th Party LogisticsDocument3 pagini4th Party Logisticsch_salmanÎncă nu există evaluări

- 4-Sided Planer & Moulder Operation Manual: For Spares and Service ContactDocument48 pagini4-Sided Planer & Moulder Operation Manual: For Spares and Service ContactAlfred TsuiÎncă nu există evaluări

- Evaporative Cooling Design Spreadsheet 2014 - MetricDocument1 paginăEvaporative Cooling Design Spreadsheet 2014 - MetricCristian MoratayaÎncă nu există evaluări

- ABSTRACT (CG To Epichlorohydrin)Document5 paginiABSTRACT (CG To Epichlorohydrin)Amiel DionisioÎncă nu există evaluări

- Forging 2Document17 paginiForging 2Amin ShafanezhadÎncă nu există evaluări

- Plant Management TafskillsDocument4 paginiPlant Management TafskillsTHEOPHILUS ATO FLETCHERÎncă nu există evaluări

- Mike She Printed v1Document370 paginiMike She Printed v1Grigoras MihaiÎncă nu există evaluări

- Sky 1Document14 paginiSky 1Vũ Quang HưngÎncă nu există evaluări

- Snmpwalk Westermo DSL ModemDocument24 paginiSnmpwalk Westermo DSL ModemAexÎncă nu există evaluări

- Tender - RCB NIT 08 20 21 IBDC - 1597146134Document124 paginiTender - RCB NIT 08 20 21 IBDC - 1597146134Guy HydÎncă nu există evaluări

- 34-Samss-718 (12-02-2015)Document14 pagini34-Samss-718 (12-02-2015)Mubin100% (1)

- Penn State: The Dickinson School of LawDocument88 paginiPenn State: The Dickinson School of LawHafiz UmmarÎncă nu există evaluări

- Lateral Pile Paper - Rev01Document6 paginiLateral Pile Paper - Rev01YibinGongÎncă nu există evaluări

- Job Schedule Sheet: 'Lead Time Monitoring GraphDocument48 paginiJob Schedule Sheet: 'Lead Time Monitoring GraphEndraÎncă nu există evaluări