Documente Academic

Documente Profesional

Documente Cultură

Point I/O Devicenet Adapter: Installation Instructions

Încărcat de

CarlosOtinianoTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Point I/O Devicenet Adapter: Installation Instructions

Încărcat de

CarlosOtinianoDrepturi de autor:

Formate disponibile

Installation Instructions

POINT I/O DeviceNet Adapter

Catalog Numbers 1734-ADN, 1734-ADNX

Inside

For This Topic

See Page

Important User Information

Preventing Electrostatic Discharge

Environment and Enclosure

About This Manual

About the Adapter

For More Information

Install the Adapter

Install a Replacement Adapter in an Existing System

10

Wire the Adapter

12

Troubleshoot with Indicators

15

North American Hazardous Location Approval

19

European Hazardous Location Approval

20

Specifications

21

Rockwell Automation Support

28

Publication 1734-IN026A-EN-P - April 2005

2 POINT I/O DeviceNet Adapter

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application, Installation and

Maintenance of Solid State Controls (Publication SGI-1.1 available from your local Rockwell

Automation sales office or online at http://literature.rockwellautomation.com) describes

some important differences between solid state equipment and hard-wired

electromechanical devices. Because of this difference, and also because of the wide variety

of uses for solid state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or

consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes.

Because of the many variables and requirements associated with any particular installation,

Rockwell Automation, Inc. cannot assume responsibility or liability for actual use based on

the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of

information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission

of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety

considerations.

WARNING

IMPORTANT

ATTENTION

Identifies information about practices or circumstances that can cause an explosion in a

hazardous environment, which may lead to personal injury or death, property damage, or

economic loss.

Identifies information that is critical for successful application and understanding of the

product.

Identifies information about practices or circumstances that can lead to personal injury or

death, property damage, or economic loss. Attentions help you:

identify a hazard

avoid a hazard

recognize the consequence

SHOCK HAZARD

Labels may be located on or inside the equipment (e.g., drive or motor) to alert people

that dangerous voltage may be present.

BURN HAZARD

Labels may be located on or inside the equipment (e.g., drive or motor) to alert people

that surfaces may be dangerous temperatures.

Publication 1734-IN026A-EN-P - April 2005

POINT I/O DeviceNet Adapter 3

ATTENTION

Preventing Electrostatic Discharge

This equipment is sensitive to electrostatic

discharge, which can cause internal damage and

affect normal operation. Follow these guidelines

when you handle this equipment:

Touch a grounded object to discharge

potential static.

Wear an approved grounding wriststrap.

Do not touch connectors or pins on

component boards.

Do not touch circuit components inside the

equipment.

If available, use a static-safe workstation.

When not in use, store the equipment in

appropriate static-safe packaging.

Publication 1734-IN026A-EN-P - April 2005

4 POINT I/O DeviceNet Adapter

ATTENTION

Environment and Enclosure

This equipment is intended for use in a Pollution

Degree 2 industrial environment, in overvoltage

Category II applications (as defined in IEC

publication 60664-1), at altitudes up to 2000 meters

without derating.

This equipment is considered Group 1, Class A

industrial equipment according to IEC/CISPR

Publication 11. Without appropriate precautions,

there may be potential difficulties ensuring

electromagnetic compatibility in other environments

due to conducted as well as radiated disturbance.

This equipment is supplied as open type

equipment. It must be mounted within an enclosure

that is suitably designed for those specific

environmental conditions that will be present and

appropriately designed to prevent personal injury

resulting from accessibility to live parts. The interior

of the enclosure must be accessible only by the use

of a tool. Subsequent sections of this publication

may contain additional information regarding

specific enclosure type ratings that are required to

comply with certain product safety certifications.

See NEMA Standards publication 250 and IEC

publication 60529, as applicable, for explanations of

the degrees of protection provided by different

types of enclosure. Also, see the appropriate

sections in this publication, as well as the

Allen-Bradley publication 1770-4.1 (Industrial

Automation Wiring and Grounding Guidelines), for

additional installation requirements pertaining to

this equipment.

Publication 1734-IN026A-EN-P - April 2005

POINT I/O DeviceNet Adapter 5

About This Manual

Use this manual as a guide to install the adapter.

The manual covers hardware installation and other information

related to get you started.

IMPORTANT

In this manual, we use 1734-ADN(X) to refer to both of

the following adapters:

1734-ADN POINT I/O DeviceNet Adapter

1734-ADNX POINT I/O DeviceNet Adapter with

Subnet Expansion

We use 1734-ADN to refer only to the 1734-ADN

adapter and 1734-ADNX to refer only to the

1734-ADNX adapter. We also refer to the 1734-ADN(X)

POINT I/O DeviceNet Adapter as the adapter.

About the Adapter

The 1734-ADN(X) POINT I/O DeviceNet Adapter is a communication

adapter for POINT I/O modules.

The adapter provides an interface for controlling and communicating

with POINT I/O modules on a DeviceNet network.

For More Information

For more detailed information about use of the adapter, refer to the

POINT I/O DeviceNet Adapter user manual, publication 1734-UM002.

It is available online at URL http://literature.rockwellautomation.com.

Publication 1734-IN026A-EN-P - April 2005

6 POINT I/O DeviceNet Adapter

Install the Adapter

To install the adapter on the DIN rail prior to installing other base

units, proceed as follows.

ATTENTION

POINT I/O is grounded through the DIN rail to

chassis ground. Use zinc-plated, yellow-chromated

steel DIN rail to assure proper grounding. The use

of DIN rail materials (e.g., aluminum, plastic, etc.)

that can corrode, oxidize, or are poor conductors,

can result in improper or intermittent grounding.

Secure DIN rail to mounting surface approximately

every 200 mm.

1. Position the adapter vertically in front of the DIN rail.

2. Press firmly to install the adapter on the DIN rail.

The locking mechanism locks the adapter to the DIN rail.

1734-ADN(X)

communication

interface

DIN rail

Orange

screw slot

31110-MC

Publication 1734-IN026A-EN-P - April 2005

POINT I/O DeviceNet Adapter 7

3. Insert the DeviceNet network plug and tighten the holding

screws.

DeviceNet

network

plug

Holding screw

Holding screw

31111-MC

WARNING

If you connect or disconnect the communication

cable with power applied to this module or any

device on the network, an electrical arc can

occur. This could cause an explosion in

hazardous location installations.

Publication 1734-IN026A-EN-P - April 2005

8 POINT I/O DeviceNet Adapter

4. Set the node address by pressing the + and - buttons on the

2-position thumbwheel switch.

Network node

address

thumbwheel

Module

Status

0 2

PointBus

Status

ControlNet A

Status

ControlNet B

Status

42510

42510

1734-ACNR

Valid physical settings range from 00 to 63.

You can also set the node address to some value between

64-99. In this case, you can change the adapters node address

via the RSNetWorx for DeviceNet software.

If you use a value between 64-99, at power-up you use the

node address stored in the adapters non-volatile memory.

Publication 1734-IN026A-EN-P - April 2005

POINT I/O DeviceNet Adapter 9

5. Slide the safety end cap to remove it.

This exposes the backplane and power interconnections.

ATTENTION

Do not discard the end cap. Use this end cap to

cover the exposed interconnections on the last

mounting base on the DIN rail. Failure to do so

could result in equipment damage or injury from

electric shock.

Safety

end

cap

31112-MC

Publication 1734-IN026A-EN-P - April 2005

10 POINT I/O DeviceNet Adapter

Install a Replacement Adapter in an Existing System

WARNING

When you insert or remove the module while

backplane power is on, an electrical arc can occur.

This could cause an explosion in hazardous

location installations.

Be sure that power is removed or the area is

nonhazardous before proceeding. Repeated

electrical arcing causes excessive wear to contacts

on both the module and its mating connector.

Worn contacts may create electrical resistance that

can affect module operation.

WARNING

When you connect or disconnect the Removable

Terminal Block (RTB) with field-side power

applied, an electrical arc can occur. This could

cause an explosion in hazardous location

installations.

Be sure that power is removed or the area is

nonhazardous before proceeding.

Your existing control application may be using another DeviceNet

adapter (for example, 1734-PDN) that you want to replace with a

1734-ADN(X) DeviceNet adapter. Remove the existing adapter from

the DIN rail as follows.

1. Remove power to the adapter and all I/O modules in your

existing system.

2. Remove the wiring assembly and DeviceNet cable from your

existing adapter.

3. Remove the adjacent I/O module.

Publication 1734-IN026A-EN-P - April 2005

POINT I/O DeviceNet Adapter 11

For information about how to remove POINT I/O modules

from the DIN rail, see the associated publications for those

modules.

RTB removal handle

42511

4. Use a small-bladed screwdriver to rotate the DIN rail locking

screw to a vertical position and release the locking

mechanism.

42417

5. Pull the adapter off of the DIN rail to remove it from the

existing system.

6. Insert the new adapter into slot 0 using the steps described in

the Install the Adapter section of this manual on page 6.

7. Reattach I/O modules to the new adapter.

Publication 1734-IN026A-EN-P - April 2005

12 POINT I/O DeviceNet Adapter

Wire the Adapter

WARNING

WARNING

If you connect or disconnect the communications

cable with power applied to this module or any

device on the network, an electrical arc can occur.

This could cause an explosion in hazardous

location installations.

If you connect or disconnect wiring while the

field-side power is on, an electrical arc can occur.

This could cause an explosion in hazardous

location installations. Be sure that power is

removed or the area is nonhazardous before

proceeding.

Publication 1734-IN026A-EN-P - April 2005

POINT I/O DeviceNet Adapter 13

Network

node address

thumbwheel

Adapter

Status

DeviceNet

Status

Adapter status

PointBus

Status

PointBus/Subnet status

DeviceNet status

1734-ADN

DeviceNet

connector

System power

System

Power

Field

Power

Field power

NC

CHAS GND

Subnet

connector

NC = No Connection

CHAS GND = Chassis Ground

C = Common

V = Supply

NC

CHAS GND

C

V

42513

Publication 1734-IN026A-EN-P - April 2005

14 POINT I/O DeviceNet Adapter

Adapter/field power

12/24V dc

NC

NC

CHAS CHAS

4

V dc

Connect this dc

supply to the

internal power bus.

You cannot supply

power to the

adapter from the

DeviceNet power

supply.

42513

NC = No Connection

C = Common

DeviceNet

connection

CHAS = Chassis Ground

V = Supply

(Do not connect 120/240V ac power to this supply.)

Black

-V

Blue

CAN - Low

Bare

Shield

White

CAN - High

Red

+V

42514

Publication 1734-IN026A-EN-P - April 2005

POINT I/O DeviceNet Adapter 15

Terminal

Notes

No connection

Reserved

No connection

Chassis Ground

Chassis Ground

Common

Common

Voltage Input

Voltage Input

Apply 12/24V dc. Connects to the

internal power bus.

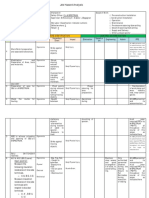

Troubleshoot with Indicators

Use the status indicators to troubleshoot your adapter.

Status indicators for 1734-ADN adapters

Adapter

Status

DeviceNet

Status

PointBus

Status

Adapter status

Network status

POINTBus status

1734-ADN

System

Power

Field

Power

System power

Field power

43932

Publication 1734-IN026A-EN-P - April 2005

16 POINT I/O DeviceNet Adapter

Status indicators for 1734-ADNX adapters

Adapter

Status

DeviceNet

Status

Subnet

Status

Adapter status

Network status

Subnet status

1734-ADNX

System

Power

Field

Power

Indicator

Indication

System

Power

Off

Not active

Field power is OFF.

DC-DC converter

problem

Green

System power is ON.

DC-DC converter is

active (5V).

Off

Not active

Field power is OFF.

Field Power

Green

Probable Cause

System power

Field power

43933

Take This Action

Check adapter

configuration.

Turn field power

ON.

Contact

Customer

Support.

None

Power is ON with 24V present. None

Publication 1734-IN026A-EN-P - April 2005

Check adapter

configuration.

Turn field power

ON.

POINT I/O DeviceNet Adapter 17

Indicator

Indication

Probable Cause

Take This Action

Adapter

Status

Off

No power is applied to device.

Power the adapter.

Green

Device is operating normally.

None

Flashing

Green

Device needs to be

commissioned because

configuration is missing,

incomplete, or incorrect

Check configuration and

recommission the adapter.

Flashing

Red

Recoverable fault is present.

Make sure the adapter does

not need a FLASH update.

Red

Unrecoverable fault may require

device replacement.

Replace the adapter.

Flashing

Red/Green

Device is in self-test.

Wait for self-test to finish.

Off

Device is not online.

- Device is autobauding .

- Device has not completed

dup_MAC_id test.

- Device is not powered.

Check adapter status

indicator to determine if you

need more time to complete

the dup_MAC_id test or if

you need to power the

adapter.

Flashing

Green

Device is online but has no

connections in the established

state.

None

Green

Device is online and has

connections in the established

state.

None

Flashing

Red

One or more I/O connections are

in timed-out states

Determine the cause of the

time-out. You may need to

increase the expected

packet rate.

Red

Critical link failure communication device failed.

Device detected error that

prevents it from communicating

on the network.

Make sure the device is

using the correct MAC ID

and baudrate.

Network

Status

Publication 1734-IN026A-EN-P - April 2005

18 POINT I/O DeviceNet Adapter

Indicator

Indication

Probable Cause

Take This Action

Subnet and

PointBus

Status

Off

Device is not online.

- Device has not completed

Dup_MAC_ID test.

- Device is not powered. - Check

module status indicator.

Check adapter status

indicator to determine if you

need more time to complete

the dup_MAC_id test or if

you need to power the

adapter.

Flashing

Green

Device is online but has no

connections in the established

state.

None

Green

Device is online and has

connections in the established

state.

None

Flashing Red

No scanlist is available.

I/O module is missing.

Max backplane MAC ID is not

set right (1734-ADNX).

Make sure all I/O modules

are connected and using the

correct MAC IDs.

Check Cycling Node

Status parameter in

RSNetWorx for DeviceNet.

For 1734-ADNX, terminate

the 1734-ADNX Subnet and

correctly set the Max

Backplane MAC ID.1

Red

Critical link failure communication device failed.

Device detected error that

prevents it from communicating

on the network.

Make sure an I/O module is

not using a MAC ID =0.

Make sure all backplane

modules are communicating

at the proper baudrate.

1Maxi(mum) Backplane MAC ID is an attribute for 1734-ADNX only. This value represents the highest

node address of a module residing on the backplane. The value must be greater than or equal to the

right-most backplane Subnet module, but less than that of any non-backplane Subnet module.

Publication 1734-IN026A-EN-P - April 2005

POINT I/O DeviceNet Adapter 19

North American Hazardous Location Approval

The 1734-ADN adapter has North American Hazardous Location

approval.

The following information applies when

operating this equipment in hazardous

locations:

Informations sur lutilisation de cet quipement

en environnements dangereux:

Products marked CL I, DIV 2, GP A, B, C, D are suitable

for use in Class I Division 2 Groups A, B, C, D, Hazardous

Locations and nonhazardous locations only. Each product

is supplied with markings on the rating nameplate

indicating the hazardous location temperature code. When

combining products within a system, the most adverse

temperature code (lowest T number) may be used to

help determine the overall temperature code of the

system. Combinations of equipment in your system are

subject to investigation by the local Authority Having

Jurisdiction at the time of installation.

Les produits marqus CL I, DIV 2, GP A, B, C, D ne

conviennent qu une utilisation en environnements de Classe I

Division 2 Groupes A, B, C, D dangereux et non dangereux.

Chaque produit est livr avec des marquages sur sa plaque

didentification qui indiquent le code de temprature pour les

environnements dangereux. Lorsque plusieurs produits sont

combins dans un systme, le code de temprature le plus

dfavorable (code de temprature le plus faible) peut tre

utilis pour dterminer le code de temprature global du

systme. Les combinaisons dquipements dans le systme

sont sujettes inspection par les autorits locales qualifies

au moment de linstallation.

EXPLOSION HAZARD -

WARNING

Do not disconnect equipment unless

power has been removed or the area

is known to be nonhazardous.

Do not disconnect connections to

this equipment unless power has

been removed or the area is known

to be nonhazardous. Secure any

external connections that mate to

this equipment by using screws,

sliding latches, threaded

connectors, or other means provided

with this product.

Substitution of components may

impair suitability for Class I, Division

2.

If this product contains batteries,

they must only be changed in an

area known to be nonhazardous.

RISQUE DEXPLOSION

AVERTISSEMENT

Couper le courant ou sassurer que

lenvironnement est class non

dangereux avant de dbrancher

l'quipement.

Couper le courant ou s'assurer que

lenvironnement est class non

dangereux avant de dbrancher les

connecteurs. Fixer tous les

connecteurs externes relis cet

quipement l'aide de vis, loquets

coulissants, connecteurs filets ou

autres moyens fournis avec ce

produit.

La substitution de composants peut

rendre cet quipement inadapt une

utilisation en environnement de

Classe 1, Division 2.

Sassurer que lenvironnement est

class non dangereux avant de

changer les piles.

Publication 1734-IN026A-EN-P - April 2005

20 POINT I/O DeviceNet Adapter

European Hazardous Location Approval

The 1734-ADN adapter has European Hazardous Location approval.

European Zone 2 Certification (The following applies when the product bears the

EEx Marking)

This equipment is intended for use in potentially explosive atmospheres as defined by

European Union Directive 94/9/EC.

DEMKO certifies that this equipment has been found to comply with the Essential Health

and Safety Requirements relating to the design and construction of Category 3 equipment

intended for use in potentially explosive atmospheres, given in Annex II to this Directive.

The examination and test results are recorded in confidential report No 03NK30347.

Compliance with the Essential Health and Safety Requirements has been assured by

compliance with EN 50021.

IMPORTANT

Observe the following additional Zone 2 certification

requirements.

This equipment is not resistant to sunlight or other sources

of UV radiation.

The secondary of a current transformer shall not be

open-circuited when applied in Class I, Zone 2

environments.

Equipment of lesser Enclosure Type Rating must be

installed in an enclosure providing at least IP54 protection

when applied in Class I, Zone 2 environments.

This equipment shall be used within its specified ratings

defined by Allen-Bradley.

Provision shall be made to prevent the rated voltage from

being exceeded by transient disturbances of more than 40%

when applied in Class I, Zone 2 environments.

Publication 1734-IN026A-EN-P - April 2005

POINT I/O DeviceNet Adapter 21

Specifications

Communication Interface Specifications

DeviceNet Communication Rate 125K bit/s (500m maximum)

250K bit/s (250m maximum)

500K bit/s (100m maximum)

DeviceNet Cable

Allen-Bradley part number 1485C-P1-Cxxx

Refer to publication NETS-SG001 for more information.

Module Location

Starter module - left side of 1734 system

Number of Powered Modules

63 maximum

Number of Integrated I/O

Channels

Number of I/O Points, Max.

504

DeviceNet Nodes with

Maximum I/O, Total

Node Address

I/O Module Capacity

63

DeviceNet Current

30mA

POINTBus Current

1000mA @5V dc + 5% (4.75...5.25V)

Publication 1734-IN026A-EN-P - April 2005

22 POINT I/O DeviceNet Adapter

Communications Interface Specifications (continued)

Expansion I/O Capacity

Up to 13 modules (13 times 75mA = 0.975, just under the

limit of 1.0A), based on POINTBus current requirements

The actual number of modules can vary. Add up the current

requirements of the modules you want to use to make sure

they do not exceed the amperage limit of the adapter. Total

expansion is up to 63 modules - 13 modules maximum with

the adapter. Add 1734-EP24DC modules for an additional

17 modules (or less based on current requirements), up to

63 modules maximum.

Cat. No.

1734-IB2

1734-IB4

1734-IB8

1734-IV2

1734-IV4

1734-OB2

1734-OB4

1734-OB8

1734-OB2E

1734-OB2EP

1734-OB4E

1734-OB8E

1734-OV2E

1734-OV4E

1734-OW2

1734-OX2

1734-IE2C

1734-OE2C

1734-IE2V

1734-OE2V

1734-IA2

1734-IM2

1734-OA2

1734-IJ2

1734-IK2

1734-IR2

1734-IT2I

1734-SSI

1734-VHSC5

1734-VHSC24

1734-232ASC

Publication 1734-IN026A-EN-P - April 2005

PointBus Current Requirements

75mA

75mA

75mA

75mA

75mA

75mA

75mA

75mA

75mA

75mA

75mA

75mA

75mA

75mA

80mA

100mA

75mA

75mA

75mA

75mA

75mA

75mA

75mA

160mA

160mA

220mA

175mA

110mA

180mA

180mA

75mA

POINT I/O DeviceNet Adapter 23

DeviceNet Power Supply Specifications

Input Voltage Rating

24V dc nominal

DeviceNet Input Voltage Range

11-25V dc DeviceNet specification

Input Overvoltage Protection

Reverse polarity protected

DeviceNet Power Requirements 24V dc (+4% = 25V dc max) @ 30mA maximum

Power Supply Specifications

Input Voltage Rating

24V dc nominal

10-28.8V dc range

Field Side Power Requirements

24V dc (+20% = 28.8V dc maximum) @ 400mA maximum

Inrush Current

6A maximum for 10ms

POINTBus Output Current

1A maximum @ 5V dc 5% (4.75 - 5.25)

Input Overvoltage Protection

Reverse polarity protected

Interruption Protection

Output voltage will stay within specifications when input

drops out for 10ms at 10V with maximum load.

Power Supply

For 1734-ADN adapters, user supplied power should be

separate from DeviceNet power.

For 1734-ADNX adapters, user supplied power should be

separate from DeviceNet and Subnet power.

Publication 1734-IN026A-EN-P - April 2005

24 POINT I/O DeviceNet Adapter

General Specifications

Indicators

3 red/green status indicators

Adapter status

DeviceNet status

POINTBus status

2 green power supply status indicators:

System Power (POINTBus 5V power)

Field Power (24V from field supply)

Mounting Type

DIN-rail

Weight

0.26 kg (0.56 lb)

Module Location

Starter module - left side of 1734 system

Network Name

DeviceNet

Termination Type

None

Number of Nodes

1 maximum

Electronic Protection

No

Diagnostics

No

Enclosure Required

Yes

Power Consumption

8.1W @ 28.8V dc

Platform/Processor

Compatibility

1747; 1756; 1761; 1762; 1764; 1789; 1794

Power Dissipation

2.8W maximum @ 28.8V

Communication Interface

Type

Adapter

Device Type

Communication Interface

Thermal Dissipation

9.5 BTU/hr maximum @ 28.8V dc

Input Byte Capacity

248

Output Byte Capacity

248

Power Supply 24V Current

Load

400mA

Field Power Bus

Nominal Voltage

Supply Voltage Range

Supply Current

24V dc

10-28.8V dc range,

10A maximum

Publication 1734-IN026A-EN-P - April 2005

POINT I/O DeviceNet Adapter 25

Isolation Voltage

(Continuous - Voltage

Withstand Rating)

50V continuous

Test to withstand 800V dc for 60s

Operating Voltage Range

10...28.8V dc

Wire Size

14 AWG (2.5mm2) - 22 AWG (0.25mm2) solid or stranded,

copper wire rated at 75oC or greater

3/64 inch (1.2mm) insulation maximum

Wire Category1,2

1 on power ports

2 on communications ports

Wire Type

Copper

Terminal Base Screw Torque 5-7 pound-inches (0.5-0.6Nm)

Field Wiring Terminations

DeviceNet

Power Supply

1 - Black Wire-V

2 - Blue WireCAN Low

3 - Bare WireShield

4 - White WireCAN High

5 - Red Wire+V

0 - No Connection

1 - No Connection

2 - Chassis Ground

3 - Chassis Ground

4 - Common

5 - Common

6 - Supply

7 - Supply

Publication 1734-IN026A-EN-P - April 2005

26 POINT I/O DeviceNet Adapter

Dimensions Inches

(Millimeters)

3.0H x 2.16W x 5.25L

(76.2H x 54.9W x 133.4L)

Operational Temperature

IEC60068-2-1 (Test Ad, Operating Cold)

IEC60068-2-2 (Test Bd, Operating Dry Heat)

IEC60068-2-14 (Test Nb, Operating Thermal Shock)

-20...55oC (-4...131oF)

Storage Temperature

IEC60068-2-1 (Test Ab, Unpackaged Non-operating Cold)

IEC60068-2-2 (Test Bb, Unpackaged Non-operating Dry Heat)

IEC60068-2-14 (Test Na, Unpackaged Non-operating Thermal

Shock)

-40...85oC (-40...185oF)

Relative Humidity

IEC60068-2-30 (Test Db, Unpackaged Non-operating Damp

Heat)

5...95% noncondensing

Vibration

IEC60068-2-6 (Test Fc, Operating)

5g @ 10-500Hz

Shock Operating

Shock Non-operating

IEC 60068-2-27 (Test Ea, Unpackaged Shock) 30g

IEC 60068-2-27(Test Ea, Unpackaged Shock) 50g

Emissions

CISPR 11: Group 1, Class A

ESD Immunity

IEC6100-4-2

6kV contact discharges

8kV air discharges

Radiated RF Immunity

IEC 61000-4-3

10V/m with 1kHz sine-wave 80%AM from 30MHz to

2000MHz

10V/m with 200HZ 50% Pulse 100%Am at 900MHz

EFT/B Immunity

IEC 61000-4-4

+4kV at 5kHz on power ports

+2kV at 5kHz on communications ports

Surge Transient Immunity

IEC 61000-4-5

+1kV line-line (DM) and +2kV line-earth (CM) on power ports

+2kV line-earth (CM) on communications ports

Conducted RF Immunity

IEC61000-4-6

10Vrms with 1kHz sine-wave 80%AM from 150kHz to 80 MHz

Enclosure Type Rating

None (open-style)

Publication 1734-IN026A-EN-P - April 2005

POINT I/O DeviceNet Adapter 27

Certification3

1734-ADNX

(when product is marked)

CE European Union 89/336/EEC EMC Directive,

compliant with:

EN 61000-6-4; Industrial Emissions

EN 50082-2; Industrial Immunity

EN 61326; Meas./Control/Lab., Industrial

Requirements

EN 61000-6-2; Industrial Immunity

C-Tick Australian Radiocommunications Act, compliant with:

AS/NZS CISPR11; Industrial Emissions

DeviceNet compatible as certified by ODVA, Inc.

Certification3

1734-ADN

(when product is marked)

CE European Union 89/336/EEC EMC Directive,

compliant with:

EN 61000-6-4; Industrial Emissions

EN 50082-2; Industrial Immunity

EN 61326; Meas./Control/Lab., Industrial

Requirements

EN 61000-6-2; Industrial Immunity

C-Tick Australian Radiocommunications Act, compliant with:

AS/NZS CISPR11; Industrial Emissions

DeviceNet compatible as certified by ODVA, Inc.

c-UL-usUL Listed for Class I, Division 2 Group A,B,C,D

Hazardous Locations, certified for U.S. and Canada

EEX

European Union 94/9/EC ATEX Directive,

compliant with:

EN 50021; Potentially Explosive Atmospheres,

Protection n (Zone 2)

Use this Conductor Category information for planning conductor routing. Refer to Industrial

Automation Wiring and Grounding Guidelines, publication 1770-4.1.

Use this Conductor Category information for planning conductor routing as described in the

appropriate System Level Installation Manual.

See the Product Certification link at www.ab.com for Declarations of Conformity, Certificates, and

other certification details.

POINT I/O and POINTBus are trademarks of Rockwell Automation.

DeviceNet is a trademark of the Open DeviceNet Vendor Association.

Publication 1734-IN026A-EN-P - April 2005

Rockwell Automation Support

Rockwell Automation provides technical information on the web to assist you

in using its products. At http://support.rockwellautomation.com, you can find

technical manuals, a knowledge base of FAQs, technical and application

notes, sample code and links to software service packs, and a MySupport

feature that you can customize to make the best use of these tools.

For an additional level of technical phone support for installation,

configuration and troubleshooting, we offer TechConnect Support programs.

For more information, contact your local distributor or Rockwell Automation

representative, or visit http://support.rockwellautomation.com.

Installation Assistance

If you experience a problem with a hardware module within the first 24 hours

of installation, please review the information that's contained in this manual.

You can also contact a special Customer Support number for initial help in

getting your module up and running:

United States

1.440.646.3223 Monday Friday, 8am 5pm EST

Outside United States

Please contact your local Rockwell Automation representative for any

technical support issues.

New Product Satisfaction Return

Rockwell tests all of its products to ensure that they are fully operational when

shipped from the manufacturing facility. However, if your product is not

functioning and needs to be returned:

United States

Contact your distributor. You must provide a Customer Support case number

(see phone number above to obtain one) to your distributor in order to

complete the return process.

Outside United States

Please contact your local Rockwell Automation representative for return

procedure.

Publication 1734-IN026A-EN-P - April 2005

PN 957955-25

Supersedes Publication 1734-IN007A-EN-P - August 2000, 1734-IN007B-EN-P - June 2001, and 1734-IN589A-EN-P - April 2003

Copyright 2005 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

S-ar putea să vă placă și

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialDe la EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialEvaluare: 3.5 din 5 stele3.5/5 (3)

- Arduino Programming Step by Step Guide To Mastering Arduino Hardware and SoftwareDocument109 paginiArduino Programming Step by Step Guide To Mastering Arduino Hardware and SoftwareMohan100% (3)

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- The IEE Wiring Regulations Explained and IllustratedDe la EverandThe IEE Wiring Regulations Explained and IllustratedEvaluare: 4 din 5 stele4/5 (14)

- GE Industrial Tube Manual 45 To 58Document813 paginiGE Industrial Tube Manual 45 To 58Pablo Oddone100% (3)

- Sodick Edm Mk25manualDocument210 paginiSodick Edm Mk25manualNguyen Anh Tu73% (11)

- MyRio Project GuideDocument243 paginiMyRio Project GuidedirizabalÎncă nu există evaluări

- 1756-In603 EthernetIP ModuleDocument28 pagini1756-In603 EthernetIP Modulewildstar001Încă nu există evaluări

- Intro ModbusTCPDocument42 paginiIntro ModbusTCPluigio34154Încă nu există evaluări

- SCE - EN - 031-600 Global Data Blocks S7-1200 - R1508Document39 paginiSCE - EN - 031-600 Global Data Blocks S7-1200 - R1508CarlosOtinianoÎncă nu există evaluări

- Pre-Inspection Report - DORC TransformersDocument9 paginiPre-Inspection Report - DORC Transformersmax MensÎncă nu există evaluări

- Ult REL Output Analog Modules 1734-In002 enDocument24 paginiUlt REL Output Analog Modules 1734-In002 enGabriel Constantin NastaseÎncă nu există evaluări

- POINT I/O 2 Port Ethernet Adapter: Installation InstructionsDocument28 paginiPOINT I/O 2 Port Ethernet Adapter: Installation InstructionszacriasÎncă nu există evaluări

- 1734 AENTR In040 - en P PDFDocument28 pagini1734 AENTR In040 - en P PDFJair PinhoÎncă nu există evaluări

- POINT I/O 4 Channel High Density Current Input Module: Installation InstructionsDocument24 paginiPOINT I/O 4 Channel High Density Current Input Module: Installation InstructionszacriasÎncă nu există evaluări

- POINT I/O Common Terminal Module and Voltage Terminal ModuleDocument16 paginiPOINT I/O Common Terminal Module and Voltage Terminal Moduleluisllumiquinga97Încă nu există evaluări

- POINT I/O™ 5V and 24V Encoder/Counter Modules: Installation InstructionsDocument24 paginiPOINT I/O™ 5V and 24V Encoder/Counter Modules: Installation InstructionsThanh BaronÎncă nu există evaluări

- Point IO1734-in058 - En-PDocument20 paginiPoint IO1734-in058 - En-PRyan EllisÎncă nu există evaluări

- 1734-AENTR - Installation InstructionsDocument24 pagini1734-AENTR - Installation Instructionskavireeshgh_007Încă nu există evaluări

- GuardPLC Digital Input Output Module PDFDocument20 paginiGuardPLC Digital Input Output Module PDFTarun BharadwajÎncă nu există evaluări

- TID00323-MANUAL MODULO 1794 OA16-1794-in103 - En-PDocument24 paginiTID00323-MANUAL MODULO 1794 OA16-1794-in103 - En-PNatalia BeltránÎncă nu există evaluări

- Flex I-O 8 Input HART Analog ModuleDocument36 paginiFlex I-O 8 Input HART Analog ModulesamuelborgesÎncă nu există evaluări

- GuardPLC Digital Output Module PDFDocument16 paginiGuardPLC Digital Output Module PDFTarun BharadwajÎncă nu există evaluări

- 1734 Aent PDFDocument20 pagini1734 Aent PDFtt cheneyÎncă nu există evaluări

- Panelview 800 Hmi Terminals: Installation InstructionsDocument28 paginiPanelview 800 Hmi Terminals: Installation Instructionspatil_555Încă nu există evaluări

- 1734 In003 - en eDocument36 pagini1734 In003 - en eOscar VelascoÎncă nu există evaluări

- GuardPLC Digital Input ModuleDocument16 paginiGuardPLC Digital Input ModuleTarun BharadwajÎncă nu există evaluări

- 1734 AentDocument20 pagini1734 AentAmit SharmaÎncă nu există evaluări

- Flex I/0 Remote I/0 Adapter (Cat. No. 1794-ASB Series E)Document20 paginiFlex I/0 Remote I/0 Adapter (Cat. No. 1794-ASB Series E)AdrianoUpÎncă nu există evaluări

- 1734 In042 - en P - Point IO EthernetIP AdapterDocument24 pagini1734 In042 - en P - Point IO EthernetIP AdapterreinaldomdÎncă nu există evaluări

- Flex I/O Devicenet Adapter Module: Installation InstructionsDocument6 paginiFlex I/O Devicenet Adapter Module: Installation Instructionsantmend1258Încă nu există evaluări

- 1756 In612 - en PDocument28 pagini1756 In612 - en PzacriasÎncă nu există evaluări

- 1794 Ie12 Oe12Document20 pagini1794 Ie12 Oe12nicolasÎncă nu există evaluări

- GuardPLC 1600 ControllersDocument20 paginiGuardPLC 1600 ControllersTarun BharadwajÎncă nu există evaluări

- Compactlogix Sercos Interface Module: Installation InstructionsDocument28 paginiCompactlogix Sercos Interface Module: Installation Instructionssharad7575Încă nu există evaluări

- 1769-If4I Analog Input ModuleDocument24 pagini1769-If4I Analog Input ModuleHilder Ramirez PuellesÎncă nu există evaluări

- 1769-Pa2, 1769-PB2, 1769-Pa4Document36 pagini1769-Pa2, 1769-PB2, 1769-Pa4Hilder Ramirez PuellesÎncă nu există evaluări

- FLEX I/O Digital Input Modules: Installation InstructionsDocument22 paginiFLEX I/O Digital Input Modules: Installation InstructionsMike Martinez LozanoÎncă nu există evaluări

- 1734-In056 - EN - Digital Output 8PTS - 1734 - OB8E Versionc PDFDocument22 pagini1734-In056 - EN - Digital Output 8PTS - 1734 - OB8E Versionc PDFThanh BaronÎncă nu există evaluări

- 1783 In008 - en PDocument32 pagini1783 In008 - en PzacriasÎncă nu există evaluări

- Panelview Plus and Panelview Plus Compact 400 and 600 TerminalsDocument30 paginiPanelview Plus and Panelview Plus Compact 400 and 600 TerminalsIyapparaj PazhaniÎncă nu există evaluări

- 1783 EtapDocument32 pagini1783 EtapIrfan KhanÎncă nu există evaluări

- 1797-In014 - En-P (1797-ACNR15) PDFDocument32 pagini1797-In014 - En-P (1797-ACNR15) PDFChago Nattino MacuadaÎncă nu există evaluări

- 1756 CN2Document32 pagini1756 CN2Sanz Flrntin SkottÎncă nu există evaluări

- ControlLogix EtherNet-IP Bridge ModuleDocument20 paginiControlLogix EtherNet-IP Bridge ModuleRaul Federico MartinezÎncă nu există evaluări

- 1756 Ob32Document20 pagini1756 Ob32downpourguyÎncă nu există evaluări

- 1756 In602 - en P PDFDocument32 pagini1756 In602 - en P PDFcyrus6_997303Încă nu există evaluări

- Devicenet 1732 Armorblock I/O, Series A: Installation InstructionsDocument16 paginiDevicenet 1732 Armorblock I/O, Series A: Installation InstructionsMariano DavicoÎncă nu există evaluări

- 2711 In009 - en PDocument20 pagini2711 In009 - en PLaura Sofia Charry OtaloraÎncă nu există evaluări

- 1492 td010 - en PDocument46 pagini1492 td010 - en Pcerberus1991Încă nu există evaluări

- 1762 In012 - en PDocument28 pagini1762 In012 - en PTa Van QuynhÎncă nu există evaluări

- 1756 In590 - en PDocument20 pagini1756 In590 - en PsenthilrsenthilÎncă nu există evaluări

- POINT I/O 8 Channel High Density Current Input Module: Installation InstructionsDocument24 paginiPOINT I/O 8 Channel High Density Current Input Module: Installation InstructionsMINH NHHUT LUUÎncă nu există evaluări

- Point I/O Dual Port Ethernet/Ip Adapter: Installation InstructionsDocument24 paginiPoint I/O Dual Port Ethernet/Ip Adapter: Installation Instructionsdarwis_idÎncă nu există evaluări

- 1794 IO Modules FlexIO DQ PDFDocument28 pagini1794 IO Modules FlexIO DQ PDFLizbeth Soto CastilloÎncă nu există evaluări

- Modulo Salida RelevadorDocument20 paginiModulo Salida RelevadorEdgar Maya PerezÎncă nu există evaluări

- 1794-In102 - En-P - Flex IODocument20 pagini1794-In102 - En-P - Flex IOmarceloÎncă nu există evaluări

- 1794 In107 - en PDocument6 pagini1794 In107 - en PSaga_10Încă nu există evaluări

- 1788 En2dnDocument56 pagini1788 En2dnManuel PedroÎncă nu există evaluări

- Stratix 8000Document52 paginiStratix 8000Call Lopez LopezÎncă nu există evaluări

- Micrologix 1762-Of4 Analog Output ModuleDocument28 paginiMicrologix 1762-Of4 Analog Output ModulelucasgianiniÎncă nu există evaluări

- LFCB 102Document211 paginiLFCB 102Văn Quang NgôÎncă nu există evaluări

- Controllogix Ethernet/Ip Bridge Module: Installation InstructionsDocument20 paginiControllogix Ethernet/Ip Bridge Module: Installation InstructionsDiogo FiaesÎncă nu există evaluări

- Micro800 4-Channel and 8-Channel Analog Voltage/Current Input and Output ModulesDocument12 paginiMicro800 4-Channel and 8-Channel Analog Voltage/Current Input and Output ModulesSyarifudin WahidÎncă nu există evaluări

- MicroLogix 1762-If4 Analog Input ModuleDocument28 paginiMicroLogix 1762-If4 Analog Input ModuleMárcio SantanaÎncă nu există evaluări

- Enhanced PLC-5 Programmable Controllers: Purpose of This DocumentDocument24 paginiEnhanced PLC-5 Programmable Controllers: Purpose of This Documenthunter73Încă nu există evaluări

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsDe la EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsÎncă nu există evaluări

- TM4Document60 paginiTM4Christian JacoboÎncă nu există evaluări

- SparkFun 09881 V-I PlotsDocument13 paginiSparkFun 09881 V-I PlotsCarlosOtinianoÎncă nu există evaluări

- Conversion Functions Example GuideDocument46 paginiConversion Functions Example GuideCarlosOtinianoÎncă nu există evaluări

- Robot BalancingDocument1 paginăRobot BalancingCarlosOtinianoÎncă nu există evaluări

- Modbus TCP DTM Add-OnDocument10 paginiModbus TCP DTM Add-OnCarlosOtinianoÎncă nu există evaluări

- Atv32 Communication Parameters A1.2ie03Document33 paginiAtv32 Communication Parameters A1.2ie03CarlosOtinianoÎncă nu există evaluări

- ATV61 Communication Parameters en V5.8 IE29Document126 paginiATV61 Communication Parameters en V5.8 IE29Anonymous kiyxz6eÎncă nu există evaluări

- Altivar™ 61 Quick Reference Guide: Altivar 61 Graphic Display TerminalDocument2 paginiAltivar™ 61 Quick Reference Guide: Altivar 61 Graphic Display TerminalCarlosOtinianoÎncă nu există evaluări

- Atv71 Communication Parameters en v5.7 Ie67Document136 paginiAtv71 Communication Parameters en v5.7 Ie67CarlosOtinianoÎncă nu există evaluări

- MARS 1.0 License - EnglishDocument1 paginăMARS 1.0 License - EnglishSydney D. BajentingÎncă nu există evaluări

- ATV12 Communication Parameters 2009Document15 paginiATV12 Communication Parameters 2009CarlosOtinianoÎncă nu există evaluări

- Vision Sensors UsDocument28 paginiVision Sensors UsCarlosOtinianoÎncă nu există evaluări

- EIP Set-Up Guide For Dualis Firmware 1060Document13 paginiEIP Set-Up Guide For Dualis Firmware 1060CarlosOtinianoÎncă nu există evaluări

- PatentsDocument8 paginiPatentsMohamedAlAmineÎncă nu există evaluări

- CryptoppDocument2 paginiCryptoppfreddie123Încă nu există evaluări

- Academic Free License v2.1 - EnglishDocument5 paginiAcademic Free License v2.1 - Englishkeyboard2014Încă nu există evaluări

- Pflex Ap011 - Conexion Electrica Variadoes 40 525Document132 paginiPflex Ap011 - Conexion Electrica Variadoes 40 525CarlosOtinianoÎncă nu există evaluări

- EIP Set-Up Guide For Dualis Firmware 1060Document13 paginiEIP Set-Up Guide For Dualis Firmware 1060CarlosOtinianoÎncă nu există evaluări

- Report Data: Date: 14/04/2016 User: AaaDocument2 paginiReport Data: Date: 14/04/2016 User: AaaCarlosOtinianoÎncă nu există evaluări

- SCE - EN - 031-600 Global Data Blocks S7-1200 - R1508Document41 paginiSCE - EN - 031-600 Global Data Blocks S7-1200 - R1508CarlosOtinianoÎncă nu există evaluări

- Elace Descarga MaterialDocument1 paginăElace Descarga MaterialCarlosOtinianoÎncă nu există evaluări

- 45A11Document66 pagini45A11CarlosOtinianoÎncă nu există evaluări

- Elace Descarga MaterialDocument1 paginăElace Descarga MaterialCarlosOtinianoÎncă nu există evaluări

- SW Composer Release NotesDocument13 paginiSW Composer Release NotesCarlosOtinianoÎncă nu există evaluări

- Logo!: Computer Based Training and Documentation CollectionDocument1 paginăLogo!: Computer Based Training and Documentation CollectionCarlosOtinianoÎncă nu există evaluări

- LicenseDocument3 paginiLicenseCarlosOtinianoÎncă nu există evaluări

- 330C EXCAVADORA Sistema ImplementoDocument8 pagini330C EXCAVADORA Sistema Implementoy2npbp6fgsÎncă nu există evaluări

- JHA - MSPECTRUM-PMFTC-ABB Project PDFDocument6 paginiJHA - MSPECTRUM-PMFTC-ABB Project PDFperquino oasanÎncă nu există evaluări

- RESISTOR COLOR CODINGDLP MichaelDocument5 paginiRESISTOR COLOR CODINGDLP MichaelAilyn BrionesÎncă nu există evaluări

- Powerscale 10-50 Kva: User ManualDocument101 paginiPowerscale 10-50 Kva: User ManualaarianÎncă nu există evaluări

- Tittle of Internship: Department of Electrical & Electronics EngineeringDocument15 paginiTittle of Internship: Department of Electrical & Electronics EngineeringmadhulavÎncă nu există evaluări

- IGNOU B SC PHE09 Optics PDFDocument261 paginiIGNOU B SC PHE09 Optics PDFMadhusudan GhoshÎncă nu există evaluări

- Improved-Power Quality Bridgeless - Converter-Based Multiple-Output SmpsDocument11 paginiImproved-Power Quality Bridgeless - Converter-Based Multiple-Output SmpsKalyan Reddy AnuguÎncă nu există evaluări

- Samsung HW F750Document62 paginiSamsung HW F750boroda2410Încă nu există evaluări

- Allied PhysicsDocument9 paginiAllied PhysicsJostin Punnassery50% (4)

- Ltspice Caveats: "Design Tool Investigation Report" by Hao FuDocument2 paginiLtspice Caveats: "Design Tool Investigation Report" by Hao Fu29377Încă nu există evaluări

- Report InternDocument70 paginiReport Interntilahun habte100% (2)

- HA17431GPATZ-E: EOS PowerDocument15 paginiHA17431GPATZ-E: EOS Powerserrano.flia.coÎncă nu există evaluări

- Digital Micro-Ohmmeter: User S GuideDocument26 paginiDigital Micro-Ohmmeter: User S GuideGabrielÎncă nu există evaluări

- Surge Impedance Loading (SIL)Document2 paginiSurge Impedance Loading (SIL)Mahmudul HassanÎncă nu există evaluări

- RAYCHEM - EPP - 0608 Tubo Aislante Termocontraible MT PDFDocument2 paginiRAYCHEM - EPP - 0608 Tubo Aislante Termocontraible MT PDFHaldirLeaoÎncă nu există evaluări

- Cell Phone Jammer Final ReportDocument10 paginiCell Phone Jammer Final ReportujwaljaiswalÎncă nu există evaluări

- AMPERESDocument1 paginăAMPERESJericho MoralesÎncă nu există evaluări

- TPK-2W The TPK Series Are Miniature, Isolated 2W DC/DC Converters in A SIP Package.Document3 paginiTPK-2W The TPK Series Are Miniature, Isolated 2W DC/DC Converters in A SIP Package.toppowerÎncă nu există evaluări

- B Braun Vista Basic Service Manual Part 2Document25 paginiB Braun Vista Basic Service Manual Part 2Alexandra JanicÎncă nu există evaluări

- Iaetsd-Jaras-Implementation of Uwb Micro-Strip Antenna WithDocument6 paginiIaetsd-Jaras-Implementation of Uwb Micro-Strip Antenna WithiaetsdiaetsdÎncă nu există evaluări

- A Compact Ultra-Wideband Power Divider With High Isolation 3.1-10.6 GHZDocument2 paginiA Compact Ultra-Wideband Power Divider With High Isolation 3.1-10.6 GHZagmnm1962Încă nu există evaluări

- DPP - EMIDocument5 paginiDPP - EMIkrishan yadavÎncă nu există evaluări

- Single Stage Isolated Bridgeless PFC Converter Achieves 98 Percent EfficiencyDocument10 paginiSingle Stage Isolated Bridgeless PFC Converter Achieves 98 Percent EfficiencyJosip LuetichÎncă nu există evaluări

- 3D Solar Cell Technology IeDocument12 pagini3D Solar Cell Technology IeYachika YadavÎncă nu există evaluări

- Annex IV - A - LABORATORY Requirements For Chem and PhysicsDocument8 paginiAnnex IV - A - LABORATORY Requirements For Chem and PhysicspicefeatiÎncă nu există evaluări

- CAMELIAS - SA2S - SummaryDocument2 paginiCAMELIAS - SA2S - SummaryJosé Luis ColmenarezÎncă nu există evaluări