Documente Academic

Documente Profesional

Documente Cultură

Good Lab Practice

Încărcat de

Vinh Do ThanhDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Good Lab Practice

Încărcat de

Vinh Do ThanhDrepturi de autor:

Formate disponibile

April 2013

GLP 10

Good Laboratory Practice

for the

Purity of Water

Water is used in two ways in the metrology laboratory. It may be used as a cleaning fluid. It may

also be used as a transfer medium in volume transfer calibrations, or as standard reference

material for gravimetric volume calibrations. In each case of these cases, the water must be clean;

in the case of gravimetric volume calibrations it must be pure, as well.

Dirty water can cause a number of problems, including depositing residues in a volumetric vessel

that could cause volumetric errors or could soil its interior. When in doubt of the cleanliness of the

water supply, filters should be attached to the supply lines used.

Cleanliness of water may be achieved by removal of physical contaminating substances, especially

by filtration. City water is ordinarily clean but may become dirty from the distribution system and

especially from prolonged standing in some kinds of pipes and tubing. Hoses used to transfer

water from and into large vessels and tanks may need internal cleaning, as well. Flushing to

remove visible contamination is all that is usually required prior to use in volume transfer

calibrations or prior to further purification.

Clean Water used in Volume Transfer Calibrations

Clean water is all that is necessary when making measurements by volumetric transfer since

volumetric comparisons are involved. When the water density value is used in a volume transfer

equation, the ratio of the density values of clean water versus pure water is essentially unchanged,

despite impurities. The coefficient of expansion for distilled water and pure water are also

essentially the same.

Note: the equations used in gravimetric calibrations do not use ratios and systematic errors will

result in the calibration relative to impurities in the water. The use of low resolution density

meters for evaluating the quality of clean water (instead of using pure water as described) is

discouraged for use in gravimetric calibrations.

Pure Water used in Gravimetric Volume Calibrations

Pure water is needed for gravimetric volume calibrations. For gravimetric calibrations, filtration

systems alone are not adequate. Pure water requires the removal of chemical contaminants and

this may be achieved by distillation, reverse osmosis, ion exchange systems, or combinations of

these systems. The purity of the water from any given system and maintenance requirement is

often dependent on the quality of the source water. Source water should be tested to determine

the best type of system to meet laboratory needs. Density calculations may be accurate even when

appreciable levels of dissolved salts remain in the water. However, since it is very difficult to know

what type and quantity of salts are tolerable before density is affected, it is prudent to use the best

system practical within budgetary constraints.

Water Quality Specifications and Purification Methods

GLP 10

Page 1 of 5

April 2013

ASTM Type III or IV Reagent Water 1* is recommended as adequate for gravimetric calibration

purposes. Such water may be produced by distillation or by ion exchange with relatively

inexpensive equipment. Type III grade of reagent water may be prepared by distillation, ion

exchange, continuous electrodeionization reverse osmosis, or a combination thereof, followed by

polishing with a 0.45 m membrane filter. Type IV grade of reagent water may be prepared by

distillation, ion exchange, continuous electrodeionization reverse osmosis, electrodialysis, or a

combination thereof.

The ASTM D-1193 specifications for conductivity and resistivity are noted in Table 1.

Table 1. Conductivity and resistivity specifications for water.

Type I

Type II

Electrical conductivity, max,

0.056

1.0

S/cm at 298 K (25 C)

Electrical resistivity, min,

18

1.0

Mcm at 298 K (25 C)

Type III

Type IV

0.25

5.0

4.0

0.20

Conductivity or resistivity (along with other water quality measurements) are often used to assess

the water quality used in cooling towers, boilers, relative humidity systems, micro and

nanoelectronic systems and in pharmaceuticals, to ensure water of sufficient purity and to

minimize corrosion or build-up within such systems.

Conductivity and resistivity measurements do not have a direct correlation to water density, which

is the critical attribute of concern for gravimetric volume calibrations. However, conductivity or

resistivity measurements are a good indicator of water quality and whether the system is in good

operating condition or needs service. Conductivity is simply the reciprocal of resistivity. For water

quality specifications and assessment purposes, conductivity is usually measured in microSiemens

per centimeter (S/cm) and resistivity is usually measured in megaohms-centimeter (Mcm),

both usually at a reference temperature of 25 C. Conductivity is greatly influenced by

temperature and is not linear. However, this is not a major concern for typical laboratory

applications requiring pure water. Either a meter or indicator light should be included in

laboratory systems to monitor water quality output. Standard reference materials are available to

test conductivity and resistivity units. But, because the measurement values are not used to

perform corrections to volume calibrations, traceable calibrations of the units are not essential.

Most manufacturers of systems at this level indicate that the resulting water will meet Type I

specifications. Sales literature will usually specify whether the equipment will provide water of the

above quality. Additionally, many manufacturers will provide a source water quality test and

recommend a system to meet the purity and volume requirements of the laboratory.

A cartridge-type ion-exchange system is recommended for its simplicity and ease of operation. It

can operate intermittently (on demand) and requires little or no maintenance except for change of

cartridges, the need for which will be indicated. A relatively small system (2 L/hr to 30 L/hr) is

adequate for laboratories calibrating glassware and test measures up to and including 20 L (5 gal)

1

ASTM D 1193 - (06)2011, Standard Specification for REAGENT WATER, ASTM, http://www.astm.org, 1916

Race St., Philadelphia, PA 19103.

GLP 10

Page 2 of 5

April 2013

standards. It may be used on demand or to fill a small (20 L to 40 L) storage bottle to assure a

continuous supply of calibration water.

There are two broad types of ion-exchange systems. Pressure cartridge systems (PCS) operate

directly from line pressure (up to 700 kPa) and need no special operation precautions. The less

expensive type operates from the water line through a needle valve to produce a specified flow

through the cartridge(s). In this system, the outlet must not become blocked or turned off to

prevent the water pressure from building up and bursting the cartridge. It is common practice to

plumb directly from the output of this cartridge to a storage tank without using a valve in

between. The unit is operated by simply turning the shut-off valve located at the water supply.

Water Density Measurements

Water density may be measured with a five- or six-place oscillation-type density meter calibrated

using suitable standard reference materials that are representative of the range of use. These

systems typically measure the density at a specific reference temperature (generally 20 C).

However, density meters are generally not needed if an appropriate water purification system is

used that includes a way to measure conductivity or resistivity and where outside validation of

water quality has been obtained.

One method that may be used in the laboratory for monitoring water over time is to maintain a

quality assurance reference flask (QARF) that is calibrated at any time a gravimetric calibration is

performed. If the results of a proficiency test (interlaboratory comparison) that is conducted at the

same time are found acceptable, one can assume that the quality of the water was acceptable on

that day. In this way, the reference value for the flask may be monitored over time. Glassware is

unlikely to change with use of pure water; thus, significant changes on a control chart for a QARF

indicate other problems that may need to be investigated such as water quality or other changes in

the calibration system or process.

Exposure of pure water in storage to air will likely cause degradation in the conductivity and/or

resistivity measurements. However, pure water has been stored for over a year with little

degradation in the density quality (provided that storage containers and lines are clean and that

there is no bacterial growth, algae, or other contamination).

Temperature equilibrium is a critical factor in the density stability of water. This is especially

important for large volumes. Water temperatures must be stable throughout the container.

Temperature accuracy is as important as purity for a correct density determination. If water is

coming straight from the tap through the purification system into the prover, the temperature may

fluctuate appreciably. Therefore, it is important to store an adequate volume of water to complete

a calibration either already purified or ready to go through the system.

Water Density Calculations

Water density tables (see Table 9.8 in NISTIR 6969) or calculations are required for most

gravimetric calculations. For use in computer programs (most often spreadsheets), the use of

calculations are preferred to the use of look-up tables.

GLP 10

Page 3 of 5

April 2013

The following equation provides the density for air-free water and is recommended for use

between 0 C and 40 C.2 This equation provides results in kg/m3. Therefore, divide by 1000 to

convert the value to g/cm3.

(t ) a5

w

(t a ) (t a )

1

2

a 3 (t a 4 )

Eqn. 1

where:

a1 = -3.983 035 C

a2 = 301.797 C

a3 = 522528.9 C2

a4 = 69.348 81 C

a5 = 999.974 950 kg/m3

tw is the temperature of the water in C.

In Excel Format:

=999.97495*(1-(((G8-3.983035)^2*(G8+301.797))/(522528.9*(G8+69.34881))))

where, G8 is the cell with the Celsius temperature and units are given in kg/m3.

Pure water that is used in the laboratory is generally air-saturated, so the density must be

corrected. The impact is approximately between 1 and 4 parts per million (or several times the

uncertainty of the water density calculation). To adjust the air-free water density in Equation 1

between 0 C and 40 C to air-saturated water (the standard laboratory condition), use the

following equation,

/ kg m 3 s0 s1t

Eqn. 2

where,

S0/(10-3 kg m-3)= -4.612

and

S1/(10-3 kg m-3 C-1)= 0.106.

In Excel Format:

=(-4.612+0.106*G8)

where, G8 is the cell with the Celsius temperature. (Add this value to the density. Air-saturated

water density will be less than air-free water density.)

M. Tanaka, G. Girard, R. Davis, A. Peuto, and N. Bignell, Recommended table for the density of water between

0 C and 40 C based on recent experimental reports, Metrologia, 38, 301-309 (2001).

GLP 10

Page 4 of 5

April 2013

Note: The units in Equation 2 are 10-3 kg/m3 or parts per million, so divide by 1 000 000 to find

the change to the water density in g/cm3. Equation 1 and Equation 2 may be combined, taking

care to match units.

Uncertainty in Water Density Values

The uncertainty in water density given by the references for the equation itself may be calculated

using Eqn. 3. The calculated uncertainty for all of the values in the example data shown below is

0.000 000 83 g/cm3.

u ( w ) 0.8394 0.00128 t 0.000110 t 2 0.00000609 t 3 0.000000116 t 4 (10 -3 kg / m 3 )

Eqn. 3

Example Data

Temperature (C)

Air-Free Water Density

(g/cm3)

10

15

20

25

0.999 702 70

0.999 102 57

0.998 206 75

0.997 047 02

Correction for Air

Saturation

(g/cm3)

-0.000 003 55

-0.000 003 02

-0.000 002 49

-0.000 001 96

Air-Saturated Water

Density

(g/cm3)

0.999 699 15

0.999 099 55

0.998 204 26

0.997 045 06

Additional References:

ASTM D 1125 (95)2009, Standard Test Method for Electrical Conductivity and Resistivity of

Water, ASTM, http://www.astm.org, 1916 Race St., Philadelphia, PA 19103.

ISO 15212-1:2002, Oscillation-type density meters Part 1: Laboratory instruments, ISO, 2002.

GLP 10

Page 5 of 5

S-ar putea să vă placă și

- Studies On Drying Kinetics of Solids in A Rotary DryerDocument6 paginiStudies On Drying Kinetics of Solids in A Rotary DryerVinh Do ThanhÎncă nu există evaluări

- Air-Fuel Ratio, Lambda and Engine Performance: AFR M MDocument12 paginiAir-Fuel Ratio, Lambda and Engine Performance: AFR M MVinh Do ThanhÎncă nu există evaluări

- Proper Air-Fuel Ratios for Starting, Idling, Accelerating & MoreDocument9 paginiProper Air-Fuel Ratios for Starting, Idling, Accelerating & MoreVinh Do ThanhÎncă nu există evaluări

- Ansi B16-104Document1 paginăAnsi B16-104Monica Suarez100% (1)

- Effects of Drying Parameters On Heat Transfer During DryingDocument13 paginiEffects of Drying Parameters On Heat Transfer During DryingVinh Do ThanhÎncă nu există evaluări

- Modelling and Simulation of A Direct Contact Rotary DryerDocument16 paginiModelling and Simulation of A Direct Contact Rotary DryerVinh Do ThanhÎncă nu există evaluări

- Modeling and Simulation of A Co-Current Rotary Dryer Under Steady ConditionsDocument8 paginiModeling and Simulation of A Co-Current Rotary Dryer Under Steady ConditionsVinh Do ThanhÎncă nu există evaluări

- Dryer CalculationsDocument4 paginiDryer CalculationsVinh Do Thanh0% (1)

- PEP Report 267A: Ihs ChemicalDocument8 paginiPEP Report 267A: Ihs ChemicalVinh Do ThanhÎncă nu există evaluări

- Aoac - Methods.1.1990. MoistureDocument2 paginiAoac - Methods.1.1990. MoistureVinh Do ThanhÎncă nu există evaluări

- NPK-15 8 15Document5 paginiNPK-15 8 15Vinh Do ThanhÎncă nu există evaluări

- Multi-Use Chair DesignDocument7 paginiMulti-Use Chair DesignVinh Do ThanhÎncă nu există evaluări

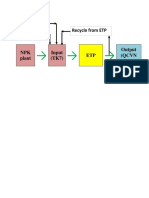

- Recycle From ETP Make Up H2O DAP, UreaDocument1 paginăRecycle From ETP Make Up H2O DAP, UreaVinh Do ThanhÎncă nu există evaluări

- The Heart of Operations - World Cement - 02-2015Document4 paginiThe Heart of Operations - World Cement - 02-2015fetniÎncă nu există evaluări

- 4244 12672 1 PB PDFDocument15 pagini4244 12672 1 PB PDFVinh Do ThanhÎncă nu există evaluări

- 4244 12672 1 PB PDFDocument15 pagini4244 12672 1 PB PDFVinh Do ThanhÎncă nu există evaluări

- Estimating Evaporation From Water SurfacesDocument27 paginiEstimating Evaporation From Water SurfacesVinh Do ThanhÎncă nu există evaluări

- How To Calculate Heat Load - 5 StepsDocument1 paginăHow To Calculate Heat Load - 5 StepsVinh Do ThanhÎncă nu există evaluări

- Natural Evaporation RateDocument16 paginiNatural Evaporation RateVinh Do ThanhÎncă nu există evaluări

- Equivalent Grades of Cast IronsDocument2 paginiEquivalent Grades of Cast IronsVinh Do ThanhÎncă nu există evaluări

- Investigation of Sensible Heat Storage and Heat Insulation in The Exploitation of Concentrated Solar EnergyDocument5 paginiInvestigation of Sensible Heat Storage and Heat Insulation in The Exploitation of Concentrated Solar EnergyradanpetricaÎncă nu există evaluări

- Review On Development of Polypropylene Manufacturing ProcessDocument11 paginiReview On Development of Polypropylene Manufacturing ProcessShweta Yadav100% (1)

- CRACKER A PC Based Simulator For Industr PDFDocument6 paginiCRACKER A PC Based Simulator For Industr PDFVinh Do ThanhÎncă nu există evaluări

- Tinh Luong Nuoc Bay HoiDocument22 paginiTinh Luong Nuoc Bay HoiVinh Do ThanhÎncă nu există evaluări

- Metal Price IndexDocument1 paginăMetal Price IndexVinh Do ThanhÎncă nu există evaluări

- Mau Giay Uy Quyen Bang Tieng AnhDocument3 paginiMau Giay Uy Quyen Bang Tieng AnhVinh Do ThanhÎncă nu există evaluări

- How To Calculate Heat Load - 5 StepsDocument1 paginăHow To Calculate Heat Load - 5 StepsVinh Do ThanhÎncă nu există evaluări

- Optimization of Wall Thickness For Minimum Heat LossesDocument9 paginiOptimization of Wall Thickness For Minimum Heat LossesVinh Do ThanhÎncă nu există evaluări

- 1 0ProjectManagementProceduresDocument8 pagini1 0ProjectManagementProceduresRamiesRahmanÎncă nu există evaluări

- DRS 279-2015 Organic Fertilizer - SpecificationDocument17 paginiDRS 279-2015 Organic Fertilizer - SpecificationVinh Do ThanhÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Tatoo Java Themes PDFDocument5 paginiTatoo Java Themes PDFMk DirÎncă nu există evaluări

- USA V BRACKLEY Jan6th Criminal ComplaintDocument11 paginiUSA V BRACKLEY Jan6th Criminal ComplaintFile 411Încă nu există evaluări

- Measuring Renilla Luciferase Luminescence in Living CellsDocument5 paginiMeasuring Renilla Luciferase Luminescence in Living CellsMoritz ListÎncă nu există evaluări

- Digital Communication Quantization OverviewDocument5 paginiDigital Communication Quantization OverviewNiharika KorukondaÎncă nu există evaluări

- PharmacologyAnesthesiology RevalidaDocument166 paginiPharmacologyAnesthesiology RevalidaKENT DANIEL SEGUBIENSE100% (1)

- Lecture 1: Newton Forward and Backward Interpolation: M R Mishra May 9, 2022Document10 paginiLecture 1: Newton Forward and Backward Interpolation: M R Mishra May 9, 2022MANAS RANJAN MISHRAÎncă nu există evaluări

- Module - No. 3 CGP G12. - Subong - BalucaDocument21 paginiModule - No. 3 CGP G12. - Subong - BalucaVoome Lurche100% (2)

- Embryo If Embryonic Period PDFDocument12 paginiEmbryo If Embryonic Period PDFRyna Miguel MasaÎncă nu există evaluări

- SEMICONDUCTORS AssignmentDocument8 paginiSEMICONDUCTORS AssignmentMaryam MuneebÎncă nu există evaluări

- Robocon 2010 ReportDocument46 paginiRobocon 2010 ReportDebal Saha100% (1)

- Lesson 2 Mathematics Curriculum in The Intermediate GradesDocument15 paginiLesson 2 Mathematics Curriculum in The Intermediate GradesRose Angel Manaog100% (1)

- Finance at Iim Kashipur: Group 9Document8 paginiFinance at Iim Kashipur: Group 9Rajat SinghÎncă nu există evaluări

- AE-Electrical LMRC PDFDocument26 paginiAE-Electrical LMRC PDFDeepak GautamÎncă nu există evaluări

- Determination of Vitamin C in FoodsDocument11 paginiDetermination of Vitamin C in FoodsDalal Shab JakhodiyaÎncă nu există evaluări

- Russian Tea Market Growth and Brand PreferenceDocument6 paginiRussian Tea Market Growth and Brand PreferenceKing KhanÎncă nu există evaluări

- Employee Engagement A Case Study at IVRCL-1Document7 paginiEmployee Engagement A Case Study at IVRCL-1Anonymous dozzql7znKÎncă nu există evaluări

- Florence Walking Tour MapDocument14 paginiFlorence Walking Tour MapNguyễn Tấn QuangÎncă nu există evaluări

- Single-Phase Induction Generators PDFDocument11 paginiSingle-Phase Induction Generators PDFalokinxx100% (1)

- Land Measurement in PunjabDocument3 paginiLand Measurement in PunjabJunaid Iqbal33% (3)

- Hawk Technology Systems v. NCLDocument6 paginiHawk Technology Systems v. NCLPriorSmartÎncă nu există evaluări

- Binomial ExpansionDocument13 paginiBinomial Expansion3616609404eÎncă nu există evaluări

- Common Size Analys3esDocument5 paginiCommon Size Analys3esSaw Mee LowÎncă nu există evaluări

- IMT Ghaziabad PGDM Timetable Term II 2020Document22 paginiIMT Ghaziabad PGDM Timetable Term II 2020Ved JhingranÎncă nu există evaluări

- AVANTIZ 2021 LNR125 (B927) EngineDocument16 paginiAVANTIZ 2021 LNR125 (B927) EngineNg Chor TeckÎncă nu există evaluări

- Lecture 1 Family PlanningDocument84 paginiLecture 1 Family PlanningAlfie Adam Ramillano100% (4)

- Ground Water Resources of Chennai DistrictDocument29 paginiGround Water Resources of Chennai Districtgireesh NivethanÎncă nu există evaluări

- Unit 1 Writing. Exercise 1Document316 paginiUnit 1 Writing. Exercise 1Hoài Thương NguyễnÎncă nu există evaluări

- Easa Ad Us-2017-09-04 1Document7 paginiEasa Ad Us-2017-09-04 1Jose Miguel Atehortua ArenasÎncă nu există evaluări

- Planview Innovation Management Maturity Model PDFDocument1 paginăPlanview Innovation Management Maturity Model PDFMiguel Alfonso Mercado GarcíaÎncă nu există evaluări

- Cianura Pentru Un Suras de Rodica OjogDocument1 paginăCianura Pentru Un Suras de Rodica OjogMaier MariaÎncă nu există evaluări