Documente Academic

Documente Profesional

Documente Cultură

Mitsubishi 4 B 12

Încărcat de

Guillermo RojasTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Mitsubishi 4 B 12

Încărcat de

Guillermo RojasDrepturi de autor:

Formate disponibile

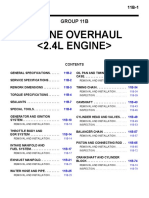

11B-1

GROUP 11B

ENGINE

MECHANICAL

<2.4L ENGINE>

CONTENTS

GENERAL DESCRIPTION. . . . . . . . .

11B-2

BASE ENGINE . . . . . . . . . . . . . . . . . .

11B-3

11B-2

ENGINE MECHANICAL <2.4L ENGINE>

GENERAL DESCRIPTION

GENERAL DESCRIPTION

M2112000102121

MIVEC (MITSUBISHI INNOVATIVE VALVE TIMING ELECTRONIC CONTROL SYSTEM) for

both the intake and exhaust valves

Cylinder block made of an aluminum alloy

Valve train with direct-acting valve tappets

Silent timing chain

Unit type balancer

This model is equipped with a 4B12 engine. It is a

4-cylinder, double overhead camshaft (DOHC)

engine with a 2,360 cm3 cylinder displacement.

This engine has adopted the following features:

MAIN SPECIFICATIONS

Item

Specification

Engine model

4B12

Type

In-line, DOHC

Number of cylinders

Combustion chamber shape

Pentroof type

Total displacement

cm3

(cu in)

2,360 (144.0)

Cylinder bore mm (in)

88 (3.5)

Piston stroke mm (in)

97 (3.8)

Compression ratio

10.5

Maximum output kW/r/min (HP/r/min)

125/6,000 (168/6,000)

Maximum torque N m/r/min (ft-lbs/r/min)

226/4,100 (167/4,100)

Fuel injection system type

Electronic control MPI

Ignition system type

Electronic spark-advance control type (4-coil)

ENGINE MECHANICAL <2.4L ENGINE>

BASE ENGINE

BASE ENGINE

11B-3

M2112001002116

CYLINDER HEAD

Exhaust side

Intake side

Valve guide

AK502483 AD

A cylinder head made of an aluminum alloy, which is

lightweight and offers a high level of cooling efficiency, has been adopted. A pentroof combustion

chamber with a center spark plug has been adopted.

It has a small valve compound angle to realize a

compact chamber.

Cross-flow type intake and exhaust ports have been

adopted. Two intake ports and two exhaust ports are

provided independently on the right and left sides.

Five camshaft bearings are provided at the intake

and exhaust sides, respectively. The No. 4 bearing

sustains the thrust load of the camshaft. Only the No.

1 bearing uses a bearing cap that integrates both the

intake and exhaust sides.

VALVE SEATS

Sintered alloy valve seats have been adopted.

The oversized (0.3 mm) service parts are available.

VALVE GUIDES

Valve guides that are common to both the intake and

exhaust have been adopted.

The oversized (0.25 mm) service parts are available.

11B-4

ENGINE MECHANICAL <2.4L ENGINE>

BASE ENGINE

CYLINDER HEAD GASKET

Oil hole

Water hole

Water hole

AK604543 AB

A dual-layer, metal type cylinder head gasket that

excels in heat resistance and sealing performance

has been adopted.

CYLINDER HEAD COVER

AK502485

A Plastic cylinder head cover has been adopted.

11B-5

ENGINE MECHANICAL <2.4L ENGINE>

BASE ENGINE

CYLINDER BLOCK

Cylinder block

Bearing cap

Oil jet

Ladderframe

AK502486 AE

A cylinder block made of an aluminum alloy has

been adopted for weight reduction.

5 bearings are used for the crankshaft journals and

the No. 3 bearing sustains the thrust load of the

crankshaft.

The water jacket is the full Siamese type.

An oil jet is used in front of the cylinder block to supply engine oil to the timing chain.

Item

Specifications

Distance between top and

crankshaft center mm (in)

230.1 (9.06)

Bore mm (in)

88 (3.5)

Bore pitch mm (in)

96 (3.8)

Stroke mm (in)

97 (3.8)

11B-6

ENGINE MECHANICAL <2.4L ENGINE>

BASE ENGINE

PISTONS

The pistons are made of a special aluminum alloy.

Their weight has been reduced by lowering their

overall height and increasing the depression at each

end of the piston pin.

The piston pin hole center is offset 0.8 mm (0.031 in)

towards the thrust side of the piston center.

The skirt portion along the perimeter of the piston is

finished with streaks that excel in oil retention and

seizure resistance.

20

A

Front mark

Piston offset

Item

Specifications

Basic diameter mm (in)

88 (3.5)

Pin hole diameter mm (in) 21 (0.8)

Overall height mm (in)

51.5 (2.03)

AK603610AB

PISTON PINS

The piston pins are the semi-floating type. Each pin

is press-fit and secured in the small end of the connecting rod, while it floats in the piston.

d2

d1

AK502996AE

Item

Specifications

Outer diameter (D) mm

(in)

21 (0.8)

Inner diameter (d1) mm

(in)

12 (0.5)

Inner diameter (d2) mm

(in)

10.5 (0.41)

Overall length (h) mm (in) 58 (2.3)

11B-7

ENGINE MECHANICAL <2.4L ENGINE>

BASE ENGINE

PISTON RINGS

Piston ring No. 1

Piston ring No. 2

Piston ring No. 1

Maker mark

Piston ring No. 2

Oil ring

Oil ring

Rail

Spacer

AK604544 AB

The piston rings consist of No. 1 and No. 2 rings and

an oil ring.

Item

Piston ring No. 1

Piston ring No. 2

Oil ring

Shape

Inside bevel, Barrel

Taper undercut

3-piece, Barrel

Surface treatment (cylinder

contact surface)

Chrome plating

Parkerizing

Hard plated Parkerizing

Supplier mark

1T

2T

None

11B-8

ENGINE MECHANICAL <2.4L ENGINE>

BASE ENGINE

CONNECTING RODS

The connecting rods are made of highly rigid, forged

carbon steel. The cross section of the rod portion is

shaped like the letter H.

A fracture-split process has been adopted for splitting the big end of the connecting rod.

The fracture split connecting rod has the high insertion force between the rod and the cap as well as the

high installation location accuracy.

The oil holes that feed oil from the main journals of

the crankshaft to the crankshaft pins lubricate the

bearings at the big ends of the connecting rods.

Item

Specifications

Small end hole diameter

(d) mm (in)

21 (0.87)

Big end hole diameter (D) 51 (2.01)

mm (in)

2204

Center-to-center distance 143.75 (5.659)

(L) mm (in)

AK502491AD

CONNECTING ROD BEARINGS

Identification

color

H

AK502492AD

The upper and lower connecting rod bearings are the

same. Each connecting rod bearing is provided with

a backing plate. Its bearing portion is made of an aluminum alloy and its backing plate is made of ordinary

sheet steel.

The width of the connecting rod bearing has been

made as narrow as possible in proportion to the

bearing cap in order to reduce friction loss.

Item

Specifications

Width (H) mm (in)

17 (0.7)

Thickness (A) mm (in)

1.5 (0.06)

11B-9

ENGINE MECHANICAL <2.4L ENGINE>

BASE ENGINE

CRANKSHAFT

Balance weight

Balance weight

Oil hole

Oil hole

Balance weight

AK502493AD

A forged crankshaft has been adopted.

It has 5 main bearings and 8 balance weights.

The crankshaft pins are located at equal 180 intervals.

The oil holes feed engine oil from the journals to the

pins.

A crankshaft sprocket and an oil pump drive shaft are

press-fit to the front of the crankshaft.

Item

Specifications

Pin outer diameter mm

(in)

48 (1.9)

Journal outer diameter

mm (in)

52 (2.0)

CRANKSHAFT BEARINGS, THRUST BEARINGS

Front

Thrust bearing

Lower bearing

Oil groove

Oil hole

Groove

Identification

color

Upper bearing

Identification

color

AK602940AC

The upper crankshaft bearings have oil grooves and

the lower crankshaft bearings do not.

Each crankshaft bearing is provided with a backing

plate. Its bearing portion is made of an aluminum

alloy and its backing plate is made of ordinary sheet

steel. A thrust bearing, which sustains the load in the

thrust direction, is provided at each end of the No. 3

bearing.

11B-10

ENGINE MECHANICAL <2.4L ENGINE>

BASE ENGINE

Item

Crankshaft bearing

Specifications

Width mm 18 (0.71)

(in)

Thickness 2.0 (0.08)

mm (in)

Crankshaft thrust

bearing

Thickness 1.5 (0.06)

mm (in)

CRANKSHAFT PULLEY

Rubber

Timing mark

AK604551 AB

The pulley is made of cast iron.

The pulley portion has grooves for the V-ribbed belt

(with 6 crests).

The flange portion of the pulley has a timing mark

notch for checking the ignition timing.

A torsion damper has been adopted to reduce the

torsional vibration of the crankshaft, as well as to

dramatically reduce noise and vibration in the

high-speed range.

ENGINE MECHANICAL <2.4L ENGINE>

BASE ENGINE

11B-11

DRIVE PLATE

Drive plate

Ring gear

AK502496AD

The drive plate is made of sheet metal.

The drive plate is mounted with 7 bolts.

FLYWHEEL

A cast iron ring gear is a shrink fit in the iron casting

of the flywheel.

The flywheel is mounted with 7 bolts.

Ring gear

AK603618AB

11B-12

ENGINE MECHANICAL <2.4L ENGINE>

BASE ENGINE

TIMING CHAIN TRAIN

Timing mark

link plate (orange)

Timing mark

Timing mark

link plate (blue)

Exhaust V.V.T. sprocket

Intake V.V.T. sprocket

Chain guide

Tensioner lever

Crankshaft sprocket

Timing chain

tensioner

Crankshaft sprocket

timing mark

Timing mark

link plate (blue)

AK502497AP

The two camshafts are driven by the timing chain via

the camshaft sprockets.

The timing chain is a silent, endless type, consisting

of 180 links. It is installed around the V.V.T. sprockets

and the crankshaft sprocket.

Three (orange) mark link plates are installed on the

timing chain to locate the sprockets.

Item

Number of teeth

V.V.T. sprockets

54

Crankshaft sprocket

27

TIMING CHAIN TENSIONER

Rack and

washer

assembly

Spring

Piston

AK502997AE

The tensioner maintains the tension of the timing

chain. It contains a piston with a built-in spring.

With the tensioner installed, its piston directly pushes

on the tension lever in order to automatically adjust

the tension of the timing chain.

11B-13

ENGINE MECHANICAL <2.4L ENGINE>

BASE ENGINE

VALVE TRAIN

Intake

camshaft

Exhaust

camshaft

Valve tappet

Intake valve

Exhaust valve

AK502499 AD

The valve train is the 4-valve, double overhead camshaft (DOHC) type in which the camshafts are

located above the valves.

Two intake and exhaust valves for each cylinder are

arranged in a V shape.

A valve tappet is interposed between the camshaft

and each valve, which allows the valve to open and

close.

VALVES

Intake

D

Exhaust

d

L

AK502500 AD

The valves are made of heat-resistant steel and are

nitrided on their entire surface.

Item

Intake valve

Exhaust valve

Head diameter

(D) mm (in)

35 (1.4)

29 (1.1)

Stem diameter

(d) mm (in)

5.5 (0.22)

5.5 (0.22)

Overall length (L) 113.180

mm (in)

(4.4559)

105.887

(4.1688)

11B-14

ENGINE MECHANICAL <2.4L ENGINE>

BASE ENGINE

VALVE STEM SEALS

The valve stem seals are integrated with the valve

spring seats.

The valve stem seal portion excels in sealing performance and is equipped with a spring to prevent oil

from descending.

Spring

AK502501AD

VALVE SPRINGS

To prevent the engine from surging at high speeds,

unequal-pitch springs are used.

Item

Specifications

Free height (h) mm (in)

47.2 (1.858)

Total number of windings 8.23

h

AK502502 AD

VALVE TAPPETS

Thickness

Identification

mark

AK502503 AD

To adjust the valve lift, 47 sizes of valve tappets are

available in 0.015 mm (0.0006 in) increments, from

3.000 mm (0.1181 inch) to 3.690 mm (0.1453 in).

11B-15

ENGINE MECHANICAL <2.4L ENGINE>

BASE ENGINE

MIVEC (MITSUBISHI INNOVATIVE VALVE TIMING ELECTRONIC CONTROL SYSTEM)

A

Exhaust V.V.T. sprocket

Section B-B

Section A-A

Intake V.V.T. sprocket

Engine oil

control valve

Engine oil

control valve

Cylinder head

Engine oil control

valve filter

Cylinder head

Cylinder block

Cylinder block

B

AK503014 AE

The MIVEC consists of the parts shown in the illustration.

This system continuously varies and optimally controls the opening and closing timing of the individual

intake and exhaust valves, in order to improve torque

and power output in all speed ranges.

V.V.T. SPROCKET (VARIABLE VALVE TIMING SPROCKET)

Intake V.V.T. sprocket

Timing mark

Vane housing

Vane roter

Advance oil

chamber

Stopper pin

Vane

bushing

V.V.T. sprocket

bolt

Sprocket

Retard oil chamber

Exhaust V.V.T. sprocket

Vane housing

Vane roter

Timing mark

Vane bushing

Advance oil

chamber

Stopper pin

Spring

V.V.T. sprocket

bolt

Sprocket

The engine oil control valve controls the hydraulic

pressure in order to move the vane rotor in the V.V.T.

Retard oil chamber

AK503061AD

sprocket to optimally control valve timing.

11B-16

ENGINE MECHANICAL <2.4L ENGINE>

BASE ENGINE

CAMSHAFT

Cam positon

sensing cam

Intake camshaft

Retard

oil channel

Advance

oil channel

Dowel pin

Hollow section

Sealing cap

Exhaust camshaft

Retard

oil channel

Advance

oil channel

AK502506 AD

The camshaft are hollow for weight reduction.

Each camshaft is provided with an oil passage to

guide the hydraulic pressure from the engine oil control valve to the V.V.T. sprocket.

Item

Overall length mm (in)

Journal outer diameter mm (in)

Specifications

Intake

435.00 (17.126)

Exhaust

438.27 (17.255)

Intake

Exhaust

Camshaft lift mm (in)

A cam position sensing cam for detecting the cam

position (used by the cam position sensor) is integrated at the back of each camshaft.

No.1

30 (1.2)

No.2 5

24 (0.9)

No.1

36 (1.4)

No.2 5

24 (0.9)

Intake

9.3 (0.37)

Exhaust

8.2 (0.32)

11B-17

ENGINE MECHANICAL <2.4L ENGINE>

BASE ENGINE

ENGINE OIL CONTROL VALVE

Insulation

coilar

Spool

Default

Pressure pressure

chamber chamber

Enameled

copper wire

Bobbin

Terminal

Tape

Plunger spring

Spring guide

Shaft

Plunger

Seal cap

Valve sleeve

Drain

Pump

Drain

O-ring

Stator

Yoke

Bracket

Guide cap

AK302997AE

The engine oil control valve consists of a solenoid

valve, which switches the hydraulic pressure that

acts on the vane rotor in the V.V.T. sprocket assembly. This valve is actuated by a signal from the

engine ECU.

TIMING CHAIN CASE

Timing chain case

Oil seal

AK502507AD

The timing chain case is made of an aluminum alloy.

A front crankshaft oil seal is press-fit into the case.

11B-18

ENGINE MECHANICAL <2.4L ENGINE>

BASE ENGINE

BALANCER SHAFT MODULE ASSEMBLY

Balancer shaft

module assembly

Counter balancer shaft

AK802150 AB

The counter balancer shaft is located inside the oil

pan to achieve a compact engine.

Items

Specifications

Effectiveness

Vertical vibromotive force

Balancer shaft

Balancer module

sprocket

AK502509 AE

The balancer shaft module assembly integrates an

oil pump and a balancer unit to realize a compact

and lightweight package.

The balancer shaft module assembly cannot be disassembled.

11B-19

ENGINE MECHANICAL <2.4L ENGINE>

BASE ENGINE

Timing mark

link plate

Balancer tensioner lever

Crankshaft sprocket

timing mark

Balancer timing

chain tensioner

Crank shaft

sprocket

Balancer moudule

sprocket timing mark

Balancer

chain guide

Timing mark

link plate

AK502508 AI

The balancer chain is a silent, endless type, consisting of 72 links. It is installed around the balancer

module sprocket and the crankshaft sprocket. Two

mark link plates (orange and blue) are installed on

the balancer chain to locate the sprockets. When the

balancer chain drives the balancer module sprocket,

the balancer gear causes the right and left balancer

shafts to rotate.

Item

Number of teeth

Crankshaft sprocket

38

Balancer module sprocket

19

NOTES

S-ar putea să vă placă și

- Manual Transmission AssemblycomponentsDocument5 paginiManual Transmission AssemblycomponentsZouhair WahbiÎncă nu există evaluări

- Torque Ford Ranger 3.2Document3 paginiTorque Ford Ranger 3.2Jaime ForeroÎncă nu există evaluări

- ARP 107-6001 Mitsubishi Torque SpecsDocument1 paginăARP 107-6001 Mitsubishi Torque SpecsJohnTexeiraÎncă nu există evaluări

- K10B PDFDocument93 paginiK10B PDFAkbar Zahid100% (1)

- Ford Laser Ovehaul SECTION 2-02 ENGINE (FS)Document44 paginiFord Laser Ovehaul SECTION 2-02 ENGINE (FS)satthatÎncă nu există evaluări

- LR4 2010 5.0LDocument832 paginiLR4 2010 5.0LLuis Ramon Arguello RealÎncă nu există evaluări

- Medidas 3.2D (Duratorq - Puma)Document3 paginiMedidas 3.2D (Duratorq - Puma)Flavia CossetinÎncă nu există evaluări

- 03en Volume 1 - Engine & EL - p475Document475 pagini03en Volume 1 - Engine & EL - p475Ibrahim Pagbelem100% (1)

- 303-01b Engine TD4Document166 pagini303-01b Engine TD4Juraci Diniz100% (1)

- Mazda6 AJ V6 Engine OverhaulDocument65 paginiMazda6 AJ V6 Engine Overhauljerry_skarbekÎncă nu există evaluări

- Workshop Manual Trooper UX 1995Document1.928 paginiWorkshop Manual Trooper UX 1995Juan Pablo Romero Puentes100% (1)

- Nissan Patrol 2007Document22 paginiNissan Patrol 2007GermánÎncă nu există evaluări

- EngineDocument522 paginiEngineredleader36100% (11)

- Engine Control System: SectionDocument501 paginiEngine Control System: SectionNilson MaldonadoÎncă nu există evaluări

- Toyota InnovaDocument1 paginăToyota InnovaJamal100% (1)

- Motor Ford Ranger PDFDocument782 paginiMotor Ford Ranger PDFPedro Aguilera100% (1)

- PB Engine Gamma EngDocument14 paginiPB Engine Gamma EngMoaed Kanbar100% (3)

- Engine Mechanical (2Rz-Fe, 3Rz-Fe) : Service DataDocument4 paginiEngine Mechanical (2Rz-Fe, 3Rz-Fe) : Service DataDavid R PaucaraÎncă nu există evaluări

- Mitsubishi 4b12 Service Manual EngineDocument90 paginiMitsubishi 4b12 Service Manual EnginePatricio OlivaresÎncă nu există evaluări

- Jeep Cherokee VM r425 Dohc and VM r428 Dohc Engine CatalogDocument3 paginiJeep Cherokee VM r425 Dohc and VM r428 Dohc Engine CatalogMarius Ţincu100% (1)

- Sqr484f Engine MechanicalDocument98 paginiSqr484f Engine Mechanicaldavid100% (2)

- Nissan 2.4Document204 paginiNissan 2.4hectorgonzalezm100% (6)

- Engine+Mechanical+System+L+1 0+LPGi+KAPPADocument124 paginiEngine+Mechanical+System+L+1 0+LPGi+KAPPAAnthonio LezcanoÎncă nu există evaluări

- 2AZ-FE FuelDocument43 pagini2AZ-FE FuelAdedeji OluwatobilobaÎncă nu există evaluări

- 3.3L 6-Cyl VinDocument28 pagini3.3L 6-Cyl VingypsyshortÎncă nu există evaluări

- Mitsubishi Galant 4g63 Engine Repair ManualDocument29 paginiMitsubishi Galant 4g63 Engine Repair ManualDominador J. Santos Jr.100% (1)

- Toyota Fortuner (EM3275E) - Relay LocationsDocument37 paginiToyota Fortuner (EM3275E) - Relay Locationsyudianto sugyty100% (2)

- Fuel Sistem D4EB 2.2 PDFDocument544 paginiFuel Sistem D4EB 2.2 PDFcarnori100% (1)

- Mitsubishi 4G9 4G92 4G93 4G94 Series Engine Repair ManualDocument112 paginiMitsubishi 4G9 4G92 4G93 4G94 Series Engine Repair Manualyosbal carballoÎncă nu există evaluări

- Toyota 1ZR TorquesDocument5 paginiToyota 1ZR TorquesSpraycrom Trading100% (1)

- 4G69 Engine Mech-11cDocument64 pagini4G69 Engine Mech-11cAchour Talet djamelÎncă nu există evaluări

- RAV2001-BE1009 0 1 ElectricalWiringDiagramCLA20Document58 paginiRAV2001-BE1009 0 1 ElectricalWiringDiagramCLA20Roberto Bianconi100% (1)

- Engine Mechanical: Precautions and Preparations Timing ChainDocument88 paginiEngine Mechanical: Precautions and Preparations Timing ChainJames HavocÎncă nu există evaluări

- Prado Manual SM - 2Document104 paginiPrado Manual SM - 2jeddo2005100% (1)

- Mitsubishi l200 1996 Mitsubishi enDocument1.723 paginiMitsubishi l200 1996 Mitsubishi enMaksym Shevchenko100% (4)

- Engine - VQ25DE and VQ35DE Lubrication SystemDocument16 paginiEngine - VQ25DE and VQ35DE Lubrication Systemscott glacken100% (1)

- Evo7 GtaDocument9 paginiEvo7 GtaBhirawich PholpokeÎncă nu există evaluări

- Installation of Cylinder Head: Downloaded From Manuals Search EngineDocument6 paginiInstallation of Cylinder Head: Downloaded From Manuals Search EngineDavid QuispeÎncă nu există evaluări

- ENGINE Timing 4ZZ-FEDocument31 paginiENGINE Timing 4ZZ-FEAriel100% (1)

- Transfer D22Document38 paginiTransfer D22Jose FigueroaÎncă nu există evaluări

- Engine Overhaul : Group 11BDocument80 paginiEngine Overhaul : Group 11BДмитрийÎncă nu există evaluări

- Toyota Hilux - Full Motores CheckDocument2 paginiToyota Hilux - Full Motores CheckDanilo PierreÎncă nu există evaluări

- WWW - Incar.tw-Kia Picanto Cylinder Head Torque Specs PDFDocument5 paginiWWW - Incar.tw-Kia Picanto Cylinder Head Torque Specs PDFOmar Albraiky0% (2)

- Trooper (2002) PDFDocument2.145 paginiTrooper (2002) PDFrafaeldiesel100% (3)

- 2GR FeDocument16 pagini2GR FeChhum PhallaÎncă nu există evaluări

- Engine: 303-01C Engine - 3.2L Duratorq-Tdci (148Kw/200Ps) - Puma 2011 - 2014 Ranger AssemblyDocument23 paginiEngine: 303-01C Engine - 3.2L Duratorq-Tdci (148Kw/200Ps) - Puma 2011 - 2014 Ranger AssemblyCamille Fajardo Danganan100% (1)

- 4m4 EngineDocument60 pagini4m4 EngineEdmar PalacioÎncă nu există evaluări

- Chery A-Series Service ManualDocument564 paginiChery A-Series Service ManualHarlinton descalzi100% (4)

- Manual de Servicio Mitsubishi Outlander 4b12 2.4l PDFDocument20 paginiManual de Servicio Mitsubishi Outlander 4b12 2.4l PDFRobinson Andres Parga Ruz100% (2)

- dw10 (Hdi)Document13 paginidw10 (Hdi)Andy Mccabe100% (3)

- C100 Service Training Manual:: Engine Mechanical (2.0L Diesel)Document40 paginiC100 Service Training Manual:: Engine Mechanical (2.0L Diesel)sertex_jo100% (1)

- Techdoc Print Page PDFDocument7 paginiTechdoc Print Page PDFSuharto ZuhriÎncă nu există evaluări

- HdiDocument103 paginiHdicirilo72100% (1)

- 206 DW8 EngineDocument25 pagini206 DW8 EngineLuís HilárioÎncă nu există evaluări

- Isuzu NKR 4jb1Document62 paginiIsuzu NKR 4jb1Jakes Schmidt79% (14)

- Basic Engine: Systems OperationDocument3 paginiBasic Engine: Systems OperationTri WahyuningsihÎncă nu există evaluări

- Group 11aDocument105 paginiGroup 11azeljkoÎncă nu există evaluări

- 806 Dw10ated EngineDocument13 pagini806 Dw10ated EngineshoxpamÎncă nu există evaluări

- Basic Engine: Systems OperationDocument2 paginiBasic Engine: Systems OperationMedo SowarÎncă nu există evaluări

- Nte 36Document2 paginiNte 36ch3o10836266Încă nu există evaluări

- SIGNAL FLOW ASHLEY Rev ADocument11 paginiSIGNAL FLOW ASHLEY Rev ABruno CamargoÎncă nu există evaluări

- Iphone 6S Plus Schematic - Vietmobile - VNDocument62 paginiIphone 6S Plus Schematic - Vietmobile - VNMiguel Angel Aguilar Moreira75% (4)

- Water Pom CivicDocument1 paginăWater Pom CivicGuillermo RojasÎncă nu există evaluări

- Accelarator Control SystemDocument4 paginiAccelarator Control Systempietruszka1Încă nu există evaluări

- Adjustable PedalDocument16 paginiAdjustable PedalSarah ThomasÎncă nu există evaluări

- CMP (Phase) MuranoDocument8 paginiCMP (Phase) MuranoGuillermo RojasÎncă nu există evaluări

- Mitsubishi 4b12 Service Manual EngineDocument90 paginiMitsubishi 4b12 Service Manual EnginePatricio OlivaresÎncă nu există evaluări

- X-Type 2003 2004 Elec GuideDocument160 paginiX-Type 2003 2004 Elec GuideTara Andrews100% (2)

- X-Type 2003 2004 Elec GuideDocument160 paginiX-Type 2003 2004 Elec GuideTara Andrews100% (2)

- Murano CVTDocument232 paginiMurano CVTactiongb1100% (3)

- Diccionario Mecanico Ingles-EspañolDocument64 paginiDiccionario Mecanico Ingles-EspañolJhon Fernandez67% (9)

- Ford ExpeditionDocument256 paginiFord ExpeditionScott Cornette100% (1)

- 三菱S4L2发动机零件图册Document111 pagini三菱S4L2发动机零件图册Baiuliang BaiuliangÎncă nu există evaluări

- 6 Manual Optibelt F. Sincrónica PDFDocument74 pagini6 Manual Optibelt F. Sincrónica PDFjesusÎncă nu există evaluări

- Engine General: 303-01B Engine - 1.4L Duratorq-Tdci (DV) Diesel 2004 - 2012 Fusion Description and OperationDocument14 paginiEngine General: 303-01B Engine - 1.4L Duratorq-Tdci (DV) Diesel 2004 - 2012 Fusion Description and OperationHenrique AlmeidaÎncă nu există evaluări

- D20Dtf Engine: 1. SpecificationDocument26 paginiD20Dtf Engine: 1. SpecificationKada Ben youcefÎncă nu există evaluări

- Atos EngineDocument80 paginiAtos Engineingenieriaelectronic100% (1)

- Recommended CAT 8CM32C - SparepartsDocument27 paginiRecommended CAT 8CM32C - SparepartsFergiKalesaranÎncă nu există evaluări

- Timing Belt Design HintsDocument6 paginiTiming Belt Design Hintsmatjidi100% (1)

- John Deere 400 Lawn Garden Tractor Service Manual PDFDocument17 paginiJohn Deere 400 Lawn Garden Tractor Service Manual PDFWalter Lazo33% (3)

- Description and Operation: Engine - 2.5L Duratec-ST (VI5) - EngineDocument13 paginiDescription and Operation: Engine - 2.5L Duratec-ST (VI5) - EngineAlejandro BrionesÎncă nu există evaluări

- Catalog - 19 JasonDocument40 paginiCatalog - 19 JasonHector HugoÎncă nu există evaluări

- CAT - C-15 Industrial Engine BEM0Document5 paginiCAT - C-15 Industrial Engine BEM0Martina FambÎncă nu există evaluări

- Description and Operation: 303-01B-10 Engine - 3.0L 303-01B-10Document11 paginiDescription and Operation: 303-01B-10 Engine - 3.0L 303-01B-10Troy J GautreauÎncă nu există evaluări

- Manual Skoda Octavia 1,8 110kWDocument88 paginiManual Skoda Octavia 1,8 110kWCornea Horatiu Sebastian100% (2)

- Konika SRX-101A SM PDFDocument152 paginiKonika SRX-101A SM PDFAlexeyÎncă nu există evaluări

- Dayco-Timing Belt Training - Entrenamiento Correa DentadaDocument9 paginiDayco-Timing Belt Training - Entrenamiento Correa DentadaDeiby CeleminÎncă nu există evaluări

- Catalogo de Pecas CMP18Document105 paginiCatalogo de Pecas CMP18Waitylla Dias0% (1)

- Ducati ST3 - 2007 Parts ListDocument130 paginiDucati ST3 - 2007 Parts ListBella AQ205Încă nu există evaluări

- KTM DUKE 200 Spare Parts Manual EngineDocument28 paginiKTM DUKE 200 Spare Parts Manual EngineHarpreet Sethi100% (2)

- Timing Gear Case Installation (4JA1)Document39 paginiTiming Gear Case Installation (4JA1)thanhÎncă nu există evaluări

- Artik 35.16 Tractor Parts CatalogueDocument247 paginiArtik 35.16 Tractor Parts CatalogueBhawani CopyÎncă nu există evaluări

- 220 6720503 enUS SMDocument320 pagini220 6720503 enUS SMGuillermo Guardia GuzmanÎncă nu există evaluări

- ACFrOgA-8u3Zi5xFimnR2twGIAR XM 1KM eb9M5yAVQlQaPUftir ttiG38JZ683E p-uvv8f8iyrSkHSm4UjBP2DaHTvFIR3JmerfXdpfovmicTsXQSp5hQFOz2sMDocument27 paginiACFrOgA-8u3Zi5xFimnR2twGIAR XM 1KM eb9M5yAVQlQaPUftir ttiG38JZ683E p-uvv8f8iyrSkHSm4UjBP2DaHTvFIR3JmerfXdpfovmicTsXQSp5hQFOz2sMYN Motors Yonnier PintoÎncă nu există evaluări

- (NISSAN) Manual de Taller Nissan Cube 2014Document123 pagini(NISSAN) Manual de Taller Nissan Cube 2014willy_net123Încă nu există evaluări

- Ram Catalogue 2015 Part1Document112 paginiRam Catalogue 2015 Part1Stephanus Van den HeeverÎncă nu există evaluări

- Training Report: "International Tractors Limited" HoshiarpurDocument25 paginiTraining Report: "International Tractors Limited" HoshiarpurDipak KumarÎncă nu există evaluări

- V70 D5244T 2002Document23 paginiV70 D5244T 2002Sleepy HollowÎncă nu există evaluări

- Bajaj Catalogo de Partes Pulsar NS160 BSIVDocument77 paginiBajaj Catalogo de Partes Pulsar NS160 BSIVPato ErazoÎncă nu există evaluări

- Cloyes Master PDFDocument154 paginiCloyes Master PDFFredy HernanÎncă nu există evaluări

- Yamaha T135 Service Manual PDFDocument349 paginiYamaha T135 Service Manual PDFdjmal87100% (2)

- Caterpillar Cat 330 L EXCAVATOR (Prefix 2EL) Service Repair Manual (2EL00001 and Up)Document27 paginiCaterpillar Cat 330 L EXCAVATOR (Prefix 2EL) Service Repair Manual (2EL00001 and Up)kfm8seuudu100% (1)