Documente Academic

Documente Profesional

Documente Cultură

GAA Bortone June02

Încărcat de

kokiskoDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

GAA Bortone June02

Încărcat de

kokiskoDrepturi de autor:

Formate disponibile

Aquatic Feed manufacturing

FEEDS

Pelleting Mill Construction

Feed enters the pelleting chamber and is

passed through the die

to make pellets.

Die

Eugenio J. Bortone, Ph.D., PAS

5416 Lafayette Lane

Frisco, Texas 75035 USA

drbortone@aol.com

Conditioning Chambers

And Inlet Chute

From the feeder, meal enters the

conditioning chambers and then passes

to the inlet chute. The inlet chute directs

the meal to the feed cone in front of the die.

The chute should be sufficiently angled to allow the meal

to slide down. It also should include an inspection gate

through which meal samples can be collected as controls

during the process run.

A magnet should be mounted on the chute to trap any

metal particles that may be in the meal. The magnet must

be cleaned periodically. Otherwise, trapped metal can build up

and disrupt the flow of the meal, or the magnet simply will

not be able to trap the metal pieces that could damage the die.

Feed Cone

Copyright 2002, Global Aquaculture Alliance. Do not reproduce without permission.

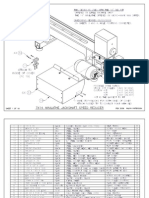

Figure 1. Typical pellet mill components.

hrimp feeds are generally high-density or sinking feeds

with bulk densities of 550-650 g/l. The most common

and cost-effective method to produce these water-stable

feeds is the pelleting process, where finely ground meal

conditioned through moisture and heat is pressed by mechanical force through a die. This meal is compacted in the

die chamber to form the cylindrical shape known as a pellet.

Figure 1 presents the schematic of a typical pellet mill,

which includes a supply bin, screw feeder, preconditioner

or conditioning chambers, feed chute, feed cone, and die.

Supply Bin

The supply bin ensures a continuous meal supply to the

pellet mill, and should be large enough to ensure at least 10

minutes of production. A properly designed supply bin includes two vertical sides, an angle wall of at least 60, a

sliding gate and side-view window, level indicators, and as

large an outlet as possible. Supply bins can also be mounted on load cells to more accurately control the feed rate.

Feeder

The feeder regulates the capacity of the pellet mill. Usually composed of a screw-type feeder with variable pitch, it

supplies a uniform flow of meal to the conditioners and the

pelleting chamber. An important function of the feeder is to

act as a plug that prevents the flow of conditioner steam

from entering the supply bin.

32

GLOBAL AQUACULTURE ADVOCATE JUNE 2002

The feed cone catches meal from the conditioners and

feeds it to the die deflectors. The feed cone is attached to

the die and rotates with it. The centrifugal force created by

this rotation allows the meal to be projected against the wall

of the cone and then to the die via the deflectors.

The deflectors distribute the meal evenly to each roller.

If the meal is not distributed correctly, the capacity of the

die is reduced. It will also cause uneven wear of the die

face. This affects pellet quality because the pellets will have

different dwell times in the compression zone, and thus different compaction profiles, which affect pellet hardness and

water stability.

Die

The die shapes the conditioned meal into pellets. The

die face provides the surface on which the rollers rotate. It

also provides opposing force to the force exerted by the

rollers when meal is pressed through the die orifices.

To prevent the die from breaking or deflecting during

operation, it must have adequate cross-sectional thickness.

The force exerted by the die cannot be greater than the opposing force produced by the rollers pushing the meal.

Excessive thickness can reduce throughput or plug up

the die. Insufficient thickness, in addition to the potential

for breaking the die, can produce pellets that are not hard

enough, which can increase the production of fines.

Proper Design

Proper die design is essential to produce good-quality

shrimp feeds. The total die thickness is the entire blank length.

Each die orifice can be counterbored or have a relief.

The actual area that compresses or forms the pellet is

known as the compression length or effective thickness.

The inlet or countersink to the pellet orifice is very important, as well. For formulations with high fat content, the

inlet should have an angle of 30. For high-fiber formulations, 60 is more common.

Corrosion and Friction

Most shrimp dies are manufactured of stainless steel, with

high chrome content to prevent corrosion since most

shrimp formulas contain acidic materials and to reduce the

coefficient of friction. When high fat or oil diets are used and

increased coefficient of friction is required, the dies should

be manufactured of carburized stainless steel.

Thickness and Compression

For shrimp feeds, it is common to use dies with an effective thickness of 40 mm for dies with 2.0-mm inside diameter orifices, which have a compression ratio of 20. The compression ratio is calculated by dividing the effective compression length by the die orifice diameter.

Relievers

In the standard relieved die, all orifices are counterbored.

The most commonly used die in farm animal feed manufacturing has its outside rows relieved, with only two of the outside rows on each side counterbored. The third type, used in

manufacturing shrimp feeds, is the standard die, which has

no counterbores.

The main reason for using standard dies for shrimp feeds

is to maintain consistent pellet length, hardness, compression

ratio, and water stability. Shrimp pellets produced with outside rows relieved dies will have different dwell times in the

effective pelleting zones. Therefore, these pellets will be less

compacted, softer, and possibly less water-stable than pellets

produced in a standard die.

If not maintained properly, standard dies can end up with

the outside rows plugged up, which results in uneven wear

of the die face. This improper wear negatively affects pellet

quality because the effective thickness is considerably reduced.

Maximizing Open Area and Throughput

Shrimp feed dies should have hole patterns that maximize

open area and throughput. As the size of the die orifice decreases, the pelleting capacity also decreases. This is because

the perforated area (total open area) is considerably smaller

in dies with small-diameter orifices than in large-diameter

ones. Some pellet mills with throughputs of 20 mt/hour with

dies of 6 mm can only produce 3-5 mt/hour of shrimp feed.

Also, the compression ratio used for poultry and swine

diets is much lower than that used to produce quality shrimp

feeds (12-14 versus 18-20, respectively). Therefore, when

comparing dies from different manufacturers, use total open

area as a selection criterion, and not just the price. When possible, request dies with more open area.

Conclusion

Pelleting, where finely ground and conditioned meal is

mechanically pressed through a die, is the most common and

cost-effective method to produce high-density, water-stable

shrimp feeds. The optimum pellet mill capacity for shrimp

feeds should be that which produces the highest quality, as

measured in water stability, pellet hardness, and lowest degree of fines. For shrimp feeds, care must be taken not to increase pellet mill capacity at the expense of water stability.

GLOBAL AQUACULTURE ADVOCATE JUNE 2002

33

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Mysteries of The Unknown - The UFO PhenomenonDocument162 paginiMysteries of The Unknown - The UFO Phenomenonanaximandre06100% (3)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Cross Slide Nut ModificationDocument3 paginiCross Slide Nut ModificationkokiskoÎncă nu există evaluări

- Ralph Patterson Tailstock Camlock 2Document13 paginiRalph Patterson Tailstock Camlock 2supremesportsÎncă nu există evaluări

- Well Stimulation TechniquesDocument165 paginiWell Stimulation TechniquesRafael MorenoÎncă nu există evaluări

- Ss1169 - Telecom Frameworx l1TMFDocument65 paginiSs1169 - Telecom Frameworx l1TMFPrince SinghÎncă nu există evaluări

- Ralph Patterson Speed Reducer 2Document27 paginiRalph Patterson Speed Reducer 2kokiskoÎncă nu există evaluări

- WO9010337 Magnetic MotorDocument23 paginiWO9010337 Magnetic MotorAndras KondratÎncă nu există evaluări

- Anti-Gravity PropulsionDocument16 paginiAnti-Gravity PropulsionTony FreelandÎncă nu există evaluări

- Anti-Gravity PropulsionDocument16 paginiAnti-Gravity PropulsionTony FreelandÎncă nu există evaluări

- Evading Thermal Imaging and Radar Detection-1Document8 paginiEvading Thermal Imaging and Radar Detection-1kokiskoÎncă nu există evaluări

- Assessing Potential Propulsion Breakthroughs: Marc G. MillisDocument21 paginiAssessing Potential Propulsion Breakthroughs: Marc G. MillisnenucarqÎncă nu există evaluări

- Tan Vs GumbaDocument2 paginiTan Vs GumbakjsitjarÎncă nu există evaluări

- Quantum Wave of Life Evolution: Written by DR Kiril Chukanov, June 2009, Calgary, CanadaDocument32 paginiQuantum Wave of Life Evolution: Written by DR Kiril Chukanov, June 2009, Calgary, CanadakokiskoÎncă nu există evaluări

- A Method of Dividing The Circumference of A CircleDocument3 paginiA Method of Dividing The Circumference of A CirclekokiskoÎncă nu există evaluări

- SMD Electrolysis PDFDocument1 paginăSMD Electrolysis PDFkokiskoÎncă nu există evaluări

- Ball Turner PrintsDocument10 paginiBall Turner PrintskokiskoÎncă nu există evaluări

- Ball Turner Prints PDFDocument10 paginiBall Turner Prints PDFkokiskoÎncă nu există evaluări

- 1769 Compound Rest AssyDocument1 pagină1769 Compound Rest AssykokiskoÎncă nu există evaluări

- Quantum Wave of Life Evolution: Written by DR Kiril Chukanov, June 2009, Calgary, CanadaDocument32 paginiQuantum Wave of Life Evolution: Written by DR Kiril Chukanov, June 2009, Calgary, CanadakokiskoÎncă nu există evaluări

- UFODocument2 paginiUFOkokiskoÎncă nu există evaluări

- Rollies Dads MethodDocument4 paginiRollies Dads Methodctin12Încă nu există evaluări

- Drive TroubleshootingDocument9 paginiDrive TroubleshootingkokiskoÎncă nu există evaluări

- Spindle, 7x10, 12 Mini LatheDocument1 paginăSpindle, 7x10, 12 Mini LatheramaaramaaÎncă nu există evaluări

- Morse Taper Dimensions and Drill Chuck ArborsDocument4 paginiMorse Taper Dimensions and Drill Chuck ArborskokiskoÎncă nu există evaluări

- Change Gears Charts For Metric Threading On The 7x MiniDocument2 paginiChange Gears Charts For Metric Threading On The 7x MinikokiskoÎncă nu există evaluări

- RB 7x12 Minilathe BedwaysDocument2 paginiRB 7x12 Minilathe BedwayskokiskoÎncă nu există evaluări

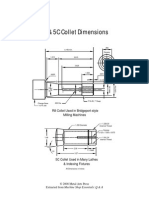

- r8 5c Collet DimensionsDocument2 paginir8 5c Collet Dimensionskokisko100% (1)

- Drilling SpeedsDocument3 paginiDrilling SpeedskokiskoÎncă nu există evaluări

- How To Make Economical BateryDocument85 paginiHow To Make Economical BaterykokiskoÎncă nu există evaluări

- Perreault, Bruce A. U.S. Patent Application Filed May 04, 2007Document9 paginiPerreault, Bruce A. U.S. Patent Application Filed May 04, 2007kokiskoÎncă nu există evaluări

- Ball Turning Toolpost - Complete PDFDocument5 paginiBall Turning Toolpost - Complete PDFRamanujam O SÎncă nu există evaluări

- Faculty of Business and Law Assignment Brief Mode E and R RegulationsDocument4 paginiFaculty of Business and Law Assignment Brief Mode E and R RegulationsSyeda Sana Batool RizviÎncă nu există evaluări

- S 101-01 - PDF - User Interface - Computer MonitorDocument130 paginiS 101-01 - PDF - User Interface - Computer Monitormborghesi1Încă nu există evaluări

- Characteristics of Planetary Candidates Observed by Kepler, IIDocument106 paginiCharacteristics of Planetary Candidates Observed by Kepler, IIRick FeedÎncă nu există evaluări

- Mathematical Geophysics: Class One Amin KhalilDocument13 paginiMathematical Geophysics: Class One Amin KhalilAmin KhalilÎncă nu există evaluări

- How Can You Achieve Safety and Profitability ?Document32 paginiHow Can You Achieve Safety and Profitability ?Mohamed OmarÎncă nu există evaluări

- Management Interface For SFP+: Published SFF-8472 Rev 12.4Document43 paginiManagement Interface For SFP+: Published SFF-8472 Rev 12.4Антон ЛузгинÎncă nu există evaluări

- U2 - Week1 PDFDocument7 paginiU2 - Week1 PDFJUANITO MARINOÎncă nu există evaluări

- Opel GT Wiring DiagramDocument30 paginiOpel GT Wiring DiagramMassimiliano MarchiÎncă nu există evaluări

- Tecplot 360 2013 Scripting ManualDocument306 paginiTecplot 360 2013 Scripting ManualThomas KinseyÎncă nu există evaluări

- Flyer Manuale - CON WATERMARK PAGINE SINGOLEDocument6 paginiFlyer Manuale - CON WATERMARK PAGINE SINGOLEjscmtÎncă nu există evaluări

- Incoterms 2010 PresentationDocument47 paginiIncoterms 2010 PresentationBiswajit DuttaÎncă nu există evaluări

- Comparative Analysis of Mutual Fund SchemesDocument29 paginiComparative Analysis of Mutual Fund SchemesAvinash JamiÎncă nu există evaluări

- Chapter 11 Walter Nicholson Microcenomic TheoryDocument15 paginiChapter 11 Walter Nicholson Microcenomic TheoryUmair QaziÎncă nu există evaluări

- Certification DSWD Educational AssistanceDocument3 paginiCertification DSWD Educational AssistancePatoc Stand Alone Senior High School (Region VIII - Leyte)Încă nu există evaluări

- List of Light Commercial LED CodesDocument8 paginiList of Light Commercial LED CodesRenan GonzalezÎncă nu există evaluări

- CENT - Company Presentation Q1 2020 PDFDocument22 paginiCENT - Company Presentation Q1 2020 PDFsabrina rahmawatiÎncă nu există evaluări

- จัดตารางสอบกลางภาคภาคต้น53Document332 paginiจัดตารางสอบกลางภาคภาคต้น53Yuwarath SuktrakoonÎncă nu există evaluări

- Qa-St User and Service ManualDocument46 paginiQa-St User and Service ManualNelson Hurtado LopezÎncă nu există evaluări

- Common Base AmplifierDocument6 paginiCommon Base AmplifierMuhammad SohailÎncă nu există evaluări

- Harga H2H Pula-Paket Data - Saldo EWallet v31012022Document10 paginiHarga H2H Pula-Paket Data - Saldo EWallet v31012022lala cemiÎncă nu există evaluări

- Appleyard ResúmenDocument3 paginiAppleyard ResúmenTomás J DCÎncă nu există evaluări

- Volvo B13R Data SheetDocument2 paginiVolvo B13R Data Sheetarunkdevassy100% (1)

- Criminal Law I Green Notes PDFDocument105 paginiCriminal Law I Green Notes PDFNewCovenantChurchÎncă nu există evaluări

- BBCVDocument6 paginiBBCVSanthosh PgÎncă nu există evaluări

- It14 Belotti PDFDocument37 paginiIt14 Belotti PDFHolis AdeÎncă nu există evaluări

- Solved - in Capital Budgeting, Should The Following Be Ignored, ...Document3 paginiSolved - in Capital Budgeting, Should The Following Be Ignored, ...rifa hanaÎncă nu există evaluări

- Key Features of A Company 1. Artificial PersonDocument19 paginiKey Features of A Company 1. Artificial PersonVijayaragavan MÎncă nu există evaluări