Documente Academic

Documente Profesional

Documente Cultură

Straw Bale

Încărcat de

SivaRamanDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Straw Bale

Încărcat de

SivaRamanDrepturi de autor:

Formate disponibile

12/12/2014

STRAW

+

STRAW BALING MACHINE

= STRAW BALE

Straw as a building material

STRAW: The dry stems (the part between the root stem and the ear) of threshed

grain (wheat, barley, oats, millet) or fibrous plants (flax, hemp, rice). Most

suitable for the production of bales for building is wheat, spelt and rye. Barley

and oats are less stable.

STRAW is not HAY. Consists cellulose, lignin, silica. Silica content extremely

slows down rotting of straw. It is similar to wood in cellulose content, and is

therefore not digestible by animals. Only 15% of the straw is used for

agricultural purposes or as bedding for animals. The remainder is considered a

waste, and is usually burned producing CO2.

Possesses a waxy, water- repellent skin. Straw has therefore been used to thatch

roofs for centuries.

It has been used as an aggregate in loam increases thermal insulation and

reduces cracks.

12/12/2014

Straw as a building material

STRAWBALE:

SMALL SIZE BALE DIMENSIONS: 32 - 35cm X 50cm X 50 - 120cm

DENSITY: 90 to 120 kg/cu.m (lower density not suitable as building material)

MID SIZE BALE DIMENSIONS: 50 cm X 80cm X 70 - 240cm

JUMBO SIZE BALE DIMENSIONS: 70cm X 120 cm X 100 300cm

DENSITY: 180 200 kg/ cu.m

The medium and jumbo size bales are used for load- bearing structures. They

have very large wall thickness difficult to handle and may require lifting

devices.

12/12/2014

Straw as a building material

Points to remember:

The MOISTURE CONTENT of the straw needs to be LESS THAN 15% to be used as

building material.

Weeds are less stable and will decay faster when damp. Hence WEEDS MUST BE

ABSENT in the bale.

Bales must have ACCURATE DIMENSIONS.

Bales should be STORED IN A DRY ENVIRONMENT and should not touch moist

ground directly and must be protected from rain. Damp bales must be spaced to

allow quicker drying, and prevent damage by micro- organisms.

Stored bales SHOULD SHOW NO SIGNS OF DECAY/ MOULD.

The tying strings should be tight POLYPROPYLENE is suitable.

ADVANTAGES

STRAW is a RENEWABLE BUILDING MATERIAL.

It is RECYCLABLE and hence disposal is not a problem. In fact, it can easily be

separated from other materials upon demolition and may be used as mulch in

the garden or in agriculture for de-compacting soil.

Relatively LESS ENERGY IS REQUIRED FOR THE PRODUCTION of straw bales

14 MJ/ cu.m of energy.

TRANSPORTATION of straw bales is fairly LESS ENERGY- INTENSIVE.

Straw is a SUSTAINABLE building material, which has minimal negative impact

on the environment even less than timber

FIRE RATING of F90 allows straw bale structures to be used in single and double

storey structures.

Strawbale structures have a LONG LIFE- SPAN as shown by existing structures.

Suitable for DO-IT-YOURSELF CONSTRUCTION = BUILDING COST SAVINGS

12/12/2014

Straw as a building material

Common Concerns:

FIRE: Loose straw easily catches fire.

But straw bale walls that are plastered on both sides achieve a fire rating of 90

mins.

MICE: Mice do not feed on straw. Moreover, the 90kg/ cu.m density strongly resists

rodents. Cavities in the bales may be problematic. Plastering strawbales further

discourage rodents.

TERMITES: Termites dont feast on straw. Though some species might be able to

digest straw, they seem to rather prefer wood.

MOULD: Mould cannot develop on dry straw (moisture content less than 15%). This

can further be ensured by the installation of a vapor barrier. However, a thick

layer of plaster can moisten the straw and prevent the drying out of straw.

Hence the next layer of plaster should be applied only after the earlier one dries.

Also, organic aggregates in plaster that slow the drying process should be less.

PHYSICAL ASPECTS

HEAT STORAGE & CONDUCTIVITY:

Straw bales have LOW THERMAL MASS, and therefore have POOR HEAT

STORAGE CAPACITY. Temperature balance is however improved by

plastering material such as 3 6 cm thick EARTH PLASTERING with a high

content of sand and fine gravel (of higher density = 1900-2100 kg/ cu.m).

THERMAL INSULATION:

Strawbale provides EXCELLENT THERMAL INSULATION. The insulation depends

on the density of the bales, the position of the stalks (better insulation is

provided if the stalk is perpendicular to the heat transition), and the humidity

content of the straw.

As an agricultural co-product, inconsistent properties (eg dimensions,

density and moisture content) can be problematic during construction

12/12/2014

PHYSICAL ASPECTS

MOISTURE PROTECTION:

Exterior walls have to be protected against

humidity/ water from all sides. The

following methods can be used to achieve

this:

Splash guard:

Walls must have a splash guard up to a

height of at least 30 cm. Ideally the first

layer of straw bales should start above

this height.

The risk of splash water can be reduced

significantly by a gravel or crush stone

bed or a dense low vegetation at the

perimeter. Hard floors in front of the wall

will have the reverse effect.

PHYSICAL ASPECTS

Weather protection:

A straw bale wall has to be protected from rain, hail and wind. This can be

achieved by deep overhangs & a weather- proof plaster coat.

Fire protection:

A non- load bearing straw bale wall with interior & exterior lime plastering

has a F90 fire rating. Fire resistance can be attributed to the plaster

itself as well as to the high compression of the bales not leaving enough

oxygen for the combustion of straw.

Sound Insulation:

Sound insulation of straw bales with double- sided plastering is higher than

single- layered elements of the same weight. This can be attributed to a

certain vibration of straw bales.

12/12/2014

STRAW BALE WALLS

STRAW BALE WALLS

12/12/2014

STRAW BALE WALLS

There are 2 basic types of

strawbale construction:

LOADBEARING and

NON-LOADBEARING (or infill).

LOADBEARING CONSTRUCTION,

utilizes straw bales as large bricks

that support all of the building loads.

NON-LOADBEARING

CONSTRUCTION utilizes an

independent structural system with

straw bales filling in between.

PLASTERING STRAW BALE WALLS

Interior render:

Plastering HARDENS AND SMOOTHES THE BALE SURFACE and PROVIDES

AIR- TIGHTNESS AND FIRE PROTECTION.

Suitable materials for plastering: Earth, stucco, lime, cement and lime-cement

Clay plaster:

Absorbs more moisture than other materials.

Usually, plaster is applied in three layers:

Undercoat smoothes the bale surface and immerses sticking- out stalks (it is best

sprayed using a high- pressure pump). High clay content ensures strong

adhesion to the straw stalks.

Second coat leaner mix (with added sand & fine aggregate) to reduce cracking in

the drying process. Addition of dust or straw chaff is preferable.

Finishing coat with coarse sand aggregate

A lime top coat may be added to improve the strength of the clay plaster with a

chicken mesh as underlay.

12/12/2014

PLASTERING STRAW BALE WALLS

Cement plaster is fairly brittle compared to clay plaster, and has a tendency to

develop cracks as a result of movements of the sub- structure, wind loads etc.

Reinforcement with glass fibre or metal meshes is advisable.

Exterior plaster:

Should prevent moisture from entering the straw bales. It should also be vapour

permeable to allow condensate to diffuse to the outside.

This makes CLAY PLASTER most suitable for exterior use if suitably protected from

rain. A paint coat could also increase water resistance. However, paint coats like

linseed oil and varnish act as a vapor barrier and may lead to collection of

condensation water within the bales.

A LIME PLASTER OVERCOAT on clay plaster is preferred over an cement overcoat.

Cement-based surface finishes are NOT recommended for use on strawbale walls IN

WET OR HUMID CLIMATES. Cements are BRITTLE and eventually form cracks

that allow water to penetrate. Also, cements are NOT BREATHABLE, and do not

allow this moisture to transpire back out at the same rate.

PLASTERING STRAW BALE WALLS

12/12/2014

STRAW BALE WALLS

S-ar putea să vă placă și

- Indian History of ArchitectureDocument174 paginiIndian History of ArchitectureSivaRamanÎncă nu există evaluări

- 1750 - Muslim Religious ArchitectureDocument145 pagini1750 - Muslim Religious ArchitectureSivaRamanÎncă nu există evaluări

- Ad9354 Architectural Acoustics L T PDocument2 paginiAd9354 Architectural Acoustics L T PSivaRamanÎncă nu există evaluări

- Prof. Babu Rajeswaran: Research BriefDocument6 paginiProf. Babu Rajeswaran: Research BriefSivaRamanÎncă nu există evaluări

- Exhibition and Conventional CenterDocument153 paginiExhibition and Conventional CenterSivaRamanÎncă nu există evaluări

- ID Unit 2Document6 paginiID Unit 2SivaRamanÎncă nu există evaluări

- Ar - Alvaro SizaDocument252 paginiAr - Alvaro SizaSivaRaman100% (1)

- Report Writing PDFDocument14 paginiReport Writing PDFSivaRamanÎncă nu există evaluări

- Clear Statement of Objectives of Research: Formulating A Research Problem Conceptualizing A Research DesignDocument2 paginiClear Statement of Objectives of Research: Formulating A Research Problem Conceptualizing A Research DesignSivaRamanÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Wall Footing Detail: Roof Framing PlanDocument1 paginăWall Footing Detail: Roof Framing PlanJerome AdduruÎncă nu există evaluări

- FCL FCL FCL FCL: Model 78 - CortinaDocument1 paginăFCL FCL FCL FCL: Model 78 - CortinaJeremiahLimÎncă nu există evaluări

- Steel Construction BCSATata Steel SCI - DesignDocument51 paginiSteel Construction BCSATata Steel SCI - Designmys85100% (1)

- Determination of Hyper Static Moments in Post-Tensioned Concrete Flat SlabDocument5 paginiDetermination of Hyper Static Moments in Post-Tensioned Concrete Flat SlabHedda StoicescuÎncă nu există evaluări

- Earthworks in Buildings PDFDocument21 paginiEarthworks in Buildings PDFCristel BurayagÎncă nu există evaluări

- DSR 12-13Document279 paginiDSR 12-13Chandrashekhar ChopdekarÎncă nu există evaluări

- LEED and ASHRAE 90.1 2007 and 2010 App G PRM - User Guide: March 2019Document46 paginiLEED and ASHRAE 90.1 2007 and 2010 App G PRM - User Guide: March 2019Jotham King DennisÎncă nu există evaluări

- Kharkopar STN Concept, Material, ServicesDocument6 paginiKharkopar STN Concept, Material, Serviceskomal100% (1)

- Laurie Baker PresentedDocument33 paginiLaurie Baker PresentedArnav DasaurÎncă nu există evaluări

- Earthwise PowerBreakfast 2010Document41 paginiEarthwise PowerBreakfast 2010majortayÎncă nu există evaluări

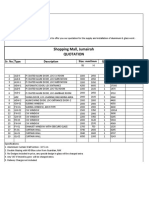

- Proposed Mall Jumairah QuotationDocument2 paginiProposed Mall Jumairah QuotationMohit RanaÎncă nu există evaluări

- Refractory SelectionDocument24 paginiRefractory Selectioncet.ranchi7024Încă nu există evaluări

- Water Tanks StructuralDesignsDocument55 paginiWater Tanks StructuralDesignsuma venkata ramanaÎncă nu există evaluări

- Pre-Cast Structural MembersDocument13 paginiPre-Cast Structural Memberszeu chÎncă nu există evaluări

- Wood Frame Prescriptive Provisions One Story Residential Construction Only Ib P bc2011 004Document9 paginiWood Frame Prescriptive Provisions One Story Residential Construction Only Ib P bc2011 004Ernesto PedrozaÎncă nu există evaluări

- PVC & UpvcDocument46 paginiPVC & UpvcKuldeep PanchalÎncă nu există evaluări

- Bearing Piles and GroupsDocument36 paginiBearing Piles and Groupsjologscresencia100% (1)

- GypDocument4 paginiGypshanky22Încă nu există evaluări

- Timber Frame Junction DetailsDocument28 paginiTimber Frame Junction DetailshemendraengÎncă nu există evaluări

- PDF Q1 Mod 1 EIM GRADE 12 NewDocument10 paginiPDF Q1 Mod 1 EIM GRADE 12 NewCloud DullasÎncă nu există evaluări

- Specifying Visual Cast Insitu Concrete Elaine ToogoodDocument45 paginiSpecifying Visual Cast Insitu Concrete Elaine ToogoodErnie Ernie100% (1)

- 01 Daikin PA Catalogue 240117 - High Res - 0Document24 pagini01 Daikin PA Catalogue 240117 - High Res - 0T Satheesh KumarÎncă nu există evaluări

- CSA 165.1 Specifications & General Specifications Notes: Canadian Concrete Masonry Producers' AssociationDocument17 paginiCSA 165.1 Specifications & General Specifications Notes: Canadian Concrete Masonry Producers' AssociationZebÎncă nu există evaluări

- Record 28 PDFDocument18 paginiRecord 28 PDFSakisÎncă nu există evaluări

- Arch 232 STEEL PROJECT Spring 2021 FinalDocument8 paginiArch 232 STEEL PROJECT Spring 2021 FinalSarah JagessarÎncă nu există evaluări

- Performance Evaluation of Structural Concrete Using Controlled QualityDocument8 paginiPerformance Evaluation of Structural Concrete Using Controlled QualityJithinRajÎncă nu există evaluări

- Dugda Construction: Sub-Structure Form Work Mat Beam Mat Slab SideDocument14 paginiDugda Construction: Sub-Structure Form Work Mat Beam Mat Slab SideAbelÎncă nu există evaluări

- Modular ConstrctnDocument4 paginiModular ConstrctnParvez Saif100% (1)

- W L 1176Document1 paginăW L 1176shama093Încă nu există evaluări

- 106000Document36 pagini106000ThaisailerÎncă nu există evaluări