Documente Academic

Documente Profesional

Documente Cultură

CAIET DE SARCINI - Eng

Încărcat de

Mihai DiaconuDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

CAIET DE SARCINI - Eng

Încărcat de

Mihai DiaconuDrepturi de autor:

Formate disponibile

TECHNICAL SPECIFICATIONS FOR BIDDINGS

Rehabilitation of Bucharest Braov railway line, component part of the Pan

European Corridor IV for the trains traffic at 160 km/h speed

Section Cmpina - Predeal

COD:

Nr.

Replace::

Page 1/7

THERMO-TECHNOLOGICAL INSTALLATION

Volume 3, Part E

Detailed Technical Specifications

Thermo-technological Installation

CONTENT

1.

General data............................................................................................................................ 2

1.1. Purpose................................................................................................................................ 2

1.2. Application domain...............................................................................................................2

1.3. Category and class of importance........................................................................................2

1.4. Risk class............................................................................................................................. 2

1.5. Normal function time............................................................................................................ 2

1.6. Required approvals.............................................................................................................. 2

1.7. Traffic safety conditions........................................................................................................2

1.8. Labor protection and hygiene conditions..............................................................................2

1.9. Environment conditions........................................................................................................3

1.10. Guaranty term..................................................................................................................3

2. Calculus sheets for dimensioning the construction elements and installations..............3

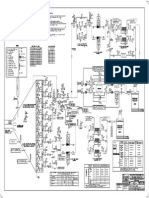

3. Specifying the drawings governing the work.......................................................................3

4. Materials, equipment and installations component of the work.........................................3

4.1. Physical-chemical, mechanical properties............................................................................3

4.2. Aspect.................................................................................................................................. 3

4.3. Dimensions, tolerances........................................................................................................3

4.4. Tests.................................................................................................................................... 4

4.4.1 Tests taking over......................................................................................................... 4

4.4.2 Test at the manufacturing factory...................................................................................4

4.4.3 Tests for the provisory taking over..................................................................................4

4.4.4 Tests for the final taking over.........................................................................................4

4.5. Reference documents..........................................................................................................5

5. Machines and outfits.............................................................................................................. 5

5.1. Denomination....................................................................................................................... 5

5.2. Technical characteristics......................................................................................................5

6. Description and sequence of the works...............................................................................5

6.1. Initial condition of the work...................................................................................................5

6.2. Designed works....................................................................................................................5

6.3. Denomination and sequence of works.................................................................................5

6.3.1 Thermal pipes................................................................................................................ 5

6.3.2 Heating with heating bodies...........................................................................................6

6.3.3 Mounting the fittings.......................................................................................................6

6.3.4 Mounting the heating bodies..........................................................................................6

6.3.5 Protection against outside corrosion..............................................................................6

6.4. Dimensions, shapes, aspect................................................................................................6

6.5. Tests, checking on stages (flow) and at the end...................................................................6

6.5.1 Checking the heating installation....................................................................................6

6.6. Reference documents..........................................................................................................6

7. Reference documents............................................................................................................ 7

8. Works taking over..................................................................................................................7

Designed

Name

Eng. C. Radu

Cod fiier: 258044560.doc

Signature

Checked

Name

Eng. R. Minea

Signature

TECHNICAL SPECIFICATIONS FOR BIDDINGS

Rehabilitation of Bucharest Braov railway line, component part of the Pan

European Corridor IV for the trains traffic at 160 km/h speed

Section Cmpina - Predeal

COD:

Nr.

Replace::

Page 2/7

THERMO-TECHNOLOGICAL INSTALLATION

Volume 3, Part E

Detailed Technical Specifications

Thermo-technological Installation

TECHNICAL SPECIFICATIONS

1.

GENERAL DATA

1.1. Purpose

The heating and air conditioning installations aim at providing the necessary climate at the working

place and keeping between the limits of the temperature and humidity parameters for the operation

of the electronic equipment.

1.2. Application domain

These technical specifications may be applied to all rehabilitated buildings that are located along

the section Bucharest North Bucharest Baneasa and Fetesti Constanta.

1.3. Category and class of importance

According to Law no. 10/18.01.1995 and to the regulations approved by H.G. 766 of 21.11.1997,

the category and class of importance is normal, namely ,,C .

1.4. Risk class

It is not the case because the works do not imply OMT Order no. 290/2000.

1.5. Normal function time

According to the Performance guide for installations (M.L.P.A.T.-C.T.S. approval no. 1828.02.1996) vol. 1 Chap. 13, the minimum service period for the central heating installations on the

whole is established to be 20 years for the specified working temperature and under the operation

conditions according to the provisions in force.

1.6. Required approvals

For the central heating works it is necessary to obtain the natural gas quantity allotment and to

draw up the gas utilization projects.

1.7. Traffic safety conditions

It is not the case.

1.8. Labor protection and hygiene conditions

The works for the installations, their checking, putting into operation, measuring, adjusting and

testing will be carried out according to the norms and standards in force (I5-1998, I5/2-1998 and

I13/2002), observing the essential requirements referring to the labor protection, safety and

hygiene (Regulation regarding the labor protection and hygiene Order 9/N/15.03.1993

M.L.P.A.T.), as well as the regulations for fire prevention and extinguishing (O.G. no. 60/1997

approved by Law 212/1997, General norms for fire prevention and extinguishing), Norms C300

Designed

Name

Eng. C. Radu

Cod fiier: 258044560.doc

Signature

Checked

Name

Eng. R. Minea

Signature

TECHNICAL SPECIFICATIONS FOR BIDDINGS

Rehabilitation of Bucharest Braov railway line, component part of the Pan

European Corridor IV for the trains traffic at 160 km/h speed

Section Cmpina - Predeal

COD:

Nr.

Replace::

Page 3/7

THERMO-TECHNOLOGICAL INSTALLATION

(Norm for fire prevention and extinguishing during the constructions works and related

installations) and P118-1999 (Norm for fire safety of the constructions).,

According to the M.T.Tc. Order 18/1978, the working points shall be equipped with material for fire

prevention and extinguishing.

1.9. Environment conditions

The environment conditions in the areas where there are Bucharest North Bneasa and Feteti

Constana sections require, in the studied buildings, heating installations for the winter period when

the temperatures may reach 320C and air conditioning installations for the summer period when

the temperatures may reach + 350C.

When carrying out the works, the contractor shall observe the laws in force referring to the

environment protection Environment protection law no. 137/30.12.1995.

After finishing the works, the contractor is bound to bring the ground to the initial condition.

1.10. Guaranty term

The guarantied working time for the equipment is minimum 1 year.

2.

CALCULUS SHEETS FOR DIMENSIONING THE CONSTRUCTION ELEMENTS AND

INSTALLATIONS

The central heating installations were dimensioned according to Norm I13-2002 as well as to the

standards and norms included in the annexes.

The air conditioning installations were dimensioned according to Norm I5-2002 as well as to the

standards and norms included in the annexes.

3.

SPECIFYING THE DRAWINGS GOVERNING THE WORK

The drawings governing the work can be found in the volume of the Th.P. (Technical project) stage

for each building and each type of installation.

4.

MATERIALS, EQUIPMENT AND INSTALLATIONS COMPONENT OF THE WORK

4.1. Physical-chemical, mechanical properties

The pipes used for the installation shall be made of black steel or equivalent materials

corresponding to the projects requirements.

4.2. Aspect

Before being put into work, all the materials and equipment shall be checked with a naked eye to

find out if there is any damage that might compromise them technically. If necessary, the

respective faults are repaired or the materials and equipment whose faults cannot be repaired shall

be replaced.

4.3. Dimensions, tolerances

o

Designed

The materials and equipment used for the heating installations shall have the

characteristics and tolerances specified in the national standards or in the

Name

Eng. C. Radu

Cod fiier: 258044560.doc

Signature

Checked

Name

Eng. R. Minea

Signature

TECHNICAL SPECIFICATIONS FOR BIDDINGS

Rehabilitation of Bucharest Braov railway line, component part of the Pan

European Corridor IV for the trains traffic at 160 km/h speed

Section Cmpina - Predeal

COD:

Nr.

Replace::

Page 4/7

THERMO-TECHNOLOGICAL INSTALLATION

producers technical prescriptions and shall fulfill the technical conditions required

by the project for the heating installation.

They shall be accompanied by:

- suppliers quality certificate

- technical sheets

- mounting, testing, maintenance and operation instructions for the

product

- guaranty certificate

- performance certificates issued by authorized institutes.

The thermal and hydraulic characteristics of the heating bodies - including the

variation curve of the heat yielding depending on the temperature and output of

the heat carrier -shall be certified and homologated.

The adjusting fittings shall be accompanied by the certification of the variation of

their characteristics.

o

o

4.4. Tests

4.4.1

Tests taking over

o

o

o

4.4.2

Test at the manufacturing factory

o

o

o

4.4.3

The tests necessary for the materials or outfits used for the supplying are

classified in 3 stages :

- tests at the manufacturing factory

- tests at the mounting place

- tests for all the installations after the guaranty period has passed

All the tests shall be carried out according to the norms in force, to the Taking

over regulation for the construction works and related installations, approved by

H.G.R. 273/14.06.1994 .

If the results of some tests prove the faulty operation or the deterioration of some

material, the contractor is bound to find the causes that brought about the failure

of the tests and to repeat the test.

These tests shall be carried out at the material or outfit manufacturing factory or

at an appropriate factory having the beneficiarys approval.

The aim of the tests is to certify that each material or outfit is absolutely fit for the

mounting, in the conditions indicated in documentation and having the foreseen

characteristics.

The positive results of the factory tests shall not exclude the testing at the

working place.

Tests for the provisory taking over

As part of the provisory taking over and based on the tests report signed by the beneficiary and the

contractor, a visual checking of the works for the heating installations shall be carried out, in point

of their compliance with the project in detail.

The tests for the taking over shall comply with Taking over regulation for the construction works

and related installations approved by H.G.R. 273 /14.06. 1994.

4.4.4

Tests for the final taking over

The tests for the final taking over contain the same tests as for the provisory taking over, after a

period of operation established by the beneficiary and grantee (the period should not be less than

the guaranty period specified by the grantee through the contract).

Designed

Name

Eng. C. Radu

Cod fiier: 258044560.doc

Signature

Checked

Name

Eng. R. Minea

Signature

TECHNICAL SPECIFICATIONS FOR BIDDINGS

Rehabilitation of Bucharest Braov railway line, component part of the Pan

European Corridor IV for the trains traffic at 160 km/h speed

Section Cmpina - Predeal

COD:

Nr.

Replace::

Page 5/7

THERMO-TECHNOLOGICAL INSTALLATION

In addition, the materials and outfits behavior in time shall be checked during the final taking over.

4.5. Reference documents

The following were taken into consideration for the selection of the materials and equipment:

-

5.

STAS 40288

Thread for thread-tightened pipes. Dimensions and tolerances.

SR 404/1-1998

Hot-rolled, seamless steel pipes.

STAS 7656-1990 Longitudinally welded steel pipes for installations.

STAS 736486

Cast iron radiators elements.

SR EN 1057-2002 Cooper and cooper aliages. Circular cooper pipes no suda for water

and gas utilised in sanitary and heating installations.

MACHINES AND OUTFITS

5.1. Denomination

The operational outfits are specified in Annex C 10 enclosed to the execution project.

5.2. Technical characteristics

The technical characteristics are the ones that resulted from the calculations for meeting the

conditions to build the installation and are indicated in sheets C 10 enclosed to the execution

project.

6.

DESCRIPTION AND SEQUENCE OF THE WORKS

6.1. Initial condition of the work

All the buildings included in the technical project must be provided with heating installations in

good condition.

6.2. Designed works

There were designed central heating installations with static bodies (radiators) with 90/700C or

80/600C hot water, thermal plants using liquid fuel (Diesel fuel) and air conditioning installations.

6.3. Denomination and sequence of works

6.3.1

Thermal pipes

The indoor thermal pipes shall be made of black pipe STAS 7656-90 and construction pipe SR

404-1/98. They shall be mounted visibly.

The routes of the pipes inside the buildings will comply with the plans,

having 2 slope, ensuring the installation emptying and aeration.

The minimum distances between the pipes and the construction

elements or other installations shall be indicated in Norm I13/2002

(heating).

Where the pipes pass through walls or floors, they shall be mounted

in protection tubes masked by rosette.

To sustain the elements of the installations (especially the pipes), it is

recommended to use the type details for installations.

The distances recommended between the mobile supports of the heating pipes are indicated in

norm I 13 - 2002.

Designed

Name

Eng. C. Radu

Cod fiier: 258044560.doc

Signature

Checked

Name

Eng. R. Minea

Signature

TECHNICAL SPECIFICATIONS FOR BIDDINGS

Rehabilitation of Bucharest Braov railway line, component part of the Pan

European Corridor IV for the trains traffic at 160 km/h speed

Section Cmpina - Predeal

Nr.

Replace::

Page 6/7

THERMO-TECHNOLOGICAL INSTALLATION

6.3.2

COD:

Heating with heating bodies

6.3.3

The heating bodies will preferably be cast iron radiators having an

increased heat density index for the lifetime (W / kg x years lifetime).

The heating bodies shall be placed at the lower part of the rooms near

the cold surfaces, under the window , if it is not possible, in its close

vicinity.

The heating bodies shall be mounted according to STAS 1797 88.

The heating bodies shall be linked to the vertical columns by

detachable joints, so that the heat carrier will circulate upwards to

downwards, observing the norm I13.

Mounting the fittings

All the fittings shall be mounted in closed position.

6.3.4

Mounting the heating bodies

The heating bodies shall be fastened into their position according to the producers mounting

instructions, using the indicated type and number of cantilevers and supports.

All the heating bodies shall be provided with covers or plugs until the mounting of the fittings and

links.

6.3.5

Protection against outside corrosion

All the pipes of the installation, as well as the heating bodies (unless they are delivered already

protected by the supplier) shall be protected against corrosion by a base corrosion-proof red layer

applied after cleaning the rust from the protected surfaces (according to STAS 10702/1-83), then

they shell be painted or insulated depending on the case.

6.4. Dimensions, shapes, aspect

The dimensions of the materials and equipment shall correspond to the ones indicated in the

project in order to meet the required technical conditions.

6.5. Tests, checking on stages (flow) and at the end

6.5.1

Checking the heating installation

The heating installations shall be checked entirely and - possibly - separately for devices or parts

of the installation; in the last cases the checking of the entire installation remains obligatory.

The main checking consists of:

o

- cold testing

o

- hot testing

o

- efficiency test

The technical conditions for checking the heating installations are foreseen in chap. 20 of Norm I

13 - 2002.

6.6. Reference documents

Designed

H.G.R. 273/14.06.1994 -,,Taking over regulation for the construction works and related

installations.

,,Performance guide for installation (M.L.P.A.L.-C.T.S. approval no. 18/28.02.96).

Name

Eng. C. Radu

Cod fiier: 258044560.doc

Signature

Checked

Name

Eng. R. Minea

Signature

TECHNICAL SPECIFICATIONS FOR BIDDINGS

Rehabilitation of Bucharest Braov railway line, component part of the Pan

European Corridor IV for the trains traffic at 160 km/h speed

Section Cmpina - Predeal

7.

Nr.

Replace::

Page 7/7

THERMO-TECHNOLOGICAL INSTALLATION

COD:

Law no. 10/18.01.1995, Quality law.

REFERENCE DOCUMENTS

For the heating installations there shall be observed Norm for designing and execution of the

central heating installations indicative I 13- 2002 with the enclosed standards and norms.

For the air conditioning installations there shall be observed Norm for designing and execution of

the ventilation and air conditioning installations indicative I5-1998 with the enclosed standards

and norms.

8.

WORKS TAKING OVER

The norms for the works taking over are the following:

-

H.G.R. 273/14.06.1994 ,,Taking over regulation for the construction works and related

installations

- Norm I 13-2002 chap. 20.

The taking over is considered accepted when the deviations of the temperature variations are

0.50C+10C, and the air speed in static rooms complies with the Labor medicine norms (Order

1957/1995 of the Health Ministry).

Designed

DEPUTY MANAGER OF R.A.I. DIVISION

eng. D. Caracaleanu

M.Q. EXPERT

eng. A. M. Blaga

TECHNICL EXPERT

eng. D. Caracaleanu

HEAD OF TEAM

eng. R. Minea

DRAWN UP

eng. C. Radu

SUPERVISOR

eng. R. Minea

Name

Eng. C. Radu

Cod fiier: 258044560.doc

Signature

Checked

Name

Eng. R. Minea

Signature

S-ar putea să vă placă și

- TechnicalDiary500MW SGTPPDocument254 paginiTechnicalDiary500MW SGTPPJoydev Ganguly100% (2)

- TCDDDocument22 paginiTCDDTango BeltzaÎncă nu există evaluări

- Mandatory Bulletin: IB No.: L410A, M/362aDocument4 paginiMandatory Bulletin: IB No.: L410A, M/362apolkmijnÎncă nu există evaluări

- 1 Memoriu Tehnic CS enDocument219 pagini1 Memoriu Tehnic CS enIuly AnaÎncă nu există evaluări

- Gis Technical Requirements Equipment GIS . KV For Reconstruction/new Building QuantityDocument11 paginiGis Technical Requirements Equipment GIS . KV For Reconstruction/new Building QuantityMA AhmedÎncă nu există evaluări

- 7 Gehrig Tunnel 2016Document8 pagini7 Gehrig Tunnel 2016Juan PerezÎncă nu există evaluări

- Massinissa Elhadjali (English)Document3 paginiMassinissa Elhadjali (English)Said Massinissa Elhadj AliÎncă nu există evaluări

- Basic Report - VentilationDocument12 paginiBasic Report - VentilationSina ParastehÎncă nu există evaluări

- Spek Teknis Mek 0 PL - AresDocument93 paginiSpek Teknis Mek 0 PL - Aresdhani7Încă nu există evaluări

- A406 - Manuale Cappa e BruciatoriDocument478 paginiA406 - Manuale Cappa e BruciatoriLuis Cruz100% (1)

- Gas Engine SpecDocument32 paginiGas Engine SpecNic RicÎncă nu există evaluări

- Installation of Power and Control Cables - CELIN - Black Sea - IrakDocument8 paginiInstallation of Power and Control Cables - CELIN - Black Sea - IrakAlinaIordacheÎncă nu există evaluări

- Tech Spec For Plate Heat ExchangersDocument37 paginiTech Spec For Plate Heat ExchangersSHIVAJI CHOUDHURY50% (2)

- P68313-Feed For Nitrogen StorageDocument2 paginiP68313-Feed For Nitrogen StorageSelvaraj BalajiÎncă nu există evaluări

- FINAL Salient Tech Features - DGP - 2x20 MWDocument11 paginiFINAL Salient Tech Features - DGP - 2x20 MWNaresh BalujaÎncă nu există evaluări

- Ventilation and Air-Conditioning System: Detailed Project Report For Ludhiana Metro May 2009Document15 paginiVentilation and Air-Conditioning System: Detailed Project Report For Ludhiana Metro May 2009Aniket SinghÎncă nu există evaluări

- Lista Standard 2006-09-01 PDFDocument6 paginiLista Standard 2006-09-01 PDFcfv2006Încă nu există evaluări

- Drawings Standard Specifications 1Document172 paginiDrawings Standard Specifications 1Suresh Ram RÎncă nu există evaluări

- Enerbit enDocument36 paginiEnerbit enCatalin MunteanuÎncă nu există evaluări

- 1584Document6 pagini1584malsttarÎncă nu există evaluări

- PS-G00-091 (Executia-Controlul-Executiei-Sudurilor-Aluminotermice)Document8 paginiPS-G00-091 (Executia-Controlul-Executiei-Sudurilor-Aluminotermice)AlinaIordacheÎncă nu există evaluări

- 04004076Document18 pagini04004076Swaraj RajanÎncă nu există evaluări

- 20 KV Transmission LineDocument21 pagini20 KV Transmission LineNdoro BeiÎncă nu există evaluări

- Additional Work Cost Data 15.12.17 PDFDocument141 paginiAdditional Work Cost Data 15.12.17 PDFdhiwakarÎncă nu există evaluări

- 2 MTR 12-01-2020Document45 pagini2 MTR 12-01-2020rakeshkaydalwarÎncă nu există evaluări

- MANUAL 2017-Elf-13-01Document32 paginiMANUAL 2017-Elf-13-01Claudia BobeÎncă nu există evaluări

- HVACDocument7 paginiHVACMohammed Hassan Mohiuddin KhanÎncă nu există evaluări

- Technical DetailsDocument5 paginiTechnical DetailsTechnologist ChemicalÎncă nu există evaluări

- 2013 07 04 03 07 51 - Manual t110d - C - eDocument2 pagini2013 07 04 03 07 51 - Manual t110d - C - eSamuel Dotou100% (1)

- EN 15265 Calc of Energy Use PDFDocument74 paginiEN 15265 Calc of Energy Use PDFDragos PastravÎncă nu există evaluări

- Useful Facts Machinery DirectiveDocument266 paginiUseful Facts Machinery DirectiveDirk Van DeveldeÎncă nu există evaluări

- CERI's Proposal CommentsDocument18 paginiCERI's Proposal CommentsAnaruzzaman SheikhÎncă nu există evaluări

- Cen TS 45545-6Document14 paginiCen TS 45545-6fraesmaÎncă nu există evaluări

- Thermische Behaglichkeit Folder eDocument16 paginiThermische Behaglichkeit Folder efernandoguedes_1953Încă nu există evaluări

- Process Control Is Vital To Heat-TreatingDocument2 paginiProcess Control Is Vital To Heat-TreatingJader PitangueiraÎncă nu există evaluări

- Schematic Rev0 - FinalDocument8 paginiSchematic Rev0 - FinalEslam ElsayedÎncă nu există evaluări

- En 12101 344 Powered Smoke Exhaust SystemsDocument6 paginiEn 12101 344 Powered Smoke Exhaust SystemspsmanasseÎncă nu există evaluări

- Skin Effect Heat Tracing SpecDocument10 paginiSkin Effect Heat Tracing SpecSaraswatapalitÎncă nu există evaluări

- F.O. Lines Steam BlowingDocument9 paginiF.O. Lines Steam Blowingsrigirisetty208Încă nu există evaluări

- PWHT Procedure PDFDocument9 paginiPWHT Procedure PDFAbhishek AnandÎncă nu există evaluări

- MP 1Document3 paginiMP 1Fake Account 1Încă nu există evaluări

- FFFDocument6 paginiFFFlogefi8653Încă nu există evaluări

- 01 .Memoriu Termo-Ventilatii - EngDocument9 pagini01 .Memoriu Termo-Ventilatii - EngPaul CristianÎncă nu există evaluări

- Normas Iec PublicadasDocument11 paginiNormas Iec PublicadasLeandro SantanaÎncă nu există evaluări

- PT BM 183 DC 00007 PWHT ProcedureDocument7 paginiPT BM 183 DC 00007 PWHT Procedureeldobie3100% (1)

- TranslateDocument5 paginiTranslateCitra VariasiÎncă nu există evaluări

- 102 v03000003 Physical LayerDocument7 pagini102 v03000003 Physical LayerhcoolmanÎncă nu există evaluări

- Tzidc-200 18348Document24 paginiTzidc-200 18348satindiaÎncă nu există evaluări

- En-DTR CMK-02Document51 paginiEn-DTR CMK-02Henry MaedaÎncă nu există evaluări

- QCVN 09 2017 BXD ENGLISH Unofficial Translation by VGBCDocument20 paginiQCVN 09 2017 BXD ENGLISH Unofficial Translation by VGBCTrần TùngÎncă nu există evaluări

- IPWE2014 Tunnel Ventilation and SafetyDocument56 paginiIPWE2014 Tunnel Ventilation and SafetyHitesh KhannaÎncă nu există evaluări

- Ips M in 200Document14 paginiIps M in 200ali1860Încă nu există evaluări

- CGE09 ID34 Advanced SPP Cziesla FinalDocument21 paginiCGE09 ID34 Advanced SPP Cziesla FinalVaibhav SarinÎncă nu există evaluări

- CGE09 ID34 Advanced SPP Cziesla FinalDocument21 paginiCGE09 ID34 Advanced SPP Cziesla FinalpvirgosharmaÎncă nu există evaluări

- Detailed Project Report For Ludhiana Metro September 2008Document20 paginiDetailed Project Report For Ludhiana Metro September 2008Ravi TanwarÎncă nu există evaluări

- How to prepare Welding Procedures for Oil & Gas PipelinesDe la EverandHow to prepare Welding Procedures for Oil & Gas PipelinesEvaluare: 5 din 5 stele5/5 (1)

- 1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerDe la Everand1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerÎncă nu există evaluări

- Electrical Energy Efficiency: Technologies and ApplicationsDe la EverandElectrical Energy Efficiency: Technologies and ApplicationsÎncă nu există evaluări

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDe la EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsÎncă nu există evaluări

- The Ketogenic DietDocument21 paginiThe Ketogenic DietDiana Meca50% (2)

- Effects of The 3.2-1 Ketogenic Diet On Behavioral Symptoms of Aut PDFDocument58 paginiEffects of The 3.2-1 Ketogenic Diet On Behavioral Symptoms of Aut PDFMihai DiaconuÎncă nu există evaluări

- Ketocal Data Card PDFDocument2 paginiKetocal Data Card PDFMihai DiaconuÎncă nu există evaluări

- Arguments in Favor of Ketogenic DietsDocument16 paginiArguments in Favor of Ketogenic DietsoddlogicÎncă nu există evaluări

- Antiepileptic DrugsDocument39 paginiAntiepileptic Drugsking_goldÎncă nu există evaluări

- Steam AchievementsDocument6 paginiSteam AchievementsMihai DiaconuÎncă nu există evaluări

- Coduri Siruta RomaniaDocument510 paginiCoduri Siruta RomaniaMihai DiaconuÎncă nu există evaluări

- Greutati Specifice Otel PDFDocument18 paginiGreutati Specifice Otel PDFFerencz ZsoltÎncă nu există evaluări

- MEMORIU TEHNIC - EngDocument13 paginiMEMORIU TEHNIC - EngMihai DiaconuÎncă nu există evaluări

- 1 SMDocument6 pagini1 SMDejan DoslicÎncă nu există evaluări

- XS4P08PC410TF: Product Data SheetDocument5 paginiXS4P08PC410TF: Product Data SheetGonzalo GarciaÎncă nu există evaluări

- Python GUI Programming With Tkinter Deve-31-118 Job 1Document88 paginiPython GUI Programming With Tkinter Deve-31-118 Job 1Shafira LuthfiyahÎncă nu există evaluări

- LogExportTool Use Guide For BeneVisionDocument23 paginiLogExportTool Use Guide For BeneVisionVivek Singh ChauhanÎncă nu există evaluări

- ABB Medium-Voltage Surge Arresters - Application Guidelines 1HC0075561 E2 AC (Read View) - 6edDocument60 paginiABB Medium-Voltage Surge Arresters - Application Guidelines 1HC0075561 E2 AC (Read View) - 6edAndré LuizÎncă nu există evaluări

- Manual de Programacao r6 N 1.3Document160 paginiManual de Programacao r6 N 1.3Ian MechuraÎncă nu există evaluări

- Silver Nanoparticles DataDocument6 paginiSilver Nanoparticles DataSanwithz SittiÎncă nu există evaluări

- First EncounterDocument14 paginiFirst EncounterMuraliÎncă nu există evaluări

- 141A Service PDFDocument101 pagini141A Service PDFAndrás SzabóÎncă nu există evaluări

- Laser Torch ProjectDocument7 paginiLaser Torch ProjectJANUVINJAMESÎncă nu există evaluări

- Chemistry Pupil Book 10 - 12Document260 paginiChemistry Pupil Book 10 - 12Mawolo WuolewuÎncă nu există evaluări

- RHE07 07c 08 Data SheetDocument7 paginiRHE07 07c 08 Data SheetAnkitÎncă nu există evaluări

- SIMULATION of EMERGENCY ROOMS USING FLEXSIMDocument10 paginiSIMULATION of EMERGENCY ROOMS USING FLEXSIMBrandon VarnadoreÎncă nu există evaluări

- 8085 and 8051 PresentationDocument54 pagini8085 and 8051 PresentationJitendra Chuugh100% (3)

- BP301T Poc Unit IiiDocument15 paginiBP301T Poc Unit IiiSUBHASISH DASHÎncă nu există evaluări

- Automatic Bug BountyDocument80 paginiAutomatic Bug BountyAlbert Luzx100% (1)

- BS en 10028-1Document24 paginiBS en 10028-1Andrei Balázs100% (1)

- Ansys ManualDocument124 paginiAnsys ManualUdamanÎncă nu există evaluări

- 2022 Cayley Contest: The Centre For Education in Mathematics and Computing Cemc - Uwaterloo.caDocument282 pagini2022 Cayley Contest: The Centre For Education in Mathematics and Computing Cemc - Uwaterloo.catony dooÎncă nu există evaluări

- Efficiency Analysis of An Aerospike Nozzle: Dipak J. Choudhari, Uday V. AsolekarDocument5 paginiEfficiency Analysis of An Aerospike Nozzle: Dipak J. Choudhari, Uday V. AsolekarAswith R ShenoyÎncă nu există evaluări

- Unit - I Dynamics of Electric Drives: Electrical Power Transmission SystemsDocument4 paginiUnit - I Dynamics of Electric Drives: Electrical Power Transmission Systemsyemane gebremichalÎncă nu există evaluări

- Erection Manual Hydro-1Document63 paginiErection Manual Hydro-1rajfab100% (1)

- Quiz Sectiunea 7Document5 paginiQuiz Sectiunea 7Bogdan BrkicÎncă nu există evaluări

- Early Thermal CrackingDocument2 paginiEarly Thermal Crackingsudhir12345Încă nu există evaluări

- Mathematical Model of Transportation ProblemDocument14 paginiMathematical Model of Transportation ProblemwasimghghÎncă nu există evaluări

- Opsis Technique Eng 2007Document4 paginiOpsis Technique Eng 2007sukumariicbÎncă nu există evaluări

- Rr212203 Transducers and Instrumentation ComponentsDocument8 paginiRr212203 Transducers and Instrumentation ComponentsSrinivasa Rao GÎncă nu există evaluări

- 74LVC14APWDHDocument11 pagini74LVC14APWDHIlie GrecuÎncă nu există evaluări

- SCC-C ManualDocument28 paginiSCC-C ManualGian Paul Ramos AcostaÎncă nu există evaluări

- MATLAB AssignmentsDocument12 paginiMATLAB AssignmentsnilimaÎncă nu există evaluări