Documente Academic

Documente Profesional

Documente Cultură

186586035

Încărcat de

straf238Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

186586035

Încărcat de

straf238Drepturi de autor:

Formate disponibile

MECHANISMS AND

MECHANICAL DEVICES

SOURCEBOOK

Fourth Edition

NEIL SCLATER

NICHOLAS P. CHIRONIS

McGraw-Hill

New York Chicago San Francisco Lisbon London Madrid

Mexico City Milan New Delhi San Juan Seoul

Singapore Sydney Toronto

PREFACE

xiii

ACKNOWLEDGMENTS

CHAPTER 1

BASICS OF MECHANISMS

Introduction

Physical Principles

Inclined Plane

Pulley Systems

Screw-Type Jack

Levers and Mechanisms

Linkages

Specialized Mechanisms

Gears and Gearing

Pulleys and Belts

Sprockets and Chains

Cam Mechanisms

CHAPTER 2

CHAPTER 5

2

2

3

3

4

4

5

9

10

14

14

14

MOTION CONTROL SYSTEMS

21

Motion Control Systems Overview

Glossary of Motion Control Terms

Mechanical Components form Specialized Motion-Control Systems

Servomotors, Stepper Motors, and Actuators for Motion Control

Servosystem Feedback Sensors

Solenoids and Their Applications

22

28

29

30

38

45

CHAPTER 3 INDUSTRIAL ROBOTS

CHAPTER 4

XV

49

Introduction to Robots

Industrial Robots

Mechanism for Planar Manipulation with Simplified Kinematics

Tool-Changing Mechanism for Robot

Piezoelectric Motor in Robot Finger Joint

Self-Reconfigurable, Two-Arm Manipulator with Bracing

Improved Roller and Gear Drives for Robots and Vehicles

Glossary of Robotic Terms

50

51

60

61

62

63

64

65

MOBILE SCIENTIFIC, MILITARY, AND

RESEARCH ROBOTS

67

Introduction to Mobile Robots

Scientific Mobile Robots

Military Mobile Robots

Research Mobile Robots

Second-Generation Six-Limbed Experimental Robot

All-Terrain Vehicle with Self-Righting and Pose Control

68

69

70

72

76

77

LINKAGES: DRIVES AND MECHANISMS

79

Four-Bar Linkages and Typical Industrial Applications

Seven Linkages for Transport Mechanisms

Five Linkages for Straight-Line Motion

Six Expanding and Contracting Linkages

80

82

85

87

vii

Four Linkages for Different Motions

Nine linkages for Accelerating and Decelerating linear Motions

Twelve Linkages for Multiplying Short Motions

Four Parallel-Link Mechanisms

Seven Stroke Multiplier Linkages

Nine Force and Stroke Multiplier Linkages

Eighteen Variations of Differential Linkage

Four-Bar Space Mechanisms

Seven Three-Dimensional Linkage Drives

Thirteen Different Toggle Linkage Applications

Hinged Links and Torsion Bushings Soft-Start Drives

Eight Linkages for Band Clutches and Brakes

Design of Crank-and-Rocker Links for Optimum

Force Transmission

Design of Four-Bar Linkages for Angular Motion

Multi-Bar Linkages for Curvilinear Motions

Roberts' Law Helps to Design Alternate Four-Bar Linkages

Slider-Crank Mechanism

CHAPTER 6

GEARS: DEVICES, DRIVES, AND MECHANISMS

Gears and Eccentric Disk Provide Quick Indexing

Odd-Shaped Planetary Gears Smooth Stop and Go

Cycloid Gear Mechanism Controls Pump Stroke

Gears Convert Rotary-to-Linear Motion

Twin-Motor Planetary Gears Offer Safety and Dual-Speed

Eleven Cycloid Gear Mechanisms

Five Cardan-Gear Mechanisms

Controlled Differential Gear Drives

Flexible Face-Gears are Efficient High-Ratio Speed Reducers

Rotary Sequencer Gears Turn Coaxially

Planetary Gear Systems

Noncircular Gears are Balanced for Speed

Sheet-Metal Gears, Sprockets, Worms, and Ratchets

for Light Loads

Thirteen Ways Gears and Clutches Can Change Speed Ratios

Gear and Clutch Shifting Mechanisms

Twinworm Gear Drive Offers Bidirectional Output

Elastomeric Gear Bearings Equalize Torque Loads

Redundant Gearing in Helicopter Transmits Torque

Worm Gear Friction Reduced by Oil Pressure

Bevel and Hypoid Gear Design Prevents Undercutting

Geared Electromechanical Rotary Joint

Geared Speed Reducers Offer One-Way Output

Design of Geared Five-Bar Mechanisms

Equations for Designing Geared Cycloid Mechanisms

Design Curves and Equations for Gear-Slider Mechanisms

CHAPTER 7

CAM, GENEVA, AND RATCHET DRIVES

AND MECHANISMS

Cam-Controlled Planetary Gear System

Five Cam-Stroke-Amplifying Mechanisms

Cam-Curve-Generating Mechanisms

Fifteen Different Cam Mechanisms

Ten Special-Function Cams

Twenty Geneva Drives

Six Modified Geneva Drives

VIII

Kinematics of External Geneva Wheels

Kinematics of Internal Geneva Wheels

Star Wheels Challenge Geneva Drives for Indexing

Ratchet-Tooth Speed-Change Drive

Modified Ratchet Drive

Eight Toothless Ratchets

Analysis of Ratchet Wheels

CHAPTER 8 CLUTCHES AND BRAKES

CHAPTER 9

203

Twelve Clutches with External or Internal Control

Spring-Wrapped Clutch Slips at Preset Torque

Controlled-Slip Expands Spring Clutch Applications

Spring Bands Improve Overrunning Clutch

Slip and Bidirectional Clutches Combine to Control Torque

Walking Pressure Plate Delivers Constant Torque

Seven Overrunning Clutches

One-Way Clutch has Spring-Loaded Pins and Sprags

Roller Clutch provides Two Output Speeds

Seven Overriding Clutches

Ten Applications for Overrunning Clutches

Eight Sprag Clutch Applications

Six Small Clutches Perform Precise Tasks

Twelve Different Station Clutches

Twelve Applications for Electromagnetic Clutches and Brakes

Roller Locking Mechanism Contains Two Overrunning Clutches

204

206

208

209

210

211

212

213

213

214

216

218

220

222

225

227

LATCHING, FASTENING, AND CLAMPING

DEVICES AND MECHANISMS

229

Sixteen Latch, Toggle, and Trigger Devices

Fourteen Snap-Action Devices

Remote Controlled Latch

Toggle Fastener Inserts, Locks, and Releases Easily

Grapple Frees Loads Automatically

Quick-Release Lock Pin has a Ball Detent

Automatic Brake Locks Hoist when Driving Torque Ceases

Lift-Tong Mechanism Firmly Grips Objects

Perpendicular-Force Latch

Two Quick-Release Mechanisms

Ring Springs Clamp Platform Elevator into Position

Cammed Jaws in Hydraulic Cylinder Grip Sheet Metal

Quick-Acting Clamps for Machines and Fixtures

Nine Friction Clamping Devices

Detents for Stopping Mechanical Movements

Twelve Clamping Methods for Aligning Adjustable Parts

Spring-Loaded Chucks and Holding Fixtures

CHAPTER 10

190

193

197

200

200

201

202

CHAIN AND BELT DEVICES AND MECHANISMS

Twelve Variable-Speed Belt and Chain Drives

Belts and Chains are Available

in Manydifferent Forms

Change Center Distance without Altering Speed Ratio

Motor Mount Pivots to Control Belt Tension

Ten Roller Chains and their Adaptations

Twelve Applications for Roller Chain

Six Mechanisms for Reducing Pulsations in Chain Drives

230

232

236

237

237

238

238

239

239

240

241

241

242

244

246

248

250

251

252

255

259

259

260

262

266

IX

CHAPTER 11

SPRING AND SCREW DEVICES AND MECHANISMS

Flat Springs in Mechanisms

Twelve Ways to Use Metal Springs

Seven Overriding Spring Mechanisms for Low-Torque Drives

Six Spring Motors and Associated Mechanisms

Twelve Air Spring Applications

Novel Applications for Different Springs

Applications for Belleville Springs

Vibration Control with Spring Linkage

Twenty Screw Devices

Ten Applications for Screw Mechanisms

Seven Special Screw Arrangements

Fourteen Spring and Screw adjusting Devices

CHAPTER 12

SHAFT COUPLINGS AND CONNECTIONS

Four Couplings for Parallel Shafts

Links and Disks Couple Offset Shafts

Disk-and-Link Couplings Simplify Torque Transmission

Interlocking Space-Frames Rex as they Transmit Shaft Torque

Coupling with Off-Center Pins Connects Misaligned Shafts

Universal Joint Transmits Torque 45 At Constant Speed

Ten Universal Shaft Couplings

Nineteen Methods for Coupling Rotating Shafts

Five Different Pin-and-Link Couplings

Ten Different Splined Connections

Fourteen Ways to Fasten Hubs to Shafts

CHAPTER 13

CHAPTER 14

MOTION-SPECIFIC DEVICES,

MECHANISMS, AND MACHINES

269

270

272

274

276

278

280

281

282

283

285

287

288

289

290

291

292

293

295

296

297

299

303

304

306

309

Timing Belts, Four-Bar linkage Team Up for Smooth Indexing

Ten Indexing and Intermittent Mechanisms

Twenty-Seven Rotary-to-Reciprocating Motion and Dwell Mechanisms

Five Friction Mechanisms for Intermittent Rotary Motion

Nine Different Ball Slides for Linear Motion

Bali-Bearing Screws Convert Rotary to Linear Motion

Nineteen Arrangements for Changing Linear Motion

Five Adjustable-Output Mechanisms

Four Different Reversing Mechanisms

Ten Mechanical Computing Mechanisms

Seven Different Mechanical Power Amplifiers

Forty-Three Variable-Speed Drives

and Transmissions

Ten Variable-Speed Friction Drives

Four Drives Convert Oscillating Motion to One-Way Rotation

Operating Principles of Liquid, Semisolid, and Vacuum Pumps

Twelve Different Rotary-Pump Actions

339

351

353

355

359

PACKAGING, CONVEYING, HANDLING,

AND SAFETY MECHANISMS AND MACHINES

361

Fifteen Devices that Sort, Feed, or Weigh

Seven Cutting Mechanisms

Two Flipping Mechanisms

One Vibrating Mechanism

Seven Basic Parts Selectors

Eleven Parts-Handling Mechanisms

Seven Automatic-Feed Mechanisms

310

312

314

320

322

324

325

329

331

332

336

362

366

368

368

369

370

372

Fifteen Conveyor Systems for Production Machines

Seven Traversing Mechanisms

for Winding Machines

Vacuum Pickup for Positioning Pills

Machine Applies Labels from Stacks or Rollers

Twenty High-Speed Machines for Applying Adhesives

Twenty-Four Automatic Mechanisms for Stopping

Unsafe Machines

Six Automatic Electrical Circuits for

Stopping Textile Machines

Six Automatic Mechanisms for Assuring

Safe Machine Operation

CHAPTER 15

CHAPTER 16

CHAPTER 17

TORQUE, SPEED, TENSION, AND LIMIT

CONTROL SYSTEMS

375

379

381

381

382

388

394

396

399

Applications of the Differential Winch to Control Systems

Six Ways to Prevent Reverse Rotation

Caliper Brakes Keep Paper Tension in Web Presses

Control System for Paper Cutting

Warning System Prevents Overloading of Boom

Lever System Monitors Cable Tension

Eight Torque-Limiters Protect Light-Duty Drives

Thirteen Limiters Prevent Overloading

Seven Ways to Limit Shaft Rotation

Mechanical Systems for Controlling Tension and Speed

Nine Drives for Controlling Tension

Limit Switches in Machinery

Nine Automatic Speed Governors

Eight Speed Control Devices for Mechanisms

400

402

403

403

404

404

405

406

409

409

415

418

422

424

INSTRUMENTS AND CONTROLS: PNEUMATIC,

HYDRAULIC, ELECTRIC, AND ELECTRONIC

425

Twenty-Four Mechanisms Actuated by Pneumatic or Hydraulic Cylinders

Foot-Controlled Braking System

Fifteen Tasks for Pneumatic Power

Ten Applications for Metal Diaphragms and Capsules

Nine Differential Transformer Sensors

High-Speed Electronic Counters

Applications for Permanent Magnets

Nine Electrically Driven Hammers

Sixteen Thermostatic Instruments and Controls

Eight Temperature-Regulating Controls

Seven Photoelectric Controls

Liquid Level Indicators and Controllers

Applications for Explosive-Cartridge Devices

Centrifugal, Pneumatic, Hydraulic, and Electric Governors

426

428

428

430

432

434

435

438

440

444

446

448

450

452

COMPUTER-AIDED DESIGN CONCEPTS

455

Introduction to Computer-Aided Design

CHAPTER 18 RAPID PROTOTYPING

Rapid Prototyping Focuses on Building

Functional Parts

Rapid Prototype Processes

Rapid Prototyping Steps

Commercial Rapid Prototyping Choices

456

461

462

462

463

463

xi

CHAPTER 19

NEW DIRECTIONS IN MECHANICAL

ENGINEERING

The Role of Microtechnology in Mechanical Engineering

Micromachines Open a New Frontier for Machine Design

Multilevel Fabrication Permits more Complex and Functional MEMS

Gallery of MEMS Electron-Microscope Images

MEMS Chips Become Integrated Microcontrol Systems

Alternative Materials for Building MEMS

LIGA: An Alternative Method for Making Microminiature Parts

Miniature Multispeed Transmissions for Small Motors

The Role of Nanotechnology in Mechanical Engineering

What are Carbon Nanotubes?

Nanoactuators Based on Electrostatic Forces on Dielectrics

INDEX

XII

473

474

476

480

480

484

486

487

488

489

491

492

495

S-ar putea să vă placă și

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Piano Graded Pieces Sorted by DifficultyDocument31 paginiPiano Graded Pieces Sorted by DifficultyRaúlSedeOrt83% (12)

- RCM SyllabusDocument142 paginiRCM SyllabusMonica Da Re100% (7)

- Snell Reper IndexDocument24 paginiSnell Reper Indexsoopy88100% (7)

- Piano Syllabus Complete 15 PDFDocument22 paginiPiano Syllabus Complete 15 PDFjedarezzo50% (2)

- Miniessay21 PDFDocument12 paginiMiniessay21 PDFstraf238100% (1)

- Astacap Viola RepertoireDocument28 paginiAstacap Viola RepertoireCarlos Guadarrama100% (2)

- Popular ListDocument0 paginiPopular ListLuna Vocalis33% (9)

- AA OrchestralKitDocument1 paginăAA OrchestralKitstraf238Încă nu există evaluări

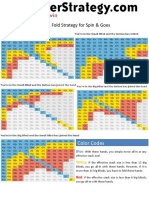

- A9s A8s A7s A6s A5s A4s A3s A2s Kjs KtsDocument1 paginăA9s A8s A7s A6s A5s A4s A3s A2s Kjs Ktsstraf238Încă nu există evaluări

- Wind Energy BGDocument3 paginiWind Energy BGDevyani TotlaÎncă nu există evaluări

- Book UploadDocument270 paginiBook Uploadchuan88100% (20)

- Savonius Generator EnglishDocument15 paginiSavonius Generator Englishstraf238Încă nu există evaluări

- GCVCDocument1 paginăGCVCstraf238Încă nu există evaluări

- Ps NL Basic Handout V3 enDocument6 paginiPs NL Basic Handout V3 enTravis Allan GarrettÎncă nu există evaluări

- Harmony NotesDocument3 paginiHarmony Notesstraf238Încă nu există evaluări

- Other Renewable Energy Technologies BGDocument3 paginiOther Renewable Energy Technologies BGoneprintÎncă nu există evaluări

- 60 Min StrategyDocument3 pagini60 Min Strategystraf238100% (1)

- Starting HandsDocument1 paginăStarting HandsMarko BjelobrkÎncă nu există evaluări

- MTP - Class 1Document12 paginiMTP - Class 1straf238Încă nu există evaluări

- Starting HandsDocument1 paginăStarting HandsMarko BjelobrkÎncă nu există evaluări

- Spin Go Basic ChartsDocument1 paginăSpin Go Basic Chartsstraf238100% (1)

- Single Line PercussionDocument1 paginăSingle Line Percussionstraf238Încă nu există evaluări

- Ryan Fee's 6 Max NL Strategy GuideDocument44 paginiRyan Fee's 6 Max NL Strategy GuidekozzovoÎncă nu există evaluări

- Single Line PercussionDocument1 paginăSingle Line Percussionstraf238Încă nu există evaluări

- Mechanisms and Mechanical Devices Sourcebook - Sclater & ChironisDocument1 paginăMechanisms and Mechanical Devices Sourcebook - Sclater & Chironisstraf23814% (7)

- PrefDocument2 paginiPreficeman1977Încă nu există evaluări

- Single Line PercussionDocument1 paginăSingle Line Percussionstraf238Încă nu există evaluări

- MBQNADocument68 paginiMBQNAstraf238Încă nu există evaluări

- Universal Declaration of Human RightsDocument8 paginiUniversal Declaration of Human RightselectedwessÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- 4357r 85 PDFDocument14 pagini4357r 85 PDFFred PrzÎncă nu există evaluări

- Tos Second Quarter Physical ScienceDocument15 paginiTos Second Quarter Physical ScienceEden Garin AmadorÎncă nu există evaluări

- Science 10 - Q2 - M4Document15 paginiScience 10 - Q2 - M4MERCADER, ERICKA JÎncă nu există evaluări

- Rheology by Design: A Regulatory Tutorial For Analytical Method ValidationDocument26 paginiRheology by Design: A Regulatory Tutorial For Analytical Method Validation17Annisa Muthmainnah067Încă nu există evaluări

- Physics - A Contextual ApproachDocument8 paginiPhysics - A Contextual ApproachXung Lenh Ho0% (1)

- Beton DrucrciDocument7 paginiBeton DrucrciCedrick TchoundaÎncă nu există evaluări

- Tensors, Stress, Strain, ElasticityDocument10 paginiTensors, Stress, Strain, ElasticitySiti Cweety MarryÎncă nu există evaluări

- PhysicsDocument234 paginiPhysicsshugufta nazneenÎncă nu există evaluări

- AE 412 - 02. Midterm PeriodDocument104 paginiAE 412 - 02. Midterm PeriodjohnclientebooklibraryÎncă nu există evaluări

- Time-Dependent Analysis of Cable Domes Using A Modi Ed Dynamic Relaxation Method and Creep TheoryDocument12 paginiTime-Dependent Analysis of Cable Domes Using A Modi Ed Dynamic Relaxation Method and Creep TheorySparrow JackÎncă nu există evaluări

- 501 Most Important Physics Questions For NEET and JEEDocument76 pagini501 Most Important Physics Questions For NEET and JEEhthjyhÎncă nu există evaluări

- Evaluation of Marshall and Hveem MixDocument9 paginiEvaluation of Marshall and Hveem MixHakob GyulzadyanÎncă nu există evaluări

- Vorticity and Turbulence Effects in Fluid Structure InteractionDocument12 paginiVorticity and Turbulence Effects in Fluid Structure InteractionAhad YektaÎncă nu există evaluări

- Thick CylinderDocument2 paginiThick CylinderUjjwal Raj AÎncă nu există evaluări

- Atc 24 PDFDocument58 paginiAtc 24 PDFNavid100% (4)

- Course2-Point Mass Dynamics & Aerodynamic Thrust Forces PDFDocument32 paginiCourse2-Point Mass Dynamics & Aerodynamic Thrust Forces PDFAmartistÎncă nu există evaluări

- Phy - Sample Paper - Xi-2023-24 - S - 01Document18 paginiPhy - Sample Paper - Xi-2023-24 - S - 01ANSUMAN SUVANKARÎncă nu există evaluări

- Physics PETA 2Document8 paginiPhysics PETA 2krlthegoatÎncă nu există evaluări

- Institute of Aeronautical EngineeringDocument172 paginiInstitute of Aeronautical Engineeringdurga sharmaÎncă nu există evaluări

- Counter Fort Reatining WAll With HORZONTAL Bach FillDocument52 paginiCounter Fort Reatining WAll With HORZONTAL Bach FillRajib Chowdhury100% (1)

- Phy CHP 8 NotesDocument16 paginiPhy CHP 8 Notesayaan ahmedÎncă nu există evaluări

- Maurer Seismic Isolation Systems With Lead Rubber Bearings (LRB)Document9 paginiMaurer Seismic Isolation Systems With Lead Rubber Bearings (LRB)BogdanBÎncă nu există evaluări

- Heat Calculation ReferenceDocument5 paginiHeat Calculation ReferenceCham SurendÎncă nu există evaluări

- Rotofluid Catalogo CompletoDocument60 paginiRotofluid Catalogo Completoawys61434100% (1)

- TM 200 ManualDocument50 paginiTM 200 ManualJhuno Silva PaulaÎncă nu există evaluări

- Meriam Kinematic Particles Dynamics 1Document26 paginiMeriam Kinematic Particles Dynamics 1antoniofortese50% (2)

- Cad Lab Viva QuestionDocument9 paginiCad Lab Viva QuestionSms RajaÎncă nu există evaluări

- Workenergyandpowerppt 131208202046 Phpapp02Document26 paginiWorkenergyandpowerppt 131208202046 Phpapp02joyÎncă nu există evaluări

- Laser GuideDocument32 paginiLaser Guiderachidbrihi brihiÎncă nu există evaluări

- Suco Centrifugal Technical ExplanationsDocument16 paginiSuco Centrifugal Technical ExplanationsAdi AdrianÎncă nu există evaluări