Documente Academic

Documente Profesional

Documente Cultură

Rare Metals Volume 27 Issue 1 2008 (Doi 10.1016/S1001-0521 (08) 60032-7) ZHU, H - Damage and Fracture Mechanism of 6063 Aluminum Alloy Under Three Kinds of Stress States

Încărcat de

Anonymous YU0QeLgtSTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Rare Metals Volume 27 Issue 1 2008 (Doi 10.1016/S1001-0521 (08) 60032-7) ZHU, H - Damage and Fracture Mechanism of 6063 Aluminum Alloy Under Three Kinds of Stress States

Încărcat de

Anonymous YU0QeLgtSDrepturi de autor:

Formate disponibile

Available online at www.sciencedirect.

com

-.&A?

?ScienceDirect

ELSFMER

RARE METALS, Vol. 27, No. I , Feb 2008, p . 64

Damage and fracture mechanism of 6063 aluminum alloy under three kinds of

stress states

ZHU Hao, ZHU Liang, and CHEN Jianhong

Key Laboratory of the Ministry of Educution of Chinafor Nonferrous Metal Alloys, Lanzhou University of Technology, Lunzhou 7300S0,China

Received 20 September 2006; received in revised form 5 December 2006; accepted 10 December 2006

Abstract

To study the damage and fracture mechanism of 6063 aluminum alloy under different stress states, three kinds of representative triaxial stress

states have been adopted, namely smooth tensile, notch tensile, and pure shear. The results of the study indicate the following. During the

notch tensile test, a relatively higher stress triaxiality appears in the root of the notch. With the applied loading increasing, the volume fraction of microvoids in the root of the notch increases continuously. When it reaches the critical volume fraction of microvoids, the specimen

fractures. During the pure shear test, the stress triaxiality almost equals to zero, and there is almost no microvoids but a shear band at the center of the butterfly specimen. The shear band results from nonuniform deformation constantly under the shear stress. With stress concentration, cracks are produced within the shear band and are later coalesced. When the equivalent plastic strain reaches the critical value (equivalent plastic fracture strain), the butterfly specimen fractures. During the smooth tensile test, the stress triaxiality in the gauge of the specimen

remains constant at 0.33. Thus, the volume of microvoids of the smooth tensile test is less than that of the notch tensile test and the smooth

specimen fractures due to shearing between microvoids. The G-T-N damage model and Johnson-Cook model are used to simulate the notch

tensile and shear test, respectively. The simulated engineering stress-strain curves fit the measured engineering stress-strain curves very well.

In addition, the empirical damage evolution equation for the notch specimen is obtained from the experimental data and FEM simulations.

Keywords: 6063 aluminum alloy; damage mechanism; fracture mechanism; G-T-N model; Johnson-Cook model

1. Introduction

Aluminum alloys are increasingly applied to produce

automobiles, since they are capable of reducing the mass of

vehicles, fuel consumption, and environmental pollution. An

important quality for vehicles is crashworthiness [I]. During

the impacting process of an automobile, the stress state at

each part in its components is different. Moreover, the stress

state at each part changes with passing time. Different stress

states result in different damage and fracture forms. There

are several reports on ductile damage and ductile fracture.

Ductile fracture (based on initiation, growth, and coalescence of voids) and shear fracture (based on shear band locahzation) are primary two kinds of fracture forms for ductile materials [2-41. El-Magd et al. [5] studied the deformation and damage behaviors of AA7075 aluminum alloy under two loadings and found that deformation localization

and shear band caused the damage in AA7075 aluminum

alloy under compression loading and under tensile loadmg,

AA7075 aluminum alloy failed due to nucleation, growth,

Corresponding author: ZHU Hao

E-mail: zhuhao@mail2.lut.cn

and coalescence of microvoids. Smerd et al. [6] found that

the damage forms of AA5754 and AA5 182 aluminum alloys

were microvoids and fracture due to shear amongst the microvoids through high strain rate tensile testing of automotive aluminum alloy sheets. The damage forms of 6063 aluminum alloy under crushmg loading change with the

changing of stress state. Thus, any one damage model cannot adequately describe the damage and deformation forms

of 6063 aluminum alloy and there are also few reports on

the damage and fracture of 6063 aluminum alloy. This article studies the damage and fracture mechanism of 6063

aluminum alloy under three kinds of stress states. At the

same time, the G-T-N model and Johnson-cook model are

used to simulate the damage behaviors of notch tensile and

pure shear, respectively.

2. Experimental

The experimental material was 6063 (T5) extruded aluminum alloy and its microstructure is shown in Fig. 1,

Zhu H. et aL, Damage and fracture mechanism of 6063 aluminum alloy under three kinds of stress states

65

which shows that the size of grains varied greatly, with the

maximum reaching 100 Fm, while the minimum was only

several microns. Its chemical composition was given in

wt.% as follows: Mg, 0.45-0.9; Si, 0.2-0.6; Zn, Cr, Ti and

Mn < 0.1; and Fe < 0.35. For the notch tensile test, double-side notch specimens were used. Tensile direction was

parallel to the direction of extrusion. The shapes and dimensions of smooth tensile specimens and the notch tensile

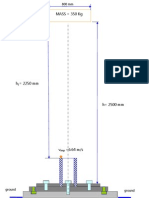

specimen are shown in Fig. 2. For the pure shear test, the

butterfly specimens and modified Arcan fixture were used

and their shapes and dimensions are shown in Fig. 3. The

schematic diagram of the pure test using modified Arcan

fixture is shown in Fig. 4.

Fig. 3. Butterfly specimen (a) and modified Arcan fiiture (b)

for the shear test.

Pure shear test

Fig. 1. Microstructure of 6063 extrusion aluminum alloy.

I L"

I

Fig. 4. Schematic diagram of the pure test.

property.

Fig. 2. Shapes and dimensions of a smooth tensile specimen (a)

and a notch tensile specimen (h).

The tests were performed on the smooth, notch, and butterfly specimens by the universal test machine with a cross

head speed of 0.5 mm/min at room temperature. The yield

stress, work hardening coefficient, and work hardening exponent were measured by the engineer stress-strain curve of

the smooth tensile test. The power-law hardening relationship was used for ABAQUS calculations as material

3. Results and discussion

3.1. Analysis of experimental curves

The engineer stress-stain curves of three kinds of experiments are shown in Fig. 5. The yield stress ny= 195.4 MPa

was drawn from the engineer stress-strain curve of the smooth tensile test. The work hardening coefficient and work

hardening exponent were 28 1.8 and 0.07, respectively,

which were drawn from the true stress-strain curve of

smooth tensile test.

Fig. 5 shows that the fracture strain of the smooth tensile

test is larger than that of the notch tensile test, and the yield

stress and peak stress of the smooth tensile test are less than

those of the notch tensile test. Those can be explained by Fig.

6, which shows the stress triaxiality distribution curves of

three kinds of tests. The stress triaxiality of smooth tensile

keeps always 0.33, but the maximal stress aiaxiality of

notch tensile can be up to 0.515. The relatively larger stress

triaxiality makes the specimen's deformation difficult and

more stress is needed to reach the same strain. Therefore, the

larger stress triaxiality has a higher fracture driving force,

which results in the fracture of the specimen at a lower strain.

Thus, the fracture strain of notch tensile test is less than that

of smooth tensile specimen [2, 71. Fig. 6 also shows that the

stress triaxiality of the pure test is close to 0.1 (because it is

difficult to get the pure shear state in experiment). The fracture strain of the pure shear test is far bigger than that of the

smooth tensile test.

3.2. Metallographic results and discussion

To study the damage mechanism, the specimens of the

smooth tensile, notch tensile, and shear tests were loaded

and then unloaded when the strain designated was reached.

The unloaded specimens were cut at the center along the

vertical planes parallel to the direction of applied load and

mounted and then polished on 180-grit paper. All the polishing was done by wet polishing papers to prevent particles

from extraction from the soft aluminum matrix. The metallographic pictures are shown in Fig. 7,

RARE METALS, Vol. 27,No. 1, Feb 2008

66

f

It

200 a

- 200

1150

-m-

-0-

,,i it

-A-

Notch tensile

Smooth tensile

Pure shear

~~

1-7"

7 0.0

0.2

0.4

0.6

0.8

1.0

EJY,

Fig. 5. Stress-strain curves of the tests.

0.2

- Notch tensile

- - - -Smooth

.

tensile

Pure shear

0.1

0.0

0.5

1.0

1.5

2.0

2.5

3.0

Path along central section of specimen / nm

Fig. 6. Curves of stress triaxiality distribution.

Fig. 7. Metallographic pictures of unloaded specimens: (a) particle and void damage in a smooth tensile specimen with an unloading strain of 0.1; (b) particle and void damage in a notch tensile specimen with an unloading strain of 0.09, (c) shear band crack in a

pure shear specimen with an unloading strain of 1.05.

Fig. 7(a) shows the unloaded metallographic pictures of a

smooth tensile specimen, from which it can be seen that

there are a few microvoids in the smooth tensile specimen

and the volume of microvoids is relatively small. This is

because the stress triaxiality amongst the smooth tensile

specimen is relatively small and the driving force of voids

growing is normal stress. The higher the normal stress is, the

higher the stress triaxiality is, the more rapidly the voids

grow and the bigger the volume of voids. Fig. 7(b) shows

the unloaded metallographic picture of a notch tensile

Zhu H. etal., Damage and fracture mechanism of 6063 aluminum alloy under three kinds of stress states

specimen, which shows that there are a lot of microvoids

amongst the unloaded notch specimen and the volume of

microvoids is bigger than that of the smooth tensile specimen. This is because the stress triaxiality amongst the notch

tensile specimen is higher than that amongst the smooth tensile specimen. At the same time, the microvoids have started

to coalesce and then microcracks are produced due to coalescence of microvoids. With coalescence of microcracks,

the notch specimen fractures. Fig. 7(c) shows that there is a

shear deformation band in the unloaded shear specimen and

the shear deformation band is a result from plastic deformation localization. Since the stress triaxiality amongst the pure

specimen is close to 0.1 and the less the stress triaxiality, the

larger the shear stress. The driving force of materials deformation is the shear stress and the higher the shear stress, the

more easily the materials deform. At the same time, there is

a crack in the shear deformation band and the crack was

produced due to deformation incompatibility. With the

cracks extending and coalescence, the butterfly specimen

fractures.

Fig. 8 shows the typical fracture surfaces of smooth tensile, notch tensile, and pure shear specimens, from which it

67

can be seen that the features of fracture surfaces of the smooth tensile specimen, notch tensile specimen, and shear

specimen are obviously different. Figs. 8(a) and 8(b) show

the fracture surfaces of the smooth tensile specimen and Fig.

8(a) is the macroscopical fracture surface, which shows that

the macroscopical fracture surface is relatively smooth and

there is no obvious change in the direction of width and

thickness. It is revealed that the smooth specimen did not

neck before fracture. Therefore, the stress triaxiality of the

smooth tensile specimen can always remain constant. Fig.

8(b) shows the magnified fracture surface, where there are a

lot of dimples and also the volume of dimples is relatively

small. At the same time, the direction of the dimples is not

perpendicular to the direction of tensile loading. Therefore,

it can be concluded that the fracture mode of the smooth

tensile specimen is the voids shearing mechanism, which is

the combination of dimpled fracture and shear fracture. Figs.

8(c) and 8(d) show the fracture surfaces of the notch tensile

specimen and Fig. 8(c) shows its macroscopical fracture

surface, which shows that there is obvious change in the direction of width and thickness for the notch tensile specimen

due to necking before fracture. Therefore, the maximum

Fig. 8. Fracture surfaces of three kinds of tests: (a, b) fracture surfaces of the smooth tensile test; (c, d) fracture surfaces of the

notch tensile test; (e, f) fracture surfaces of the shear test.

RARE METALS, Vol. 27, No. 1, Feb 2008

68

stress triaxiality amongst the notch specimen can be up to

0.515. At the same time, it also can be seen that the macroscopical fracture surface takes on a cup-cone shape. It is

because the stress triaxiality along the path of minimum

transverse area is different, as shown in Fig. 6 and the stress

triaxiality can reach the maximum value of 0.5 15 at the center of the specimen. Therefore, the fracture mechanism is

voids-coalescence fracture at the center of the specimen,

while the fracture mechanism is shearing fracture on the

surface of the specimen and the parts close to it. Fig. 8(d)

shows the magnified fracture surface, which shows several

dimples on the fracture surfaces of the notch tensile specimen and the dimples are the produce of microvoids. The direction of dimples is perpendicular to the direction of tensile

loading and the volume of dimples is bigger than that of the

smooth tensile specimen. In a word, for ductile materials,

the material instability starts with the forming of a necking.

It is followed by the initiation of fracture at the center of the

necking with linkage of adjacent voids due to hydrostatic

stress. The coalescence of voids usually forms a zig-zag

configuration and this is perpendicular to the loading direction. Figs. 8(e) and 8(f) show the fracture surfaces of the

shear specimen and Fig. 8(e) is its macroscopical fracture

surface, which shows that the macroscopical fracture surface

is very flat and smooth. Fig. 8(f) shows the magnified fracture surface, where there are typical snaky slipping and

ripple waves on the shear fracture surfaces and the direction of shear fracture surfaces is parallel to that of the

maximum shear stress. Under the shear stress, the microvoids are elongated and form the parabola or half-ellipse

dimples on the fracture surfaces [2-31. Therefore, it is revealed that the fracture mechanism is shear fracture.

4. Finite element simulations

The G-T-N model [7-81 was used to give a numerical

description of the notch tensile test. The yield flow function

is

where Q is the macroscopical Mises equivalent stress, P

is the macroscopical hydrostatic stress, R ( 3 )is the yield

stress of the undamaged matrix material, 41, qa and q3 are

modulation parameters considering the interaction of voids,

and f * is the volume fraction of voids revised.

In the notch tensile test, the parameters of the G-T-N

model flow function are set as the following. ql = 1.25, q 2 =

1.O, q3 = 1.625;fo,initial volume fraction of voids, = 0.0025;

fc, volume fraction of voids at coalescence, = 0.035; &,

volume fraction of voids at fracture, = 0.0475; fn, volume

fraction of voids forming particles, = 0.02; EN, medium

strain for voids formation, = 0.3; SN, standard deviation, =

0.1.

The Johnson-Cook model [9-1I] was used to simulate the

pure shear test. The Johnson-Cook constitutive relation and

fracture strain relation are as follows.

The constitutive relation:

cr = ( A + B E ) (1+ C l n E ) [ 1- (T)]

EO

The fracture strain relation:

Ef =

Dl+D2exp D3-z ) ] ( l + i ) D 4 ( l + D 5 T * )

(3)

Here, T * = (T - T, ) /(Tm- T ) ,& is the strain rate, go is

the reference strain rate, T, is the reference temperature,

T, is the melt temperature, 3 is the hydrostatic stress,

6, is the equivalent stress. A, B , C, n, m,Dl, D2,

D3, D4.

and D5are materials constants.

In the Johnson-Cook model: A = 176.45 MPa, B = 63.99

MPa, n = 0.07, C = 0.0036, m = 0, D l= 0.07413, 02 =

0.0892, D3= -2.441, 0 4 = -4.76, and Ds= 0. Simulated results by ABAQUS are shown in Fig. 9.

Fig. 9(a) shows that the engineering stress-strain curves

of simulation with the G-T-N model is close to the measured

engineering stress-strain curve of the notch tensile. It proves

that the G-T-N model can be used to simulate the damage

behavior of the notch tensile test. The engineering

stress-strain curve of simulation without adopting the G-T-N

damage model overestimates the stress of the notch tensile

test. Fig. 9(b) shows that the Johnson-Cook model can be

used to simulate the shear test. Fig. 9(c) shows the curve of

voids growth versus time by simulating the notch tensile test.

As can be seen in Fig. 9(c), voids grow stably before A, and

the curve produces fluctuation from A to B, indicating that

certain voids start to coalesce. During the process of growth,

several voids start to coalesce after B, so it results in fracture

of the specimen. The following empirical damage evolution

equation in the root of the notch specimen is obtained from

the experimental data on void volume fraction and the corresponding local equivalent plastic strain and stress triaxiality computed from FEM simulations:

f = a + bln(Z,,) + c (Bm/ 6,)

(4)

where a, b, and c are empirical constant whose values depend on the alloys composition, heat treatment, and microstructure. Eq. (4) is only applied to 6063 (T5) Al-alloy. In

this experiments, a = -0.35, b = 0.25, and c = 1.32.

5. Conclusions

(1) The damage mechanism and fracture mechanism are

Zhu H. eta/., Damage and fracture mechanism of 6063 aluminum alloy under three kinds of stress states

the specimen.

(2) The G-T-N damage model and Johnson-Cook model

can be used to simulate the notch tensile test and pure shear

test, respectively.

(3) The empirical damage evolution equation in the notch

specimen of 6063 (T5) Al-alloy is obtained:

.

b'

69

100

f =-0.35+0.251nFp+1.32(8,/o,).

-m-

Experiment

This equation is only applied to 6063 (T5) aluminum alloy.

-0- Without damage model

-V-

Curson model

Acknowledgement

0.00

0.02

0.04

0.06

0.08

Ec

References

I60

120

f:eU

80

-0-

-0-

0.030

F>

Experiment

Johnson-Cook model

1'"

J;=0.035

HT

Coalescence

0.020 -

.....................................................

Nuleation

G

!orwht

0.0 10 0.000

0.000

'I"research is financially supported by the Ministry of

Science and Technology of China (No. 2004CCA04900).

0.002

0.004

0.006

Time / s

Fig. 9. Simulation results of FEM: (a) notch tensile simulation; (b) shear simulation; (c) VVFG (void volume fraction due

to growth) versus time of notch tensile.

obviously different for smooth tensile, notch tensile, and

pure shear. In the smooth tensile test, the specimen fractures

due to shearing between microvoids. In the notch tensile test,

the specimen fractures due to microvoid-coalescence. In the

pure test, the shear deformation band is produced at the center of the butterfly specimen and the cracks are produced

and later coalesced in the shear band and result in fracture of

Pikett A.K., Pyttel T., and Payen F., Failure prediction for advanced crashworthiness of transportation vehicles, Int. J. Impact Eng., 2004,30: 853.

Tang A.M., Experimental analysis of fracture modes changing

rule for aluminum alloy, J. Xian Oniv. Technol. (in Chinese),

2003.19 (3): 226.

Hopperstad S., Borvik T., Langseth M., Labibes K., and Albertini C., On the influence of stress hiaxiality and strain rate

on the behaviors of a structural steel. Part I Experiments, Eur.

J. Mech. NSolids, 2003.22: 1.

Hooputra H., Gese H., Dell H., and Werner H., A comprehensive failure model for crashworthiness simulation of aluminum extrusion, Int. J. Crashworthiness, 2004,9 (5):449.

El-Magd E. and Abouridouane M., Characterization, modeling and simulation of deformation and fracture behaviour of

the light-weight wrought alloys under high strain rate loading,

Int. J. Impact Eng., 2006,321 741.

Smerd R., Winkler S., Salisbury C., Worswick M., and Lloyd

D., High strain rate tensile testing of automotive aluminum

alloy sheet, Int. J. Impact Eng., 2005,32: 541.

Yu S.W. and Feng X.Q., Damage Mechanics (in Chinese),

Tsinghua University Press, Beijing, 1997.

Schmitt W., Sun D.Z., and Blauel J.G., Damage mechanics

analysis (Gurson model) and experimental verification of the

behaviors of a crack in a weld-cladded, Nucl. Eng. Des., 1997,

174: 237.

Batra R.C. and b a r M.H., Adiabatic shear banding in plane

strain tensile deformations of 11 thermoelastoviscoplastic

materials with finite thermal wave speed, Int. J. Plast., 2005,

21: 1521.

Warren T.L. and Forrestal M.J., Effect of strain hardening

and strain-rate sensitivity on the penetration of aluminum targets with spherical-nosed rods, Int. J. Solid Struct., 1998, 35

(28-29): 3737.

Wierzbicki T., Bao Y.B., Lee Y.W., and Bai Y.L., Calibration and evaluation of seven fracture models, Int. J. Mech. Sci.,

2005,47: 719.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- 2013 832471Document13 pagini2013 832471Anonymous YU0QeLgtSÎncă nu există evaluări

- A Constitutive Model and Data For MetalsDocument7 paginiA Constitutive Model and Data For Metalsbouazoth100% (1)

- 613 ltt24 en 01-2013Document4 pagini613 ltt24 en 01-2013Anonymous YU0QeLgtSÎncă nu există evaluări

- Climb Every MountainDocument4 paginiClimb Every MountainAnonymous YU0QeLgtSÎncă nu există evaluări

- Ac80 Ac100 Ac115 Ac135 Ac150 Ac200: Armaform Pet/W Ac: Structural Foam CoreDocument1 paginăAc80 Ac100 Ac115 Ac135 Ac150 Ac200: Armaform Pet/W Ac: Structural Foam CoreAnonymous YU0QeLgtSÎncă nu există evaluări

- Serialnwn 2Document1 paginăSerialnwn 2Anonymous YU0QeLgtSÎncă nu există evaluări

- Pareto Front (Surr.) Initial Sample Points (FEM) Design in (REF)Document1 paginăPareto Front (Surr.) Initial Sample Points (FEM) Design in (REF)Anonymous YU0QeLgtSÎncă nu există evaluări

- SIMLab Annual Report 2013Document56 paginiSIMLab Annual Report 2013Anonymous YU0QeLgtS100% (1)

- Torre Caid A 350Document1 paginăTorre Caid A 350Anonymous YU0QeLgtSÎncă nu există evaluări

- Borodin Songs PDFDocument65 paginiBorodin Songs PDFAnonymous YU0QeLgtSÎncă nu există evaluări

- Grieg-Ginzburg in The Hall of The Mountain KingDocument4 paginiGrieg-Ginzburg in The Hall of The Mountain KingGabriel Ramirez Gonzalez100% (2)

- 613 ltt24 en 01-2013Document4 pagini613 ltt24 en 01-2013Anonymous YU0QeLgtSÎncă nu există evaluări

- Adaptive Vehicle Structure To Optimize Crash PulsesDocument10 paginiAdaptive Vehicle Structure To Optimize Crash PulsesAnonymous YU0QeLgtSÎncă nu există evaluări

- P2Document2 paginiP2Anonymous YU0QeLgtSÎncă nu există evaluări

- LshortDocument171 paginiLshortCXBBAÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- User Manual For Emvólio: WWW - Blackfrog.InDocument22 paginiUser Manual For Emvólio: WWW - Blackfrog.InmariaÎncă nu există evaluări

- Castlegar & Slocan Valley Pennywise Dec. 9, 2014Document49 paginiCastlegar & Slocan Valley Pennywise Dec. 9, 2014Pennywise PublishingÎncă nu există evaluări

- Use of Information Technology in The Flight Catering ServicesDocument32 paginiUse of Information Technology in The Flight Catering ServicesAbhiroop SenÎncă nu există evaluări

- Polymer Structures: Issues To Address..Document34 paginiPolymer Structures: Issues To Address..Eugene Embalzado Jr.Încă nu există evaluări

- A Butterfly Effect Volume 1 (Years 1 - 2)Document362 paginiA Butterfly Effect Volume 1 (Years 1 - 2)xdyj2005Încă nu există evaluări

- Samyung SI-30 ManualDocument2 paginiSamyung SI-30 ManualYan Naing0% (1)

- MCQ DTSDocument3 paginiMCQ DTSraja93satÎncă nu există evaluări

- 21 Century Mind ControlDocument7 pagini21 Century Mind ControltrswartzÎncă nu există evaluări

- Business Description: Apollo TyresDocument4 paginiBusiness Description: Apollo TyresSrijit SahaÎncă nu există evaluări

- JCB Catalogue ADocument9 paginiJCB Catalogue Asaneesh81100% (2)

- Bolt Group Coefficient For Eccentric Loads PDFDocument5 paginiBolt Group Coefficient For Eccentric Loads PDFdvelchevÎncă nu există evaluări

- The Determinants of Service Quality and Customer Satisfaction in Malaysian e Hailing ServicesDocument8 paginiThe Determinants of Service Quality and Customer Satisfaction in Malaysian e Hailing ServicesYoannisa AtinaÎncă nu există evaluări

- 23 - Eave StrutsDocument2 pagini23 - Eave StrutsTuanQuachÎncă nu există evaluări

- Systems of Linear Equations With Two VariablesDocument34 paginiSystems of Linear Equations With Two VariablesFatima KausarÎncă nu există evaluări

- Bruker d8 XRD TutoriallDocument16 paginiBruker d8 XRD TutoriallravarÎncă nu există evaluări

- Shell Omala S2 GX 150: Performance, Features & Benefits Main ApplicationsDocument2 paginiShell Omala S2 GX 150: Performance, Features & Benefits Main ApplicationsVelibor KaranovicÎncă nu există evaluări

- Hebrew and TamilDocument98 paginiHebrew and TamilSreshta JustinÎncă nu există evaluări

- UD11T4107 English Maritime History Human FactorDocument4 paginiUD11T4107 English Maritime History Human FactorParminder singh parmarÎncă nu există evaluări

- Green Revolution: It's Acheivements and FailuresDocument24 paginiGreen Revolution: It's Acheivements and FailuresSingh HarmanÎncă nu există evaluări

- MIMSDocument3 paginiMIMSFrancineAntoinetteGonzalesÎncă nu există evaluări

- PVC Duct DesignDocument10 paginiPVC Duct DesigncitramuaraÎncă nu există evaluări

- Zbus and Symmetrical Fault AnalysisDocument20 paginiZbus and Symmetrical Fault Analysishj203800Încă nu există evaluări

- 24 - Al Nahda The Sheffeild Privat To International City, Greece K12 Dubai Bus Service TimetableDocument10 pagini24 - Al Nahda The Sheffeild Privat To International City, Greece K12 Dubai Bus Service TimetableDubai Q&AÎncă nu există evaluări

- 1965 Elio R. Freni - Electrolytic Lead Refining in SardiniaDocument9 pagini1965 Elio R. Freni - Electrolytic Lead Refining in SardiniaGeorgettaÎncă nu există evaluări

- Score Fusion of Finger Vein and Face For Human Recognition Based On Convolutional Neural Network ModelDocument9 paginiScore Fusion of Finger Vein and Face For Human Recognition Based On Convolutional Neural Network ModelFressy NugrohoÎncă nu există evaluări

- 12abmb2 Group4 Chapter1Document20 pagini12abmb2 Group4 Chapter1Kenneth Del RosarioÎncă nu există evaluări

- Inhalation AnestheticsDocument27 paginiInhalation AnestheticsMarcelitaTaliaDuwiriÎncă nu există evaluări

- Honda Bikes and ScootersDocument6 paginiHonda Bikes and ScootersShamrjit AgrahariÎncă nu există evaluări

- Nature Generator (Emtech Concept Paper)Document3 paginiNature Generator (Emtech Concept Paper)Min SugaÎncă nu există evaluări

- HP 300s+ Scientific Calculator: Sophisticated Design Ideal For Math and Science StudentsDocument3 paginiHP 300s+ Scientific Calculator: Sophisticated Design Ideal For Math and Science StudentsgemaÎncă nu există evaluări