Documente Academic

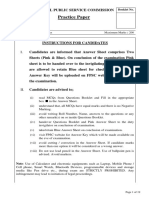

Documente Profesional

Documente Cultură

Modelling of Repairable Items For Production Inventory With Random Deterioration

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Modelling of Repairable Items For Production Inventory With Random Deterioration

Drepturi de autor:

Formate disponibile

IOSR Journal of Mathematics (IOSR-JM)

e-ISSN: 2278-5728, p-ISSN: 2319-765X. Volume 11, Issue 1 Ver. IV (Jan - Feb. 2015), PP 56-69

www.iosrjournals.org

Modelling of repairable items for production inventory with

random deterioration

Dr.Ravish Kumar Yadav1, RajeevKumar2

1,

Associate Professor ,Department of mathematics ,Hindu College, Moradbad,

2

Devta Mahavidhyal, Bijnoor

Abstract: Keeping in view the concern about environmental protection, the study incorporate the concept of

repairing in a production inventory model consisting of production system and repairing system over infinite

planning horizon. This study presents a forward production and reverse repairing system inventory model with

a time dependent random deterioration function and increasing exponentially demand with the finite production

rate is proportional to the demand rate at any instant. The shortages allow and excess demand is backlogged.

Expressions for optimal parameter are obtained .We also obtained Production and repairing scheduling period,

maximum inventory level and total average cost. Using calculus, optimum production policy is derived, which

minimizes the total cost incurred

I.

Introduction

An inventory system the effect of deterioration plays an important role. Deterioration is derived as

decay or damage such that the item cannot be used for its original propose. Foods, pharmaceuticals, chemicals,

blood, drugs are a few examples of such items in which sufficient deterioration can take place during the storage

period of the units and the importance of this loss must be taken into account when analyzing the system.

When describing optimum policies for deteriorating items Ghare and Schrader (1963) proposed a

constant rate of deterioration and constant rate demand. In recent year, inventory problem for deterioration items

have been widely studied after Ghare and Schrader (1963), Covert and Philip (1973) formulated the model

for variable deterioration rate with two parameters Weibull disturbation Goswami and Chaudhuri (1991),

Bose et al (1995) assumed either instantaneous or finite production with different assumption on the pattern of

deterioration.

Balkhi and Benkheroot (1996) considered a production a production lot size inventory model with

arbitrary production and demand rate depends on the time function.

Bhunia and Maitis (1977) model to formulate a production inventory model. Chang and Deve

(1999) investigated an EOQ model allow shortage and backlogging. It is assumed that the backlogging rate is

variable and dependent on the length of waiting time for the next replenishment. Recently, many researchers

have modified inventory policies by considering the time proportional partial backlogging rate such as Wang

(2002), Perumal (2002), Teng et al (2003), Skouri and Papachristos (2003) etc.

Schrady (1967) first studied the problem on optimal lot sizes for production/procurement and

recovery. For issues in the greening process, Nahmias and Rivera (1979) studied an EPQ variant of Schradys

model (1967) with a finite recovery rate. Richter (1996a, 1996b, 1997) and Richter and Dobos (1999)

investigated a waste disposal model by considering the returned rate as a decision variable. Dobos and Richter

(2003, 2004) investigated a production/remanufacturing system with constant demand that is satisfied by

noninstantaneous production and remanufacturing for single and multiple remanufacturing and production

cycle. Dobos and Richter (2006) extended their previous model and assumed that the quality of collected

returned items is not always suitable for further repairing. Konstantaras and Skouri (2010) presented a model

by considering a general cycle pattern in which a variable number of reproduction lots of equal size were

followed by a variable number of manufacturing lots of equal size. They also studied a special case where

shortages were allowed in each manufacturing and reproduction cycle and similar sufficient conditions, as the

non-shortages case, are given.El Saadany and Jaber (2010) extended the models developed by Dobos and

Richter (2003, 2004) by assuming that the collection rate of returned items is dependent on the purchasing price

and the acceptance quality level of these returns. That is, the flow of used/returned items increases as the

purchasing price increases, and decreases as the corresponding acceptance quality level increases. Alamri

(2010) developed a general reverse logistics inventory model. Chung and Wee (2011) developed an inventory

model on short life-cycle deteriorating product remanufacturing in a green supply chain model

In this paper we present a realistic inventory model in which the production rate depends on the

demand and demand is an exponentially increasing function time and deterioration is random function says that

deterioration of an item depends upon the fluctuation of humidity, temperature, etc. It would be more reasonable

and realistic if we assume the deterioration function to depend upon a parameter "" in addition to time t

DOI: 10.9790/5728-11145669

www.iosrjournals.org

56 |Page

Modelling of repairable items for production inventory with random deterioration

.This model is developed for deteriorating item by assuming that the deterioration rate is uniform and the finite

production rate is proportional to the demand rate & the demand rate increasing exponentially. Repairable Items

are collected at time of production run and repairs at time of no production no shortage completely. These

repaired items as good as new and consumed at time of shortage. When shortages is maximum production start

and items consumed from both the channels forward production and repaired items as well. We derive an

expressions for different cost associated in the model and total average cost .We derive equations, solution of

these equations gives the optimal cycle and optimal cost of repairable items.

Fig. 1. Flow of inventory in the integrated supply system

II.

Assumption and Notation

The mathematical model of the production inventory problem with repairable system considered herein is

developed on the basic of the following assumptions-:

a. A single item is considered over a prescribed period of T units of time, which is subject to a time dependent

Random deterioration rate.

b.

c.

d.

e.

f.

g.

h.

Deteriorate D (t) is known and increasing exponentially D( t ) Ae , t 0 , A is initial demand,

is a constant governing the increasing rate of demand.

Production rate P(t) at any instant depends on the demand that is, at time t, t > 0, P(t ) a bD(t ) , a > 0,

0 b 1 and P(t) > D(t).

Deterioration of the units is considered only after they have been received into the inventory.

Items are returnable and are repaired. Repaired items are as good as new ones and they are used during the

shortage period of forward production.

The time horizon of the inventory system is infinite. Only a typical planning schedule of length T is

considered, all remaining cycles are identical.

Shortages are allowed and backlogged.

The production time interval for forward production coincides with the collection time interval for reverse

repairing system.

Notations for production system and repairing system:

(1) I(t) = Inventory level at any time t, t 0

(2) 0 ( )t the items deterioration rate is random.

(3) Im = Maximum inventory level.

(4) Ib = Maximum shortages level.

(5) C = Setup cost for new cycle.

(6) CS = Shortage cost per unit.

(7) K = The total average cost of system.

(8) CHP=Holding cost per unit per unit of time during the production.

(9) CDP=Deteriorating cost per unit per unit of time during the production.

(10) Pcp = Production cost per item.

(11) CHC= Holding cost per unit per unit of time during the collecting and consuming process for the repairing

system.

(12) CDC= Deteriorating cost per unit per unit of time during the collecting and consuming process for the

repairing system.

(13) CHR = Deteriorating cost per unit per unit of time during the repairing process for the repairing system.

(14) CDR =Holding cost per unit per unit of time during the repairing process for the repairing system.

(15) Ic(t) = Inventory level during the collecting process for the returnable items.

(16) I1(t)= Inventory level during the repairing process for the returnable items.

(17) z =Fraction of the production lot size 0 <z<1.

(18) Rc =Rate of collection of returnable items.

(19) M =Rate of repair of returnable items to be repaired.

DOI: 10.9790/5728-11145669

www.iosrjournals.org

57 |Page

Modelling of repairable items for production inventory with random deterioration

(20)

(21)

(22)

(23)

(24)

(25)

(26)

(27)

t1 = Time when production stops and also the time when collecting process for returnable items stops. At

this very time repairing of collected items start.

t2 = Time period when repairing of returnable items stops and also the time when accumulated inventory of

production system vanishes.

t3 = Time when shortages is maximum.(t= t1+ t2+ t3)

t4 = Period of time when production starts again during the period of shortage.

T = (t1 t 2 t3 t 4 ) is the cycle time.

IS = Maximum inventory level of repaired items.

Pcc= Cost of purchasing the returnable items per unit.

Pcr =Repair cost of repaired items per unit.

III.

Mathematical Model :

Initially, the inventory level is start with zero. The forward production inventory level starts at time

t=0 and it reaches at maximum inventory level I m unit after t1 time. At that time production is stopped and the

inventory level is decreasing continuously and reaches zero at time t 2,at this time shortages start developing at

time t3 it reaches to maximum shortage level Ib . This time fresh production start to remove backlog by the time

t4 .

At the beginning of each cycle, the inventory is zero. The production starts at the very beginning of the

cycle. As production progresses the inventory of finished goods piles up even after meeting the market demand,

deterioration. At the beginning of each cycle, the process of collecting returnable items in a separate store also

begins. At a point where the production from the forward production system stops; the collection process of

returnable items also stops at the same point .It is assumed there is no collection of used items once the repairing

of collected items starts. At this very point the repairing of reusable items begin at a constant rate. The

accumulated inventory produced from the advanced production system in the meanwhile starts getting

consumed and ultimately becomes nil. The accumulated inventory of repairing products, which are assumed to

be as good as the newly produced products, is consumed when the shortages from the forward production

system begin to surface. Thereafter, production starts when shortages is maximum in forward inventory system

and shortages are gradually cleared after meeting demand by repairable items and produced item from forward

system simultaneously and the cycle ends with zero inventories. Here our aim is to find out the optimal values

of t1, t2, t3 , t4, Im & Ib that minimize the total average cost (K) over the time planning horizon cycle(0,T).

Forward production system

Repairing System

Fig. 2. Inventory of production and repairing system

The differential equation governing the stock status during the period

0tT

dI (t )

a (b 1) Ae t 0 ( )tI (t ) , I(0) = 0,( I1) =Im, 0 t t1

dt

DOI: 10.9790/5728-11145669

www.iosrjournals.org

can be written as

(1)

58 |Page

Modelling of repairable items for production inventory with random deterioration

dI (t )

Aet 0 ( )tI (t ) , I(t1) =Im , I(t2) = 0 , 0 t t 2

dt

dI (t )

Aet , I(0) =o, I(t3) =Ib, 0 t t3

dt

,

dI (t )

a (b 1) Aet , I(0) = Ib,I(t4)=0, 0 t t4

dt

(2)

.(3)

.(4)

Differential equations representing repairing system in collecting time & consuming time

dI c (t )

Rc 0 ( ) t I c (t ) ,

dt

dI c (t )

M 0 ( ) t I c (t ) ,

dt

Ic(0) = 0

0 t t1

(5)

Ic(t1) = Bz , 0 t t2

(6)

Where

B=Production lot size during production system=Production- Deterioration

t1

t1

t1

Pdt 0 ( )tPdt (1 0 ( )t )(a bAe t )dt

t1

{a bAet 0 ( )t (a bAet )}dt

0

bA

(1

0 ( ) a 0 ( )t12

( )

bAet

)

}

{1 0 ( )t1 ) 0 }

Differential equations representing inventory of repaired items.

dI1 (t )

M 0 ( ) t I1 (t ) I1(0) = 0, I1(t2) =Is, 0 t t2 ,

dt

,

dI (t )

Aet 0 ( )tI (t ) ,I(0) =Is,I (t3 t4 ) 0 , I(t3) =Ib1 , 0 t t3 t4

dt

.(7)

(8)

Solution of equation (1) , (2) , .3) and (4) by adjusting the constant of integration using boundary condition are

given by

( ) t

( )t 3 0 ( )t 2 2 (b 1) 0 2 t 0 ( )t

I (t ) a t 0

Ae

e

1

6

2

t

( )t

( )e

( )

0

0 2

0 2 e t 0 t t1

2

(9)

I (t )

I (t )

e 0 ( )t

( )t 2 0 ( )

0

2

1

2

( )t 2 0 ( )t 0 ( )

e t 1 0

2 0 t t2

2

,

A

e 0 ( )t

(1 e t )

I (t ) a(t t 4 )

t 2

, 0 t t3

A(b 1)

(10)

(11)

( e t e t4 ) 0 t t4

(12)

Solving (5) and (6)

DOI: 10.9790/5728-11145669

www.iosrjournals.org

59 |Page

Modelling of repairable items for production inventory with random deterioration

( )t 3 0 ( )t 2 2

I c (t ) Rc t 0

, 0 t t1

e

6

( )t13 0 ( )t12 2

I c (t1 ) Rc t1 0

Bz,

e

6

(13)

Bze0 ( )t1 2

RC

0 ( )t13

t1

0 ( )t 3 0 ( )t 2 2

0 ( )t13 0 ( )t12 2

I c (t ) Bz M t

M t1

, 0 t t2

e

e

6

6

(14)

Solution of equation (7) and (8) by adjusting the constant of integration using boundary condition are given by

( )t 3 0 ( )t 2 2

I1 (t ) M t 0

, 0 t t2

e

6

I (t )

0 ( ) t

t

2

(15)

2

t

( )

0 ( )t 0 ( )t 0 ( )e

0 2 e t , 0 t t3 t4

2

1 2

(16)

I b1

0 ( ) t3

t3

2

0 ( )t3 0 ( )t3 0 ( )e

1

2

2

t3

0 ( ) t

e

2

(16)

The inventory level of production start initially at time unit t = 0 to t = t 1 at maximum level Im is obtained by

equation (9)

( ) t1

( )t13 0 ( )t12 2 (b 1) 0 2

I m a t1 0

Ae

e

6

0 ( )t12 0 ( )e t1 0 ( ) t1

2 e

2

2

t1

0 ( )t1

1

A t2 0 ( )t12 0 ( )t 2 0 ( )

2 1

e 1

2

(17)

and after time t 1 the production is stopped and stock level is decreasing continuously and become zero at time

t=t2 at that time shortages are develop and reaching to Ib at time

I b I b1

(1 et3 ) at4

A(b 1)

t t3

is obtained .

(1 et4 )

(.18)

Thus by equation (17) we observed that t 1 and t 2 are dependent so they are related by the equation

(19)

t 2 R(t1 )

and by equation (18) t 3 and t 4 are dependent to each other so related by the equation

t3 R1 (t4 )

(20)

Total amount of deteriorated units ( I DP ) of production inventory

t1

t2

(0, T)

is given by

I DP 0 ( )tI (t )dt 0 ( )tI (t )dt

DOI: 10.9790/5728-11145669

www.iosrjournals.org

60 |Page

Modelling of repairable items for production inventory with random deterioration

t 2 ( )t15 0 ( )t14 02 ( )t17

a 0 ( ) 1 0

2

30

8

72

(6 )t1 t12 ( 5) t13

0 ( )(b 1) Ae t

0 ( )

3

42t1 (3 12 )t12 7t13

3t1

( ) 5

25

23 42

( )(b 1) A 62 t1 6 0 ( )t 0 ( )2 t13 02 ( )t13

62

Ae t ( )t 22 0 ( )t 2 0 ( )

( ) t

1 e

2 1 0

t 2

t 2

A ( ) ( )t 2 e

e

1 0 2 0

2

2

0

02 ( )e t t 32 3t 22 6t 2 6 3 02 ( ) 1

2 3 4

2

2

4

A 02 ( ) t t 23 3t 22 6t 2 6

e

2 3 4

2

0 ( )e t t 25

5t 4 20t 3 60t 2 120t 120

22 3 2 4 2 5 2 6

2

6 60 0 ( ) A 02 ( ) t2 t 22 2t 2 2 t 24

4

e

2 3

6

24 2 24

(21)

5 3 5

Total amount of deteriorated units ( I DC ) of collected items of repairable inventory channel in (0, t 2 ) is given

4t 23

2

12t 23

3

24t 2

4

by

t1

t2

I DC 0 ( )tI C (t )dt 0 ( )tI C (t )dt

( )t 3 0 ( )t 2 2

0 ( )tRc t 0

dt

e

6

0

t2

0 ( )t 3 0 ( )t 2 2

0 ( )t13 0 ( ) t12 2

)

t

Bz

M

t

t1

e

dt

0 0

6

6

3

2 5

2

3

2 5

( )t1 0 ( ) t1 0 ( ) Bzt2

( )t2 0 ( ) t2

Rc 0

M 0

3

15

2

3

15

t1

0 ( )t2 2 M

2

t1

0 ( )t13

6

(22)

0 ( ) t12 2

Total amount of deteriorated units ( I DR ) of Repaired items of repairable inventory channel is given by

DOI: 10.9790/5728-11145669

www.iosrjournals.org

61 |Page

Modelling of repairable items for production inventory with random deterioration

t2

t3 t4

I DR 0 ( )tI1 (t )dt

0 ( )tI (t )dt

( )t 3 0 ( )t 2 2

0 ( )tM t 0

dt

e

6

0

t2

t3 t4

0 ( )t

0 ( ) t

t

2

2

t

0 ( ) t

0 ( )t 0 ( )t 0 ( )e

1

e dt

2

(23)

( )t23 0 ( ) 2 t25

(t3 t4 ) 2 (t3 t4 )3 0 ( )(t3 t4 ) 4

M 0

0

3

15

2

3

8

During period (0, T ) total inventory of produced items ( I HP ) in forward production channel can be obtained

as

t1

t2

I HP I (t )dt I (t )dt

( )t13 a 02 ( )t16 (b 1) A e t1

1

a t1 0

t1

6

72

1

4t

5t 2 3t 3

t4

2

t

e t1 0 ( ) 12 3 e t1 02 ( ) 41 31 12 1 4

4

t

t3

t3 2

6t

6

2

7

5 0 ( ) 12 1 3 02 ( ) 1 3 31 4 5

6

2 e t 2 t 2 e t 2

t 24 e t2 t 23 e t2

A

0 3

0

2

2

2

4

t 22 e t2 3t 22 e t2 t 2 e t2 3t 2 e t2 e t2 1 3e t2 3

2

4 4 5 5

22

23

e t

2 ( )t 3 ( )t

( )t 22

1 Ae t

1

2 t 2 0 ( )t 23 0 2 2 0 2 2 0

3

03 ( )t 25

12

0 ( )t 24

(24)

During period (0, T ) total inventory of collected items ( I HC ) can be obtained as

t1

t2

I HC I C (t )dt I C (t )dt

( )t 3 0 ( )t 2 2

Rc t 0

dt

e

6

0

t2

0 ( )t 3 0 ( )t 2 2

0 ( )t13 0 ( )t12 2

Bz

M

t

t1

e

dt

0

6

6

2

2 4

2

( )t1 0 ( ) t1

0 ( )t2 0 ( ) 2 t2 4

Rc 0

)

Bzt

2

2

12

2

12

t1

0 ( )t13

0 ( )t2 M t1

DOI: 10.9790/5728-11145669

(25)

0 ( ) t12 2

www.iosrjournals.org

62 |Page

Modelling of repairable items for production inventory with random deterioration

During period (0, T ) total inventory of repaired items ( I HR ) can be obtained as

t2

t3 t4

I HR I1 (t )dt

I (t )dt

0 ( )t 3 0 ( )t 2 2

0 ( )M t

dt

e

6

0

t2

t3 t4

0 ( )

0 ( ) t

t

2

2

t

( )

0 ( )t 0 ( )t 0 ( )e

0 2 e t dt

2

1 2

( )t2 2 0 ( ) 2 t2 4

(t3 t4 ) 2 0 ( )(t3 t4 )3

M 0

)

(

t

t

)

3 4

0

2

12

2

6

(26)

Total amount of shortage units (Is) during the period (0, T) is given by

A e t3

1 at 2 A(b 1) e t4 1

I S I (t )dt I (t )dt

t 3 4

t 4 e t4

2

0

0

t3

t4

(27)

P=Production cost +Collection cost +Repaired cost

t1

t1

t2

P PCP (a bAe )dt PCC Rc dt PCR Mdt

t

PCP (at1

bAe

t1

) PCC Rct1 PCR Mt2

Hence the total average cost of the inventory system is

K = setup cost +production cost+ deterioration cost + inventory carrying

cost + shortage cost

1

C P CDP I DP CDC I DC CDR I DR CHP I HP CHC I HC CHR I HR CS I S

T

(28)

and putting the value of IDP, IDC, IDR,IHP, IHC, IHR and IS we getting the total average cost of the inventory system.

In many cases

IV.

and

The Approximation Solution Procedure

0 () are extremely small hence to use Maclaurin series for approximation

e t 1 t

2 t 2

(29)

By using equation (4.29) the total average cost of system

C

1

bAet1

[C PCP (at1

) PCC Rct1 PCR Mt2 ] DP

T

T

2

0 ( )at1 0 ( )(b 1) At1 A 0 ( ) 3 3

t2 2t22 2 4 2 4t2 2 2 2)

4

2

0 ( )t13 0 ( ) 2 t15 0 ( ) Bzt2 2

0 ( )t23 0 ( ) 2 t25

Rc

3

15

2

3

15

CDC

2

3

T 0 ( )t2 M 0 ( )t1 ( )t 2 2

0

1

e

1

2

6

DOI: 10.9790/5728-11145669

www.iosrjournals.org

63 |Page

Modelling of repairable items for production inventory with random deterioration

(t3 t4 )2 (t3 t4 )3 0 ( )(t3 t4 ) 4

CDR 0 ( )t23 0 ( )2 t25

M

A0 ( )

T

3

15

2

3

8

a0 ( )t13 (b 1) A 2 0 ( )t13 A 2 0 ( )

t1

at1

6

3

3

0 ( ) 0 ( ) 0 ( )t 22 0 ( )

t2 2

2

2

C

HP

T

2 0 ( )t 23 22 0 ( ) 0 ( ) 4 0 ( ) 5

A 0 ( )

2

t 2

1

t2

2

3

6

6

2

2

0 ( )t12 0 ( ) 2 t14

0 ( )t2 2 0 ( ) 2 t2 4

R

)

Bzt

c

0

2

2

12

2

12

CHC

+

3

T

2

)

t

( ) t 2

1

0 ( )t2 M t1 0

e 0 1

(t3 t4 )2 0 ( )(t3 t4 )3

H HR 0 ( )t2 2 0 ( )2 t2 4

)

(

t

t

)

3 4

0

T

2

12

2

6

CS At32 at42 A(b 1) 2

t4

T 2

2

2

(30)

And

C

1

bAet1

[C PCP (at1

) PCC Rct1 PCR MR(t1 )] DP

T

T

2

0 ( )at1 0 ( )(b 1) At1 A 0 ( ) 3

R(t1 )3 2 R(t1 ) 2 2 4 2 4 R(t1 ) 2 2 2)

4

2

0 ( )t13 0 ( ) 2 t15 0 ( ) BzR(t1 ) 2

0 ( ) R(t1 )3 0 ( ) 2 R(t1 )5

R

3

15

2

3

15

CDC

T 0 ( ) R(t1 ) 2 M 0 ( )t13 ( )t 2 2

0

1

2

6

( R1 (t4 ) t4 ) 2 ( R1 (t4 ) t4 )3

CDR 0 ( ) R(t1 )3 0 ( ) 2 R(t1 )5

2

3

A0 ( )

4

T

3

15

)(

R

(

t

)

t

)

0

1 4

4

3

3

a ( )t1 (b 1) A 2 0 ( )t1 A 2 0 ( )

C

t1

HP at1 0

T

6

3

3

2

0 ( ) 0 ( ) 0 ( ) R(t1 ) 0 ( )

R(t1 ) 2

2

2

DOI: 10.9790/5728-11145669

www.iosrjournals.org

64 |Page

Modelling of repairable items for production inventory with random deterioration

20 ( ) R(t1 )3 2 20 ( ) 0 ( )

A 0 ( )

2

4

2 1 2 R(t1 ) R(t1 )

R(t1 )

3

6

0 ( )

R(t1 )5

6

0 ( )t12 0 ( ) 2 t14

0 ( ) R(t1 ) 2 0 ( ) 2 R(t1 ) 4

Rc

0 ( ) Bzt2 M

2

12

2

12

CHC

+

3

T

2

)

t

( ) t 2

1

0 ( ) R(t1 ) M t1 0

e 0 1

( R1 (t4 ) t4 )

( R1 (t4 ) t4 )

( ) R(t ) 2 ( ) 2 R(t ) 4

H HR

2

0

1

0

1

A 0 ( )

T

2

12

0 ( )( R1 (t4 ) t4 )3

CS AR1 (t4 )2 at42 A(b 1) 2

t4

T

2

2

2

(31)

According to equation (30) contain four variables t1, t2, t3 and t4 and these are dependent variable and

related by equation (19) and (20). Also we have K > 0, hence the optimum value of t 1 and t4 which minimize

total average cost are the solutions of the equations

K

K

0 and

0

t1

t 4

(.32)

Provided that these values of t1 satisfy the conditions

2

2K

2K

2 K 2 K 2 K

0

.

,

and

0

t12 t42 t1 t4

t12

t 42

Now differentiating (31) with respect to t1 and t4, we get

C

K 1

bAet1

2 [C PCP (at1

) PCC Rct1 PCR MR (t1 )] 1 R(t1 ) DP

t1 T

T2

0 ( )at12 0 ( )(b 1) At1 A 0 ( ) 3

R(t1 )3 2 R(t1 ) 2 2 4 2 4 R(t1 ) 2 2 2)

4

2

1 R(t1 )

CDC

T2

0 ( )t13 0 ( ) 2 t15 0 ( ) BzR(t1 ) 2

0 ( ) R(t1 )3 0 ( ) 2 R(t1 )5

R

3

15

2

3

15

2

0 ( )t13 0 ( )t12 2

0 ( ) R(t1 ) M

2

6

1 R(t1 )

CDR

T2

0 ( ) R(t1 )3 0 ( ) 2 R(t1 )5

3

15

2

( R1 (t4 ) t4 )

( R1 (t4 ) t4 )3

2

3

A 0 ( ) ( )( R (t ) t ) 4

0

1 4

4

DOI: 10.9790/5728-11145669

1 R(t )

1

www.iosrjournals.org

65 |Page

Modelling of repairable items for production inventory with random deterioration

a0 ( )t13 (b 1) A 2 0 ( )t13 A 2 0 ( )

CHP

t1

at

1

T 2

6

3

3

2

( ) 0 ( ) 0 ( ) R(t1 ) 0 ( )

R(t1 ) 2 0

2

2

0 ( )

20 ( ) R(t1 )3 2 20 ( ) 0 ( )

A

2

4

1

R

(

t

)

R

(

t

)

R(t1 )

1

1

2

2

3

6

0 ( )t12 0 ( ) 2 t14

Rc

0 ( ) BzR(t1 )

2

12

2

2

4

( )

C 0 ( ) R(t1 ) 0 ( ) R(t1 )

1 R(t1 )

0

R(t1 )5 1 R(t1 ) HC

M

T2

2

12

0 ( )t13 0 ( )t12 2

e

0 ( )t2 M t1

( R1 (t4 ) t4 )2

(

R

(

t

)

t

)

( ) R(t ) 2 ( ) 2 R(t ) 4

1 4

4

H HR

2

0

1

0

1

1 R(t1 )

2 M

A 0 ( )

3

T

2

12

)(

R

(

t

)

t

)

0

1 4

4

2

2

C AR (t ) at

A(b 1) 2

S2 1 4 4

t4 1 R(t1 )

T

2

2

2

C

1

[ PCP (a bAet1 ) PCC Rc PCR MR(t1 )] DP

T

T

0 ( )(b 1) A A0 ( )

3 3 R(t1 )2 R(t1 ) 2 2 R(t1 ) R(t1 ) 2 4 R(t1 )

4

0 ( )at1

3 0 ( )t12 0 ( ) 2 t14 2 0 ( ) BzR(t1 ) R(t1 )

Rc

3

3

2

2

2

4

M 3 0 ( ) R(t1 ) R (t1 ) 0 ( ) R(t1 ) R (t1 )

3

3

CDC

3

T 2 0 ( ) R(t1 ) R(t1 ) M 0 ( )t1 ( )t 2 2 0 ( ) R(t1 ) 2 M

t1

e 0 1

2

6

2

2 0 ( ) t1 R(t1 ) 2 M 0 ( )t13 ( )t 2 2

t1

e 0 1

2

6

0 ( )t12 0 ( ) t12

1

e

2

CDR 30 ( ) R(t1 ) 2 R(t1 ) 0 ( ) 2 R(t1 ) 4 R(t1 )

T

3

3

DOI: 10.9790/5728-11145669

www.iosrjournals.org

66 |Page

Modelling of repairable items for production inventory with random deterioration

a0 ( )t12 (b 1) A

0 ( )t1 A

a

2t1

2

1

( ) 0 ( ) 20 ( ) R(t1 ) R(t1 )

R(t1 ) 2 0

2

( )

2 ( ) R(t1 )2 R(t1 ) 2 20 ( ) 0 ( )

A

3

2 1 0 2 R(t1 ) 2 R(t1 ) R(t1 ) 0

2 R(t1 ) R(t1 )

1

3

C

HP

T

50 ( )

R(t1 )4 R(t1 )

6

2 0 ( )t1 0 ( ) 2 t13

2 0 ( ) R(t1 ) R(t1 ) 0 ( ) 2 R(t1 )3

)

BzR

(

t

)

Rc

0

1

2

3

2

3

3

2

0 ( )t1 0 ( )t12 2

0 ( )t1 0 ( )t12 2

CHC

+

0 ( ) R (t1 ) M t1

0 ( ) R(t1 ) M 1

e

e

T

6

2

2

2

0 ( ) t1 R(t1 ) M 0 ( )t1 0 ( )t12 2

1

e

H HR 20 ( ) R(t1 ) R(t1 ) 0 ( ) 2 R(t1 )3 R(t1 )

M

0

T

2

3

(33)

C

K 1

bAet1

2 [C PCP (at1

) PCC Rct1 PCR MR(t1 )] 1 R1(t4 ) DP

t4 T

T2

0 ( )at12 0 ( )(b 1) At1 A 0 ( )

4

2

1 R1(t4 )

3

3

2

2

4

4

2

R(t1 ) R(t1 ) 2 2 R(t1 ) 2 2)

0 ( )t13 0 ( ) 2 t15 0 ( ) BzR(t1 ) 2

Rc

3

15

2

3

2

5

CDC

0 ( ) R(t1 ) 0 ( ) R(t1 )

1 R1(t4 )

M

T2

3

15

2

3

0 ( ) R(t1 ) M 0 ( )t1 0 ( )t12 2

t1

e

2

6

3

2

5

0 ( ) R(t1 ) 0 ( ) R(t1 )

3

15

2

3

CDR

( R1 (t4 ) t4 ) ( R1 (t4 ) t4 ) 1 R(t )

2

1 4

2

3

)

0

0 ( )( R1 (t4 ) t4 ) 4

DOI: 10.9790/5728-11145669

www.iosrjournals.org

67 |Page

Modelling of repairable items for production inventory with random deterioration

C

HP

T2

a0 ( )t13 (b 1) A 2 0 ( )t13 A 2 0 ( )

t1

at1

6

3

3

2

( ) 0 ( ) 0 ( ) R(t1 ) 0 ( )

R(t1 ) 2 0

2

2

20 ( ) R(t1 )3 2 20 ( ) 0 ( )

A 0 ( )

2

4

1

R

(

t

)

R

(

t

)

R(t1 )

1

1

2

2

3

6

( )

0

R(t1 )5 1 R1(t4 )

6

0 ( )t12 0 ( ) 2 t14

0 ( ) R(t1 ) 2 0 ( ) 2 R(t1 ) 4

R

)

BzR

(

t

)

c

0

1

2

12

2

12

CHC

3

T

0 ( )t1 0 ( )t12 2

0 ( )t2 M

e

1

1 R1(t4 )

0 ( ) R(t1 ) 2 0 ( ) 2 R(t1 ) 4

2

12

2

H HR

( R1 (t4 ) t4 ) 1 R(t )

2

1 4

( R1 (t4 ) t4 )

A 0 ( ) ( )( R (t ) t )3

0

1

4

4

CS AR1 (t4 )2 at42 A(b 1) 2

2

t4 1 R1(t4 )

T

2

2

2

( R1 (t4 ) t )( R1(t4 ) 1) ( R1 (t4 ) t4 ) 2 ( R1(t4 ) 1)

CDR

1

1

A0 ( )

T

0 ( )( R1 (t4 ) t4 )3 ( R1(t4 ) 1)

H

( R1 (t4 ) t4 )( R1(t4 ) 1) 0 ( )( R1 (t4 ) t4 )2 ( R1(t4 ) 1)

+ HR A 0 ( ) ( R1(t4 ) 1)

T

1

2

CS

AR1 (t4 ) R1(t4 ) at4 A(b 1)t4 0

T

(34)

Here we obtain two simultaneous non-linear equation in of t1 and t4 can be find out optimal value by using some

suitable computational numerical method and the optimum value of t2, t3, Im, Ib and minimum total average cost

K can be obtained from equations.

V.

Special Cases:

Case I : If b = 0 then the discussed model convert to production inventory model in which production rate is

constant and independent on the demand.

Case II : If 0 () 0 then the discussed model reduces to production inventory model with out

deterioration

Case III : If 0 , b 0 the model reduce to uniform production rate and constant demand.

DOI: 10.9790/5728-11145669

www.iosrjournals.org

68 |Page

Modelling of repairable items for production inventory with random deterioration

VI.

Conclusion

In the proposed model a production inventory model is formulated for random deteriorating item with a

increasing market demand rate with time and production rate is dependent on the demand. Result in this study

can provide a valuable reference for decision markers in planning the production and controlling the inventory.

The model proposed here in is resolved by using maclaurin series and cost minimization technique is used to get

the approximate expression for total average cost and other parameters & some special cases of model are also

discussed. We derive an expressions for different cost associated in the model. We derive equations, solution of

these equations gives the optimal cycle and optimal cost of repairable items. A future study will incorporate

more realistic assumption in the proposed model.

References

[1].

[2].

[3].

[4].

[5].

[6].

[7].

[8].

[9].

[10].

[11].

[12].

[13].

[14].

[15].

[16].

[17].

[18].

[19].

[20].

[21].

[22].

Alamri, A.A. (2010). Theory and methodology on the global optimal solution to a Reverse logistics inventory model for

deteriorating items and time varying rates. Computer & Industrial Engineering,(60), 236-247.

Balkhi, Z. T. and Benkherouf, L. (1996 b)On the optimal replenishment schedule for an inventoy system with

deteriorating items and time varying demand and production rates.Computers & Industrial Engineering, 30 ; 823-829..

Bhu nia , A. K . an d M aiti , M . (1 9 9 8 ) A two warehouse inventory model for deteriorating items with a linear trend in

demand and shortages.Jou r of Opl. Res. Soc., 49 : 2 87 -2 92 .

Chang , H . J . and Dye , C. Y. (19 99) An EOQ model for deteriorating items with time varying demand and partial

backlogging.J o u r , o f O p l . R e s . S o c . , 5 0 : 1 1 7 6 -1 1 8 2 .

Chung, C. J., & Wee, H. M. (2011). Short life-cycle deteriorating product remanufacturing in a green supply chain inventory

control system. International Journal of Production Economics, 129(1), 195-203.

Covert, R.P., and Philip, G.C.,( 1973), An EOQ Model for Item with Weibull Distribution Deterioration, AIIE Transactions, 5,

(4), 323-326,

Dobos, I., & Richter, K. (2003), A production/recycling model with stationary demand and return rates.Central European journal

of Operations Research, 11(1), 35-46.

Dobos, I., & Richter, K. (2004), An extended production/recycling model with stationary demand and return rates. International

Journal of production Economics, 90(3), 311-323.

Dobos, I., & Richter, K. (2006), A production/recycling model with quality considerations. International Journal of Production

Economics, 104(2), 571-579.

El Saadany A. M. A., & Jaber M. Y. (2010)., A production/ remanufacturing inventory model with price and quality dependant

return rate. Computers and Industrial Engineering, 58(3), 352362.

Ghare, P.M., and Schrader, G.F.,(1963), A Model for An Exponentially Decaying Inventory, The Journal of Industrial

Engineering, 14, (5), 238-243.

Goswami, A and Chaudhuri, K. S. (1991) EOQ model for an inventory with a linear trend in demand and finite rate of

replenishment considering shortages.i nt . J ou r. Sy st S cL , 2 2 , 1 8 1 -1 8 7 .

Konstantaras, I., & Skouri, K. (2010), Lot sizing for a single product recovery system with variable set up numbers. European

Journal of Operations Research, 203(2), 326-335.

Perumal, V. and Arivarignan, G. (2002)A production inventory model with two rates of production a nd

backorders.In t. J o ur o f M g t. & S yst ., 1 8 (1 ) : 1 0 9 -1 1 9 .

Pyke, D. (1990 )Priority Repair and Dispatch Policies for Reparable-Item Logistics Systems.Naval Research Logistics v37 n1 130 Feb.

Raafat, F., Wolfe, P.M. and Eldin, H.K. An Inventory Model for Deteriorating Item, Computers & Industrial Engineering, 20,

(1), 89-94, 1991.

Richter, K, (1996b). The extended EOQ repair and waste disposal model. International Journal of Production Economics, 45(1-3),

443-447.

Richter, K. (1996), The EOQ repair and waste disposal model with variable setup numbers. European Journal of Operational

Research, 95(2), 313-324.

Richter, K., & Dobos, I. (1999). Analysis of the EOQ repair and waste disposal model with integer set up numbers. International

journal of production economics, 59(1-3), 463-467.

Schrady, D.A. (1967). A deterministic inventory model for repairable items. Naval Research Logistics Quarterly, 14, 391398.

Teng, J. T. & Chang, C. T. (2005). Economic production quantity models for deteriorating items with price and stock-dependent

demand. Computational Operations Research, 32 (2), 297-308.

Te ng , J . T. (1 9 9 6 ) A deterministic replenishment model with linear trend in demand. O pn s. R es. L ett . 1 9 : 3 3 -4 1 .

DOI: 10.9790/5728-11145669

www.iosrjournals.org

69 |Page

S-ar putea să vă placă și

- Volume (11) Issue (3) 416-430Document15 paginiVolume (11) Issue (3) 416-430Indah RahmadaniÎncă nu există evaluări

- Energy Autonomy of Batteryless and Wireless Embedded Systems: Aeronautical ApplicationsDe la EverandEnergy Autonomy of Batteryless and Wireless Embedded Systems: Aeronautical ApplicationsÎncă nu există evaluări

- On A Production-Inventory System of Deteriorating Items Subject Torandom Machine Breakdowns With A Fixed Repair TimeDocument13 paginiOn A Production-Inventory System of Deteriorating Items Subject Torandom Machine Breakdowns With A Fixed Repair TimeVolca CmmÎncă nu există evaluări

- Kumar - An EOQ Model For Deteriorating Items With Time-DependentDocument13 paginiKumar - An EOQ Model For Deteriorating Items With Time-DependentTrung NguyễnÎncă nu există evaluări

- An Inflationary Inventory Model For Weibull Deteriorating Items With Constant Demand and Partial Backlogging Under Permissible Delay in PaymentsDocument9 paginiAn Inflationary Inventory Model For Weibull Deteriorating Items With Constant Demand and Partial Backlogging Under Permissible Delay in PaymentsAJER JOURNALÎncă nu există evaluări

- Ijbgm - An Epq Model For Deteriorating Items With Demand and Time - G.v.arunamayiDocument14 paginiIjbgm - An Epq Model For Deteriorating Items With Demand and Time - G.v.arunamayiiaset123Încă nu există evaluări

- Rev LogDocument18 paginiRev LogSHRAYANSH AGARWALÎncă nu există evaluări

- Apiems2004 34.7 PDFDocument16 paginiApiems2004 34.7 PDFRussell JacobÎncă nu există evaluări

- Supply Chain Models With Imperfect Production Process and Volume Flexibility Under InflationDocument17 paginiSupply Chain Models With Imperfect Production Process and Volume Flexibility Under InflationSaptarshi MitraÎncă nu există evaluări

- Multi Item Inventory S R Singh, Urvashi, IJORODocument10 paginiMulti Item Inventory S R Singh, Urvashi, IJOROshivrajpundirÎncă nu există evaluări

- Optimal Replenishment Policies With Allowable Shortages For A Product Life CycleDocument13 paginiOptimal Replenishment Policies With Allowable Shortages For A Product Life Cycle翁慈君Încă nu există evaluări

- An Inventory-Dependent Demand Model With DeterioraDocument7 paginiAn Inventory-Dependent Demand Model With Deterioraአንድ ለእናቱÎncă nu există evaluări

- AnOperatorTrainingSimulatorSystemforMMM HoneywellDocument6 paginiAnOperatorTrainingSimulatorSystemforMMM HoneywellRoberto BianchiÎncă nu există evaluări

- An Epq Model With Varying Rate of Deterioration and Mixed Demand PatternDocument10 paginiAn Epq Model With Varying Rate of Deterioration and Mixed Demand PatternTJPRC PublicationsÎncă nu există evaluări

- Jean Pierre2010Document13 paginiJean Pierre2010Gabriel Leiva ContrerasÎncă nu există evaluări

- Inventory TheoryDocument18 paginiInventory TheoryIsaac LeeÎncă nu există evaluări

- Deterministic and Probabilistic Models IDocument6 paginiDeterministic and Probabilistic Models IprashanthÎncă nu există evaluări

- Writing SampleDocument13 paginiWriting SampleMonika Aditia PutriÎncă nu există evaluări

- Inventory Policies For Deteriorating Item With Stock Dependent Demand and Variable Holding Costs Under Permissible Delay in PaymentDocument11 paginiInventory Policies For Deteriorating Item With Stock Dependent Demand and Variable Holding Costs Under Permissible Delay in PaymentInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- JULY-DEC 2022 BTME 7 SEM V6 BTMEOE704E Notes BTMEOE704E OR UNIT VDocument12 paginiJULY-DEC 2022 BTME 7 SEM V6 BTMEOE704E Notes BTMEOE704E OR UNIT VAjay LoharÎncă nu există evaluări

- Inventory Model With Time Dependent Demand Rate Under Inflation When Supplier Credit Linked To Order QuantityDocument14 paginiInventory Model With Time Dependent Demand Rate Under Inflation When Supplier Credit Linked To Order QuantityAkshay BhattÎncă nu există evaluări

- Int. J. Production Economics: Changyuan Yan, Avijit Banerjee, Liangbin YangDocument5 paginiInt. J. Production Economics: Changyuan Yan, Avijit Banerjee, Liangbin Yangritu malikÎncă nu există evaluări

- Content ServerDocument23 paginiContent Serverakhilyerawar7013Încă nu există evaluări

- Multi Item Inventory Control Model With Space Constrains For Deteriorable ItemsDocument7 paginiMulti Item Inventory Control Model With Space Constrains For Deteriorable ItemsRijadh ReeznanÎncă nu există evaluări

- EOQ Model For Time-Deteriorating Items Using Penalty Cost: Meenakshi Srivastava and Ranjana GuptaDocument10 paginiEOQ Model For Time-Deteriorating Items Using Penalty Cost: Meenakshi Srivastava and Ranjana GuptafewieÎncă nu există evaluări

- Uncertain Supply Chain ManagementDocument16 paginiUncertain Supply Chain Managementvcpc2008Încă nu există evaluări

- 01 ArticuloIndustrialDocument15 pagini01 ArticuloIndustrial__Caro26__Încă nu există evaluări

- Optimal Common Manufacturing Cycle Length For A Multi-Product Inventory System With Rework and An Outside ContractorDocument16 paginiOptimal Common Manufacturing Cycle Length For A Multi-Product Inventory System With Rework and An Outside ContractormarAA123Încă nu există evaluări

- Hinsdale: Holt, Richard and Winston Sounders College Publishing, 2000Document11 paginiHinsdale: Holt, Richard and Winston Sounders College Publishing, 2000Joshua Del Rosario SaculoÎncă nu există evaluări

- Louly Dolgui 2002 IglsDocument6 paginiLouly Dolgui 2002 IglsKate Marulanda JimenezÎncă nu există evaluări

- Decision Support System For Periodic Review Inventory Model With Backorder Price Discounts Under Controllable Lead TimeDocument13 paginiDecision Support System For Periodic Review Inventory Model With Backorder Price Discounts Under Controllable Lead TimeJoko PrasetyoÎncă nu există evaluări

- MSE - UNIT - 3 (1) .PPTMDocument23 paginiMSE - UNIT - 3 (1) .PPTMJoel ChittiproluÎncă nu există evaluări

- Perishable Inventory System With A Finite Population and Repeated AttemptsDocument15 paginiPerishable Inventory System With A Finite Population and Repeated AttemptsinventionjournalsÎncă nu există evaluări

- A Closed Loop Supply Chain System With Flexible Manufacturing and Reverse Logistics Operation Under Shortages For Deteriorating ItemsDocument10 paginiA Closed Loop Supply Chain System With Flexible Manufacturing and Reverse Logistics Operation Under Shortages For Deteriorating ItemsdjolisimoÎncă nu există evaluări

- Int. J. Production Economics: Allen H. Tai, Wai-Ki ChingDocument8 paginiInt. J. Production Economics: Allen H. Tai, Wai-Ki ChingSamuel ZelibeÎncă nu există evaluări

- Generic Model of Reverse Logistics Network Design 2008 Journal of Transportation Systems Engineering and Information TechnologyDocument8 paginiGeneric Model of Reverse Logistics Network Design 2008 Journal of Transportation Systems Engineering and Information TechnologySahas SakhareÎncă nu există evaluări

- Supply Chain Design and Analysis: Models and MethodsDocument22 paginiSupply Chain Design and Analysis: Models and MethodssankofakanianÎncă nu există evaluări

- Inventory Management 1 PDFDocument31 paginiInventory Management 1 PDFfew.fearlessÎncă nu există evaluări

- What Is InventoryDocument7 paginiWhat Is Inventorydeepmangal222Încă nu există evaluări

- The Optimal Production and Shipment Policy For The Single Vendor Single Buyer Integrated Production Inventory ProblemDocument14 paginiThe Optimal Production and Shipment Policy For The Single Vendor Single Buyer Integrated Production Inventory ProblemSaad MemonÎncă nu există evaluări

- Production Scheduling For Apparel Manufacturing SystemsDocument21 paginiProduction Scheduling For Apparel Manufacturing SystemsGarmentLearnerÎncă nu există evaluări

- Q1. Safety Stock Determination Based On Parametric Lead TimeDocument18 paginiQ1. Safety Stock Determination Based On Parametric Lead TimeFaridz Mohammad EdrieÎncă nu există evaluări

- Tailieuxanh Eps2004035lis 9058920585 Debrito 2 9343Document150 paginiTailieuxanh Eps2004035lis 9058920585 Debrito 2 9343Mỹ HạnhÎncă nu există evaluări

- Ibp1533 12Document9 paginiIbp1533 12Marcelo Varejão CasarinÎncă nu există evaluări

- The Value of Setup Cost Reduction and Process Impr - CleanedDocument11 paginiThe Value of Setup Cost Reduction and Process Impr - CleanedGino PinoÎncă nu există evaluări

- Simulated Annealing and Joint Manufacturing Batch-SizingDocument15 paginiSimulated Annealing and Joint Manufacturing Batch-SizingLinDã ArifãniÎncă nu există evaluări

- AlokDatta - 10BM60009 - Assignment SolutionDocument5 paginiAlokDatta - 10BM60009 - Assignment SolutionAnkit KumarÎncă nu există evaluări

- European Journal of Operational Research: Sandra Duni Eksßiog LuDocument9 paginiEuropean Journal of Operational Research: Sandra Duni Eksßiog LuDiego Soto De la VegaÎncă nu există evaluări

- Probabilistic Multi Item Inventory Model With Varying Mixture Shortage Cost Under RestrictionsDocument13 paginiProbabilistic Multi Item Inventory Model With Varying Mixture Shortage Cost Under Restrictionsleminem eminemÎncă nu există evaluări

- Economic Production: A D D Y O U R T E X T H E R EDocument36 paginiEconomic Production: A D D Y O U R T E X T H E R EAimee ReenÎncă nu există evaluări

- 07 - Production Planning and Scheduling of Parallel Continuous ProcessesDocument10 pagini07 - Production Planning and Scheduling of Parallel Continuous ProcessesAzat SuleimenovÎncă nu există evaluări

- Thesis With LogoDocument71 paginiThesis With LogoAnonymous 5oTiSrÎncă nu există evaluări

- Inventory Theory (Quantitative Techniques)Document41 paginiInventory Theory (Quantitative Techniques)Lexter Smith Albay100% (2)

- Dynamic Capacitated Lot-Sizing Problems: A Classification and Review of Solution ApproachesDocument31 paginiDynamic Capacitated Lot-Sizing Problems: A Classification and Review of Solution ApproachesezffsdgÎncă nu există evaluări

- Computers& Industrial EngineeringDocument10 paginiComputers& Industrial EngineeringNoldy SinsuÎncă nu există evaluări

- A Survey of Lot Sizing and Scheduling ModelsDocument10 paginiA Survey of Lot Sizing and Scheduling ModelsClebson CardosoÎncă nu există evaluări

- 1997 - GIRI, CHAUDHURI - International Journal of Systems Science - Heuristic Models For Deteriorating Items With Shortages and Time-Varying DDocument8 pagini1997 - GIRI, CHAUDHURI - International Journal of Systems Science - Heuristic Models For Deteriorating Items With Shortages and Time-Varying DVaibhav ChaudharyÎncă nu există evaluări

- Dynamic Optimization Model For Mining Equipment ReDocument11 paginiDynamic Optimization Model For Mining Equipment ReMantenimiento MineroÎncă nu există evaluări

- Project Based Learning Tools Development On Salt Hydrolysis Materials Through Scientific ApproachDocument5 paginiProject Based Learning Tools Development On Salt Hydrolysis Materials Through Scientific ApproachInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Effects of Formative Assessment On Mathematics Test Anxiety and Performance of Senior Secondary School Students in Jos, NigeriaDocument10 paginiEffects of Formative Assessment On Mathematics Test Anxiety and Performance of Senior Secondary School Students in Jos, NigeriaInternational Organization of Scientific Research (IOSR)100% (1)

- Philosophical Analysis of The Theories of Punishment in The Context of Nigerian Educational SystemDocument6 paginiPhilosophical Analysis of The Theories of Punishment in The Context of Nigerian Educational SystemInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- The Effect of Instructional Methods and Locus of Control On Students' Speaking Ability (An Experimental Study in State Senior High School 01, Cibinong Bogor, West Java)Document11 paginiThe Effect of Instructional Methods and Locus of Control On Students' Speaking Ability (An Experimental Study in State Senior High School 01, Cibinong Bogor, West Java)International Organization of Scientific Research (IOSR)Încă nu există evaluări

- Necessary Evils of Private Tuition: A Case StudyDocument6 paginiNecessary Evils of Private Tuition: A Case StudyInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Study The Changes in Al-Ahwaz Marshal Using Principal Component Analysis and Classification TechniqueDocument9 paginiStudy The Changes in Al-Ahwaz Marshal Using Principal Component Analysis and Classification TechniqueInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Geohydrological Study of Weathered Basement Aquifers in Oban Massif and Environs Southeastern Nigeria: Using Remote Sensing and Geographic Information System TechniquesDocument14 paginiGeohydrological Study of Weathered Basement Aquifers in Oban Massif and Environs Southeastern Nigeria: Using Remote Sensing and Geographic Information System TechniquesInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Youth Entrepreneurship: Opportunities and Challenges in IndiaDocument5 paginiYouth Entrepreneurship: Opportunities and Challenges in IndiaInternational Organization of Scientific Research (IOSR)100% (1)

- Students' Perceptions of Grammar Teaching and Learning in English Language Classrooms in LibyaDocument6 paginiStudents' Perceptions of Grammar Teaching and Learning in English Language Classrooms in LibyaInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Development of Dacum As Identification Technique On Job Competence Based-Curriculum in High Vocational EducationDocument5 paginiDevelopment of Dacum As Identification Technique On Job Competence Based-Curriculum in High Vocational EducationInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Child Mortality Among Teenage Mothers in OJU MetropolisDocument6 paginiChild Mortality Among Teenage Mothers in OJU MetropolisInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Factors Affecting Success of Construction ProjectDocument10 paginiFactors Affecting Success of Construction ProjectInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Enhancing Pupils' Knowledge of Mathematical Concepts Through Game and PoemDocument7 paginiEnhancing Pupils' Knowledge of Mathematical Concepts Through Game and PoemInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Need of Non - Technical Content in Engineering EducationDocument3 paginiNeed of Non - Technical Content in Engineering EducationInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Lipoproteins and Lipid Peroxidation in Thyroid DisordersDocument6 paginiLipoproteins and Lipid Peroxidation in Thyroid DisordersInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Comparison of Psychological Variables Within Different Positions of Players of The State Junior Boys Ball Badminton Players of ManipurDocument4 paginiComparison of Psychological Variables Within Different Positions of Players of The State Junior Boys Ball Badminton Players of ManipurInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Comparison of Selected Anthropometric and Physical Fitness Variables Between Offencive and Defencive Players of Kho-KhoDocument2 paginiComparison of Selected Anthropometric and Physical Fitness Variables Between Offencive and Defencive Players of Kho-KhoInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Advancing Statistical Education Using Technology and Mobile DevicesDocument9 paginiAdvancing Statistical Education Using Technology and Mobile DevicesInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Study of Effect of Rotor Speed, Combing-Roll Speed and Type of Recycled Waste On Rotor Yarn Quality Using Response Surface MethodologyDocument9 paginiStudy of Effect of Rotor Speed, Combing-Roll Speed and Type of Recycled Waste On Rotor Yarn Quality Using Response Surface MethodologyInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Microencapsulation For Textile FinishingDocument4 paginiMicroencapsulation For Textile FinishingInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Comparative Effect of Daily Administration of Allium Sativum and Allium Cepa Extracts On Alloxan Induced Diabetic RatsDocument6 paginiComparative Effect of Daily Administration of Allium Sativum and Allium Cepa Extracts On Alloxan Induced Diabetic RatsInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Auxin Induced Germination and Plantlet Regeneration Via Rhizome Section Culture in Spiranthes Sinensis (Pers.) Ames: A Vulnerable Medicinal Orchid of Kashmir HimalayaDocument4 paginiAuxin Induced Germination and Plantlet Regeneration Via Rhizome Section Culture in Spiranthes Sinensis (Pers.) Ames: A Vulnerable Medicinal Orchid of Kashmir HimalayaInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Core Components of The Metabolic Syndrome in Nonalcohlic Fatty Liver DiseaseDocument5 paginiCore Components of The Metabolic Syndrome in Nonalcohlic Fatty Liver DiseaseInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Comparison of Explosive Strength Between Football and Volley Ball Players of Jamboni BlockDocument2 paginiComparison of Explosive Strength Between Football and Volley Ball Players of Jamboni BlockInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Application of Xylanase Produced by Bacillus Megaterium in Saccharification, Juice Clarification and Oil Extraction From Jatropha Seed KernelDocument8 paginiApplication of Xylanase Produced by Bacillus Megaterium in Saccharification, Juice Clarification and Oil Extraction From Jatropha Seed KernelInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- A Review On Refrigerants, and Effects On Global Warming For Making Green EnvironmentDocument4 paginiA Review On Refrigerants, and Effects On Global Warming For Making Green EnvironmentInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Investigation of Wear Loss in Aluminium Silicon Carbide Mica Hybrid Metal Matrix CompositeDocument5 paginiInvestigation of Wear Loss in Aluminium Silicon Carbide Mica Hybrid Metal Matrix CompositeInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Parametric Optimization of Single Cylinder Diesel Engine For Specific Fuel Consumption Using Palm Seed Oil As A BlendDocument6 paginiParametric Optimization of Single Cylinder Diesel Engine For Specific Fuel Consumption Using Palm Seed Oil As A BlendInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Research Analysis On Sustainability Opportunities and Challenges of Bio-Fuels Industry in IndiaDocument7 paginiResearch Analysis On Sustainability Opportunities and Challenges of Bio-Fuels Industry in IndiaInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Circular PlatformDocument6 paginiCircular PlatformRamzi GameelÎncă nu există evaluări

- Practicals OS GTU For PracticeDocument34 paginiPracticals OS GTU For PracticeAashish JanardhananÎncă nu există evaluări

- Remedial Class NoticeDocument3 paginiRemedial Class NoticeAman BhardwajÎncă nu există evaluări

- Math - Ap - Periodical Test ReviewDocument5 paginiMath - Ap - Periodical Test ReviewMae OrtizÎncă nu există evaluări

- All Cases of HCF & LCMDocument10 paginiAll Cases of HCF & LCMmail.kaivalyasharma14Încă nu există evaluări

- Tran2019 PDFDocument10 paginiTran2019 PDFRamot Hamonangan AgusDian SitompulÎncă nu există evaluări

- Neowave Theory by Glenn Neely. Corrections. Rules To Spot A Flat and Zigzag. Variations of Corrections and Formal Logic RulesDocument12 paginiNeowave Theory by Glenn Neely. Corrections. Rules To Spot A Flat and Zigzag. Variations of Corrections and Formal Logic RulesSATISHÎncă nu există evaluări

- Business Research Methods: Problem Definition and The Research ProposalDocument29 paginiBusiness Research Methods: Problem Definition and The Research ProposalS- AjmeriÎncă nu există evaluări

- ECE 470 Introduction To Robotics Alternative Lab 4 and 5 Manual Spring 2020Document22 paginiECE 470 Introduction To Robotics Alternative Lab 4 and 5 Manual Spring 2020SELVAKUMAR RÎncă nu există evaluări

- A Miniature Cross-Coupled Wide Band Microstrip Bandpass FilterDocument3 paginiA Miniature Cross-Coupled Wide Band Microstrip Bandpass FilterAnil Pandey100% (1)

- Math IgcseDocument13 paginiMath IgcseminthantphoneÎncă nu există evaluări

- VelestDocument31 paginiVelestTanaya WahengbamÎncă nu există evaluări

- The "Big Bang" Is Just Religion Disguised As ScienceDocument6 paginiThe "Big Bang" Is Just Religion Disguised As ScienceSean BarryÎncă nu există evaluări

- 5000 Satoshi ScriptDocument3 pagini5000 Satoshi Scripthar08Încă nu există evaluări

- Formative Assessment TemplateDocument2 paginiFormative Assessment Templatehodaero BITÎncă nu există evaluări

- Quiz 2Document4 paginiQuiz 2Clash ClanÎncă nu există evaluări

- Chapter One - 1.1. - Geometry NotesDocument8 paginiChapter One - 1.1. - Geometry NotesKayse HusseinÎncă nu există evaluări

- Analytical Geometry, 1e 2D and 3D by Vittal, P. RDocument753 paginiAnalytical Geometry, 1e 2D and 3D by Vittal, P. RCatan Addicts100% (1)

- VHDL CodesDocument9 paginiVHDL CodesSaneesh KarayilÎncă nu există evaluări

- Fibre Reinforced CompositesDocument2 paginiFibre Reinforced CompositesDikshant HasbeÎncă nu există evaluări

- m2 CH 3 Binomial Theorem Supp ExDocument1 paginăm2 CH 3 Binomial Theorem Supp Exapi-303501215Încă nu există evaluări

- Practice Paper: I. Candidates Are Informed That Answer Sheet Comprises TwoDocument19 paginiPractice Paper: I. Candidates Are Informed That Answer Sheet Comprises TwoRashid Ibn AkbarÎncă nu există evaluări

- C. E. R. A. E: (Content, Experience, Reflection, Analysis and Evaluation)Document13 paginiC. E. R. A. E: (Content, Experience, Reflection, Analysis and Evaluation)Patricia NikolaÎncă nu există evaluări

- Methods Ws2 Answer KeyDocument2 paginiMethods Ws2 Answer KeybobÎncă nu există evaluări

- Circumference Lesson PlanDocument3 paginiCircumference Lesson Planapi-395816684Încă nu există evaluări

- K2 MathsDocument49 paginiK2 MathsNaina Mohamed HÎncă nu există evaluări

- Introduction To CrystallographyDocument25 paginiIntroduction To Crystallography坏豆腐Încă nu există evaluări

- Time, Temporal Geometry, and CosmologyDocument28 paginiTime, Temporal Geometry, and CosmologyclonejksÎncă nu există evaluări

- Mathematics: Circle and Its PartsDocument30 paginiMathematics: Circle and Its PartsDom Martinez100% (2)

- Xy-Graph: Ordered PairsDocument14 paginiXy-Graph: Ordered PairsmsooflooÎncă nu există evaluări

- The End of Craving: Recovering the Lost Wisdom of Eating WellDe la EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellEvaluare: 4.5 din 5 stele4.5/5 (80)

- Sully: The Untold Story Behind the Miracle on the HudsonDe la EverandSully: The Untold Story Behind the Miracle on the HudsonEvaluare: 4 din 5 stele4/5 (103)

- Highest Duty: My Search for What Really MattersDe la EverandHighest Duty: My Search for What Really MattersÎncă nu există evaluări

- Hero Found: The Greatest POW Escape of the Vietnam WarDe la EverandHero Found: The Greatest POW Escape of the Vietnam WarEvaluare: 4 din 5 stele4/5 (19)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaDe la EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaÎncă nu există evaluări

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindDe la EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindÎncă nu există evaluări

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyDe la EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyÎncă nu există evaluări

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestDe la EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestEvaluare: 4 din 5 stele4/5 (28)

- The Fabric of Civilization: How Textiles Made the WorldDe la EverandThe Fabric of Civilization: How Textiles Made the WorldEvaluare: 4.5 din 5 stele4.5/5 (57)

- A Place of My Own: The Architecture of DaydreamsDe la EverandA Place of My Own: The Architecture of DaydreamsEvaluare: 4 din 5 stele4/5 (242)

- Transformed: Moving to the Product Operating ModelDe la EverandTransformed: Moving to the Product Operating ModelEvaluare: 4 din 5 stele4/5 (1)

- Broken Money: Why Our Financial System is Failing Us and How We Can Make it BetterDe la EverandBroken Money: Why Our Financial System is Failing Us and How We Can Make it BetterEvaluare: 5 din 5 stele5/5 (3)

- The Weather Machine: A Journey Inside the ForecastDe la EverandThe Weather Machine: A Journey Inside the ForecastEvaluare: 3.5 din 5 stele3.5/5 (31)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationDe la EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationEvaluare: 4.5 din 5 stele4.5/5 (46)

- System Error: Where Big Tech Went Wrong and How We Can RebootDe la EverandSystem Error: Where Big Tech Went Wrong and How We Can RebootÎncă nu există evaluări

- Mini Farming: Self-Sufficiency on 1/4 AcreDe la EverandMini Farming: Self-Sufficiency on 1/4 AcreEvaluare: 4 din 5 stele4/5 (76)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDe la EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansÎncă nu există evaluări

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerDe la EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerEvaluare: 4.5 din 5 stele4.5/5 (54)

- Pale Blue Dot: A Vision of the Human Future in SpaceDe la EverandPale Blue Dot: A Vision of the Human Future in SpaceEvaluare: 4.5 din 5 stele4.5/5 (588)

- The Future of Geography: How the Competition in Space Will Change Our WorldDe la EverandThe Future of Geography: How the Competition in Space Will Change Our WorldEvaluare: 4.5 din 5 stele4.5/5 (5)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDe la EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterÎncă nu există evaluări

- Packing for Mars: The Curious Science of Life in the VoidDe la EverandPacking for Mars: The Curious Science of Life in the VoidEvaluare: 4 din 5 stele4/5 (1395)

- Reality+: Virtual Worlds and the Problems of PhilosophyDe la EverandReality+: Virtual Worlds and the Problems of PhilosophyEvaluare: 4 din 5 stele4/5 (24)

- How to Do Nothing: Resisting the Attention EconomyDe la EverandHow to Do Nothing: Resisting the Attention EconomyEvaluare: 4 din 5 stele4/5 (421)

- 35 Miles From Shore: The Ditching and Rescue of ALM Flight 980De la Everand35 Miles From Shore: The Ditching and Rescue of ALM Flight 980Evaluare: 4 din 5 stele4/5 (21)