Documente Academic

Documente Profesional

Documente Cultură

17ooc, by

Încărcat de

Fari PratomosiwiTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

17ooc, by

Încărcat de

Fari PratomosiwiDrepturi de autor:

Formate disponibile

THERMAL AGING OF OIL INSULATION COMPARING CONVENTIONAL AND

THERMALLY UPGRADED PAPERS

Vera Lucia d'hlmeida e Silva

CEPEL - Centro de Pesquisas de Energia Eletrica

C.P. 2754, 20001-970 Rio de Janeiro, Brasil

ABSTRACT

Oil-paper insulating system is widely used in electrical

eguipments and, even though aging can be affected by heating

of oil, one should consider that the rate of degradation of

the paper is the main factor for life assessments.

This paper reports on experiments on two conventional

and four thermally upgraded kraft papers and naphtenic

mineral insulating oil. These materials were aged, in

specially designed glass cells, at 125, 140, 155 and 17OoC,

between 100 and 4000 hr, under nitrogen atmosphere.

Degradation was evaluated by tests on papers and oil.

The results available to date are presented and

discussed.

INTRODUCTION

Degradation of oil-paper insulating system affects

directly eguipments aging and may be responsible for

failures, increased maintenance costs or loss of reliability

or availability.

However both paper and oil take part in eguipments

aging, paper determines the end of useful life.

Accelerated thermal aging of oil-paper insulating

systems was studied, comparing conventional and thermally

upgraded papers, and results obtained were analysed.

TEST PROCEDURE

Materia1s

- Four thermally upgraded insulating kraft papers, named A,

B, C and D.

456/D4

- Two conventional insulating kraft papers, named E and F.

- Mineral insulating oil of a naphtenic base, in accordance

with Brazilian Specification CNP 18/85.

Experimental ProcedureEl]

The accelerated thermal aging of the oil-paper

insulating system was conducted in specially designed glass

cells, under constant temperature and nitrogen atmosphere.

The conditions were: 125OC - 300, 600, 1200, 2400, 4800 hr;

14OoC - 100, 200, 400, 800, 1600, 3200 hr; 155OC - 100, 200,

400, 800, 1600 hr, for conventional papers and 14OoC - 150,

200, 300, 600, 800, 1000, 1200, 2400, 4800 hr; 155OC - 200,

400, 800, 1600, 2900, 3200hr; 17OoC - 100, 200, 400, 800,

1600 hr, for thermally upgraded papers.

For each aging test, paper samples were prepared wih six

pieces of 1.5 x 30 cm, for tensile strength and elongation

tests, and one piece of 24 x 27,5 cm for burstiing strength

and degree of polymerization (DP) tests. Each cell contains

these paper samples and 1700 ml of mineral insulating oil.

Paper samples were dried directly in the test cell at

8OoC during 16 hr, followed by 24 hr under vacuum at 105OC.

After drying, the samples were vacuum impregnated with

insulating oil that had been previously degassified and

dehumidified.

The test cells, thus prepared, were returned t o the oven

for the moisture equilibrium process, in a super dry

nitrogen atmosphere at 105OC for 24 hr, after which oil

samples were taken for moisture tests.

After each aging step the following tests were

conducted:

- insulating oil: moisture content, dissolved gas content, 2

- furfuraldehyde (FAL) content, neutralization number,

interfacial tension, dielectric breakdown dissipation

factor and color.

- insulating paper: tensile strength and elongation,

bursting strength and degree of polymerization.

Prior to the aging process, equally prepared samples

were tested to ascertain the initial values for paper and

oil. Nitrogen contents of new paper samples were also

determined.

457

RESULTS AND DISCUSSPONS

Too many test results were obtained and only the most

relevant are presented here.

The retention percentage of each paper property tested

was related to aging time, at different temperatures. From

these plots, paper end-point criterion of 80% of tensile

strength retention was taken. Corresponding criteria of

bursting strength, elongation and DP were also taken. After

construction of Arrhenius'curves for each paper, temperature

indexes (TI) were compared, as shown in Table I.

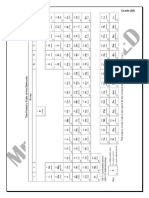

TABLE I

Temperature indexes of six oil-paper systems,

after accelerated thermal aging

I

Insulating Paper

I

I

Tensile

Strength

Elongation I

Bursting I

Strength I

FAL I

I ContentI

DP

Iin O i l I

I

,

1Initial I

4

,

IDesignationlNitrogenIInitial 1RetentionI TIIRetentionl TIIRetention1 TIIRetention: TI1 (ppm) I

!Content I DP

I

(8)

I

I

(8)

I

I (8)

I

I

(8)

1

:

I

I

I

(8)

~

3

I

,,

80

I1371

I

I 1090

2.90

1.65

I 1113

80

I1321

8

I - I - + ~ 1 _ ~ - 1 _ 1 - 4

1.20

~

80

I

~

0,22

0,ZB

I 911

1 951

80

i 1092

1-1

8 -I_

61

tC

I

!

,

I

63

63

<

1130:

I1231

66

0.05;

,

18-

I1051

0,051

&

I1081

(

I 941

I106I

I

0,051

50

I 531

I

I

38

___

99:

I

I_*-

I 881

I

0,5 1

58

I 941

76

1 951

31

1 951

44

I 991

I 581

52

I 861

35

55

,

8

1 841

62

n_ept

I1081

t

-1-1-If

36

73

,

_

60

8

t

I 851

I

-D

-1-1-I

I 60;

I

50

72

t

50

I

- 8

I

1

11321

I

,

_

(_Ipl_l-I

I1241

67

I1061

8

_

80

I 1226

69

I1071

I

I

,

_)-1_1-1

I 1254

b

I

1

72

I1111

60

I1331

,,

II

11341

I

80

~

61

I

I

I 1190

3,42

38

I

I

I_

#--I_

1.0 I

I

I

8,0

I 661

2,O 1

,,

I 911

8.0 I

I

I

I

I

I

All of the new paper samples were tested in accordance

with IEC 554 and the best mechanical properties were showed

by papers C and D.

The discussion will be focused on the FAL test, which is

the newest aging evaluation parameter. Figures 1 to 6 show

the relation of FAL content to aging time, for each paper

studied. FAL content values were obtained by high

performance liquid chromatography.

458

FIG2

- PAPER B

g 0.a

; I

2

FlL3

- PAPER C

0

155c

140 C

155c

17C C

0.15

01

0.10

i

[I

0.10

0.10

FIG4

- PAPER

r14UL

Fig.1 to 6-Relation of FAL content to aging time, with

papers A to F

Thermally upgraded papers A and B didn't show FAL

evolution with time.

Figures 7 to 12 show the correlation of FAL content in

oil and insulating paper DP, for each paper studied.

flG.7

- PAPER A

FIG.8

- PA

RB

* 140 C

155c

0.15

_I

0.05

..

a

I..

'bl"

.

~

FIG12

J 40

- PAPER F

..

155c

'bluk'

Fig.7 to 12-Relation of FAL content to DP of papers A to F

Comparative analysis of the data can be seen in Fig.13.

459

D!

0.

*\',

-..*__4

,D

b-=

E

INSULbTING PbPLR

Fig.13-Comparative analysis of TI, FAL and nitrogen contents

Temperature indexes showed to be similar for the four

properties studied and the lower dispersion was presented by

papers A, E and F.

Thermally upgraded papers showed higher TI than that

showed by conventional ones and coherent with nitrogen

contents: the higher nitrogen content, the higher TI.

FAL content at the end-point criterion also follows TI

obtained: papers with lower TI showed higher FAL contents in

oil.

CONCLUSIONS

However thermally upgraded papers with lower nitrogen

content showed the best initial mechanical properties, they

presented lower mechanical and chemical stability during

aging.

FAL content in oil follows TI obtained for papers

studied; the lower TI, the higher FAL evolution.

Correlation of FAL content in oil to aging time and

paper DP depends on the type and quality of paper studiedREFERENCES

[ll R. Morais and E. Engelstein, 10th Int. Conf. on Cond.

and Breakd. in Dielectric Liquids, France, 1990.

ACKNOWLEDGEMENT

This work is part of a research project of the

Transmission Department of ELETROBRAS, holding of Brazilian

Electrical Sector.

460

S-ar putea să vă placă și

- Polypropylene Practical GuideDocument40 paginiPolypropylene Practical Guidejotadislexia100% (1)

- 5.dissolved Gas Analysis (DGA) of Alternative Fluids For Power TransformersDocument10 pagini5.dissolved Gas Analysis (DGA) of Alternative Fluids For Power TransformersMuhamad FahrulÎncă nu există evaluări

- APITECH 03 DecryptedDocument23 paginiAPITECH 03 Decryptedjokerveloz100% (2)

- Photoelectric Effect NotesDocument3 paginiPhotoelectric Effect Notessaifi_786Încă nu există evaluări

- Thermodynamic Properties of Real Moist Air, Dry Air, Steam, Water, and Ice (RP-1485)Document27 paginiThermodynamic Properties of Real Moist Air, Dry Air, Steam, Water, and Ice (RP-1485)Caleb FalcoteloÎncă nu există evaluări

- HVT 5 Applications of Insulating Materials, 3Document6 paginiHVT 5 Applications of Insulating Materials, 3sahiiiiÎncă nu există evaluări

- Reduce Bicine Corrosion PDFDocument7 paginiReduce Bicine Corrosion PDFmahesh070Încă nu există evaluări

- Thermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualDe la EverandThermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualÎncă nu există evaluări

- 10.1007 - s13202 013 0051 4Document4 pagini10.1007 - s13202 013 0051 4Luis FloresÎncă nu există evaluări

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringDe la EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringÎncă nu există evaluări

- 99041-Prediction of Scale and CO2 Corrosion in Oil Field SystemsDocument16 pagini99041-Prediction of Scale and CO2 Corrosion in Oil Field SystemsdhireshmahajanÎncă nu există evaluări

- Distillation PDFDocument6 paginiDistillation PDFAmit SawantÎncă nu există evaluări

- A Study of Acrylic Dispersions Used in The Treatment of PaintingsDocument12 paginiA Study of Acrylic Dispersions Used in The Treatment of PaintingsMilica Stojanov100% (1)

- Pyrolysis of Waste Tires, A Modeling and Parameter Estimation Study Using Aspen Plus PDFDocument12 paginiPyrolysis of Waste Tires, A Modeling and Parameter Estimation Study Using Aspen Plus PDFJosé Miguel GonzálezÎncă nu există evaluări

- KAONG Elementary Heat Transfer LessonDocument9 paginiKAONG Elementary Heat Transfer Lessonjeraldine endeno100% (1)

- DemineralizationDocument26 paginiDemineralizationraraeiÎncă nu există evaluări

- Experimental Densities, Vapor Pressures, and Critical Point, and ADocument13 paginiExperimental Densities, Vapor Pressures, and Critical Point, and AAllah BakhshÎncă nu există evaluări

- Ea 934naDocument4 paginiEa 934nalacsmm982Încă nu există evaluări

- EnergyDocument16 paginiEnergyPooriÎncă nu există evaluări

- D1 - 111 - Cigre2012 - 1LAB000505 - Thermal Aging Study of Cellulosic Materials in Natural Ester Liquid For Hybrid Insulation SystemsDocument10 paginiD1 - 111 - Cigre2012 - 1LAB000505 - Thermal Aging Study of Cellulosic Materials in Natural Ester Liquid For Hybrid Insulation Systemsreza515heiÎncă nu există evaluări

- (283.15 To 353.15) K at Pressures Up To 25 Mpa: PGT Measurements and Eos Predictions of Glycol Ethers FromDocument6 pagini(283.15 To 353.15) K at Pressures Up To 25 Mpa: PGT Measurements and Eos Predictions of Glycol Ethers FromCarlos FerreraÎncă nu există evaluări

- PS2 - 1 - The Impact of Laminated Cellulosic Products On Transformer LifetimeDocument5 paginiPS2 - 1 - The Impact of Laminated Cellulosic Products On Transformer Lifetimegiovanni MarzoloÎncă nu există evaluări

- Advise 1Document15 paginiAdvise 1adlinkÎncă nu există evaluări

- Drying of Already Impregnated Oil - Paper InsulationDocument4 paginiDrying of Already Impregnated Oil - Paper InsulationBalajiÎncă nu există evaluări

- We're Going Global: The Impact of Product TemperatureDocument6 paginiWe're Going Global: The Impact of Product TemperaturebabushleshaÎncă nu există evaluări

- Art DIPE - 3Document6 paginiArt DIPE - 3Alex PintoiuÎncă nu există evaluări

- (283.15 To 353.15) K at Pressures Up To 25 MP A: PGT Measurements and Eos Predictions of Glycol Ethers FromDocument6 pagini(283.15 To 353.15) K at Pressures Up To 25 MP A: PGT Measurements and Eos Predictions of Glycol Ethers FromCarlos FerreraÎncă nu există evaluări

- PVC Plasticized with Alkyl Esters of Pinic AcidDocument3 paginiPVC Plasticized with Alkyl Esters of Pinic AcidDuzzysÎncă nu există evaluări

- Iupac Macro'83Document2 paginiIupac Macro'83htopaven4340Încă nu există evaluări

- Correlations For Predicting Oil Recovery by Steamflood: SPE-AIME, Standard Oil Co. of CaliforniaDocument8 paginiCorrelations For Predicting Oil Recovery by Steamflood: SPE-AIME, Standard Oil Co. of CaliforniaVasundhara SinghÎncă nu există evaluări

- Assessment of J Oil As InsulatingDocument16 paginiAssessment of J Oil As InsulatingYaru HageÎncă nu există evaluări

- Performance of Aluminium Trays For SteriDocument18 paginiPerformance of Aluminium Trays For Steridavid catur widodoÎncă nu există evaluări

- Tech Data 8APPENDIXAPolymerQuenchingDocument13 paginiTech Data 8APPENDIXAPolymerQuenchingBalram JiÎncă nu există evaluări

- Ijct 25 (4) 336-344Document9 paginiIjct 25 (4) 336-344hari reddyÎncă nu există evaluări

- Application of Vegetable Oil-Based Insulating Fluids To Hermetically Sealed Power TransformersDocument8 paginiApplication of Vegetable Oil-Based Insulating Fluids To Hermetically Sealed Power TransformersR0B0T2013Încă nu există evaluări

- D4714 PDFDocument4 paginiD4714 PDFHuy NguyenÎncă nu există evaluări

- Pressure-Volume-Temperature Behavior of High Density PolyethyleneDocument9 paginiPressure-Volume-Temperature Behavior of High Density PolyethyleneRaúl AponteÎncă nu există evaluări

- DSC Studies of Tactic Polypropylenes: The Correlation of Polymer Stereochemistry With Thermal PropertiesDocument20 paginiDSC Studies of Tactic Polypropylenes: The Correlation of Polymer Stereochemistry With Thermal PropertiesNaufal ArisÎncă nu există evaluări

- Burfield1990 PDFDocument20 paginiBurfield1990 PDFNaufal ArisÎncă nu există evaluări

- Isothermal Calorimetry LULEADocument36 paginiIsothermal Calorimetry LULEAMike2322100% (1)

- Twenty Years of Progress with TEG DehydrationDocument5 paginiTwenty Years of Progress with TEG Dehydrationsejerson07Încă nu există evaluări

- Comparation of Oxidation Stability in Natural Insulating OilsDocument3 paginiComparation of Oxidation Stability in Natural Insulating OilsRomán M Martín del C100% (1)

- Low chain esters of stearic acid as phase change materials for thermal energy storage in buildingsDocument12 paginiLow chain esters of stearic acid as phase change materials for thermal energy storage in buildingsfabio1199Încă nu există evaluări

- Degradation of Insulating Materials of TransformerDocument6 paginiDegradation of Insulating Materials of TransformerPaulomario RemuzgoÎncă nu există evaluări

- Isothermal Crystallization of Isotactic Poly (Propylene) Studied by Superfast Calorimetry - 2007 - Macromolecular Rapid CommunicationsDocument7 paginiIsothermal Crystallization of Isotactic Poly (Propylene) Studied by Superfast Calorimetry - 2007 - Macromolecular Rapid CommunicationsLubomirBenicekÎncă nu există evaluări

- Simulation Study For Production of Hydrocarbons From WasteDocument9 paginiSimulation Study For Production of Hydrocarbons From WasteAJER JOURNALÎncă nu există evaluări

- DSC and Torque Rheometry Determine Thermoset ProcessingDocument7 paginiDSC and Torque Rheometry Determine Thermoset Processinggunawan refiadiÎncă nu există evaluări

- IEEE-010 Aging Paper InsDocument6 paginiIEEE-010 Aging Paper InsAndri Sembiring MelialaÎncă nu există evaluări

- Appendix 1: Pressure Calibration of 12.7 MM Diameter Piston-Cylinder AssembliesDocument8 paginiAppendix 1: Pressure Calibration of 12.7 MM Diameter Piston-Cylinder AssembliesSam SalasamÎncă nu există evaluări

- Poster Expo Quim I A 2008Document1 paginăPoster Expo Quim I A 2008Steven ObrienÎncă nu există evaluări

- VASCONCELLOS, V - Artigo - 2018Document10 paginiVASCONCELLOS, V - Artigo - 2018RichardÎncă nu există evaluări

- Pierce 1991Document7 paginiPierce 1991Anonymous sAmJfcVÎncă nu există evaluări

- 11 - Thermal Oxidation Stability of Aviation Turbine Fuels ASTMDocument5 pagini11 - Thermal Oxidation Stability of Aviation Turbine Fuels ASTMmrjevinÎncă nu există evaluări

- PDFDocument6 paginiPDFMuttanna KadalÎncă nu există evaluări

- Aging of Cellulose at TransformerDocument7 paginiAging of Cellulose at TransformerluispaloÎncă nu există evaluări

- 3527303855Document6 pagini3527303855marraezÎncă nu există evaluări

- SCE Research Paper PDFDocument12 paginiSCE Research Paper PDFmuoi2002Încă nu există evaluări

- Heat Capacity and Thermodynamic Properties of Poly (Vinyl Chloride)Document10 paginiHeat Capacity and Thermodynamic Properties of Poly (Vinyl Chloride)alireza198Încă nu există evaluări

- Chemical Degradation of Cellulosic Insulation Paper For Power TransformersDocument4 paginiChemical Degradation of Cellulosic Insulation Paper For Power TransformersFari PratomosiwiÎncă nu există evaluări

- Water-Soluble Acidity or Alkalinity of Paper: Standard Test Method ForDocument3 paginiWater-Soluble Acidity or Alkalinity of Paper: Standard Test Method ForAngel ValladaresÎncă nu există evaluări

- Caking: An Hditiiig For' 1%'otwtimDocument4 paginiCaking: An Hditiiig For' 1%'otwtimperezru_20006444Încă nu există evaluări

- Energies10 05 2018Document18 paginiEnergies10 05 2018mohamedalimami852Încă nu există evaluări

- CIRED2011 1253 FinalDocument3 paginiCIRED2011 1253 FinalSellappan MuthusamyÎncă nu există evaluări

- Barrel Temperature Profiles ResinsDocument6 paginiBarrel Temperature Profiles ResinsVitor PachecoÎncă nu există evaluări

- Indonesia Solar Power Mapping Study Using Secondary Data Paulus Agus Winarso Supriadi LeginoDocument7 paginiIndonesia Solar Power Mapping Study Using Secondary Data Paulus Agus Winarso Supriadi LeginoFari PratomosiwiÎncă nu există evaluări

- HVT 7 Pedrow Measurement o High Voltages and CurrentsDocument5 paginiHVT 7 Pedrow Measurement o High Voltages and CurrentsFari PratomosiwiÎncă nu există evaluări

- 04591226Document7 pagini04591226Fari PratomosiwiÎncă nu există evaluări

- HVT 7 Measurement of HVDocument20 paginiHVT 7 Measurement of HVFari PratomosiwiÎncă nu există evaluări

- Electric Breakdown in Gases: Department of Electric Power EngineeringDocument30 paginiElectric Breakdown in Gases: Department of Electric Power EngineeringFari PratomosiwiÎncă nu există evaluări

- ManualDocument221 paginiManualFari PratomosiwiÎncă nu există evaluări

- Mineral Oil TransformersDocument9 paginiMineral Oil TransformersAnonymous 9VcxlFErfÎncă nu există evaluări

- Mineral Oil TransformersDocument9 paginiMineral Oil TransformersAnonymous 9VcxlFErfÎncă nu există evaluări

- Materials in High Voltage TechnologyDocument27 paginiMaterials in High Voltage TechnologyFari PratomosiwiÎncă nu există evaluări

- Dynamic Properties of Dielectrics E F (T) : P + P (T) 0 P (T) (P P)Document24 paginiDynamic Properties of Dielectrics E F (T) : P + P (T) 0 P (T) (P P)Fari PratomosiwiÎncă nu există evaluări

- HVT 6 Pedrow OvervoltagesDocument26 paginiHVT 6 Pedrow OvervoltagesFari PratomosiwiÎncă nu există evaluări

- Introduction To Power SystemsDocument21 paginiIntroduction To Power SystemsPhil KerrÎncă nu există evaluări

- Surface DischargesDocument18 paginiSurface DischargesFari PratomosiwiÎncă nu există evaluări

- Electric Fields: - Exact Methods - Approximate Solutions - Computer SimulationsDocument17 paginiElectric Fields: - Exact Methods - Approximate Solutions - Computer SimulationsFari PratomosiwiÎncă nu există evaluări

- The Invisible Supply of Reliable Power Power Cables MV, HV & EhvDocument44 paginiThe Invisible Supply of Reliable Power Power Cables MV, HV & EhvFari Pratomosiwi100% (1)

- HVT 4 Breakdown in Liquids ChalmersDocument16 paginiHVT 4 Breakdown in Liquids ChalmersFari PratomosiwiÎncă nu există evaluări

- HVT 7 Pedrow Insulation CoordinationDocument4 paginiHVT 7 Pedrow Insulation CoordinationFari PratomosiwiÎncă nu există evaluări

- HVT 2 Electrical Breakdown in Gases - Part2 From Pedrow Washington StateDocument16 paginiHVT 2 Electrical Breakdown in Gases - Part2 From Pedrow Washington StateFari PratomosiwiÎncă nu există evaluări

- HVT 3 Conduction N Breakdown in Solids PedrowDocument12 paginiHVT 3 Conduction N Breakdown in Solids PedrowFari PratomosiwiÎncă nu există evaluări

- HVT 6 Generation of HV Part1Document7 paginiHVT 6 Generation of HV Part1Fari PratomosiwiÎncă nu există evaluări

- HVT 6 Generation of HV Part2 PDFDocument19 paginiHVT 6 Generation of HV Part2 PDFFari PratomosiwiÎncă nu există evaluări

- HVT 2 Electrical Breakdown in Gases - Part1Document11 paginiHVT 2 Electrical Breakdown in Gases - Part1Fari PratomosiwiÎncă nu există evaluări

- Maintain High-Voltage BushingsDocument10 paginiMaintain High-Voltage BushingsNoé Rafael Colorado SósolÎncă nu există evaluări

- 1304 5516Document22 pagini1304 5516Fari PratomosiwiÎncă nu există evaluări

- HV BushingsDocument5 paginiHV BushingssabrahimaÎncă nu există evaluări

- F 048 CHM F PDFDocument5 paginiF 048 CHM F PDFFari PratomosiwiÎncă nu există evaluări

- Use of The BRESSER MikroCam AdaptersDocument2 paginiUse of The BRESSER MikroCam AdaptersFari PratomosiwiÎncă nu există evaluări

- B 049 Wie F PDFDocument4 paginiB 049 Wie F PDFFari PratomosiwiÎncă nu există evaluări

- Numerical Modelling of A Direct Contact Condensation Experiment Using The AIAD FrameworkDocument25 paginiNumerical Modelling of A Direct Contact Condensation Experiment Using The AIAD FrameworkAmin AlAhmadyÎncă nu există evaluări

- PMT HPS SmartSensors Analytical Instruments BrochureDocument8 paginiPMT HPS SmartSensors Analytical Instruments BrochureSharad GargÎncă nu există evaluări

- Statistical Mechanics Lecture Notes (2006), L5Document11 paginiStatistical Mechanics Lecture Notes (2006), L5OmegaUserÎncă nu există evaluări

- Chemical Engineering Mass Transfer NotesDocument19 paginiChemical Engineering Mass Transfer NotesLebohang Czar NkuÎncă nu există evaluări

- Biology Notes - WaterDocument1 paginăBiology Notes - WaterHilary YuÎncă nu există evaluări

- PHYSICAL CHEMISTRY-phase Diagram 3 ComponentsDocument22 paginiPHYSICAL CHEMISTRY-phase Diagram 3 ComponentsMuhammad YanuarÎncă nu există evaluări

- Air Cycle Refrigeration SystemsDocument12 paginiAir Cycle Refrigeration SystemsginupaulÎncă nu există evaluări

- GAC Regeneration Via FentonDocument235 paginiGAC Regeneration Via FentonNelson EnviromatchÎncă nu există evaluări

- AAR Newsletter August2015 006 PDFDocument24 paginiAAR Newsletter August2015 006 PDFAnil KumarÎncă nu există evaluări

- Density of Liquid MercuryDocument2 paginiDensity of Liquid MercuryQuốc ThắngÎncă nu există evaluări

- 2f6a9970-a13a-4b69-89e5-de446c92af3c-1712045056045-4102607658133849 (2)Document44 pagini2f6a9970-a13a-4b69-89e5-de446c92af3c-1712045056045-4102607658133849 (2)chaitubudatiÎncă nu există evaluări

- Ch. 1 Particulate Nature of MatterDocument10 paginiCh. 1 Particulate Nature of MatterهندÎncă nu există evaluări

- Process For Preparing Rhodium Nitrate Solution.Document3 paginiProcess For Preparing Rhodium Nitrate Solution.Richard.nlÎncă nu există evaluări

- Nonlinear Fiber Optics: Its History and Recent ProgressDocument10 paginiNonlinear Fiber Optics: Its History and Recent ProgressEwerton Gustavo Soares GomesÎncă nu există evaluări

- Chapter 11 Powerpoint LDocument53 paginiChapter 11 Powerpoint LKhaleq MohammadÎncă nu există evaluări

- Chapter (2) Part (1) (PN Junction Diode)Document20 paginiChapter (2) Part (1) (PN Junction Diode)Ahmed SalehÎncă nu există evaluări

- UNIT 4 - T V NGDocument7 paginiUNIT 4 - T V NGKiều TrangÎncă nu există evaluări

- PaperLUBMAT FinalDocument7 paginiPaperLUBMAT FinalluisA1923Încă nu există evaluări

- Bloch Electrons in SSPDocument6 paginiBloch Electrons in SSPThushanan AnanthalingamÎncă nu există evaluări

- The Kinetic Energy of The Recoil ElectronDocument1 paginăThe Kinetic Energy of The Recoil ElectronJu KaÎncă nu există evaluări

- Thermo LabDocument2 paginiThermo Labmuhyideen6abdulganiyÎncă nu există evaluări

- Analysisof Spectra BRUKERDocument916 paginiAnalysisof Spectra BRUKERscarllee rogerÎncă nu există evaluări

- MindmapDocument1 paginăMindmapSudhish ThapaÎncă nu există evaluări

- Western Mindanao Chemistry WorksheetDocument2 paginiWestern Mindanao Chemistry WorksheetArvhenn BarcelonaÎncă nu există evaluări

- D399DDocument5 paginiD399DHilarie Jonathan100% (1)