Documente Academic

Documente Profesional

Documente Cultură

Process Pipework Vibration

Încărcat de

pgltuDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Process Pipework Vibration

Încărcat de

pgltuDrepturi de autor:

Formate disponibile

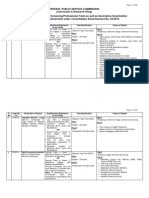

PROCESS PIPEWORK

Understanding

Vibration-Induced

Pipework Failure

Neil Parkinson

ibration induced fatigue of process

piping systems is an important and

fundamental failure mechanism. Data

published by the UKs Health & Safety

Executive (HSE) for the offshore industry has

shown that in the UK sector of the North Sea,

fatigue and vibration failures account for 21% of all

hydrocarbon releases. Although overall statistics

are not available for onshore facilities, available

data for individual plants indicates that in Western

Europe, between 10-15% of pipework failures are caused by

vibration induced fatigue. Neil Parkinson, technical director

at asset integrity specialist AV Technology Ltd (AVT),

explains the six phases in understanding, correcting and

preventing vibration-induced pipework failure.

Based on the Energy Institute publication Guidelines

for the Avoidance of Vibration Induced Fatigure Failure

in Process Pipework*, current best practice is aimed at

minimising the risk of incurring loss of containment from

vibration-induced failures. An enhanced and expanded

version of the former Marine Technology Directorate

Guidelines (1999), the document plays a key role in

Unsupported SBC, gas refinery

Visco-elastic damper

maintaining integrity in the design and maintenance of

process pipework within the oil, gas and petrochemical

industries.

The Energy Institute guidelines break down

into two main scenarios proactive and reactive

assessments and aim to ensure compliance with

statutory duty, improve safety and reliability, reduce

liability from leakeage, and minimise plant downtime.

Proactive assessments can be used to routinely

evaluate all pipework on a site, whether existing or

planned, to ensure that best practice has been adopted

and to identify possible areas of concern. Reactive

assessments follow, and are used to further investigate

known vibration issues or troubleshoot actual failures

within both mainline pipework as well as small bore

connections (SBCs). There are six key phases to

achieving pipework vibration assessments in line with

requirements of the guidelines:

Qualitative assessment

Visual assessment

Basic vibration monitoring

Specialist measurement techniques

Specialist predictive techniques

Corrective actions

The qualitative assessment phase is perhaps the

most challenging to implement and involves numerous

calculations for assessing the likelihood of encountering

a vibration-induced fatigue issue on either an existing

or planned plant. This assessment takes into account

many relevant factors, from fluid energy, flow velocities

and cyclic operation to the construction quality of

infrastructure including process machinery and types

of valves. It also assesses the chance of flashing or

cavitation, and includes a calculation process for

scoring likely excitation factors which are combined

with conditional and operational factors to predict the

ME | Mar/Apr 2014 | 31

PROCESS PIPEWORK

Example before

bracing

likelihood of failure (LOF) for each pipe branch.

Visual inspection is a quick and effective method

for identifying potential areas for concern. Many pipework

vibration problems are simply the result of operators

not following recommended good practice, and visual

inspection by skilled assessors can quickly flag up areas

for improvement relating to pipe infrastructure. This may

include installing more effective pipe supports or replacing

worn or damaged supports, proper bracing of SBCs,

avoiding fretting and poor geometry, and allowing for

thermal expansion of tubing.

The basic piping vibration measurement phase

identifies areas of concern based on measured values

of pipework vibration. In this phase specialist engineers

will first use a single axis accelerometer connected to

a portable data collector to take initial vibration levels,

ranging from 1-300 Hz. These measurements are

presented as vibration amplitude versus frequency and

enable the vibration to be classified as acceptable, concern

or problem, based on comparison with assessment criteria

in the Energy Institute guidelines.

If vibration is assessed as being at a concern or

problem level, or for pipework with a higher frequency

vibration of more than 300 Hz, the next phase used by

vibration engineers is based on specialist measurement

techniques. Here, a variety of more in-depth tests can

be deployed depending on need, including: dynamic strain

measurement and fatigue analysis; experimental modal

analysis; operating deflection shape analysis; and dynamic

pressure (pulsation) measurement. In addition, engineers

can implement specialist predictive techniques, applying

sophisticated tools and modelling to provide a more

detailed assessment of the dynamics of specific pipelines

throughout their lifecycles. A high percentage of the work

carried out by our own special projects division is

concerned with on-site measurements of dynamic strain

and vibration data, using multi-channel instrumentation

systems together with the previously measured data.

32 | Mar/Ap

May/June

2014

2011

| ME

| ME

Specialist predictive techniques include finite element

analysis (FEA), computational fluid dynamics, and pulsation

and surge analysis.

The final stage of any pipework assessment is to

recommend corrective actions to reduce vibration levels

and the likelihood of future vibration-induced fatigue

failures. These actions vary from improving the support

infrastructure around pipework including bracing and

dampening, or modifying the process conditions themselves

to reduce fluid loadings.

The design of practical and appropriate corrective

actions is important in achieving cost effective yet thorough

solutions, and often utilises FEA techniques to predict the

effect of remedial repairs, alongside CAD software for

mechanical design of supports and bracing systems.

Vibration in pipework can be affected by a number

of direct and indirect factors, not limited to the pipework

itself but also including the adjacent support structures and

buildings. It is therefore vital to develop a comprehensive

overview of vibration patterns in order to recommend

constructive improvements. Strain gauging and FEA are

powerful tools in this analysis process and although these

are often perceived as being distinct and alternative

assessment technologies, AVT has long recognised the

power of combining practical strain gauge work with

theoretical FEA.

While FEA models can provide important predictions

of stress, displacement and frequency, results can often

be unreliable unless validated with actual in-service data

such as strain measurements. Conversely, while actual

strain gauge data can yield accurate information on

stress amplitudes and fatigue, they are generally limited

to measurements at just a few positions along the line

therefore not giving a complete three-dimensional picture

of the modal behaviour of a structure.

avtechnology.co.uk

* 2nd edition 2008, current edition. ISBN 978 0 85293 453 1.

NB. Neil

Parkinson is

delivering a

seminar at the

forthcoming

Plant & Asset

Management Exhibition on Tuesday 8 April. He will

be outlining recommended vibration assessment

methods; suggesting corrective actions for many

common problems to help reduce the risk of major

incidents caused by pipework vibration; as well as

underpinning HSE responsibilities under the COMAH

and Offshore Installations (Safety Case) Regulations

2005 (OSCR). For further information and to register

visit maintenanceuk-expo.com

Wish to Comment?

Find this article at maintenanceonline.co.uk and at

the end of the editorial there is the option to add a

comment eg Was it relevant?, Can you add to it?

S-ar putea să vă placă și

- Numerical Simulation On Dilute Phase Pneumatic TransportDocument92 paginiNumerical Simulation On Dilute Phase Pneumatic TransportpgltuÎncă nu există evaluări

- Belzona High Performance Linings For Storage Tanks: Guide Only Contact Belzona For Specific Chemicals Zero WastageDocument2 paginiBelzona High Performance Linings For Storage Tanks: Guide Only Contact Belzona For Specific Chemicals Zero WastagepgltuÎncă nu există evaluări

- Pressure Temp Rating Cast IronDocument1 paginăPressure Temp Rating Cast IronpgltuÎncă nu există evaluări

- FBV 2Document1 paginăFBV 2pgltuÎncă nu există evaluări

- FBV 1Document1 paginăFBV 1pgltuÎncă nu există evaluări

- Pipe Size For ACDocument8 paginiPipe Size For ACLamii BedoÎncă nu există evaluări

- Lightning and Standard 90.1Document2 paginiLightning and Standard 90.1pgltuÎncă nu există evaluări

- Tank Jet MixersDocument2 paginiTank Jet MixersGabriela Axinte100% (1)

- Protective Coating For Surfaces Operating Under Immersion: Belzona® 5811Document2 paginiProtective Coating For Surfaces Operating Under Immersion: Belzona® 5811pgltuÎncă nu există evaluări

- BS 5045-2 Transportable Gas ContainersDocument48 paginiBS 5045-2 Transportable Gas Containerspgltu0% (1)

- HakDocument4 paginiHakpgltuÎncă nu există evaluări

- 1998 V3 No2 52585452551Document12 pagini1998 V3 No2 52585452551pgltuÎncă nu există evaluări

- Horizontal Directional DrillingDocument4 paginiHorizontal Directional DrillingpgltuÎncă nu există evaluări

- In-House EngineeringDocument4 paginiIn-House EngineeringpgltuÎncă nu există evaluări

- Calculating Condensate Load For Steam Tracer LinesDocument3 paginiCalculating Condensate Load For Steam Tracer LinespgltuÎncă nu există evaluări

- Directional Drilling: Trenchless TechnologyDocument2 paginiDirectional Drilling: Trenchless TechnologypgltuÎncă nu există evaluări

- Mini Jet Directional Drilling: Trenchless TechnologyDocument2 paginiMini Jet Directional Drilling: Trenchless TechnologypgltuÎncă nu există evaluări

- Aço Sa 537 cl1Document23 paginiAço Sa 537 cl1pcorreia68100% (1)

- Auger Drillings and Impact RammingDocument4 paginiAuger Drillings and Impact RammingpgltuÎncă nu există evaluări

- Notes On Two Phase Flow, Boiling Heat Transfer, and Boiling Crises in Pwrs and BwrsDocument34 paginiNotes On Two Phase Flow, Boiling Heat Transfer, and Boiling Crises in Pwrs and Bwrsمحمد سالمÎncă nu există evaluări

- R 091825471Document5 paginiR 091825471pgltuÎncă nu există evaluări

- Quality 23Mnb4: Lucefin GroupDocument1 paginăQuality 23Mnb4: Lucefin GrouppgltuÎncă nu există evaluări

- Wedge Gate ValvesDocument4 paginiWedge Gate ValvespgltuÎncă nu există evaluări

- Cast Steel Gate Valves: Class 600 - Outside Screw & Yoke - Flexible Wedge DiscDocument1 paginăCast Steel Gate Valves: Class 600 - Outside Screw & Yoke - Flexible Wedge DiscpgltuÎncă nu există evaluări

- 1.alignment of PipeDocument2 pagini1.alignment of Pipevuong100% (1)

- MinWool PipeDocument4 paginiMinWool PipepgltuÎncă nu există evaluări

- Slug FlowDocument42 paginiSlug FlowTochi Krishna Abhishek100% (1)

- LappcDocument56 paginiLappcpgltuÎncă nu există evaluări

- DZL Series of Steam Boiler AsDocument2 paginiDZL Series of Steam Boiler AspgltuÎncă nu există evaluări

- Summary ISO TR 15608 Metallic Materials Grouping SystemDocument4 paginiSummary ISO TR 15608 Metallic Materials Grouping SystemV SwamiÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Chapter One - Fundamental of Transport and Highway EngineeringDocument30 paginiChapter One - Fundamental of Transport and Highway Engineeringmollalignm100% (1)

- HAT Series Air Circuit Breaker Hyundai ElectricDocument67 paginiHAT Series Air Circuit Breaker Hyundai Electricthanhlangdai67% (6)

- ARCA Fly ReglerInstr GBDocument6 paginiARCA Fly ReglerInstr GBavikbhaiÎncă nu există evaluări

- Tubes and PipesDocument40 paginiTubes and PipesRamazan Erdinç100% (1)

- Resume & CV FakhruddinDocument3 paginiResume & CV FakhruddinnuelyabastaÎncă nu există evaluări

- Engineering Project Management PDFDocument401 paginiEngineering Project Management PDFLuis Carlos Ayllón Escobar100% (3)

- ZDocument265 paginiZAdal ContrerasÎncă nu există evaluări

- Tolerance and FitsDocument36 paginiTolerance and Fitsdevin wibowoÎncă nu există evaluări

- Suitability of Fixed Base and Pinned Base PEB Structure With Pile FoundationDocument4 paginiSuitability of Fixed Base and Pinned Base PEB Structure With Pile FoundationKarthik SgÎncă nu există evaluări

- Green Energy BricksDocument8 paginiGreen Energy BricksSriram NandipatiÎncă nu există evaluări

- A Prototype Construction Duration: Estimating System (CODES) For Mid-Rise Building ConstructionDocument57 paginiA Prototype Construction Duration: Estimating System (CODES) For Mid-Rise Building ConstructionAdonis AlabiÎncă nu există evaluări

- UPSC ESE Mechanical Subject Wise Weightage 2024 - All Exam ReviewDocument4 paginiUPSC ESE Mechanical Subject Wise Weightage 2024 - All Exam Reviewlalit tyagiÎncă nu există evaluări

- Iec 44-2Document83 paginiIec 44-2Munkhbaatar ShagdarsurenÎncă nu există evaluări

- Combined Ad No 4Document66 paginiCombined Ad No 4HassanÎncă nu există evaluări

- Workshop On Staad Pro PDFDocument4 paginiWorkshop On Staad Pro PDFankurshah1986Încă nu există evaluări

- Lpower Design Method UPFDocument12 paginiLpower Design Method UPFumeshÎncă nu există evaluări

- Transcript PattranithDocument1 paginăTranscript Pattranithapi-598948089Încă nu există evaluări

- Wbs and Obs-ModelDocument1 paginăWbs and Obs-ModelJonel TaburaÎncă nu există evaluări

- Electrical InstallationDocument71 paginiElectrical Installationpemma4958Încă nu există evaluări

- Structural Design of g+4 Mixeduse Building and Software DevelopmentDocument343 paginiStructural Design of g+4 Mixeduse Building and Software DevelopmentyimamÎncă nu există evaluări

- Crash Cushion Selection ProcedureDocument4 paginiCrash Cushion Selection ProcedureKOLD News 13Încă nu există evaluări

- Gravity DamDocument50 paginiGravity DamSajid Nazir100% (5)

- Mecart BrochureDocument20 paginiMecart BrochureDineshÎncă nu există evaluări

- As 2327.1-2003 Composite Structures - Simply Supported BeamsDocument129 paginiAs 2327.1-2003 Composite Structures - Simply Supported BeamsMikeChanÎncă nu există evaluări

- Ge6075 - Professional Ethics in Engineering: 2 Marks Questions and AnswersDocument16 paginiGe6075 - Professional Ethics in Engineering: 2 Marks Questions and Answerseee2014.rvsÎncă nu există evaluări

- Mitsubishi Robot Catalog.L (NA) 09051ENG ADocument16 paginiMitsubishi Robot Catalog.L (NA) 09051ENG Ack_peyÎncă nu există evaluări

- English For Chemical EngineerDocument94 paginiEnglish For Chemical EngineerKresna Thufail AÎncă nu există evaluări

- CE 416 Prestressed Concrete Sessional (Lab Manual)Document64 paginiCE 416 Prestressed Concrete Sessional (Lab Manual)julesÎncă nu există evaluări

- .Power Quality Improvement in Power Distribution System Using D-STATCOMDocument5 pagini.Power Quality Improvement in Power Distribution System Using D-STATCOMMuhammad AzisÎncă nu există evaluări

- Material Testing Quality ControlDocument22 paginiMaterial Testing Quality Controlsarbjeet singhÎncă nu există evaluări