Documente Academic

Documente Profesional

Documente Cultură

Shrimp Farming in Indonesia

Încărcat de

Hana KhalidaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Shrimp Farming in Indonesia

Încărcat de

Hana KhalidaDrepturi de autor:

Formate disponibile

Production

Shrimp Farming in Indonesia

Evolving Industry

Responds to

Varied Issues

Summary:

Indonesian

shrimpfarming practices vary

somewhat from region

to region depending on

the local conditions and

financial pressures. In

general, however, the

introduction of SPF L.

vannamei to Indonesia

prompted moves toward less water exchange, higher stocking

densities, greater biosecurity, and the use

of concrete- or HDPElined ponds.

Copyright 2005, Global Aquaculture Alliance. Do not reproduce without permission.

Nyan Taw, Ph.D.

Senior Technical Advisor/Vice President

P.T. Central Pertiwi Bahari

SHS Building, Second Floor

Jl Ancol Barat Block A5E No.10

Jakarta, Indonesia

nyan.taw@cpbahari.com

nyantaw@yahoo.com

Water Systems

About five variations of recirculation and flowthough water systems are used by the shrimp farms in

Indonesia. Most were developed during the late 1980s and

early 1990s before the emergence of various viral diseases in the mid-1990s. Since then, many farms have been

modified with reservoirs and incoming/outgoing water

treatment systems.

Recirculation

Outside Indonesia, farms like the Red Sea Shrimp

Farm in Saudi Arabia and Belize Aquaculture in Belize

practice very efficient water utilization with a balance of

reservoirs, production ponds, and settling basins. In Indonesia, the farm design that most closely resembles the

above examples is operated by the Charoen Pokphand

group at P.T. Central Pertiwi Bahari (CPB) in Lampung,

South Sumatra.

The farm operates on a modular basis, where each

module consists of 40-60 square, 0.5-ha ponds with its

own reservoirs and effluent treatment ponds, including a

recirculating canal from the production ponds that flows

to the sedimentation ponds. The water surface area of

The shrimp-farming industry

developed strongly in Indonesia in

the late 1980s, initially in East Java.

Specific pathogen-free (SPF) pacific

white shrimp, Litopenaeus vannamei, were introduced in Indonesia

in 2002. Now shrimp farming has

spread throughout the country,

from Sumbawa to the east and

South Sumatra to the west to Kalimantan, Sulawesi, and Maluku to

the north.

Indonesian shrimp-farming practices vary from region to region depending on the environmental conditions and financial pressures. As At the P.T. Central Pertiwi Bahari farm in Lampung, production modules cycle

in other major shrimp-farming water from clusters of growout ponds (top) to treatment reservoirs (foreground).

countries, the Indonesian industry

has evolved due to environmental

the reservoirs/sedimentation ponds is 20-25% that of the

and human health issues (mangroves, effluents, antibiproduction ponds.

otics, chemicals), as well as such social, political, legal,

This arrangement was a possible factor during disand economic elements as antidumping and bioterrorease outbreaks after facility start-up. Since mid-2001,

ism. The production technology has also evolved due to

the farm systems have been redesigned with minimum

the effects of bacterial and viral diseases, new technoloor zero water exchange at certain periods of the culgies, and changing market demands.

ture cycle.

GLOBAL AQUACULTURE ADVOCATE

August 2005

65

Flow-Through Systems

Flow-through systems pump in sea water for use in

production ponds, treat it, and finally discharge it back

into the sea. Flow-through culture systems are widely

implemented in Indonesia at various levels of application. In Lampung, the CPB farm is one of few farms that

have a complete flow-through system.

Most shrimp farms in Java have modified the original

flow-through design to include reservoirs, but generally

still do not have effluent treatment facilities. The accumulated effluent sediments in production ponds are normally dried, collected, and discarded away from the farm

area. Effluent water from production ponds is discharged

away from the main farm inlets into river estuaries or

back to the ocean.

In Bali and elsewhere, newly established shrimp farms

use sea water directly and discharge effluents back into

the ocean. Similar practices exist in the southern part of

West Java. However, the SEKAR shrimp farm at West

Sumbawa uses sea water directly for production ponds,

but has efficient effluent treatment with settling, where

effluents are treated before discharge back to the ocean.

Pond Construction

There are six types of ponds in Indonesia (Table 1).

The most common type uses concrete dikes and exposed

bottom soils. At large integrated shrimp farms in Lampung, most production ponds are lined with high-density

polyethylene plastic (HDPE).

Table 1. Types of production pond

construction in Indonesia.

Construction Type

Earthen

Fully HDPE-lined

Partially HDPE-lined

Concrete-lined

Concrete-/HDPE-lined

dikes

Biocrete-lined

Specifications

Earthen dikes and bottom

HDPE dikes and bottom

Dikes and 75% of bottom lined

with 25% of bottom center soil

exposed

Concrete dikes and bottom

Concrete dikes lined with HDPE,

bottom soil exposed

Concrete dikes, bottom lined

with plastic covered with sand

At a shrimp farm recently built in Bali, ponds especially built for L. vannamei culture are fully lined with concrete and even have ramps to allow access by small trucks

during pond preparation and maintenance activities.

These deep ponds have operational water levels over 2 m.

Another type is the biocrete-lined pond, which was

started a few years ago in Indonesia. The dikes are built

with concrete, and the pond bottoms are lined with locally available polyethylene plastic tugged onto the dikes.

Layers of sand are spread on the plastic to keep it in place.

With the recent introduction of L. vannamei, shrimp

productivity in HDPE- or concrete-lined ponds with sufficient supplemental aeration can nearly double that of

typical earthen ponds. The carrying capacity of lined

ponds has also increased at least 25%.

The most common pond type

uses concrete dikes and

exposed bottom soils.

66

August 2005

GLOBAL AQUACULTURE ADVOCATE

The typical carrying capacity of earthen ponds with

both normal- and high-density culture is about 430 kg

shrimp/hp of energy input, but carrying capacity of over

560 kg/hp has been achieved in semilined ponds without

floc. During recent trials in fully lined ponds at high stocking density, a maximum carrying capacity of 631 kg/hp

almost that of a bacterial floc system was achieved.

Production performance in earthen ponds is based

largely on soil condition and pond preparation. If pond

soil is of good quality and can be cleaned, oxidized, and

compacted after each operation, pond carrying capacity in

earthen ponds can be as high as that of fully lined ponds.

Regular pond bottom maintenance is possible for

small farms, but not feasible for large farms, especially

during the wet season, when compacting pond bottoms

and dikes with rollers becomes impossible. With the growing importance of biosecurity and introduction of SPF

L. vannamei, new facilities are investing in ponds lined

with HDPE or concrete.

Culture Technology

With the arrival of SPF L. vannamei in Indonesia, a

number of technologies have emerged to take advantage

of their wide range of tolerance and adaptability. Various technologies and production strategies have been

tried (Table 2), including monoculture with normal and

high density, partial harvesting, polyculture of L. vannamei and P. monodon, two-step culture with minimum

water exchange, and zero-water-exchange bacterial floc

systems for L. vannamei.

With the introduction of SPF

L. vannamei to Indonesia,

a number of technologies have

emerged to take advantage

of their wide range of tolerance

and adaptability.

L. vannamei can withstand very high stocking density as long as production ponds are deep and of high quality. Monoculture systems with paddlewheel aerators and

compressed air diffusers can produce up to 30 mt/ha. In

bacterial floc systems, production as high as 49.7 mt/ha

has been recorded.

Many farms use earthen production ponds lined

with high-density polyethylene plastic.

Table 2. Characteristics of various shrimp culture technologies used in Indonesia.

System

Objective

L. vannamei

Monoculture

Normal stocking density 60-80/m2/16-20 hp energy

High stocking density 100-150/m2/24-34 hp energy

Achievements (Source)

Sustainable production

Increase pond productivity with

increased energy input (aerators

or air diffusers)

8.0-10.0 mt/ha, 16-20 g sizes

14.0-30.0 mt/ha, 14-18 g sizes

(Java, Bali, Lombok, CPB)

Monoculture partial harvest

Stocking density 200-260/m2/28-30 hp energy

Increase pond productivity

25.0-35.0 mt/ha. 12-20 g sizes

(Lampung, CPB trials)

Bacterial floc (zero water exchange)

Stocking density 130-150/m2/30-32 hp energy

Increase biosecurity, productivity,

and efficiency

20-24 mt/ha, 16-20 g sizes

Record: 49.7 mt/ha after stocking at

280/m2 (CPB)

L. vannamei and P. monodon

Two-step culture

High survival through nursery phase Higher survival (CPB)

Minimum water exchange

Increase biosecurity

Higher biosecurity (CPB)

Polyculture (L. vannamei and P. monodon)

Stocking density 70/m2 (40-50 vannamei,

20-30 monodon

Utilize 100% of pond water column

and bottom area to increase pond

productivity

7.5 vannamei, 3.5 monodon mt/ha

(Lampung, CPB trials)

Partial harvesting is a method

that can greatly increase pond production and quality of shrimp when

culturing L. vannamei. Polyculture of

L. vannamei and P. monodon has also

been studied at P.T. Central Pertiwi

Bahari amid criticism because one

species is SPF and the other is not.

However, a number of tests successfully implemented the polyculture

with consistent results. The approach capitalizes on the different

habitat use and behavior of L. vannamei and P. monodon, thus utilizing

the whole pond water environment to

increase overall pond productivity.

The most common pond construction in Indonesia uses concrete dikes and exposed

bottom soils. This pond in northern Bali, which has a central drain and compressed air

aeration, is fully lined with concrete. Photo courtesy of Tommy Chandra.

GLOBAL AQUACULTURE ADVOCATE

August 2005

67

S-ar putea să vă placă și

- Regulation of The President of The Republic of Indonesia Number 44 Year 2016Document65 paginiRegulation of The President of The Republic of Indonesia Number 44 Year 2016matt_nadÎncă nu există evaluări

- Corruption in IndonesiaDocument1 paginăCorruption in IndonesiaHana KhalidaÎncă nu există evaluări

- Corruption in IndonesiaDocument1 paginăCorruption in IndonesiaHana KhalidaÎncă nu există evaluări

- Marine ManagementDocument9 paginiMarine ManagementHana KhalidaÎncă nu există evaluări

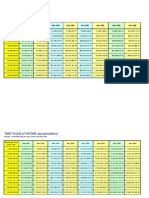

- Time Value For Increament IncomeDocument13 paginiTime Value For Increament IncomeHana KhalidaÎncă nu există evaluări

- Things To Do in LondonDocument1 paginăThings To Do in LondonHana KhalidaÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Role of Aquaculture in Improving The Livelihoods of Rural CommunitiesDocument4 paginiThe Role of Aquaculture in Improving The Livelihoods of Rural CommunitiesKIU PUBLICATION AND EXTENSIONÎncă nu există evaluări

- Organic Salmon vs. Wild Salmon vs. Farmed Salmon - What Is The Better Choice?Document3 paginiOrganic Salmon vs. Wild Salmon vs. Farmed Salmon - What Is The Better Choice?SunisaÎncă nu există evaluări

- AquaCulture Asia Pacific Jan - Feb 18 - FA - LR174 PDFDocument72 paginiAquaCulture Asia Pacific Jan - Feb 18 - FA - LR174 PDFJoanna MordenÎncă nu există evaluări

- Final Chapter I - GalicayoDocument47 paginiFinal Chapter I - GalicayoMegustas tearsÎncă nu există evaluări

- "Freshwater Aquaculture" (FAC-211) : BooksDocument154 pagini"Freshwater Aquaculture" (FAC-211) : BooksjoshigautaÎncă nu există evaluări

- AquacultureDocument74 paginiAquacultureFlorenda IguinÎncă nu există evaluări

- Water Quality Status and Pollution Waste Load From Floating Net Cages at Maninjau Lake, West Sumatera IndonesiaDocument10 paginiWater Quality Status and Pollution Waste Load From Floating Net Cages at Maninjau Lake, West Sumatera IndonesiaHastari Nurul SukmaÎncă nu există evaluări

- China Seafood Market Report 2015-2019Document41 paginiChina Seafood Market Report 2015-2019tapioca leÎncă nu există evaluări

- Analysis of Profitability of Fish Farming in Ogun State, NigeriaDocument7 paginiAnalysis of Profitability of Fish Farming in Ogun State, NigeriaWella ChristafariÎncă nu există evaluări

- 3rd Mekong Mangrove Forum QaADocument11 pagini3rd Mekong Mangrove Forum QaASuhaniÎncă nu există evaluări

- Targets and Plans For FY2021 Province: ABRADocument8 paginiTargets and Plans For FY2021 Province: ABRAKristian Karl Bautista Kiw-isÎncă nu există evaluări

- Amaranthus Spinosus Leaf Meal As Potential DietaryDocument10 paginiAmaranthus Spinosus Leaf Meal As Potential DietaryAbd YasinÎncă nu există evaluări

- Effects of Dietary Single Cell Protein On African CatfishDocument5 paginiEffects of Dietary Single Cell Protein On African CatfishCoonzeeÎncă nu există evaluări

- Aquaculture Development Strategy Plan For Timor-Leste (2012-2030)Document32 paginiAquaculture Development Strategy Plan For Timor-Leste (2012-2030)JhoyFalsonÎncă nu există evaluări

- Contributors: Color Profile: Disabled Composite Default ScreenDocument3 paginiContributors: Color Profile: Disabled Composite Default ScreenCláudio CastroÎncă nu există evaluări

- Fish Market Analysis of North BengalDocument42 paginiFish Market Analysis of North BengalAlinjar GuhaÎncă nu există evaluări

- The Microbial Loop in A Eutrophic Bay and Its Contribution To Bivalve AquacultureDocument10 paginiThe Microbial Loop in A Eutrophic Bay and Its Contribution To Bivalve AquacultureJhimy Pnz RjsÎncă nu există evaluări

- DR Stefan Holler Ireland Artisanal Fishery Certification1Document18 paginiDR Stefan Holler Ireland Artisanal Fishery Certification1api-123092549Încă nu există evaluări

- Cultivation Method Slides-1Document9 paginiCultivation Method Slides-1Azam TavarehÎncă nu există evaluări

- Proximate Composition of Para-Grass (Brachiaria Mutica) Produced in Integrated Fish-Fodder Culture SystemDocument7 paginiProximate Composition of Para-Grass (Brachiaria Mutica) Produced in Integrated Fish-Fodder Culture SystemNgoc HoangÎncă nu există evaluări

- Proximate Composition of Fish Feed Ingredients Available in Shibpur Upazila, Narsingdi District, BangladeshDocument9 paginiProximate Composition of Fish Feed Ingredients Available in Shibpur Upazila, Narsingdi District, BangladeshAbdulla-Al-AsifÎncă nu există evaluări

- Metode PenelitianDocument6 paginiMetode PenelitianSartika PuluÎncă nu există evaluări

- Revised Chapter I - Galicayo Restaurant 1Document23 paginiRevised Chapter I - Galicayo Restaurant 1Megustas tearsÎncă nu există evaluări

- Shrimp Fisheries and Aquaculture in Berau, IndonesiaDocument250 paginiShrimp Fisheries and Aquaculture in Berau, IndonesiarahmatfajriÎncă nu există evaluări

- NML Serie 44 Indonesia Maritime HotspotDocument108 paginiNML Serie 44 Indonesia Maritime Hotspotabdul malik al fatahÎncă nu există evaluări

- WATER, WATER, WATER, EVERYWHERE - An Enigma!Document202 paginiWATER, WATER, WATER, EVERYWHERE - An Enigma!Akinola Oluwatoyin CharlesÎncă nu există evaluări

- Evaluation of Integrated Fish Farming With Chicken and Vegetables in Silte District of Southern EthiopiaDocument9 paginiEvaluation of Integrated Fish Farming With Chicken and Vegetables in Silte District of Southern EthiopiazelekeÎncă nu există evaluări

- Thesis Aquaculture)Document88 paginiThesis Aquaculture)Eric Hammond100% (1)

- Analysis of Growth Nutrition and Economical Profitability of Gibal CarpDocument12 paginiAnalysis of Growth Nutrition and Economical Profitability of Gibal CarpYousaf JamalÎncă nu există evaluări

- DIY: Urban Aquaculture ManualDocument43 paginiDIY: Urban Aquaculture ManualEvan Schoepke95% (39)