Documente Academic

Documente Profesional

Documente Cultură

PERKINS Piston Pin Bushing January 2012

Încărcat de

marcosluna68Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

PERKINS Piston Pin Bushing January 2012

Încărcat de

marcosluna68Drepturi de autor:

Formate disponibile

General

231 Issue 1

Piston Pin Bushing - Remove and Install

January 2012

This engine news article applies to 1000, 1100 and 1200 Series 3, 4 and 6 cylinder engines.

Caution: Specialist equipment and personnel with the correct training are needed to carry out the procedure

in this article.

Types of Connecting Rods

There are five types of connecting rods that can possibly be found in the above engines.

(A) Flat butt face connecting rod

(B) Serrated connecting rod

(C1) Fracture split connecting rod that have locating tags.

(D1) Fracture split connecting rod without locating tags.

(E) Angled fracture split connecting rod that have locating tags

A0072

A0073

Engine News - General 231 Issue 1

January 2012

C

E

Piston Pin Bushing - Remove and Install

Prior to removing the piston pin bushing and machining procedure the connecting rod bolts/nuts should be

tightened to 20Nm (15 lb ft).

Before removing the original piston pin bushing from the connecting rod the connecting rod should be fully

inspected to ensure that the connecting rod is serviceable. The correct grade of the connecting rod should be

established to enable the connecting rod to be machined to the connecting rod original specifications. Refer to

Table 4 for full specification.

Fabrication of a suitable tooling jig in order to remove and install the piston pin bushing will be required. The

tooling must be capable of supporting the connecting rod at both ends as the connecting rod is of an offset

design.

Fabricate the suitable jig tools, made of steel and soft type material as required, in order to press the original

piston pin bushing out of the connecting rod and the new piston pin bushing into the connecting rod. Refer to

Table 1, Table 2, illustration (A) and illustration (B) for the correct dimensions.

1

2

3

4

5

7

Engine News - General 231 Issue 1

January 2012

Table 1

Dimension

Connecting Rod Number

Values

4115C331

4115C334

4115C335

4115C336

4115C337

4115C321

67mm (2.638 inch)

4115C322

A1

4115C311

4115C312

4115C313

4115C314

4115C315

4115C316

A1

4115C341

76mm (2.99 inch)

A2

3mm (0.118 inch)*

A3

10 Degrees

A4

As Required

A5

8mm (0.315 inch)*

A6

44mm (1.73 inch)

A7

As Required

Notes:

A soft type of material should be used for dimension A2* in order to prevent damage to the

connecting rod surface.

A soft type of material should be used for dimension A5* in order to prevent damage to the

connecting rod surface. The thickness of A5* will vary from connecting rod to connecting rod.

Ensure that the size of A5* is adjusted in order to ensure that connecting rod is fully supported.

Ensure that the connecting rod assembly is securely clamped to the tooling jig.

7

10

11

12

Engine News - General 231 Issue 1

January 2012

Table 2

Dimension

Values

B7

As Required

B8

50mm (1.97 inch)

B9

37.5mm (1.48 inch)

B10

As Required

B11

43mm (1.69 inch)

B12

10 Degrees

1 Position the connecting rod onto the fabricated tooling jig. Ensure that the connecting rod is well supported

at both ends. Install the assembly onto a suitable press.

L

1

2

3

D

2 Using the fabricated mandrel (C1) in order to remove piston pin bushing from the connecting rod.

3 Inspect the bore (D2) for the piston pin bushing in the connecting rod for wear or damage. If necessary,

remove any burrs in the bore for the piston pin bushing in the connecting rod.

4 Position the new piston pin bushing on top of the bore (D2) of the connecting rod.

5 Ensure that the lubrication hole (D1) in piston pin bushing is aligned to the with the oil hole in connecting rod

(D3).

Note: Some connecting rods have no lubrication hole (D3).

6 Position the fabricated tooling onto a suitable press in order to press the new piston pin bushing into the

connecting rod. Ensure that the lubrication hole in the piston pin bushing (D1) is still aligned with the hole in

the connecting rod (D3).

7 Using the fabricated mandrel (C1) in order to install the piston pin bushing to the connecting rod.

Engine News - General 231 Issue 1

January 2012

8 Machine the profile of the parallel piston pin bushing (Perkins part number 3112E041) to the connecting rod

profile of 10 degrees. This machining procedure is required prior the machining of the finished bore of the

piston pin bushing.

9 Machine the partially finished bushing to the correct diameter. Obtain the correct grade of connecting rod.

Refer to Table 3 and Table 4 for the correct information.

10 Obtain the correct clearance and surface finish between the piston pin and piston pin bushing. Refer to

Table 3 and Table 4 for the correct information.

11 Ensure that the distance between the parent bores of the connecting rod is still within tolerance. Refer to

the relevant Workshop Manual or Service Manual for the correct dimensions.

Caution: Do not stamp the connecting rod.

12 Check that the grade letter on the connecting rod is correct. If necessary, delete the letter and etch a new

letter on the side of the connecting rod.

Table 3

Connecting Rod

Assembly Part Number

Bushing Part Number

Finished Inside Diameter

(mm/inch)

Roundness

Surface Finish

3112E041 or 3112A005

39.723-39.738 (1.5631.564)

0.006

0.8

3112A006

38.117-38.136 (1.5001.501)

0.006

0.8

3112E031

39.723-39.738 (1.5631.564)

0.006

0.8

4115C311

4115C312

4115C313

4115C314

4115C315

4115C316

4115C321

4115C322

4115C341

4115C342

4115C343

Table 4

Connecting Rod

Assembly Part

Number

Bushing Part

Number

Connecting Rod

Grade Lengths L

(mm)

Grade Code

Colour Code

4115C311

165.761 to 165.728

Red

4115C312

165.715 to 165.682

Orange

4115C313

165.670 to 165.637

White

165.624 to 165.591

Green

4115C315

165.578 to 165.545

Purple

4115C316

165.532 to 165.499

Blue

166.425 to 166.392

Brown

166.562 to 166.529

Pink

219.100 to 219.050

White

161.2.92 to 161.259

Red

161.216 to 161.183

Green

161.140 to 161.107

Blue

4115C314

4115C321

4115C322

4115C334

3112E041 or

3112A005

3112A006

3112E041 or

3112A005

4115C341

4115C342

4115C343

3112E031

Notes:

Bushing (Perkins part number 3112E041) is installed on 1004 engines and bushing (Perkins part number

3112A005) on 1104 engines.

Bushing (Perkins part number 3112E011) has been replaced with bushing (Perkins part number

3112E041)

5

Engine News - General 231 Issue 1

January 2012

End

Perkins Confidential Yellow. Issued by Perkins Engines Company Ltd, Peterborough PE1 5NA, England. Proprietary information of

Perkins Engines Company Ltd 2012, all rights reserved. The information is correct at the time of print. This Engine News article is for

technical information only and cannot be used as a basis for any claim including but not limited to warranty.

To enable the distribution lists for engine news articles to be maintained, If you currently receive engine news articles, but no

longer require them, please contact Matthew OHare by email at o_hare_matthew@perkins.com

S-ar putea să vă placă și

- sebf8734 гильза с-9Document13 paginisebf8734 гильза с-9Евгений АбрамовÎncă nu există evaluări

- Pistons and Connecting Rods - AssembleDocument5 paginiPistons and Connecting Rods - Assembleeshopmanual limaÎncă nu există evaluări

- C6.6 Connecting Rod FittingDocument5 paginiC6.6 Connecting Rod FittingsenÎncă nu există evaluări

- SEBF 8164 гизьзы 3500Document19 paginiSEBF 8164 гизьзы 3500Aminadav100% (1)

- Alignment PDFDocument12 paginiAlignment PDFVictor Nunez100% (1)

- Install Piston & Conrod 320 GCDocument3 paginiInstall Piston & Conrod 320 GCJebrodÎncă nu există evaluări

- Pistons and Connecting Rods - Assemble: Shutdown SISDocument3 paginiPistons and Connecting Rods - Assemble: Shutdown SISВиталийÎncă nu există evaluări

- Char-Lynn: Series 10 Steering Control Units 001 Disassembly/ReassemblyDocument9 paginiChar-Lynn: Series 10 Steering Control Units 001 Disassembly/ReassemblyIslam ShoukryÎncă nu există evaluări

- Crankshaft Main Bearing Bolts Torque (Converted)Document5 paginiCrankshaft Main Bearing Bolts Torque (Converted)Nasser Ayoub100% (3)

- Rover 100 TUD5 Overhaul ManualDocument59 paginiRover 100 TUD5 Overhaul ManualAndy Moe63% (8)

- Yanmar 4tne88 TNE Series PDFDocument15 paginiYanmar 4tne88 TNE Series PDFluna281068Încă nu există evaluări

- Unit Injector - Install: Installation ProcedureDocument6 paginiUnit Injector - Install: Installation ProceduredayanaÎncă nu există evaluări

- Pistons and Connecting Rods - Assemble: Previous ScreenDocument4 paginiPistons and Connecting Rods - Assemble: Previous ScreenqwuLzÎncă nu există evaluări

- Ace3 0620.06 GB PDFDocument12 paginiAce3 0620.06 GB PDFduhgrandoÎncă nu există evaluări

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDe la EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceÎncă nu există evaluări

- Overhaul 4 & 5 SpeedDocument22 paginiOverhaul 4 & 5 SpeedJeff PascoeÎncă nu există evaluări

- 19d Impeller SpacingDocument9 pagini19d Impeller Spacingbtgottlieb100% (1)

- TM 9 3416 235 14 and PDocument67 paginiTM 9 3416 235 14 and PMikeÎncă nu există evaluări

- Guia Overhaul 212Document13 paginiGuia Overhaul 212Eirick Wayne Zuñigga De-ItzelÎncă nu există evaluări

- Pistons and Connecting Rods - InstallDocument5 paginiPistons and Connecting Rods - Installeshopmanual limaÎncă nu există evaluări

- Volkswagen Taro 2Y 4Y Engine ManualDocument186 paginiVolkswagen Taro 2Y 4Y Engine ManualManos StavrouÎncă nu există evaluări

- Servodirectii EatonDocument14 paginiServodirectii Eatonwappii100% (1)

- Use Again: Thrust Washer ReusabilityDocument19 paginiUse Again: Thrust Washer ReusabilityGanbat JargalÎncă nu există evaluări

- Installation Procedure: NoticeDocument7 paginiInstallation Procedure: NoticeВиталий ОрловÎncă nu există evaluări

- Serie 60 Informacion AdicionalDocument51 paginiSerie 60 Informacion AdicionalMauricio Campos QuirosÎncă nu există evaluări

- f2013-013 CASE N SBDocument11 paginif2013-013 CASE N SBVictor PinedoÎncă nu există evaluări

- Unit Injector - Install: Disassembly and AssemblyDocument13 paginiUnit Injector - Install: Disassembly and AssemblyAnung Nugroho100% (1)

- Instalacion y Pueta PuntoDocument5 paginiInstalacion y Pueta PuntoBrayan Sánchez ParedesÎncă nu există evaluări

- Tornamesas HolladDocument2 paginiTornamesas HolladJL OlivaÎncă nu există evaluări

- Injector InstalacionDocument6 paginiInjector Instalacionjose luis herreraÎncă nu există evaluări

- 8218 спецификация головки 3116 -с7Document19 pagini8218 спецификация головки 3116 -с7Евгений АбрамовÎncă nu există evaluări

- Sturmey Archer S RF3 Hub InstructionsDocument4 paginiSturmey Archer S RF3 Hub Instructionsdupazbita11Încă nu există evaluări

- Injector Installation 107 EngineDocument5 paginiInjector Installation 107 EnginevalterripÎncă nu există evaluări

- Pistons and Connecting Rods - DisassembleDocument4 paginiPistons and Connecting Rods - Disassembleeshopmanual limaÎncă nu există evaluări

- Cylinder Liner Projection - Inspect: Testing and AdjustingDocument5 paginiCylinder Liner Projection - Inspect: Testing and AdjustingВиталийÎncă nu există evaluări

- 3408E and 3412E Crankshaft Main Bearings - InstallDocument6 pagini3408E and 3412E Crankshaft Main Bearings - Installalonso100% (1)

- C11 PistonDocument4 paginiC11 PistonHebert GahujfaÎncă nu există evaluări

- 2001 Oldsmobile Aurora 2000 Pontiac Bonneville 2000 Buick Lesabre Collision Repair ManualDocument25 pagini2001 Oldsmobile Aurora 2000 Pontiac Bonneville 2000 Buick Lesabre Collision Repair ManualPedro Angel Alvarez NarvaezÎncă nu există evaluări

- Repair Manual MP 1Document11 paginiRepair Manual MP 1Tiffany DacinoÎncă nu există evaluări

- 3S AWD Trans Service ManualDocument103 pagini3S AWD Trans Service ManualMatt BushnellÎncă nu există evaluări

- CS 533 ManualDocument9 paginiCS 533 ManualbagoesÎncă nu există evaluări

- SEBF8155 цил.головка 3500Document30 paginiSEBF8155 цил.головка 3500Евгений Абрамов100% (1)

- X30592Document16 paginiX30592CTN2010Încă nu există evaluări

- Food Processor ŽDocument15 paginiFood Processor ŽAndrei Și Mihaela GeantăÎncă nu există evaluări

- 722.6 AtraDocument10 pagini722.6 AtraTransmisiones Guero100% (7)

- D130E1Document3 paginiD130E1Hakim GOURAIAÎncă nu există evaluări

- Detroit Diesel Series40 Technical Bulletin CollectionDocument16 paginiDetroit Diesel Series40 Technical Bulletin CollectionTomáš MoserÎncă nu există evaluări

- Sebf 8269 Привод 3408Document16 paginiSebf 8269 Привод 3408mohamed hamedÎncă nu există evaluări

- H22A H22A1 H23 Balance Shaft Eliminator Installation InstructionsDocument3 paginiH22A H22A1 H23 Balance Shaft Eliminator Installation InstructionsedÎncă nu există evaluări

- Piston GrptsDocument46 paginiPiston GrptsPramono AdiÎncă nu există evaluări

- Connecting Rod Bearings - Install - Connecting Rods in PositionDocument4 paginiConnecting Rod Bearings - Install - Connecting Rods in PositionTatiano BrolloÎncă nu există evaluări

- Crankshaft - InstallDocument7 paginiCrankshaft - InstallCamila Vasques QuispeÎncă nu există evaluări

- 61SNC01 - 07 - Engine Mechanical - BlockDocument30 pagini61SNC01 - 07 - Engine Mechanical - BlockangelvalladaresÎncă nu există evaluări

- Orbitrol Repairing1Document30 paginiOrbitrol Repairing1Islam ShoukryÎncă nu există evaluări

- 1300 Edi Series 80 SplitDocument10 pagini1300 Edi Series 80 Split何青Încă nu există evaluări

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDe la EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementÎncă nu există evaluări

- Newage MX341 Automatic Voltage Regulator PDFDocument6 paginiNewage MX341 Automatic Voltage Regulator PDFosanebi100% (2)

- Cummins Speed ControllerDocument7 paginiCummins Speed Controllermarcosluna68100% (1)

- SX44Document4 paginiSX44Mk MakyÎncă nu există evaluări

- SX44Document4 paginiSX44Mk MakyÎncă nu există evaluări

- Especificaciones Tecnicas AVR Stamford SX440Document4 paginiEspecificaciones Tecnicas AVR Stamford SX440MH..2023Încă nu există evaluări

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Perkins 100 PDFDocument86 paginiPerkins 100 PDFmarcosluna68Încă nu există evaluări

- Course 1B. Unit Twenty: Affirmative Short AnswersDocument10 paginiCourse 1B. Unit Twenty: Affirmative Short Answersmarcosluna68Încă nu există evaluări

- Newage Sx440 Avr, Replacement: Same Fit Form and Function As The Original Newage SX440Document4 paginiNewage Sx440 Avr, Replacement: Same Fit Form and Function As The Original Newage SX440marcosluna68Încă nu există evaluări

- 424 Parts CarrierDocument173 pagini424 Parts Carriermarcosluna68Încă nu există evaluări

- Spec Manager ClaveDocument1 paginăSpec Manager Clavemarcosluna68Încă nu există evaluări

- Mechanical Tachometer Driv1 PDFDocument2 paginiMechanical Tachometer Driv1 PDFmarcosluna68Încă nu există evaluări

- The Codes Listed Are Sorted by PID.: PID FMI DDC Code # (Flashed) DescriptionDocument7 paginiThe Codes Listed Are Sorted by PID.: PID FMI DDC Code # (Flashed) Descriptionmarcosluna68Încă nu există evaluări

- Miguel Atlantico Center2Document1 paginăMiguel Atlantico Center2marcosluna68Încă nu există evaluări

- Lube Oil Cooler PDFDocument4 paginiLube Oil Cooler PDFmarcosluna68Încă nu există evaluări

- 6.7L DieselDocument94 pagini6.7L DieselBrendan Brodie100% (15)

- Final Speech 2Document8 paginiFinal Speech 2marcosluna68Încă nu există evaluări

- Kit, Aux Pump MTGDocument2 paginiKit, Aux Pump MTGmarcosluna68Încă nu există evaluări

- Hello Welcome To My Final Speech: Luigi Leonardo Luna LozanoDocument8 paginiHello Welcome To My Final Speech: Luigi Leonardo Luna Lozanomarcosluna68Încă nu există evaluări

- 1 - 5302 - 858 - MO - 1003 Asia MotorDocument86 pagini1 - 5302 - 858 - MO - 1003 Asia MotormarjanstipÎncă nu există evaluări

- Lube Oil Pump PDFDocument2 paginiLube Oil Pump PDFmarcosluna68Încă nu există evaluări

- Mechanical Tachometer Driv PDFDocument2 paginiMechanical Tachometer Driv PDFmarcosluna68Încă nu există evaluări

- 424 Parts CarrierDocument173 pagini424 Parts Carriermarcosluna68Încă nu există evaluări

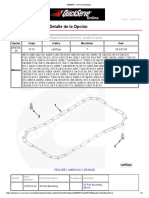

- Catálogo Electrónico de Partes Detalle de OpciónDocument2 paginiCatálogo Electrónico de Partes Detalle de Opciónmarcosluna68Încă nu există evaluări

- Oil Pan PDFDocument4 paginiOil Pan PDFmarcosluna68Încă nu există evaluări

- Catálogo Electrónico de Partes Detalle de OpciónDocument2 paginiCatálogo Electrónico de Partes Detalle de Opciónmarcosluna68Încă nu există evaluări

- Rocker Levers PDFDocument3 paginiRocker Levers PDFmarcosluna68Încă nu există evaluări

- Plumbing, Block VentDocument3 paginiPlumbing, Block Ventmarcosluna68Încă nu există evaluări

- Rear Engine Support PDFDocument2 paginiRear Engine Support PDFmarcosluna68Încă nu există evaluări

- AR Series: Hydraulic Impact BreakerDocument28 paginiAR Series: Hydraulic Impact BreakerJack KongÎncă nu există evaluări

- MESYS Shaft CalculationDocument51 paginiMESYS Shaft Calculationdd hhÎncă nu există evaluări

- 689 06 Fenner Shaft Fixings PDFDocument18 pagini689 06 Fenner Shaft Fixings PDFJorgeÎncă nu există evaluări

- Moduspec ChecklistDocument64 paginiModuspec Checklistbehnam197100% (8)

- Lubricants 09 00026 v2Document18 paginiLubricants 09 00026 v2MBADJOUN DanielÎncă nu există evaluări

- Reachstacker: RS45-27CH, RS45-30CH, RS45-27IH, RS46-33CH, RS46-30IH, RS46-36CH, RS46-33IH (A222)Document40 paginiReachstacker: RS45-27CH, RS45-30CH, RS45-27IH, RS46-33CH, RS46-30IH, RS46-36CH, RS46-33IH (A222)stefan corjucÎncă nu există evaluări

- 8209-Models D, DA, DAB and DB Retainer Production Packers FoDocument12 pagini8209-Models D, DA, DAB and DB Retainer Production Packers Fodanonnino0% (1)

- Steam Turbine Governor ControlDocument2 paginiSteam Turbine Governor Controlashishmundra89Încă nu există evaluări

- Mastil y Horquillas p5000Document44 paginiMastil y Horquillas p5000jorge humberto arellano almaguer100% (1)

- Software For Calculation of Hydrodynamic PlainDocument9 paginiSoftware For Calculation of Hydrodynamic Plainjorgeluis2000Încă nu există evaluări

- Application of Composites For Centrifugal PumpsDocument4 paginiApplication of Composites For Centrifugal Pumpsravide76Încă nu există evaluări

- Manual ING SHJ 7005Document59 paginiManual ING SHJ 7005ricardo assaf marchetiÎncă nu există evaluări

- TB - 09 - 2016 - KOMATSU D475A-5 - Rev00 - (30 - 09 - 2016)Document12 paginiTB - 09 - 2016 - KOMATSU D475A-5 - Rev00 - (30 - 09 - 2016)Francisco GonzalezÎncă nu există evaluări

- Pressure Relief Valve: Disassembly, Inspection, and AssemblyDocument34 paginiPressure Relief Valve: Disassembly, Inspection, and AssemblyVRV.RELATORIO.AVARIA RELATORIO.AVARIAÎncă nu există evaluări

- Lug Analysis MechaniCalcDocument29 paginiLug Analysis MechaniCalcOSCARDELTAÎncă nu există evaluări

- Practical Solutions To Machinery and Maintenance Vibration ProblemsDocument23 paginiPractical Solutions To Machinery and Maintenance Vibration Problemsjameel babooramÎncă nu există evaluări

- 4607 17705 Rep ManualDocument46 pagini4607 17705 Rep Manualjosit31415Încă nu există evaluări

- Manual Trans Overhaul Chevrolet S10Document11 paginiManual Trans Overhaul Chevrolet S10Maxi Sardi100% (1)

- Spare Parts Manual: Engine: ART - NO.: 3CM089350MENDocument28 paginiSpare Parts Manual: Engine: ART - NO.: 3CM089350MENcharles100% (1)

- BMRC BushingsDocument5 paginiBMRC BushingsDaniel DelgadoÎncă nu există evaluări

- BD2F BS3F Service Manual OCRDocument340 paginiBD2F BS3F Service Manual OCRpiteng194575% (4)

- Section Vi: Parts ListDocument19 paginiSection Vi: Parts ListManuel Alcedo MeleroÎncă nu există evaluări

- Group 3 AxleDocument32 paginiGroup 3 AxleSaidi JalelÎncă nu există evaluări

- Dodge Gear BoxDocument452 paginiDodge Gear BoxBernardo Orozco LariosÎncă nu există evaluări

- Lagermetall Slide Bearings CatalougeDocument28 paginiLagermetall Slide Bearings CatalougeClaesÎncă nu există evaluări

- Multiplex Plunger Pumps: Installation, Care and Operation ManualDocument0 paginiMultiplex Plunger Pumps: Installation, Care and Operation ManualDavid Rios CruzÎncă nu există evaluări

- Clark Transmission PartsDocument63 paginiClark Transmission PartsFaizal Jamal100% (1)

- T 44Document4 paginiT 44Tony_Black99Încă nu există evaluări

- Shaft and Housing FitsDocument36 paginiShaft and Housing FitsGilberto De MarchÎncă nu există evaluări

- OKS Soft Catalogue (Powders and Pastes)Document41 paginiOKS Soft Catalogue (Powders and Pastes)B3N100% (1)