Documente Academic

Documente Profesional

Documente Cultură

Piping Specification - Model PDF

Încărcat de

Victor MacoveiDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Piping Specification - Model PDF

Încărcat de

Victor MacoveiDrepturi de autor:

Formate disponibile

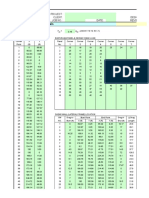

ENGIEERING STANDARD - Piping Specification

Page 1 of 8

home sitemap about abbreviations fun question conversion advertising copyright relax contact

EXPLOREtheWORLDofPIPING

DOCS MATL SOCY PIPES FLANGES FTTG VALVES BOLTS GASKETS EQPT SPECIALS STEEL DIN STEAM OTHERS

PIPING SPECIFICATION

Standard No.:

Title:

PIPING LINE CLASS 150

PLC 150

Page : 1 of Issue Date : December, 2014

Approvals:

Sponsor

Manager, Stationary Equipment

Director, Specialty Engineering

Name:

M.C. Donald

A. Lincoln

S. Stallone

Signature:

on org file

on org file

on org file

Date:

2014-11-12

2014-11-12

2014-11-12

PART 1 GENERAL

1.1 SCOPE

A. This specification covers carbon steel piping for general non-corrosive gas and liquid

process service.

B. Design limits based on ASME B16.42 Class 150 ductile iron Valves & on EWP's

temperature limit on PTFE in gaskets.

C. Corrosion Allowance: 0.0625 inch.

Sizes

NPS

1/2-24

Maximum Pressure

Design Temperature

psig

kPag

barG

250

1724

17.2

-20 to +100

-29 to +38

235

1621

16.2

200

93

215

1483

14.8

300

149

205

1414

14.1

350

177

1.2 RELATED DOCUMENTS

A. Specification Doc. No..., "Piping, General Notes"

B. Specification Doc. No..., "Piping, General Fabrication"

C. Specification Doc. No..., "Piping, General Installation"

D. Specification Doc. No..., "Piping, General Testing"

http://www.wermac.org/documents/plc150.html

2/6/2015

ENGIEERING STANDARD - Piping Specification

Page 2 of 8

E. Specification Doc. No..., "Piping, General Welding"

F. Specification Doc. No..., "Piping, Carbon Steel Welding"

G. Specification Doc. No..., "Pipe Weld Inspection and Testing"

H. Specification Doc. No..., "Piping, General Cleaning"

I. Standard Details Doc. No..., Doc. No..., Doc. No...,Doc. No...

1.3 REFERENCES

1.3.1 American Petroleum Institute (API)

1. API 594 Wafer Check Valves

2. API 600 Steel Gate Valves, Flanged or Buttwelding Ends

3. API 602 Compact Carbon Steel Gate Valves

4. API 607 Fire Test for Soft-Seated Quarter Turn Valves

5. API 608 Metal Ball Valves

6. API 609 Butterfly Valves, Lug Type and Wafer Type

1.3.2 American Society of Mechanical Engineers (ASME)

1. ASME B31.3 Process Piping

2. ASME B1.20.1 Pipe Threads, General Purpose (inch)

3. ASME B16.5 Steel Pipe Flanges and Pipe Fittings

4. ASME B16.9 Wrought Steel Buttweld Fittings

5. ASME B16.10 Face-to-Face and End-to-End Dimensions Ferrous Valves

6. ASME B16.11 Forged Steel Fittings Socketwelding and Threaded

7. ASME B16.21 Nonmetallic Flat Gaskets for Pipe Flanges

8. ASME B16.25 Buttwelding Ends

9. ASME B16.34 Steel Valves - Flanged and Buttwelding Ends

10. ASME B16.36 Orifice Flanges

11. ASME B16.48 Steel Line Blanks

12. ASME B31.1 Power Piping

13. ASME B31.3 Chemical Plant and Petroleum Refinery Piping

14. ASME B36.10 Welded and Seamless Wrought Steel Pipe

1.3.3 Manufacturer Standard Society Practice (MSS)

1. MSS SP-25 MSS Standard Marking System for Valves, Fittings, Flanges and Unions

2. MSS SP-79 Socket-Welding Reducer Inserts

3. MSS SP-83 Class 3000 Steel Pipe Unions, Socket Welding and Threaded

4. MSS SP-95 Swage(d) Nipples and Bull Plugs

5. MSS SP-97 Integrally Reinforced Forged Branch Outlet Fittings - Socket Welding,

Threaded and Buttwelding Ends

1.3.4 Process Industry Practice (PIP)

1. PIP PNSM0001 Piping Line Class Designator System

PART 2 PRODUCTS

NPS

DESCRIPTION

NOTE CODE

ASTM A106-B CS SMLS PE XS/80

02

PIPE:

1/2-2

2

-10

12-24

201322

ASTM A53-B TYPE-E CS ERW BE STD/40

203270

ASTM A53-B TYPE-E CS ERW BE STD/0.375

203270

http://www.wermac.org/documents/plc150.html

2/6/2015

ENGIEERING STANDARD - Piping Specification

Page 3 of 8

FITTINGS:

1/2-2

CAP ASTM A105 CS 3000 SW ASME B16.11

206799

1/2-2

COUPLING ASTM A105 CS 3000 SW ASME B16.11

207497

1/2-2

COUPLING RED ASTM A105 CS 3000 SW ASME B16.11

203384

1/2-2

ELL 45 ASTM A105 CS 3000 SW ASME B16.11

203385

1/2-2

ELL 90 ASTM A105 CS 3000 SW ASME B16.11

207091

1/2-2

INSERT SW RED ASTM A105 CS 3000 MSS SP-79

203383

1/2-2

TEE ASTM A105 CS 3000 SW ASME B16.11

207008

1/2-2

RED TEE ASTM A105 CS 3000 SW ASME B16.11

203386

1/2-2

UNION ASTM A105 CS 3000 SW MSS SP-83

207007

2-24

CAP ASTM A234-WPB CS BW STD ASME B16.9

203343

2-24

ELL 45 ASTM A234-WPB CS BW STD ASME B16.9

203344

2-24

ELL 90 LR ASTM A234-WPB CS BW STD ASME B16.9

203345

2-24

ELL 90 SR ASTM A234-WPB CS BW STD ASME B16.28

203346

2-24

RED CONC ASTM A234-WPB CS BW STD ASME B16.9

203347

2-24

RED ECC ASTM A234-WPB CS BW STD ASME B16.9

203348

2-24

TEE ASTM A234-WPB CS BW STD ASME B16.9

203349

2-24

TEE RED ASTM A234-WPB CS BW STD ASME B16.9

205300

1/2-2

ELBOLET ASTM A105 CS 3000 SW MSS SP-97

205512

1/2-2

LATROLET ASTM A105 CS 3000 SW MSS SP-97

...

1/2-2

SOCKOLET ASTM A105 CS 3000 SW MSS SP-97

203425

2 -6

WELDOLET ASTM A105 CS BW STD MSS SP-97

203405

O'LETS:

SWAGES, NIPPLES, THREADED ITEMS:

1/2-1

NIPPLE PIPE TBE NPT ASTM A106-B CS XS

1/2-1

NIPPLE PIPE POE-TOE NPT ASTM A106-B CS XS

1/2-4

200151

05

SWAGE NIPPLE CONC ASTM A234 WPB CS XS BLE-PSE MSS

203433

207151

SP-95

1/2-3

SWAGE NIPPLE CONC ASTM A234-WPB CS BBE XS MSS SP-95

203435

1/2-2

SWAGE NIPPLE ECC ASTM A234-WPB CS BBE XS MSS SP-95

205515

FITTINGS - THREADED:

1/2-2

BUSHING ASTM A105 CS NPT HEX ASME B16.11

05

203362

1/2-2

CAP ASTM A105 CS 3000 NPT ASME B16.11

05

200147

1/2-1

COUPLET (VOGT) ASTM A105 CS 6000 NPT

05

206998

1/2-2

COUPLING ASTM A105 CS 3000 NPT ASME B16.11

05

203363

1/2-2

COUPLING RED ASTM A105 CS 3000 NPT ASME B16.11

05

203364

1/2-2

CROSS ASTM A105 CS 2000 NPT ASME B16.11

05, 06

...

1/2-2

ELL 45 ASTM A105 CS 2000 NPT ASME B16.11

05, 06

203366

http://www.wermac.org/documents/plc150.html

2/6/2015

ENGIEERING STANDARD - Piping Specification

Page 4 of 8

1/2-2

ELL 90 ASTM A105 CS 2000 NPT ASME B16.11

05, 06

203367

1/2-2

PLUG ASTM A105 CS 3000 NPT HEX HD ASME B16.11

05

203371

1/2-2

TEE ASTM A105 CS 2000 NPT ASME B16.11

05, 06

203370

1/2-2

TEE RED ASTM A105 CS 3000 NPT ASME B16.11

05

203431

1/2-2

THREDOLET ASTM A105 CS 3000 NPT MSS SP-97

05

203422

1/2-2

UNION ASTM A105 CS 3000 NPT MSS SP-83

05

203372

FLANGES:

1/2-24

BLIND ASTM A105 CS ASME B16.5-150 RF

200153

1/2-24

FLANGE SO ASTM A105 CS ASME B16.5-150 RF

200158

1-2

FLANGE ORIFICE WN ASTM A105 CS ASME B16.36-300 RF XS

206424

2-6

FLANGE ORIFICE WN ASTM A105 CS ASME B16.36-300 RF

206425

STD

FLANGES, ALTERNATES:

1/2-2

FLANGE THREAD NPT ASTM A105 CS ASME B16.5-150 RF

1/2-2

FLANGE SW ASTM A105 CS ASME B16.5-150 RF

2-24

FLANGE WN ASTM A105 CS ASME B16.5-150 RF STD

05

200155

...

03

205382

GASKETS:

1/2-24

1-6

FLAT RING ASME B16.5-150 F-PTFE 1/16 THK, ASME B16.21

205867

TABLE 4

FLAT RING ASME B16.5-300 F-PTFE 1/16 THK, ASME B16.21

205815

TABLE 5

BOLTING:

...

STUD ASTM A193-B7 STL

200021

...

NUT HEAVY HEX ASTM A194-2H STL

200029

MISCELLANEOUS:

1/2-24

SPACER LINE ASTM A516-70 CS 150 RF

14

205415

2-24

STRAINER TEMPORARY CONICAL CS 150 RF

18

205516

1/2-2

Y-STRAINER ASTM A105 CS 600 NPT SS SCREEN

05

...

1-12

Y-STRAINER ASTM A216-WCB CS ASME B16.5-150 RF

ITEM,

NPS

DESCRIPTION

205892

NOTE INDEX CODE

VALVES:

BALL ASTM A216-WCB CS 1000 SW 316 SS BALL 23,

1/2-2

1/2-6

FULL PORT

32,

3-PC R-PTFE SEATS

34

BALL ASTM A216 STL 150 RF PTFE SEATS,

GRAPH PKG, Grounded

3-14

http://www.wermac.org/documents/plc150.html

31

206

206157

268

205020

204L

206257

2/6/2015

ENGIEERING STANDARD - Piping Specification

Page 5 of 8

BUTTERFLY LUG ASTM A216-WCB CS 150 RF,

NPS 10 & >GEAR

PTFE SEATS & SEALS

1/2-2

CHECK H-LIFT ASTM A105 CS 800 SW GRAPH

2-12

CHECK SWING ASTM A216-WCB CS 150 RF

6-14

1/2-2

3-14

1/2-14

CHECK WAFER ASTM A216-WCB CS 150 W/

SPRING

228

200201

34

215

205010

22, 34

236

205553

261

200206

240

200203

239

200202

GATE ASTM A105 CS 800 SW CR TR GRAPH

GATE ASTM A216-WCB CS 150 BW STD HF NPS

14 & >GEAR GRAPH

24

GATE ASTM A216-WCB CS 150 RF HF NPS 14 &

>GEAR GRAPH

1/2-2

GLOBE ASTM A105 CS 800 SW HF GRAPH

283

200210

3-12

GLOBE ASTM A216-WCB CS 150 RF HF GRAPH

272

205191

3-6

GLOBE ASTM A216-WCB CS 300 BW STD GRAPH

24

272C

205726

36

270K

208503

33

195

205562

34

180K

205062

35

180

208521

1-6

3-10

1/2-6

1/2-8

GLOBE 3-PORT ASTM A216-WCB CS 150 RF

GRAPH

PLUG CI 150 RUBBER LINED ECCENTRIC PLUG

LIMIT TO 180F

PLUG DUCTILE IRON 150 RF PTFE SLEEVE

PLUG (LOW EMISSION) D-IRON PTFE SLEEVE

150 RF

Notes:

02 - Pipe Bending shall be used ONLY where specified on the drawings or where

approved in writing by the EWP project engineer.

03 - Specify WN flanges adjacent to welded fittings and/or Butterfly Valves as alternates

only.

05 - Threaded joints are permitted only at terminal of vent, drain, and hydrostatic test

connections, and at instrument take-off points, and to match equipment.

06 - EWP's TED site preference, class 2000 threaded FS fittings are made only in 45

and 90 elbows, tees, and crosses. The class 2000 fittings are rated same as sch XS/80

(max) threaded pipe. Class 3000 fittings found in existing lines may be replaced by

class 2000.

14 - Line blinds, spacers, restricting orifices, and spectacle blinds shall be per Standard

Details Doc. No...01 thru 04.

18 - Conical Strainer to be used as temporary start-up strainer at pumps.

20 - Thread sealant to be used on all thread joints except if seal welding is used. Refer

to Specification Doc. No....

22 - These Valves have no flanges but are installed between line flanges with extra

length bolts.

23 - Cast Valves used in "critical service" or "very critical" service should be considered

for radiographic inspection.

24 - BW gate or globe is for alternate use.

25 - Reducing fittings that have ends of different thickness must show thickness (e.g.,

Conc. Red - SCH XS x SCH STD).

31 - Butterfly Valves NPS 6 & smaller w/ handle; NPS 8 & larger w/ gear operator. Do

not use above 177C service.

32 - Intended for orifice taps only.

http://www.wermac.org/documents/plc150.html

2/6/2015

ENGIEERING STANDARD - Piping Specification

Page 6 of 8

33 - Doc. No... for slurry service.

34 - Valves with PTFE may be chosen for use in the OXO reactor loop piping.

35 - Valve Index 180 is alternate for 180K.

36 - May be used for Relief Valve changeover.

PART 3 EXECUTION

3.1 Piping, General Notes

See Specification Doc. No...

3.2 Assembly Details

Following are recommended vent/drain and instrument connections.

Other connections may be shown on design:

HDR SIZE

DESCRIPTION

DETAIL

VENT & DRAIN CONNECTION ASSEMBLIES (STANDARD DETAILS DOC. NO...):

1/2

UNVALVED VENT/DRAIN 1/2 SW TEE FLG

Doc. No...

3/4

UNVALVED VENT/DRAIN 3/4 SW TEE FLG

Doc. No...

1-2

UNVALVED VENT/DRAIN SW TEE/INS 3/4 FLG

Doc. No...

2-6

UNVALVED VENT/DRAIN 3/4 SOL FLG

Doc. No...

8-24

UNVALVED VENT/DRAIN 1 SOL FLG

Doc. No...

1/2

VALVED VENT/DRAIN 1/2 SW TEE 1/2 GATE

Doc. No...

3/4

VALVED VENT/DRAIN 3/4 SW TEE 3/4 Gate Valve

Doc. No...

1-2

VALVED VENT/DRAIN SW TEE/INS 3/4 Gate Valve

Doc. No...

2-6

VALVED VENT/DRAIN 3/4 SOL Gate Valve

Doc. No...

8-24

VALVED VENT/DRAIN 1 SOL Gate Valve

Doc. No...

PRESSURE CONNECTION ASSEMBLIES (STANDARD DETAILS DOC. NO...):

1/2

PRESSURE CONN 1/2 SW TEE GATE COUPLET

Doc. No...

3/4

PRESSURE CONN 3/4 SW TEE GATE COUPLET

Doc. No...

1-2

PRESSURE CONN SW TEE/INS 3/4 GATE COUPLET

Doc. No...

2-24

PRESSURE CONN SOL 3/4 GATE COUPLET

Doc. No...

TEMPERATURE CONNECTION ASSEMBLIES (STANDARD DETAILS DOC. NO...):

1/2-1

TEMPERATURE CONN 1-1/2 SW TEE/INSERT FLANGE

Doc. No...

TEMPERATURE CONN 1-1/2 SW TEE FLANGE

Doc. No...

TEMPERATURE CONN 2" SW TEE/INS 1-1/2 FLANGE

Doc. No...

2-24

TEMPERATURE CONN 1-1/2 SW ELBOLET FLANGE

Doc. No...

2-24

TEMPERATURE CONN 1-1/2 SOL 1-1/2 FLANGE

Doc. No...

ORIFICE TAP CONNECTION ASSEMBLIES (STANDARD DETAILS DOC. NO...):

2-4

ORIFICE FLANGES 1/2 SW Ball Valves

http://www.wermac.org/documents/plc150.html

Doc. No...

2/6/2015

ENGIEERING STANDARD - Piping Specification

6-24

Page 7 of 8

ORIFICE VENA TAPS 1/2 SW Ball Valves

Doc. No...

3.3 FABRICATION

A. See Specification Doc. No..., "Piping, General Fabrication," Specification Doc. No...,

"Piping, General Welding,"

Specification Doc. No..., "Piping, Carbon Steel Welding," and Specification Doc. No..., "Pipe

Weld Inspection & Testing."

3.4 INSTALLATION

A. See Specification Doc. No..., "Piping, General Installation"

3.5 TESTING

A. See Specification Doc. No..., "Piping, General Testing"

B. Vacuum Piping System: Apply Pneumatic Leak Test with internal pressure at 1.5 times

the maximum operating external pressure, or minimum 15 psig (103 kPag, 1.03 bar-g,

1.06 kgf/cm2)

C. Category D Piping System: Apply Initial Service Leak Test

D. Normal Service Piping System: Apply standard Hydrostatic Leak Test.

E. Category M Piping System: Apply both a standard Hydrostatic Leak Test & a Sensitive

Leak Test with helium tracer gas.

F. Maximum Hydrostatic Test Pressure: 413 psig (2848 kPag, 28.4 bar-g, 29.0 kgf/cm2)

3.6 CLEANING

A. See Specification Doc. No..., "Piping, General Cleaning"

90 DEGREE BRANCH TABLE

CONNECTION TYPE

1/2

3/4

S

I

Z

E

N

P

S

10

12

14

16

18

H

E

A

D

E

R

http://www.wermac.org/documents/plc150.html

2/6/2015

ENGIEERING STANDARD - Piping Specification

Page 8 of 8

20

24

1/2

3/4

10

12

14

16

18

20

24

BRANCH

SIZES

NPS

D = TEE & REDUCER

E = REDUCING TEE

P = REINFORCING PAD

S = SOCKOLET

T = TEE

U = UNREINF. STUB-IN

V = SW TEE W/ INSERT

W = WELDOLET

D or V may be substituted by E.

S or W may be substituted by P (minimum pad width = 1").

P = Reinforcing pad with minimum thickness equal to header thickness, and width

equal to 1/2 of the branch nominal pipe size. Drill 1/8" (3mm) diameter hole in each

pad section for venting (a weld gap is acceptable as a means of venting).

END OF PIPING SPECIFICATION

The primary purpose of the Pipe Fabrication Institute is to promote the highest

standards of excellence in the pipe fabrication industry.

Werner Slken 2008 - 2015. All rights reserved.

Do not worry about your difficulties in Mathematics. I can assure you mine are still greater. Albert Einstein

http://www.wermac.org/documents/plc150.html

2/6/2015

S-ar putea să vă placă și

- Iso 12944-5 PDFDocument31 paginiIso 12944-5 PDFMarco Cruz67% (3)

- En 10253-4Document100 paginiEn 10253-4Victor Macovei100% (1)

- Msds Hvu Hilti (En)Document8 paginiMsds Hvu Hilti (En)Victor MacoveiÎncă nu există evaluări

- En 10204-2004 Metallic Products - Types of Inspection DocumentsDocument10 paginiEn 10204-2004 Metallic Products - Types of Inspection DocumentsDalamagas KwnstantinosÎncă nu există evaluări

- He ADocument5 paginiHe Aanon_455434837Încă nu există evaluări

- Din 8063-4 (1983) PDFDocument12 paginiDin 8063-4 (1983) PDFVictor MacoveiÎncă nu există evaluări

- Din 8074Document18 paginiDin 8074Matheus TorresÎncă nu există evaluări

- Tabel Euronormen ENG PDFDocument1 paginăTabel Euronormen ENG PDFFadzil NorÎncă nu există evaluări

- Management Trafic Michelangelo v3Document1 paginăManagement Trafic Michelangelo v3Victor MacoveiÎncă nu există evaluări

- October 2009: in Case of Doubt, The German-Language Original Shall Be Considered AuthoritativeDocument15 paginiOctober 2009: in Case of Doubt, The German-Language Original Shall Be Considered AuthoritativeVictor Macovei100% (1)

- Norma Aceros PDFDocument3 paginiNorma Aceros PDFpibemauÎncă nu există evaluări

- Pump Standards ComparisonDocument4 paginiPump Standards ComparisonAnish Dani50% (2)

- 1987 404 EC Directive EN Harmonization The Law Relating To Simple Pressure Vessels PDFDocument12 pagini1987 404 EC Directive EN Harmonization The Law Relating To Simple Pressure Vessels PDFVictor MacoveiÎncă nu există evaluări

- BS EN ISO 15609-5 2004 Resistance WeldingDocument19 paginiBS EN ISO 15609-5 2004 Resistance WeldingNguyen Quang TienÎncă nu există evaluări

- Din en 735Document5 paginiDin en 735Anonymous METdvGew100% (1)

- Piping Specification - Model PDFDocument8 paginiPiping Specification - Model PDFVictor MacoveiÎncă nu există evaluări

- Stas 6648 1 82Document51 paginiStas 6648 1 82Radu LupuÎncă nu există evaluări

- DIN-En-558-1 - Face-To-face and Centre-To-face Dimensions of Metal Industrial Valves For Use in Flanged Pipe SystemsDocument18 paginiDIN-En-558-1 - Face-To-face and Centre-To-face Dimensions of Metal Industrial Valves For Use in Flanged Pipe SystemsVictor MacoveiÎncă nu există evaluări

- SR en 10025-04Document8 paginiSR en 10025-04pukla100% (2)

- Directive 2006-42-CE - Machinery PDFDocument63 paginiDirective 2006-42-CE - Machinery PDFeng13Încă nu există evaluări

- October 2009: in Case of Doubt, The German-Language Original Shall Be Considered AuthoritativeDocument15 paginiOctober 2009: in Case of Doubt, The German-Language Original Shall Be Considered AuthoritativeVictor Macovei100% (1)

- 1987 404 EC Directive EN Harmonization The Law Relating To Simple Pressure Vessels PDFDocument12 pagini1987 404 EC Directive EN Harmonization The Law Relating To Simple Pressure Vessels PDFVictor MacoveiÎncă nu există evaluări

- October 2009: in Case of Doubt, The German-Language Original Shall Be Considered AuthoritativeDocument15 paginiOctober 2009: in Case of Doubt, The German-Language Original Shall Be Considered AuthoritativeVictor Macovei100% (1)

- 08 - Pipes and TubesDocument20 pagini08 - Pipes and Tubesado31Încă nu există evaluări

- EN 1092-1-Flange PDFDocument18 paginiEN 1092-1-Flange PDFSimona Adriana100% (1)

- Tabel Euronormen ENG PDFDocument1 paginăTabel Euronormen ENG PDFFadzil NorÎncă nu există evaluări

- Tabel Euronormen ENG PDFDocument1 paginăTabel Euronormen ENG PDFFadzil NorÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Reservoirs Spillways Energy Dissipators CE154Document75 paginiReservoirs Spillways Energy Dissipators CE154Bhaskar Reddy0% (2)

- Plate Type Fresh Water Generatoren-R7Document36 paginiPlate Type Fresh Water Generatoren-R7primoÎncă nu există evaluări

- Bomba Neumatica Wilden P200 PlasticaDocument28 paginiBomba Neumatica Wilden P200 PlasticaPablo Enrique Hernandez ZavalaÎncă nu există evaluări

- Hydraulically Operated 4/2 and 4/3 Directional Control Valve Technical SpecsDocument2 paginiHydraulically Operated 4/2 and 4/3 Directional Control Valve Technical SpecsVito LaudicinaÎncă nu există evaluări

- New ServicesDocument45 paginiNew ServicesMudassar MaqsoodÎncă nu există evaluări

- Flare System PDFDocument138 paginiFlare System PDFVivek ChavanÎncă nu există evaluări

- Combustion TuningDocument9 paginiCombustion TuningRamakrishnan NatarajanÎncă nu există evaluări

- News - Free Cooling Using Water Economizers PDFDocument8 paginiNews - Free Cooling Using Water Economizers PDFlipi8Încă nu există evaluări

- Engineering Interview Questions and MCQs on Fluid MechanicsDocument20 paginiEngineering Interview Questions and MCQs on Fluid MechanicspiluÎncă nu există evaluări

- Septic Vault Plan: National Housing AuthorityDocument1 paginăSeptic Vault Plan: National Housing AuthorityDJÎncă nu există evaluări

- Well Testing ProcedureDocument7 paginiWell Testing ProceduremofiyinfoluÎncă nu există evaluări

- SOP For 100L Glass Filter Reactor by Jimmytian8 at Future4200Document5 paginiSOP For 100L Glass Filter Reactor by Jimmytian8 at Future4200entropyxpÎncă nu există evaluări

- Experiment 4 - Flow MeasurementDocument24 paginiExperiment 4 - Flow MeasurementKhairil Ikram67% (6)

- Oil Pressure Is Low: C4.4 and C7.1 EnginesDocument8 paginiOil Pressure Is Low: C4.4 and C7.1 Engines李文琪Încă nu există evaluări

- Thermal Energy Storage For Building HVAC SystemDocument20 paginiThermal Energy Storage For Building HVAC SystemabhijeetÎncă nu există evaluări

- SAUDI ARAMCO INSPECTION CHECKLIST FOR PRESSURE VESSELSDocument2 paginiSAUDI ARAMCO INSPECTION CHECKLIST FOR PRESSURE VESSELSkarthi51289Încă nu există evaluări

- Indicating Valves Butterfly or Ball Type 1Document1 paginăIndicating Valves Butterfly or Ball Type 1Omar ElamirÎncă nu există evaluări

- Chlorine Leak at A Hypochlorite Bleach Plant - pg12 - 14Document3 paginiChlorine Leak at A Hypochlorite Bleach Plant - pg12 - 14Soeryanto SlametÎncă nu există evaluări

- Computation Water Hammer With Finite ElementDocument6 paginiComputation Water Hammer With Finite ElementyousefÎncă nu există evaluări

- 07 Katalog ALCO PDFDocument161 pagini07 Katalog ALCO PDFBhavesh PatelÎncă nu există evaluări

- Sitecna Tailored Solutions For Crytical Service ApplicationsDocument4 paginiSitecna Tailored Solutions For Crytical Service Applicationstoto.gmbhÎncă nu există evaluări

- University of Mindanao Civil Engineering Program Physically Distanced but Academically Engaged Self-Instructional Manual (SIM) for Self-Directed Learning (SDLDocument141 paginiUniversity of Mindanao Civil Engineering Program Physically Distanced but Academically Engaged Self-Instructional Manual (SIM) for Self-Directed Learning (SDLSHALOM EMMANUEL OHAOÎncă nu există evaluări

- Diaphragm Analysis and DesignDocument18 paginiDiaphragm Analysis and DesignMukhlish AkhatarÎncă nu există evaluări

- 1.2.2 Optional Piping Systems and Fluid Services: 2 Normative ReferencesDocument1 pagină1.2.2 Optional Piping Systems and Fluid Services: 2 Normative ReferencesRana Ishtiaq FarooqÎncă nu există evaluări

- 7733 OostlanderDocument97 pagini7733 Oostlanderpich222Încă nu există evaluări

- Industry-Portfolio-Catalogue-Saudi-Arabia-EN-60Hz Low ResDocument82 paginiIndustry-Portfolio-Catalogue-Saudi-Arabia-EN-60Hz Low ResHafi UddinÎncă nu există evaluări

- Experiment 2 CHM207 Intermediate Organic Chemistry Distillation Technique and To Determine The Boiling Point of A LiquidDocument3 paginiExperiment 2 CHM207 Intermediate Organic Chemistry Distillation Technique and To Determine The Boiling Point of A LiquidMUADZ ARÎncă nu există evaluări

- Pre Notes 6th Semcode CH 604Document42 paginiPre Notes 6th Semcode CH 604SurajPandeyÎncă nu există evaluări

- ASME B31.8 Gas Transmission & Distribution Piping SystemsDocument3 paginiASME B31.8 Gas Transmission & Distribution Piping SystemsDiego E. Quispe GarciaÎncă nu există evaluări

- Instruction For HP-SCRDocument48 paginiInstruction For HP-SCRboris345678Încă nu există evaluări