Documente Academic

Documente Profesional

Documente Cultură

Us 3292539

Încărcat de

dgfhjsdg hfsdhyjDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Us 3292539

Încărcat de

dgfhjsdg hfsdhyjDrepturi de autor:

Formate disponibile

Dec.

20, 1966

E. BEHR ET AL

3,292,539

SMALL SHOT CARTRIDGE CASE

Filed July 6, 1964

CARBON

BLACK

CROSSLINKED

FILLED,

LOW

PRESSURE POLYETHYLENE

BY

INVENTORS

Erich Behr

Thomas Schinnerer

Arron/v52;

United States Patent 0 rice

3,292,539

Patented Dec. 20, 1966

3,292,539

cause the manufacture of a biaxially stretched polyethyl

ene tube meeting and satisfying all the requirements is

difficult. Moreover, the two-partite construction of the

Erich Behr, Troisdorf, and Thomas Schinnerer, Furth,

Bavaria, Germany, assignors to Dynamit Nobel Aktien

case as well as the subsequent connection or combination

of the two case parts with one another requires a rela

SMALL SHOT CARTRIDGE CASE

gesellschaft, Troisdorf, Germany

tively high expenditure with regard to material and labor.

Filed July 6, 1964, Ser. No. 380,614

It is the object of the present invention to provide a

small shot cartridge case from plastic material which not

D 41,939

only affords the assurance of a faultless ?ring behavior

3 Claims. (Cl. 102-43)

10 within the required temperature range, but which may

also be manufactured simply and inexpensively in a

The manufacture of cartridge cases for training am

weight-saving manner as well as in a single working step

munition from thermoplastic synthetic materials is a well

or operation in one piece, thus reducing the high expendi

known and frequently employed measure. In view of

ture of material and labor previously required.

the favorable experience had with these types of plastic

In accordance with the present invention, a small shot

cases, thermoplastic materials, such as polyethylene, poly 15

cartridge case is thus provided which is characterized

propylene, polyvinyl chloride, and polyamides, have been

by being manufactured in a single working step in one

used also in the manufacture of small shot cartridge cases.

piece and consisting of cross-linked polyethylene, pref

However, it has been found that these plastics do not

erably carbon black-?lled low-pressure polyethylene. It

satisfy the high requirements needed with this type of

has surprisingly been found that this known material,

ammunition. In other words, the rigidity properties of

which may be processed or treated in a simple manner

the cartridge cases corresponding to the high standards

according to conventional ?ow-molding techniques pos

required in small shot cartridge cases cannot be achieved

Claims priority, application Germany, July 9, 1963,

sesses to a high degree all the properties essential for use

in small shot cartridge cases.

As is well known, a small shot cartridge must be usable

The low-pressure polyethylene that is used in pro

at temperatures of from about 20 to about +50 C., 25

ducing the small shot cartridge cases of the present in

i.e., its faultless operation within this temperature range

vention is well known in the art. This type of poly

must be absolutely guaranteed. When a plastic case is

ethylene has a density of about 0.94 to 0.96 and a mo

used for the cartridge, this means that the plastic must

lecular weight in excess of 50,000. Low-pressure poly

not become brittle at the low temperatures and should

not lose its ?rmness and form stability at the high tem 30 ethylene can be made by polymerizing ethylene at low

pressures, e.g., about 100 to 200 pounds per square inch.

peratures. Moreover, the plastic material must not ab

The low-pressure polyethylene is cross-linked by the

sorb any water. At least, the plastic case should not

addition of a suitable cross-linking agent. Organic per

swell. Additionally, the plastic in such cases must be

oxides are quite suitable for this purpose, especially those

chemically inert to the powder charge or charges in the

with the thermoplastic materials previously employed.

35

that decompose into oxy-radicals at high temperature.

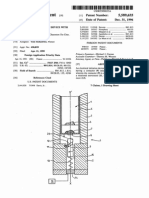

The drawing shows one piece plastics cartridge case

which is partly in section to show the speci?c plastics

composition of the invention.

If the cartridge case, i.e., the shaft of the case and the 40

Peroxides containing an oxygen bonded to a tertiary car

cartridge.

bon atom are particularly useful.

The preferred cross

linking agent is dicumyl peroxide. Other cross-linking

agents include, by way of example, di-t-butyl peroxide,

base thereof, are made together of one piece, which is

di-t-amyl peroxide, 2,5-dimethyl-2,5'-di - t - butylperoxy

shot cartridge case consisting of shaft and base and cor

responding to the practical requirements needed with re~

gard to strength and ridigity could not be achieved.

Therefore, small shot cartridge cases have been made

consisting of a case shaft made from a tough, solid, pri

the small shot cartridge cases.

carbon content of 95% and above, small proportions of

such a small shot cartridge case with a shaft made from

an amount of peroxide of from about 1 to 6%, based on

hexane, 2,5-dimethyl-2,5~di-t-butylperoxy hexyne, blS(d

advisable because of the considerable savings in material

t-butyl-pisopropylbenzyl) peroxide, and bis(a-t-butyl-m

and Working expenditures that can be attained thereby,

isopropylbenzyl) peroxide.

the plastic material that is used must be so rigid in its

The carbon black used as a ?ller in the compositions

formed shape and much have such notch-strength that 45

of

the present invention can be any of those well known

the operation of the loader, feed mechanism and ejector

in the art for such purposes. For example, the commer

of the weapon from which the cartridge is ?red is ?aw

cial carbon blacks prepared by the incomplete combus

less with absolute certainty within the temperature range

tion of hydrocarbon gases or liquids may be used. Some

indicated above. When small shot cartridges are ?red

from semiautomatic weapons, the strength of the plastic 50 of the carbon blacks that may be used satisfactorily in

clude GPF (general purpose furnace), HAF (high abra

must be great enough that the cartridge cases will be able

sive furnace), SRF (semi-reinforcing channel), and HPC

to withstand ejection from these weapons without im

(hard processing channel) carbon blacks. Carbon

pairing their functioning by deformation or breakage.

blacks having a grain size of between 100 and 1,000 A.,

From among the plastics previously employed for small

shot cartridge cases, polyethylene seems to have most 55 particularly 200 to 400 A., have been found most satis

factory in providing high mechanical resistance, such

nearly met the above-speci?ed requirements. But even

as

good tensile strength and resistance against shock, in

with this material, the manufacture of a one-piece small

In order to obtain good

cross-linking of the polyethylene, very pure carbon black,

for example, 98% carbon and above, is preferred. Fur

nace carbon blacks, such as GPF black, having a pure

volatile constituents, and a pH of more than 6 are espe

marily crystalline polyethylene having a density of at

cially preferred.

least 0.94 after tempering and consisting of at least 90%

The amount of cross-linking agent used in making the

of ethylene, whereby the polymer has a Z-dimensionally 65 cr0ss~linked polyethylene small shot cartridge cases may

oriented molecular structure which is stable up to tem

be varied widely depending on the type of polyethylene

peratures of 65.6 C., the case shaft being used in con

used, the ratio of polyethylene to carbon black, and the

junction with a metallic base or bottom piece. Although

cross-linking effectiveness of the peroxide. Generally,

biaxially stretched polyethylene assures a satisfactory ?r 70 the weight of the mixture, is effective. Preferably, an

ing behavior within the temperature range of from --20

amount of peroxide of from 2 to 5%, based on the weight

of the mixture, is used. The amount of carbon black

to +50 0., this material is not entirely satisfactory be

3,292,539

may vary from about 10 to 50%, based on the weight

ally observed with cartridge cases made from polyethyl

of the mixture, depending on the results, desired. Prefer

ene did not occur.

ably, an amount of 20 to 40% by weight of carbon black

While the invention has been described with reference

is used. The optimum amounts of the various constitu

ents forming the mixtures from which the small shot car

tridge cases of the present invention are made depend

to certain speci?c embodiments thereof, it is obvious that

there may be many variations which fall within the true

scope and spirit of the invention. Accordingly, the in

vention should be limited in scope only as outlined in the

appended claims.

We claim:

upon the particular ingredients used, the time and tem

perature of treatment, and the degree of cure desired in

the polymer.

. Admixture of the components can be effected by any 10

1. A shot cartridge comprising a case shaft and a

of the conventional methods, for example, working on

base of a carbon black ?lled cross-linked low pressure

a roller mill, in a Banbury mixer, in a kneader, etc.

polyethylene both formed as one homogeneous part con

Preferably, the polyethylene is added ?rst, then the car

sisting essentially of:

bon black, and the cross-linking agent last. The poly

55-75 percent by weight of low pressure polyethylene

ethylene and carbon black are admixed at temperatures 15

with a nred between 2 and 3 and i5-value of l2,

above the softening point of the polyethylene. After a

45-25 percent by weight of carbon black and

thorough blending thereof, the peroxide is worked in

25 percent by weight relative to the total mixture of

at temperatures of, for example, 110 to 130 C. The

an organic peroxide cross linking agent.

mixing of the components may be accomplished over a

2. A shot cartridge comprising a case shaft and a base,

wide range of temperatures but care should be exercised 20 of a carbon black ?lled, cross linked low pressure poly

in preventing scorching. In general, blending is carried

ethylene both formed as one homogeneous part, consist

out at a temperature just below the activation tempera

ing essentially of:

ture of the peroxide or cross-linking agent used.

40-90 percent by weight of low pressure polyethylene

After the mixture has become homogeneous, the com

position is molded in a conventional manner to give the 25

desired small shot cartridge case in one piece and in one

working operation. The temperature at which the mold

ing operation is e?ected can vary, but, usually, the molds

are pre-heated and the molding operation is carried out

with a nred between 2 and v3 and i5-value of 12,

10-50 percent by weight of carbon black and

16 percent by weight relative to the total mixture, of

an organic cross linking agent.

3. A shot cartridge comprising a case shaft and a base

of a carbon black ?lled, cross linked low pressure poly

at around 180 C. Molding pressures, of from about 30 ethylene both formed as one homogeneous part consist

500 to 1500 kg./cm.2 are suitable. Curing of the com

ing essentially of:

position can be accomplished at ordinary pressures or at

40-90 percent by weight of low pressure polyethylene

super-atmospheric pressures, such as from 10 to 1,000

with a nred between 2 and 3 and i5-value of 1-2,

pounds per square inch or more in the mold or press

used to make the cartridge cases. Generally, the cure 35

takes place at temperatures of between 150 and 200 C.

20-40 percent by weight of carbon black and

1-6 percent by weight relative to the total mixture of

an organic cross linking agent.

The curing time is dependent upon the wall thickness of

the cartridge cases and varies from 30 to 60 seconds per

millimeter of wall thickness.

References Cited by the Examiner

The following example is given by way of illustration 40

and is not to be considered as limiting.

EXAMPLE

UNITED STATES PATENTS

2,825,721

2,953,990

3/ 19518

9/1960

Hogan et a1. _______ __ 102-43

Miller _________ ______ 10242

OTHER REFERENCES

Polythene, second edition, edited by A. Renfrew and

P. Morgan, Interscience Pub. Inc, New York, January

of carbon black (GPF quality) was worked on heated

4, 1961, pp. 65, 321, and 426 required.

rollers until it became homogeneous. Dicumyl peroxide

The Condensed Chemical Dictionary, edited by A.

in an amount of 3% by weight of the mixture was added

Rose and E. Rose, Reinhold Pub. Corp., New York,

and worked in at about 120 C. Small shot cartridge

cases were molded in one piece and in one working op 50 April 4, 1957, p. 879 (required).

A mixture containing 65% by weight of low-pressure

polyethylene (nred:2.5 and i5=1.5) and 35% by weight

eration from the homogeneous batch at 180 C. in a

?ow-molding press. The resultant small shot cartridge

45

SAMUEL FEINBERG, Primary Examiner.

cases showed no errors whatsoever during ?ring tests at

BENJAMIN A. BORCHELT, Examiner.

20_ C., nor were any longitudinal cracks or breaking

R.

F. STAHL, Assistant Examiner.

of the case base noted. Even at +60 C., the errors usu 55

S-ar putea să vă placă și

- U.S. Patent 4,293,314: Gelled Fuel-Air Explosive October 6, 1981.De la EverandU.S. Patent 4,293,314: Gelled Fuel-Air Explosive October 6, 1981.Încă nu există evaluări

- Us3317361 PDFDocument4 paginiUs3317361 PDFchecolonoskiÎncă nu există evaluări

- WM 100////// 44/1? .... .-A S 1: G. B. Young EtalDocument6 paginiWM 100////// 44/1? .... .-A S 1: G. B. Young EtalchecolonoskiÎncă nu există evaluări

- Us7247372 PDFDocument12 paginiUs7247372 PDFrevider451Încă nu există evaluări

- Sept. 20, 1966 - Alfllle 3,274,069: Filed June 17. 1965 5 Sheets $heet 1Document6 paginiSept. 20, 1966 - Alfllle 3,274,069: Filed June 17. 1965 5 Sheets $heet 1kikkuri13Încă nu există evaluări

- Notes on upgrading plastics structures with resistant liningsDocument2 paginiNotes on upgrading plastics structures with resistant liningsmehdi10000Încă nu există evaluări

- United States Patent (19) 11 4,226,186: Peck 45 (Oct. 7, 1980Document4 paginiUnited States Patent (19) 11 4,226,186: Peck 45 (Oct. 7, 1980KundanÎncă nu există evaluări

- Process and Apparatus For The Pyrolysis of Organic CompoundsDocument4 paginiProcess and Apparatus For The Pyrolysis of Organic CompoundsAÎncă nu există evaluări

- Us 3257801 Pyrotechnic Composition Comprising Solid Oxidizer, Boron and Aluminum Additive and BinderDocument3 paginiUs 3257801 Pyrotechnic Composition Comprising Solid Oxidizer, Boron and Aluminum Additive and Binderpepixx985Încă nu există evaluări

- United States Patent (191 (111 4,379,197: Cipriani Et A1. (45) Apr. 5, 1983Document3 paginiUnited States Patent (191 (111 4,379,197: Cipriani Et A1. (45) Apr. 5, 1983Siswand BIn Mohd AliÎncă nu există evaluări

- Waste Tire Pyrolysis: Heat-Mass Balances & New Engineering Solutions With SteamDocument33 paginiWaste Tire Pyrolysis: Heat-Mass Balances & New Engineering Solutions With SteamZakaria ChalheÎncă nu există evaluări

- Composite Materials Journal of ThermoplasticDocument12 paginiComposite Materials Journal of ThermoplasticMehmet ÖzdemirÎncă nu există evaluări

- Advancedmaterials PDFDocument13 paginiAdvancedmaterials PDFshaonaaÎncă nu există evaluări

- United States Patent Office: Patented July 28, 1964Document2 paginiUnited States Patent Office: Patented July 28, 1964Alexander Franco CastrillonÎncă nu există evaluări

- Ijct 25 (4) 336-344Document9 paginiIjct 25 (4) 336-344hari reddyÎncă nu există evaluări

- Basalt, Glass and Carbon Fibers and Their Fiber Reinforced Polymer Composites Under Thermal and Mechanical LoadDocument16 paginiBasalt, Glass and Carbon Fibers and Their Fiber Reinforced Polymer Composites Under Thermal and Mechanical Loadprasanna hamsikaÎncă nu există evaluări

- Environmental TechnologyDocument12 paginiEnvironmental TechnologySara NaseriÎncă nu există evaluări

- Sim900 - Https at Command Set - v1 00Document11 paginiSim900 - Https at Command Set - v1 00ram sriÎncă nu există evaluări

- Sintering Boron Carbide Under High Pressures for Hard Materials ApplicationsDocument6 paginiSintering Boron Carbide Under High Pressures for Hard Materials ApplicationsJohn JohnsonÎncă nu există evaluări

- US4199486Document7 paginiUS4199486fadrolÎncă nu există evaluări

- Pilot-Scale Pyrolysis of Scrap Tires in A Continuous Rotary Kiln ReactorDocument13 paginiPilot-Scale Pyrolysis of Scrap Tires in A Continuous Rotary Kiln ReactorAlexanderRodriguezGamboaÎncă nu există evaluări

- Us 5237927Document4 paginiUs 5237927wewewewÎncă nu există evaluări

- Properties and Morphology of Polypropylene/Big Bags CompoundsDocument8 paginiProperties and Morphology of Polypropylene/Big Bags CompoundsKaori OubaÎncă nu există evaluări

- N2 MarkedDocument8 paginiN2 MarkedEkansh ChoudharyÎncă nu există evaluări

- Polymer Quasicrystal CompositeDocument4 paginiPolymer Quasicrystal CompositemiercastroÎncă nu există evaluări

- ASTM D 1603 - 01 Standard Test Method Carbon Black in Olefin PlasticsDocument4 paginiASTM D 1603 - 01 Standard Test Method Carbon Black in Olefin Plasticsuocmogiandi_a100% (1)

- Carbon Fibers2Document3 paginiCarbon Fibers2Ankur SagarÎncă nu există evaluări

- The Effects of Epoxy Resin Nano ParticleDocument29 paginiThe Effects of Epoxy Resin Nano ParticleWellington C. de AraujoÎncă nu există evaluări

- Ket Hop NhomDocument9 paginiKet Hop Nhománh nguyễnÎncă nu există evaluări

- July 19, 1960: ObjectDocument3 paginiJuly 19, 1960: ObjectVansala GanesanÎncă nu există evaluări

- Fire Retardant Mechanism of Aliphatic Bromine Compounds in PS and PP J. Kaspersma - C. Doumen S. Munro - A-M. PrinsDocument7 paginiFire Retardant Mechanism of Aliphatic Bromine Compounds in PS and PP J. Kaspersma - C. Doumen S. Munro - A-M. PrinsVictor CastrejonÎncă nu există evaluări

- Ablative Flash Pyrolysis of Straw and Wood Bench-Scale ResultsDocument9 paginiAblative Flash Pyrolysis of Straw and Wood Bench-Scale ResultsGiriraj JoshiÎncă nu există evaluări

- EP0603753A1Document10 paginiEP0603753A1xfactor gangaarÎncă nu există evaluări

- United States Patent (191 4,717,695Document14 paginiUnited States Patent (191 4,717,695Samar RashidÎncă nu există evaluări

- Hydrocarbon Fuel From Waste Plastic-2018!07!13Document6 paginiHydrocarbon Fuel From Waste Plastic-2018!07!13jorge moraÎncă nu există evaluări

- EP2952536A2Document45 paginiEP2952536A2Yahya AlmundzirÎncă nu există evaluări

- Predel2000 CROMA PPDocument13 paginiPredel2000 CROMA PPJuan Carlos FigueroaÎncă nu există evaluări

- An Investigation On The Processing of Sisal Fibre Reinforced Polypropylene CompositesDocument4 paginiAn Investigation On The Processing of Sisal Fibre Reinforced Polypropylene CompositesThines RajÎncă nu există evaluări

- An Experimental Evaluation of Fiber Reinforced PolypropyleneDocument6 paginiAn Experimental Evaluation of Fiber Reinforced PolypropyleneRafael ZanettiÎncă nu există evaluări

- Activation of Waste Tire Char Upon Cyclic Oxygen Chemisorption#DesorptionDocument8 paginiActivation of Waste Tire Char Upon Cyclic Oxygen Chemisorption#DesorptionFrancisco HerasÎncă nu există evaluări

- PS2 - 1 - The Impact of Laminated Cellulosic Products On Transformer LifetimeDocument5 paginiPS2 - 1 - The Impact of Laminated Cellulosic Products On Transformer Lifetimegiovanni MarzoloÎncă nu există evaluări

- PET Pyrolysis Conditions in Conical ReactorDocument6 paginiPET Pyrolysis Conditions in Conical ReactorZahid FarooqÎncă nu există evaluări

- Feasible Processes for Plastics PyrolysisDocument4 paginiFeasible Processes for Plastics PyrolysisNishant Ketan SinghÎncă nu există evaluări

- Simulation Study For Production of Hydrocarbons From WasteDocument9 paginiSimulation Study For Production of Hydrocarbons From WasteAJER JOURNALÎncă nu există evaluări

- PP Honeycomb Polymer MaterialDocument8 paginiPP Honeycomb Polymer MaterialMuchammad IrwanÎncă nu există evaluări

- Plastics and Aircraft Part 2Document1 paginăPlastics and Aircraft Part 2veence spenglerÎncă nu există evaluări

- Metallurgical and Other ProcessesDocument4 paginiMetallurgical and Other ProcessesKeila Mariana Campos ChambiÎncă nu există evaluări

- Waste Plastic to FuelDocument9 paginiWaste Plastic to FuelTanya PanwarÎncă nu există evaluări

- Victorian Institute of Engineers: 1948, SEPTEMBER, 26TH ProceedingsDocument11 paginiVictorian Institute of Engineers: 1948, SEPTEMBER, 26TH ProceedingsYash DumaswalaÎncă nu există evaluări

- Thermal Degradation of Mixed Plastic Wasteto Aromatics and GasDocument9 paginiThermal Degradation of Mixed Plastic Wasteto Aromatics and GasMubshir MughalÎncă nu există evaluări

- Turning Plastic Waste Into OilDocument10 paginiTurning Plastic Waste Into OilSanjana SharmaÎncă nu există evaluări

- Gun Burner. Materi 1Document10 paginiGun Burner. Materi 1DwiIndraswari100% (1)

- New Materials by Agglomeration of Petroleum Coke FinesDocument5 paginiNew Materials by Agglomeration of Petroleum Coke Finesbragi89Încă nu există evaluări

- Wind Turbine BladesDocument6 paginiWind Turbine BladesSudhanwa KulkarniÎncă nu există evaluări

- 1218 MSFCDocument8 pagini1218 MSFCAgosh McÎncă nu există evaluări

- Cryogenic Grinding: An Independent Voice: CryogenicsDocument3 paginiCryogenic Grinding: An Independent Voice: CryogenicsJainy ShahÎncă nu există evaluări

- European Patent Specification: Printed by Jouve, 75001 PARIS (FR)Document17 paginiEuropean Patent Specification: Printed by Jouve, 75001 PARIS (FR)quyÎncă nu există evaluări

- Polyester Fiber: Applications of Porous CeramicsDocument12 paginiPolyester Fiber: Applications of Porous CeramicsJane DocdocÎncă nu există evaluări

- Analysis of Coal Mill OperationDocument16 paginiAnalysis of Coal Mill OperationAnonymous knICaxÎncă nu există evaluări

- Us 6776102Document4 paginiUs 6776102dgfhjsdg hfsdhyjÎncă nu există evaluări

- Us 6776102Document4 paginiUs 6776102dgfhjsdg hfsdhyjÎncă nu există evaluări

- Ulllted States Patent (19) (11) Patent Number: 6,038,955: 2 I J J E '7" OperationDocument4 paginiUlllted States Patent (19) (11) Patent Number: 6,038,955: 2 I J J E '7" Operationdgfhjsdg hfsdhyjÎncă nu există evaluări

- Us 6131519Document4 paginiUs 6131519dgfhjsdg hfsdhyjÎncă nu există evaluări

- Us 3345945Document3 paginiUs 3345945dgfhjsdg hfsdhyjÎncă nu există evaluări

- Us 5589655Document4 paginiUs 5589655dgfhjsdg hfsdhyjÎncă nu există evaluări

- Us 6019217Document5 paginiUs 6019217dgfhjsdg hfsdhyjÎncă nu există evaluări

- Us 5610365Document5 paginiUs 5610365dgfhjsdg hfsdhyjÎncă nu există evaluări

- Us 7025165Document5 paginiUs 7025165dgfhjsdg hfsdhyjÎncă nu există evaluări

- Us 20040158969Document5 paginiUs 20040158969dgfhjsdg hfsdhyjÎncă nu există evaluări

- Us 1530692Document2 paginiUs 1530692dgfhjsdg hfsdhyjÎncă nu există evaluări

- Us 2920443Document2 paginiUs 2920443wewewewÎncă nu există evaluări

- Us 4676137Document6 paginiUs 4676137fghdfjerÎncă nu există evaluări

- Unlted States Patent (10) Patent N0.2 US 8,291,806 B2Document12 paginiUnlted States Patent (10) Patent N0.2 US 8,291,806 B2dgfhjsdg hfsdhyjÎncă nu există evaluări

- Us 4207797Document7 paginiUs 4207797fghdfjerÎncă nu există evaluări

- Nun M.: BC BM 0000Document12 paginiNun M.: BC BM 0000shdhsjkÎncă nu există evaluări

- United States Patent (191: Sullivan Et A1Document21 paginiUnited States Patent (191: Sullivan Et A1fghdfjerÎncă nu există evaluări

- EP0365145B1Document12 paginiEP0365145B1fghdfjerÎncă nu există evaluări

- Unlted States Patent (19) (11) Patent Number: 5,335,579Document8 paginiUnlted States Patent (19) (11) Patent Number: 5,335,579fghdfjerÎncă nu există evaluări

- Aazzzs 2112291252:: Ulllted States Patent (19) (11) Patent Number: 6,048,379Document45 paginiAazzzs 2112291252:: Ulllted States Patent (19) (11) Patent Number: 6,048,379dgfhjsdg hfsdhyjÎncă nu există evaluări

- EP0363079A2Document8 paginiEP0363079A2fghdfjerÎncă nu există evaluări

- SOIL ASSESSMENT AND PLANT PROPAGATION OF BELL PEPPERS (Capsicum Annuum)Document35 paginiSOIL ASSESSMENT AND PLANT PROPAGATION OF BELL PEPPERS (Capsicum Annuum)Audrey Desiderio100% (1)

- Detection and Attribution Methodologies Overview: Appendix CDocument9 paginiDetection and Attribution Methodologies Overview: Appendix CDinesh GaikwadÎncă nu există evaluări

- DENSO COMMON RAIL INJECTOR REPAIR GUIDEDocument22 paginiDENSO COMMON RAIL INJECTOR REPAIR GUIDEMarcoÎncă nu există evaluări

- LTE EPC Technical OverviewDocument320 paginiLTE EPC Technical OverviewCristian GuleiÎncă nu există evaluări

- TILE QUOTEDocument3 paginiTILE QUOTEHarsh SathvaraÎncă nu există evaluări

- Naukri LalitaSharma (3y 4m)Document2 paginiNaukri LalitaSharma (3y 4m)rashika asraniÎncă nu există evaluări

- KAC-8102D/8152D KAC-9102D/9152D: Service ManualDocument18 paginiKAC-8102D/8152D KAC-9102D/9152D: Service ManualGamerAnddsÎncă nu există evaluări

- Aleister Crowley and the SiriansDocument4 paginiAleister Crowley and the SiriansJCMÎncă nu există evaluări

- Sap ThufingteDocument10 paginiSap ThufingtehangsinfÎncă nu există evaluări

- TutorialDocument324 paginiTutorialLuisAguilarÎncă nu există evaluări

- Motor GraderDocument24 paginiMotor GraderRafael OtuboguatiaÎncă nu există evaluări

- JK Paper Q4FY11 Earnings Call TranscriptDocument10 paginiJK Paper Q4FY11 Earnings Call TranscriptkallllllooooÎncă nu există evaluări

- Evolutionary PsychologyDocument10 paginiEvolutionary PsychologyShreya MadheswaranÎncă nu există evaluări

- ROMUS 2012 Flooring CatalogueDocument20 paginiROMUS 2012 Flooring CatalogueDan George IIIÎncă nu există evaluări

- Traffic Violation Monitoring with RFIDDocument59 paginiTraffic Violation Monitoring with RFIDShrëyãs NàtrájÎncă nu există evaluări

- Steam Turbines: ASME PTC 6-2004Document6 paginiSteam Turbines: ASME PTC 6-2004Dena Adi KurniaÎncă nu există evaluări

- Introduction To Finite Element Methods (2001) (En) (489s)Document489 paginiIntroduction To Finite Element Methods (2001) (En) (489s)green77parkÎncă nu există evaluări

- Qualitative Research EssayDocument9 paginiQualitative Research EssayMichael FoleyÎncă nu există evaluări

- Rectifiers and FiltersDocument68 paginiRectifiers and FiltersMeheli HalderÎncă nu există evaluări

- Peptic Ulcer Disease: Causes, Symptoms and TreatmentDocument24 paginiPeptic Ulcer Disease: Causes, Symptoms and TreatmentOktaviana Sari Dewi100% (1)

- Lesson Plan: Lesson: Projectiles Without Air ResistanceDocument4 paginiLesson Plan: Lesson: Projectiles Without Air ResistanceeltytanÎncă nu există evaluări

- Nickel-Metal Hydride Battery Safety Data SheetDocument8 paginiNickel-Metal Hydride Battery Safety Data SheetYeong WheeÎncă nu există evaluări

- O2 Orthodontic Lab Catalog PDFDocument20 paginiO2 Orthodontic Lab Catalog PDFplayer osamaÎncă nu există evaluări

- Sradham ChecklistDocument9 paginiSradham ChecklistpswaminathanÎncă nu există evaluări

- Cost Analysis and Financial Projections for Gerbera Cultivation ProjectDocument26 paginiCost Analysis and Financial Projections for Gerbera Cultivation ProjectshroffhardikÎncă nu există evaluări

- Front Wheel Steering System With Movable Hedlights Ijariie5360Document6 paginiFront Wheel Steering System With Movable Hedlights Ijariie5360Ifra KhanÎncă nu există evaluări

- KINETIC THEORY OF GASES TUTORIALDocument6 paginiKINETIC THEORY OF GASES TUTORIALMat SyafiqÎncă nu există evaluări

- Gas Natural Aplicacion Industria y OtrosDocument319 paginiGas Natural Aplicacion Industria y OtrosLuis Eduardo LuceroÎncă nu există evaluări

- Design of Fixed Column Base JointsDocument23 paginiDesign of Fixed Column Base JointsLanfranco CorniaÎncă nu există evaluări

- Fundermax Exterior Technic 2011gb WebDocument88 paginiFundermax Exterior Technic 2011gb WebarchpavlovicÎncă nu există evaluări