Documente Academic

Documente Profesional

Documente Cultură

IPTC16669

Încărcat de

jangolovaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

IPTC16669

Încărcat de

jangolovaDrepturi de autor:

Formate disponibile

IPTC 16669

Development Optimization of a Marginal Oil Field in Bohai Bay, China

Integrated Solutions to Overcome Challenges in Offshore Horizontal Well

Construction

Chaomin Nie, Yongsheng Zhao, Lv Tan, Yong Jia, and Gang Zhai, CNOOC Tianjin (CCLT); and Parlindungan

Monris Halomoan, Xu Chong Hui, Wang Yong, Wang Fei, and Dong Jianyi, Schlumberger

Copyright 2013, International Petroleum Technology Conference

This paper was prepared for presentation at the International Petroleum Technology Conference held in Beijing, China, 2628 March 2013.

This paper was selected for presentation by an IPTC Programme Committee following review of information contained in an abstract submitted by the author(s). Contents of the paper, as

presented, have not been reviewed by the International Petroleum Technology Conference and are subject to correction by the author(s). The material, as presented, does not necessarily

reflect any position of the International Petroleum Technology Conference, its officers, or members. Papers presented at IPTC are subject to publication review by Sponsor Society

Committees of IPTC. Electronic reproduction, distribution, or storage of any part of this paper for commercial purposes without the written consent of the International Petroleum Technology

Conference is prohibited. Permission to reproduce in print is restricted to an abstract of not more than 300 words; illustrations may not be copied. The abstract must contain conspicuous

acknowledgment of where and by whom the paper was presented. Write Librarian, IPTC, P.O. Box 833836, Richardson, TX 75083-3836, U.S.A., fax +1-972-952-9435

Abstract

A total of nine horizontal wells including one injector well were drilled to cover the small, 9 km2, oil-bearing area of a

marginal oil field that is isolated by secondary faults and stratigraphic depositional borders in Bohai Bay, China.

A pilot study showed that the reservoirs are distributary channel sands of a shallow water deltaic depositional system.

Seismic inversion indicated that the sand properties and connectivity vary dramatically across the field. A multiple-aquifer

system was apparent, and the gas/oil contact (GOC) and oil/water contact (OWC) levels were unknown. Furthermore, the only

well control was from three vertical exploration wells and two directional offset wells.

An advance distance-to-boundary well placement technique using azimuthal deep directional electromagnetic loggingwhile-drilling (LWD) technology was applied to overcome these challenges and to enhance reservoir understanding. A

multifunction LWD formation evaluation tool was deployed to evaluate fluid properties where the top gas might occur. In

addition, a rotary steerable drilling system (RSS) was assembled to achieve drilling efficiency and smooth trajectory control.

One injector well and eight producer horizontal wells were precisely placed in optimum position for injection and drainage

with a 100% success rate; one producer horizontal well was retracted while another producer well was added based on finding

definite GOC and OWC levels. Increasing the drilling penetration rate and avoiding adjustments following reservoir exits led

to a 60% improvement in drilling efficiency, which is equivalent to a cost savings of USD 32 million. Production from these

horizontal wells surpasses the set production target by 30%, with extremely low water cut. The integrated LWD, well

placement, and RSS solution optimized the marginal oil field into a much more economic development oil field.

Introduction

The BZ oilfield is located at the southern part of Bohai Bay, approximately 160 km southeast of Tanggu, Tianjin (Fig. 1). It is

a small oil-bearing area9 km2that is isolated by secondary faults and stratigraphic depositional borders. A total of 10

horizontal wells, including one injector well, were planned to develop this marginal oil field.

Two other producing oil fields are located in the northern and western parts of the BZ area. Although the original oil in

place (OOIP) of oil field is estimated at only 1261.89104 m3, this marginal oil field is expected to be economic to develop and

put into production by sharing the facilities of the other two oil fields.

IPTC 16669

Fig. 1BZ26-3 oil field is located at the southern part of Bohai Bay, approximately 160 km southeast of Tanggu, Tianjin.

Background

The BZ structure is part of the complex fault system in the northwest side of the Huanghekou depression, at the west side of

the Bonan uplift.

The main reservoir targets are the lower Neogene Minghuazhen formation (referred to as Nm) and the upper Guantao

(referred to as Ng). The lower Nm is divided into seven groups (from top to bottom): Nm0, Nm, Nm, Nm, Nm, Nm

, and Nm. The upper Ng is divided into two groups (from top to bottom): Ng and Ng. These groups were defined

based on high-resolution sequence stratigraphy.

The oil field is isolated not only by primary faults, but also by various secondary faults generated at different geological

periods (Fig. 2). Because of this isolation, a multiple-aquifer system exists, and the oil-bearing area of this trap system is not

more than 9 km2.

Fig. 2Isolation of the reservoir by primary and secondary faults.

IPTC 16669

A pilot study based on core and sequence stratigraphy analysis of multiple wells shows that the reservoirs are distributary

channel sands of a shallow lake delta plain. Seismic inversion indicates that the sand properties and connectivity vary

dramatically across the field (Fig. 3).

Fig. 3 Seismic inversion indicates variable sand properties and connectivity across the field.

The channel sands have medium to high porosity and permeability. The seismic data analysis suggests that the properties

may vary laterally.

Meanwhile, uncertainty in the top gas and bottom water levels adds to the complexity of this field. The data from three

vertical wells and two directional wells drilled during the exploration phase indicated that a multiple-aquifer system exists,

while the GOC and OWC levels were unknown prior to this horizontal drilling program (Fig. 4).

Fig. 4Reservoir profile of BZ26-3 oil field where GOC and OWC levels were unknown.

IPTC 16669

Horizontal well drilling program

Two platforms were designed to develop this complex oil field (Fig. 5): BZ-A platform to drill 11 wells and BZ-B platform to

drill 5 wells. Among these 16 wells, 10 horizontal wells were designed as producer wells, 5 deviated wells were designed as

injector wells for formation pressure maintenance, and 1 deviated well was designed to supply water for the injector wells.

Fig. 5Platform A and B were designed to developed the BZ26-3 oil field.

The planned cumulative oil production for a 30-year period is 257.3104 m3 (Fig. 6), with an expected recovery factor of

24.3%. The planned cumulative gas production after 20 years is 17.7108 m3, with an expected recovery factor of 60.9%.

Fig. 6The planned cumulative oil production for a 30-years.

Challenges

During the planning stage of the horizontal well drilling program execution, the team identified multiple major subsurface

challenges:

1. The lack of offset well control in the area, increased structural uncertainty

2. The field lies within a highly faulted area, which increased the risk of exit from reservoir and the need to make

adjustments to re-enter the reservoir.

3. A multiple-aquifer system may exist, and the OWC was unknown. This increased the risk of approaching the

OWC and of early water breakthrough if the lateral section of the horizontal well were not placed properly, close

to reservoir top.

IPTC 16669

4.

5.

6.

7.

The uncertainty in the top of gas and GOC might affect the oil production and recovery factor if the lateral section

of the horizontal well were not placed properly below the GOC.

Poor sand connectivity of the channel sands might affect the production and recovery factor if the sands are not

well connected by the lateral section of the horizontal well.

The seismic impendence inversion profile analysis showed that the distribution of the lateral sand properties is

variable; the strategy was to evaluate the upper target sand quality while drilling the earlier deeper target wells in

sequence.

Because of the complexity and relatively small volume of the OOIP, the field is considered as marginal; drilling

efficiency and the ability to minimize the drilling risk of exit from reservoir that may result in sidetracking were

required to lower the overall well construction cost.

Solution

To overcome these challenges and to enhance reservoir understanding, the advance distance-to-boundary well placement

technique using azimuthal deep directional electromagnetic logging-while-drilling (LWD) technology was applied (Fig. 7).

Fig. 7Top: Deep directional electromagnetic azimuthal LWD technology has the features of multiple frequencies and transmitterreceiver spacings and integrates two tilted receivers and one transverse transmitter. Bottom: The tool provides the ability to

simultaneously map multiple key boundaries in distance including the fluid contact, the top and bottom of the reservoir

structure, and the resistivity value of the target, upper bed, and lower bed.

A multifunction LWD formation evaluation tool (Fig. 8) was deployed to evaluate reservoir quality and fluid properties

where the top of the gas may occur. A real-time density image was also applied to determine the formation dip while drilling.

In addition, a rotary steerable drilling system (RSS) was assembled to achieve drilling efficiency, smooth trajectory control,

and full control of the well path within the drilling or steering window.

Fig. 8Multifunction LWD service integrates a full suite of formation evaluation, well placement, and drilling optimization

measurements into a single collar.

IPTC 16669

Execution

Field operation examples from four challenging wells that demonstrate the subsurface complexities are described below.

The application of fit-for-purpose multifunction LWD formation evaluation tool and azimuthal LWD bed boundary mapping

tool in overcoming these challenges and facilitating decision making within the team are also discussed.

Case 1: Sand Boundary Identification

The plan for well HW#5 was to place the horizontal section for 350 m within the middle part of the reservoir (Fig. 9). The

well was planned near the main fault, and the seismic impedance profile showed that there was a possibility of discontinuity

between the channel sands (Fig. 10). A requirement was to avoid entry into the gas cap or bottom-water.

Fig. 9The well HW#5 was planned near the main fault with placement of the horizontal section for 350 m within the middle part of

the reservoir.

Fig. 10The seismic impedance profile shows the possibility of discontinuity between the channel sands at the well.

During the landing, the well was placed approximately 5 m below the reservoir top after entering the sweet spot zone (Fig.

11).

IPTC 16669

Fig. 11Well landing approximately 5 m below the reservoir top in the sweet spot zone.

During the horizontal section drilling (Fig. 12), the top target was mapped by the azimuthal deep directional

electromagnetic tool, and subsequently the well trajectory was placed toward the middle of the reservoir. After drilling more

than 150 m, the bottom of the sand reservoir was clearly detected and delineated 4.6 m above the boundary. The trajectory was

then adjusted accordingly to level-off about 4 m away from the bottom. Toward the end of the well, the trajectory was

intentionally steered toward the upper zone to detect the top target. The target top was eventually detected and mapped toward

the total depth (TD) of the well.

Fig. 12Well trajectory placed optimally along the middle of the reservoir.

Without the ability to detect and map the boundaries, the horizontal section could have not been placed along the middle of

the reservoir and the trajectory could have exited from the bottom of the reservoir.

Finally, the 346-m horizontal section was drilled with 100% net-to-gross in about 7.5 hours, much faster than the 54 hours

of the plan.

IPTC 16669

Case 2: Placing Trajectory Accurately Below the Gas Cap

The unknown GOC level was one of the major challenges in placing the horizontal section for well HW#10. The well was

planned near the fault in the crest area of the reservoir controlled by the channel depositional system (Fig. 13). The gas cap

exists in the crest area, but the GOC level was unknown. The objective of the well was to place the horizontal section within

the oil zone approximately 2 m below the GOC. Entry to the gas cap during the horizontal section was prohibited.

Fig. 13Well HW#10 planned near the fault in the crest area of the reservoir controlled by the channel depositional system. The gas

cap exists in the crest area, but the GOC level was unknown.

The option to drill a pilot well to confirm the GOC level was initially part of the original plan. However, the team was

aware that the real-time gas identification while drilling provided by the LWD tool could be a better alternative than the pilot

well and could potentially result in considerable savings in the AFE (Authorization for Expenditure) costs.

It was decided to rely on LWD data and eliminate the pilot well. The team recognized that the precise GOC level

identification during the landing section would be very critical to placement of the horizontal section below the gas cap to

avoid entering this prohibited zone.

To overcome this challenge, the multifunction LWD formation evaluation tool was deployed during the landing section.

Eventually, the GOC was identified at the level of 1536 m true vertical depth subsea (TVDSS) or 5 m deeper than the original

prognosis (Fig. 14), and the well then landed 2 m below the contact. Then the horizontal section was continued by keeping the

trajectory in the same level all the way to TD of the well.

IPTC 16669

Fig. 14Well trajectory placed optimally along the middle of the reservoir.

The ability of the advance multifunction LWD tool to perform real-time formation evaluation while drilling allowed the

team to identify the GOC accurately, place the well below the gas cap properly, and save the cost of drilling a pilot well.

Case 3: Placement along the Braided Channel Sand Body

Well HW#2 demonstrated the complexity of the channel sand depositional system in the Bohai Bay area. As can be seen in

Fig. 15, the trend of the channel sand body is in the southeast/northwest direction, and then it turns to the opposite,

southwest/northeast, direction. The objective of HW#2 was to land the well near the edge right wing of the channel sand and

place the 800-m lateral section along the northeast/southwest direction. From the seismic inversion model, the trajectory may

approach the edge of the channel left wing toward the end.

During the landing section, the well was landed smoothly below the reservoir target top despite the reservoir found

shallower by 3 m compared to the original plan (Fig. 16).

10

IPTC 16669

Fig. 15A horizontal well was planned to be drilled along the channel sand body.

Fig. 16The well landed smoothly despite the reservoir found 3 m shallower than the plan.

In the lateral section, the azimuthal LWD bed boundary mapper tool clearly delineated the channel sand body boundaries

along the horizontal section (Fig. 17). It was observed that the reservoir body consists of series of braided channel sands

surrounded by shaly sand. The trajectory was finally completed to TD and was optimally placed within the clean channel

sands while also setting a new record for lateral section length in the field. The team recognized that without the detailed

IPTC 16669

11

information of the boundaries and the reservoir profiles, the trajectory would have not been placed within the clean channel

sands and might even have been placed out of the target reservoir body.

Fig. 17The azimuthal LWD bed boundary mapper tool clearly delineated the channel sand body boundaries along the horizontal

section.

Case 4: Well Type Adjustment While Drilling Based on Real-Time Information

Well Inj#2 was designed as an injector well for reservoir pressure maintenance (Fig. 18). The plan was to drill a directional

well from the top to the bottom of the reservoir (Fig. 19).

Fig. 18Well Inj#2 was designed as an injector well for reservoir pressure maintenance.

12

IPTC 16669

Fig. 19The Inj#2 plan was to drill a directional well from the top to the bottom of the reservoir.

The multifunction LWD formation evaluation tool was used to evaluate the reservoir while drilling. Eventually, during the

drilling operation, the team decided to change the directional well into a horizontal well based on real-time formation

evaluation data (Fig. 19). The team found out that the quality of some intervals in the reservoir zone is not as good as was

expected, which may affect the efficiency of the injector well.

Fig. 19The directional well was shifted to a horizontal well based on real-time formation evaluation data during the drilling

operation.

IPTC 16669

13

Therefore, the decision was made to extend the reservoir exposure by drilling a horizontal well rather than a directional

well. After 500 m of lateral section were achieved, the trajectory was intentionally drilled down the structure to tag the bottom,

thereby covering the entire reservoir section.

The success of shifting the directional injector well into a horizontal injector well has ensured the effectiveness of the

injector well within the area. The team also evaluated the adequacy of this injector horizontal well to support pressure

maintenance within this particular oil trap compartment. Cost savings were achieved by eliminating the need to drill another

injector well in the future.

Results

Nine horizontal wellsone injector well and eight producer wellswere precisely placed in the optimum position for

injection and drainage. A total of 4303 m of horizontal section was drilled and placed within the target reservoir with 100%

net-to-gross.

The injector well was begun as a directional well and then shifted to a horizontal well. One of the producer horizontal wells

was retracted upon discovery that the target sand was not developed within the targeted area, and another producer horizontal

well was canceled because of engineering considerations.

Despite the reduction in the number of producer wells from the original plan of 10 wells to 8 wells, the total production

from the 8 producer wells is even higher than the set goals of the total production of the 10 wells. The total production rate of

the 8 producer wells exceeded the expected total production rate of the 10 wells by 3.3%. This represents 30% additional

production per well compared to the original set goals (Table 1).

TABLE 1HORIZONTAL WELL PRODUCTION

PERFORMANCE

Well

Actual Production

Water Cut

(%)

(m /d)

HW Producer#1

85

1.2

HW Producer#2

86

23.9

HW Producer#3

116

0.3

HW Producer#4

69

HW Producer#5

125

19.3

HW Producer#6

200

0.4

HW Producer#7

212

2.1

HW Producer#8

171

15.4

Furthermore, the capability to increase the drilling penetration rate and avoid adjustments or sidetracks because of reservoir

exits led to a 60% improvement in drilling efficiency (Table 2), equivalent to a savings of USD 32 million.

TABLE 2DRILLING EFFICIENCY

Well

Horizontal length

Drilling time

Time saved

(hours)

(m)

(hours)

HW Producer#1

800

47

HW Producer#2

304

17.5

36.5

HW Producer#3

305

14.5

39.5

HW Producer#4

385

28.7

25.3

HW Injector

560

20

34

HW Producer#5

490

13.3

40.7

HW Producer#6

667

26

28

HW Producer#7

346

7.5

46.5

HW Producer#8

447

22

32

a

Drilling efficiency achieved by optimizing penetration rate and avoiding adjustments and

sidetracks because of reservoir exits.

14

IPTC 16669

Conclusion

The development optimization of the BZ marginal oil field in Bohai Bay, China was successful, and the following factors

contributed to the success:

1. There was strong team work within multifunctional disciplines of the assets, drilling teams, and service providers.

2. The comprehensive field development plan to develop the complex and marginal oil field included horizontal /

deviated wells designed as producer / injector wells.

3. A contingency plan was formulated for each of the planned horizontal producer / injector wells based on the actual

findings of GOC and OWC level and the reservoir quality.

4. The horizontal well drilling approach utilized the drilling, LWD, and well placement fit-for-purpose technology.

5. The applications of fit-for-purpose technologies including advance multifunction formation evaluation and advance

deep directional electromagnetic azimuthal LWD with distance-to-boundary technique for well placement has

improved our understanding of the reservoir characteristics by accurately mapping multiple key boundaries in

distance, including the top and bottom of the reservoir structure, and by identifying the GOC and OWC levels. These

advantages enabled the team to make effective real-time decisions for placing the trajectory in the best place to drain

the remaining hydrocarbon. Furthermore, this information enabled the team to change the original plan of the well

into the contingency plan on the fly while drilling.

These key factors can be applied in similar marginal fields to overcome the challenges and transform the marginal oil field

into an economic oil field.

Acknowledgments

The authors would like to thank CCLS (CNOOC Tianjin) and Schlumberger for the permission to publish this information.

References

Deng Jian Ming, Liu Peng, Zhao Yong Sheng, et al. 2010. Proactive Well Placement Integrated into a Systematical Approach Enhances

Productivity in a Complex Offshore Field, Bohai Bay. Paper SPE 131133 presented at the SPE International Oil & Gas Conference and

Exhibition, Beijing, China, 810 June.

Hongqing, Y., Ping, W, Xiang, T., et al. 2008. Horizontal Well Best Practices to Reverse Production Decline in Mature Fields in South

China Sea. Paper SPE 116528 presented at the SPE Asia Pacific Oil and Gas Conference and Exhibition, Perth, Australia, 2022 October.

Lian JiHong, Huang YingShi, Thanh Tran, et al. 2012. New Approach and Innovative Technology Application in Complex and Mature

ReservoirsAchieving Ultimate Reserve Recovery and Economic Objectives for Huizhou Field, Offshore South China. Paper IPTC SPE

14687 presented at the International Petroleum Technology Conference, Bangkok, Thailand, 79 February.

Tran, T., Huang, Y. S., Tiger Lian, J. H., et al. 2010. Attic Thin Oil Column Horizontal Well Optimization Through Advanced Application

of ICD and Well-Placement Technologies in South China. Paper IADC/SPE 126675 presented at the IADC/SPE Drilling Conference and

Exhibition, New Orleans, Louisiana, USA, 24 February.

Daveridge, S., Hiebert, S., al Harthy, M., et al., 2005. An Innovative Business Model to Leverage Innovative Well-Placement Technology.

OTC 17591-MS presented at the Offshore Technology Conference, Houston, Texas, USA, 25 May.

S-ar putea să vă placă și

- Spe 116528 MSDocument14 paginiSpe 116528 MSlilivaca28Încă nu există evaluări

- Spe 170789 MS PDFDocument17 paginiSpe 170789 MS PDFerikaberriomÎncă nu există evaluări

- Clevo W940tu Service ManualDocument93 paginiClevo W940tu Service ManualBruno PaezÎncă nu există evaluări

- The Acceptability of Rubber Tree Sap (A As An Alternative Roof SealantDocument7 paginiThe Acceptability of Rubber Tree Sap (A As An Alternative Roof SealantHannilyn Caldeo100% (2)

- Cargo ManagementDocument45 paginiCargo ManagementShubham Chaurasia75% (8)

- SPE-177659-MS Field Development and Optimization Plan For Compartmentalized Oil Rim ReservoirDocument23 paginiSPE-177659-MS Field Development and Optimization Plan For Compartmentalized Oil Rim ReservoirDenis GontarevÎncă nu există evaluări

- Paper 2 Word FixDocument16 paginiPaper 2 Word FixICHSAN AL SABAH LÎncă nu există evaluări

- Spe 182930 MSDocument25 paginiSpe 182930 MSMohamed MoftiÎncă nu există evaluări

- IPTC 16616 A Case Study: Innovative Open Hole Well Completion Provides Superior Results in Tight Gas Formation in Jilin District, ChinaDocument12 paginiIPTC 16616 A Case Study: Innovative Open Hole Well Completion Provides Superior Results in Tight Gas Formation in Jilin District, ChinaAmr HegazyÎncă nu există evaluări

- Feng2013 PDFDocument12 paginiFeng2013 PDFAmr HegazyÎncă nu există evaluări

- 2-New Completion Technology4Document7 pagini2-New Completion Technology4klibiÎncă nu există evaluări

- Jurnal 23Document10 paginiJurnal 23TAUFIQ HIDAYATÎncă nu există evaluări

- Alklih 2014Document8 paginiAlklih 2014arispriyatmonoÎncă nu există evaluări

- Anomalous Fluid Distribution Due To Late Stage Gas Migration in A Tight Oil and Gas Deltaic Sandstone ReservoirDocument6 paginiAnomalous Fluid Distribution Due To Late Stage Gas Migration in A Tight Oil and Gas Deltaic Sandstone ReservoirhijoetigreÎncă nu există evaluări

- Advanced Reservoir Characterization in Vaca Muerta PDFDocument12 paginiAdvanced Reservoir Characterization in Vaca Muerta PDFojrfgmrfÎncă nu există evaluări

- Sci Hub Panichelli2017Document12 paginiSci Hub Panichelli2017TOMAS ANTONIO CAMATICO FLORESÎncă nu există evaluări

- SPE 119620 Metodos de Stimulación en Pozos Hor 2009 - HLBDocument14 paginiSPE 119620 Metodos de Stimulación en Pozos Hor 2009 - HLBLuis Eduardo SeguraÎncă nu există evaluări

- Iptc 14538 MSDocument11 paginiIptc 14538 MSTanaskumarKanesanÎncă nu există evaluări

- NDX - Elgazar Compartmentalized PDFDocument27 paginiNDX - Elgazar Compartmentalized PDFManuel ChÎncă nu există evaluări

- Anand 2018Document35 paginiAnand 2018umair qureshiÎncă nu există evaluări

- SPE-176752-MS Autonomous Inflow Control Devices (AICD) : Application in Horizontal Wells Completions in Rubiales Area, Heavy Oil ReservoirDocument11 paginiSPE-176752-MS Autonomous Inflow Control Devices (AICD) : Application in Horizontal Wells Completions in Rubiales Area, Heavy Oil Reservoirnhora1985Încă nu există evaluări

- QIR 2019 Paper 77Document16 paginiQIR 2019 Paper 77Alkhi Hafiz SyahdaÎncă nu există evaluări

- Geren CIADocument22 paginiGeren CIACristian ParedesÎncă nu există evaluări

- Abdel Bak y 2018Document9 paginiAbdel Bak y 2018arispriyatmonoÎncă nu există evaluări

- Ep Petrochina MangroveDocument3 paginiEp Petrochina MangroveStiveGrajalesÎncă nu există evaluări

- Otc 19762Document7 paginiOtc 19762flowline2010Încă nu există evaluări

- Ijedr1602157 PDFDocument10 paginiIjedr1602157 PDFAditya SumanÎncă nu există evaluări

- Use of Well Test Results in Oilfield Development Planning in The Timor SeaDocument11 paginiUse of Well Test Results in Oilfield Development Planning in The Timor SeashamsulazharÎncă nu există evaluări

- 2011 Horizontal Underbalanced Drilling Technology Successfully Applied in Field AA - Libya PDFDocument11 pagini2011 Horizontal Underbalanced Drilling Technology Successfully Applied in Field AA - Libya PDFcarlorgsÎncă nu există evaluări

- SPE 166918 Extended Reach Exploratory Well Successfully Drilled On D-41 Structure of Baltic Sea Shelf (Russian Sector)Document10 paginiSPE 166918 Extended Reach Exploratory Well Successfully Drilled On D-41 Structure of Baltic Sea Shelf (Russian Sector)RIFKI RAMADHANÎncă nu există evaluări

- Cocchiere 2020Document12 paginiCocchiere 2020Nasim KazemiÎncă nu există evaluări

- 1-Introduction: Reservoir Formation MissedDocument68 pagini1-Introduction: Reservoir Formation MissedMahmoud NaDaaÎncă nu există evaluări

- SPE 59464 Full Field Model Study of A Dense Highly Fractured Carbonate ReservoirDocument5 paginiSPE 59464 Full Field Model Study of A Dense Highly Fractured Carbonate ReservoircmkohÎncă nu există evaluări

- Iptc-19182-Ms An Innovative Reservoir Engineering Method To Identify Bypassed Oil and Derisk The Further Development of A Complex Mature FieldDocument16 paginiIptc-19182-Ms An Innovative Reservoir Engineering Method To Identify Bypassed Oil and Derisk The Further Development of A Complex Mature FieldGilbert OmittaÎncă nu există evaluări

- SPE/IADC-173074-MS Blowout Well-Flow Simulation For Deepwater Drilling Using High-Pressure/ High-Temperature (HP/HT) Black-Oil Viscosity ModelDocument14 paginiSPE/IADC-173074-MS Blowout Well-Flow Simulation For Deepwater Drilling Using High-Pressure/ High-Temperature (HP/HT) Black-Oil Viscosity ModelHaider AshourÎncă nu există evaluări

- Directional Drilling For Enhanced Oil RecoveryDocument26 paginiDirectional Drilling For Enhanced Oil Recoveryknorhan38Încă nu există evaluări

- SPE 68721 Umm Gudair Dumpflood Pilot Project, The Applicability of Dumpflood To Enhance Sweep & Maintain Reservoir PressureDocument9 paginiSPE 68721 Umm Gudair Dumpflood Pilot Project, The Applicability of Dumpflood To Enhance Sweep & Maintain Reservoir PressuresciencetalkfreeÎncă nu există evaluări

- SPE 114878 - Performance of Polymer Flood in Sanand Field, India - A Case StudyDocument9 paginiSPE 114878 - Performance of Polymer Flood in Sanand Field, India - A Case StudyMahesh KulkarniÎncă nu există evaluări

- SPE-196631-MS Locate The Remaining Oil Ltro and Predictive Analytics Application For Development Decisions On The Z FieldDocument24 paginiSPE-196631-MS Locate The Remaining Oil Ltro and Predictive Analytics Application For Development Decisions On The Z FieldMohamed SlimaniÎncă nu există evaluări

- Kawasaki, 2014Document9 paginiKawasaki, 2014Jose Roberto LoureiroÎncă nu există evaluări

- SPE 137232 First Surface Driven PCP Application On Alaska's North SlopeDocument5 paginiSPE 137232 First Surface Driven PCP Application On Alaska's North SlopeJosé TimanáÎncă nu există evaluări

- SPE/IADC-179188-MS Managed Pressure, Deep Water Drilling, and Logging Under Continuous Reservoir Cross Flow Conditions - A Case HistoryDocument32 paginiSPE/IADC-179188-MS Managed Pressure, Deep Water Drilling, and Logging Under Continuous Reservoir Cross Flow Conditions - A Case HistoryVeronica ArronithaÎncă nu există evaluări

- Maple Field Rejuvenation - A Practical and Effective Approach For Field Production Increase Through GasliftDocument11 paginiMaple Field Rejuvenation - A Practical and Effective Approach For Field Production Increase Through GasliftTunde FarotimiÎncă nu există evaluări

- Bending Deformation and Ultimate Moment Calculation of Screen Pipes in Offshore Sand Control CompletionDocument20 paginiBending Deformation and Ultimate Moment Calculation of Screen Pipes in Offshore Sand Control CompletionGanesh ZambreÎncă nu există evaluări

- Khedr 2012Document11 paginiKhedr 2012Mahfoud AMMOURÎncă nu există evaluări

- SPE 143431 Well Production Enhancement Results With Inflow Control Device (ICD) Completions in Horizontal Wells in EcuadorDocument15 paginiSPE 143431 Well Production Enhancement Results With Inflow Control Device (ICD) Completions in Horizontal Wells in EcuadorDaniel SánchezÎncă nu există evaluări

- OTC-28103-MS Intelligent Completions Used During Extended Well Test of Exploratory Wells in BrazilDocument5 paginiOTC-28103-MS Intelligent Completions Used During Extended Well Test of Exploratory Wells in BrazilFernando SteimetzÎncă nu există evaluări

- 9 Log InterpretationDocument29 pagini9 Log InterpretationSunny BbaÎncă nu există evaluări

- IPTC 19608 AbstractDocument14 paginiIPTC 19608 AbstractKeyner NúñezÎncă nu există evaluări

- Al Qenaie2019Document14 paginiAl Qenaie2019jcbaezmÎncă nu există evaluări

- The Petroleum System ConceptDocument12 paginiThe Petroleum System ConceptSumit KumarÎncă nu există evaluări

- SPE 81443 Rigless Water Shut-Off Experience in Offshore Saudi ArabiaDocument6 paginiSPE 81443 Rigless Water Shut-Off Experience in Offshore Saudi ArabiaJose AntonioÎncă nu există evaluări

- Using Down Hole ChokesDocument5 paginiUsing Down Hole ChokesScott YoungÎncă nu există evaluări

- SPE-170621-MS Waterflooding Surveillance and Optimization For A Super-Giant Carbonate ReservoirDocument11 paginiSPE-170621-MS Waterflooding Surveillance and Optimization For A Super-Giant Carbonate Reservoirartha firmÎncă nu există evaluări

- Spe 153967Document16 paginiSpe 153967Hans Forenza ArataÎncă nu există evaluări

- Spe 120265Document14 paginiSpe 120265Heron Gachuz MuroÎncă nu există evaluări

- Announcing The Release of F.A.S.T. CBM™ Version 2.6: Fall 2006Document4 paginiAnnouncing The Release of F.A.S.T. CBM™ Version 2.6: Fall 2006Pedraza Velandia JhonÎncă nu există evaluări

- Oil and Gas Field Delopment PDFDocument97 paginiOil and Gas Field Delopment PDFManish SoniÎncă nu există evaluări

- CT Intervention On Snake WellsDocument8 paginiCT Intervention On Snake WellsRamanamurthy PalliÎncă nu există evaluări

- First Applications of Inflow Control Devices (ICD) in Open Hole Horizontal Wells in Block 15, Ecuador SPE-123008-MSDocument14 paginiFirst Applications of Inflow Control Devices (ICD) in Open Hole Horizontal Wells in Block 15, Ecuador SPE-123008-MSUser UserÎncă nu există evaluări

- SPE-199074-MS Solving The Challenges of A Complex Integrated Production System in Camisea Field Using Novel Modeling TechniquesDocument16 paginiSPE-199074-MS Solving The Challenges of A Complex Integrated Production System in Camisea Field Using Novel Modeling TechniquesEfrain Alex Morales CaballeroÎncă nu există evaluări

- Kawahara 2018Document15 paginiKawahara 2018Her LambangÎncă nu există evaluări

- Oil Spill Remediation: Colloid Chemistry-Based Principles and SolutionsDe la EverandOil Spill Remediation: Colloid Chemistry-Based Principles and SolutionsÎncă nu există evaluări

- The Types of Training That Has Been Held by CCITDocument1 paginăThe Types of Training That Has Been Held by CCITjangolovaÎncă nu există evaluări

- 3 - 62371 - LotDocument1 pagină3 - 62371 - LotjangolovaÎncă nu există evaluări

- Corrosion Engineering: Oil and Gas ServicesDocument2 paginiCorrosion Engineering: Oil and Gas ServicesjangolovaÎncă nu există evaluări

- Addendum-01b Equipment Calibration: My ASNT Level III UT Study Notes 2014-JuneDocument87 paginiAddendum-01b Equipment Calibration: My ASNT Level III UT Study Notes 2014-JunejangolovaÎncă nu există evaluări

- SPE-102200 Waterflooding SurveillanceDocument10 paginiSPE-102200 Waterflooding Surveillancejangolova100% (4)

- American BreakfastDocument4 paginiAmerican BreakfastHamilton Valenzuela ChipongianÎncă nu există evaluări

- Contemporary Philippine Arts From The Regions: Quarter 2 - Module 9 Different Contemporary Art Techniques and PerformanceDocument25 paginiContemporary Philippine Arts From The Regions: Quarter 2 - Module 9 Different Contemporary Art Techniques and PerformanceGrace06 Labin100% (7)

- Tugas 2-TRK Lanjut Kelompok 3 Andre-Arief-IstiaDocument18 paginiTugas 2-TRK Lanjut Kelompok 3 Andre-Arief-IstiaAndre Fahriz Perdana HarahapÎncă nu există evaluări

- Syllabus Unit Iv Unit Commitment and Economic DispatchDocument23 paginiSyllabus Unit Iv Unit Commitment and Economic DispatchBALAKRISHNANÎncă nu există evaluări

- Week 1 - NATURE AND SCOPE OF ETHICSDocument12 paginiWeek 1 - NATURE AND SCOPE OF ETHICSRegielyn CapitaniaÎncă nu există evaluări

- Arbor APS STT Unit 01 Design Basics 25 Jan2018Document31 paginiArbor APS STT Unit 01 Design Basics 25 Jan2018masterlinh2008Încă nu există evaluări

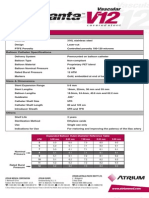

- Advanta V12 Data SheetDocument2 paginiAdvanta V12 Data SheetJuliana MiyagiÎncă nu există evaluări

- 12.5 Collision Theory - ChemistryDocument15 pagini12.5 Collision Theory - ChemistryAri CleciusÎncă nu există evaluări

- Grade - 2 Subject - Mathematics Unit - Geometry Topic - Geometrical Shapes School - Army School Roorkee Prepared by Mrs. RanjanaDocument25 paginiGrade - 2 Subject - Mathematics Unit - Geometry Topic - Geometrical Shapes School - Army School Roorkee Prepared by Mrs. RanjanaPenke Mejado BelenÎncă nu există evaluări

- WPBSA Official Rules of The Games of Snooker and Billiards 2020 PDFDocument88 paginiWPBSA Official Rules of The Games of Snooker and Billiards 2020 PDFbabuzducÎncă nu există evaluări

- Lecture 12Document8 paginiLecture 12Mechanical ZombieÎncă nu există evaluări

- Sales 20: Years Advertising Expense (Millions) X Sales (Thousands) yDocument8 paginiSales 20: Years Advertising Expense (Millions) X Sales (Thousands) ybangÎncă nu există evaluări

- Course Registration SlipDocument2 paginiCourse Registration SlipMics EntertainmentÎncă nu există evaluări

- Passenger Lift Alert - Health and Safety AuthorityDocument4 paginiPassenger Lift Alert - Health and Safety AuthorityReginald MaswanganyiÎncă nu există evaluări

- Managing Diabetic Foot Ulcers ReadingDocument21 paginiManaging Diabetic Foot Ulcers Readinghimanshugupta811997Încă nu există evaluări

- Table Equivalent Schedule 40 Steel PipeDocument1 paginăTable Equivalent Schedule 40 Steel PipeorisÎncă nu există evaluări

- NCP Orif Right Femur Post OpDocument2 paginiNCP Orif Right Femur Post OpCen Janber CabrillosÎncă nu există evaluări

- Dawn of Solar PV CookingDocument5 paginiDawn of Solar PV CookingAbhinav AgrawalÎncă nu există evaluări

- Napoleonic WargamingDocument13 paginiNapoleonic WargamingandyÎncă nu există evaluări

- S TR GEN ID (Component Marking) (Rev 3 2009) - AN Marked UpDocument6 paginiS TR GEN ID (Component Marking) (Rev 3 2009) - AN Marked UpsnclgsraoÎncă nu există evaluări

- 2022 Audi e Tron 22Document318 pagini2022 Audi e Tron 22Alejandro Alberto Robalino MendezÎncă nu există evaluări

- DudjDocument4 paginiDudjsyaiful rinantoÎncă nu există evaluări

- 5G Transport Slice Control in End-To-End 5G NetworksDocument19 pagini5G Transport Slice Control in End-To-End 5G NetworksmorganÎncă nu există evaluări

- Presentation On 4G TechnologyDocument23 paginiPresentation On 4G TechnologyFresh EpicÎncă nu există evaluări

- Bomba MixerDocument2 paginiBomba MixerBinelli79Încă nu există evaluări

- ZF-FreedomLine TransmissionDocument21 paginiZF-FreedomLine TransmissionHerbert M. Zayco100% (1)

- Semi Finals in Tle 2015Document3 paginiSemi Finals in Tle 2015LoraineTenorioÎncă nu există evaluări