Documente Academic

Documente Profesional

Documente Cultură

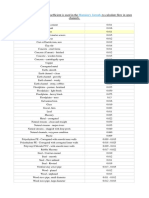

General Pump Selection: According To Iso Cusn12Ni2 According To Astm (Usa) C91700

Încărcat de

Sohail Hanif0 evaluări0% au considerat acest document util (0 voturi)

16 vizualizări1 pagină1. This document discusses pump selection and installation for waste water systems. It describes wet-installed pumps, which are installed directly in the suction chamber and surrounded by waste water during operation. These were mainly used for smaller flow rates up to 1,600 qpm.

2. For pipe connections on wet-installed pumps, the inside diameter of discharge lines must be equal to or greater than the pump nozzle diameter. Valves and fittings must comply with standards, and butterfly valves are not suitable for waste water. Isolating gate valves with specific material requirements are recommended.

3. Material selection for pipes and supports is also discussed, noting corrosion resistance requirements. Pipes should have a smooth inner surface and be

Descriere originală:

data26

Titlu original

data26

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest document1. This document discusses pump selection and installation for waste water systems. It describes wet-installed pumps, which are installed directly in the suction chamber and surrounded by waste water during operation. These were mainly used for smaller flow rates up to 1,600 qpm.

2. For pipe connections on wet-installed pumps, the inside diameter of discharge lines must be equal to or greater than the pump nozzle diameter. Valves and fittings must comply with standards, and butterfly valves are not suitable for waste water. Isolating gate valves with specific material requirements are recommended.

3. Material selection for pipes and supports is also discussed, noting corrosion resistance requirements. Pipes should have a smooth inner surface and be

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

16 vizualizări1 paginăGeneral Pump Selection: According To Iso Cusn12Ni2 According To Astm (Usa) C91700

Încărcat de

Sohail Hanif1. This document discusses pump selection and installation for waste water systems. It describes wet-installed pumps, which are installed directly in the suction chamber and surrounded by waste water during operation. These were mainly used for smaller flow rates up to 1,600 qpm.

2. For pipe connections on wet-installed pumps, the inside diameter of discharge lines must be equal to or greater than the pump nozzle diameter. Valves and fittings must comply with standards, and butterfly valves are not suitable for waste water. Isolating gate valves with specific material requirements are recommended.

3. Material selection for pipes and supports is also discussed, noting corrosion resistance requirements. Pipes should have a smooth inner surface and be

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 1

1

General Pump Selection

1.13

lines must be equal to or greater

of direction. Pipe connections and

Concept of wet-instal-

than the inside diameter of the

fittings must comply with the

led pumps

discharge nozzle [1.20]. Use

relevant product standards.

pipe connections without

The most straightforward

narrowing and make sure that

Butterfly valves are unsuitable as

concept for a pumping station is

open valves do not obstruct the

isolating valves in the waste water

the installation of wet-installed

flow [1.21; 1.22]. Calculate the

sector (see overview in Fig.

pumps. The pumps are installed

optimum diameter based on the

4.2.3a). We recommend soft-

directly in the suction chamber

minimum flow velocity and use

seated isolating gate valves with

and completely or partly

the next largest pipe diameter

external thread, body made of

surrounded by waste water

available. For longer discharge

GGG (ductile iron), stem made of

during operation. The pumps

lines measures to reduce surge

1.4571(stainless steel) , stem nut

can either be operated with a

pressure have priority over

and seat rings made of 2.1060.

vertical shaft driven by a motor

measures to maintain the

Choose actuators whose

mounted above the fluid level,

minimum flow velocity. For

maximum actuation force cannot

or the entire pump sets can be

discharge line lengths of up to

damage the gate valve [1.24].

used under water as submersible

1,640 ft a maximum velocity of

motor pumps.

2,5 m/s (8.2 ft/s) applies [1.23].

Especially suitable as non-return

valves are swing check valves with

In practice, wet-installed pumps

The piping material must be

lever and weight. The body

were mainly used in smaller

suitable for the waste water to

material we recommend is

pumping stations (flow rates up

be transported. Make sure it is

lamellar graphite cast iron (GGL)

to approximately 1,600 qpm);

corrosion-resistant (hydrogen

or nodular cast iron (GGG)

they are called packaged pump

sulphide!). This also applies to

[1.25]. For low flow velocities,

stations [1.17; 1.18].

the material of the pipe

non-return ball valves can be used

supports, which need to be

[1.26].

The benefits of a wet instal

closely spaced. The piping must

The non-return valve should

lation are also increasingly

be fastened without

be arranged vertically and as high

employed in large pumping

transmitting any forces to the

as possible above the pump to

stations (flow rates up to ap

pump. The pipes should have a

allow the rising fluid level to

proximately 255,000 qpm). The

smooth inner surface, be able to

release the air it displaces in the

advantages and disadvantages

withstand cyclical loads and be

pump. If this condition is met, a

of this arrangement are listed in

selected, depending on the

venting device for the pump is not

Table 1.1 [1.19].

discharge head, for an

required [1.27].

operating pressure of 87 to 145

To prevent clogging,

psi. The discharge line from the

narrowing the pipes in the

pump must be connected to the

direction of flow must

main line with a horizontal

absolutely be avoided. The

section. Avoid abrupt changes

inside diameter of the discharge

GGG

nodular cast iron

GGL

lamellar cast iron

1.4517

Stainless steel

2.1060

tin bronze

according to ISO CuSn12Ni2

according to ASTM (USA) C91700

24

S-ar putea să vă placă și

- Reverse Circulation Pump PDFDocument4 paginiReverse Circulation Pump PDFthawdarÎncă nu există evaluări

- Sewage Disposal Works: Their Design and ConstructionDe la EverandSewage Disposal Works: Their Design and ConstructionÎncă nu există evaluări

- Plunger LiftDocument5 paginiPlunger LiftrocacantuÎncă nu există evaluări

- Simple Plumbing Repairs for the Home and FarmsteadDe la EverandSimple Plumbing Repairs for the Home and FarmsteadÎncă nu există evaluări

- Sump Pit Design ConsiderationDocument8 paginiSump Pit Design ConsiderationkhalloudeeÎncă nu există evaluări

- Oil and Gas Artificial Fluid Lifting TechniquesDe la EverandOil and Gas Artificial Fluid Lifting TechniquesEvaluare: 5 din 5 stele5/5 (1)

- Chapter Three Liquid Piping SystemDocument51 paginiChapter Three Liquid Piping SystemMelaku TamiratÎncă nu există evaluări

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshDe la EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshÎncă nu există evaluări

- Pump Station Design For Storm Water Retention Ponds PDFDocument3 paginiPump Station Design For Storm Water Retention Ponds PDFAnonymous CX51waI100% (1)

- Centrifugal Pump InstallationDocument4 paginiCentrifugal Pump Installationjfisher2534Încă nu există evaluări

- Piping Recommendations For Pump PipingDocument3 paginiPiping Recommendations For Pump Pipingkapoorkunal26Încă nu există evaluări

- Offshore Orifice-Plate Impulse Line ArrangementDocument5 paginiOffshore Orifice-Plate Impulse Line ArrangementTimothy LeonardÎncă nu există evaluări

- Flygt Design Recommendations For Centrifugal PumpsDocument10 paginiFlygt Design Recommendations For Centrifugal PumpsOzren DjuricÎncă nu există evaluări

- Sump DesignDocument4 paginiSump DesignThiru AnanthÎncă nu există evaluări

- Basic Pump Station DesignDocument24 paginiBasic Pump Station Designzaldy1985Încă nu există evaluări

- General Guidelines of Pump Piping LayoutDocument8 paginiGeneral Guidelines of Pump Piping LayoutbainÎncă nu există evaluări

- A Block Flow DiagramDocument35 paginiA Block Flow DiagramJerry SimonÎncă nu există evaluări

- Centrifugal PumpsDocument2 paginiCentrifugal Pumpsshameer_sanju1049Încă nu există evaluări

- Tank Arrangement: 1. Active SystemDocument5 paginiTank Arrangement: 1. Active SystemRakefsÎncă nu există evaluări

- Proper Piping For Vacuum SystemsDocument5 paginiProper Piping For Vacuum SystemsDowni Oader100% (1)

- Knockout DrumDocument9 paginiKnockout Drumgautam_96948069Încă nu există evaluări

- HP237Document20 paginiHP237Asif HameedÎncă nu există evaluări

- Pump Design by An IlDocument5 paginiPump Design by An IlANILÎncă nu există evaluări

- Water PipelinesDocument8 paginiWater PipelinesBilal AmjadÎncă nu există evaluări

- Slug Catcher SizingDocument11 paginiSlug Catcher Sizingsohail06100% (2)

- Graham - Proper Piping For Vacuum SystemDocument5 paginiGraham - Proper Piping For Vacuum SystemAnonymous DJrec2Încă nu există evaluări

- Ce 370 - Water Distribution NetworksDocument45 paginiCe 370 - Water Distribution NetworksUsman Zafar RajaÎncă nu există evaluări

- Centrifugal Pumps TipsDocument34 paginiCentrifugal Pumps TipsFaizan AbbasiÎncă nu există evaluări

- Vent Manifold Flare Manifold DesignDocument10 paginiVent Manifold Flare Manifold Designahsan888Încă nu există evaluări

- TECHNICAL Layne Engineering ManualDocument34 paginiTECHNICAL Layne Engineering ManualAnonymous CMS3dL1TÎncă nu există evaluări

- 44 IG BlowersDocument4 pagini44 IG BlowersSarvesh SangleÎncă nu există evaluări

- Gravity FlowDocument11 paginiGravity FlowAnonymous U18LFvdfD100% (4)

- Details of KO DrumDocument7 paginiDetails of KO Drumnishank soniÎncă nu există evaluări

- Condenser Siphon Seal-WellsDocument3 paginiCondenser Siphon Seal-Wellstwins19564839100% (1)

- Sewer Bypass Fundamentals PDFDocument4 paginiSewer Bypass Fundamentals PDFHung Leung Sang Eddy0% (1)

- Details of KO DrumDocument7 paginiDetails of KO Drumadam.rial00Încă nu există evaluări

- Control Valve Technical Specification For Severe Service - CCIDocument5 paginiControl Valve Technical Specification For Severe Service - CCIVikas SinghÎncă nu există evaluări

- Sucker Rod PumpingDocument27 paginiSucker Rod Pumpingzezo2011100% (4)

- Force Main SewersDocument8 paginiForce Main SewersljupkaÎncă nu există evaluări

- Compressor Horsepower: Gas Distribution and ControlDocument3 paginiCompressor Horsepower: Gas Distribution and ControlRahmat AbdullahÎncă nu există evaluări

- Centrifugal Compressor GuidenceDocument4 paginiCentrifugal Compressor GuidenceChem.Engg100% (1)

- Mist EliminatorsDocument6 paginiMist EliminatorspskarthikÎncă nu există evaluări

- DP 3102013Document20 paginiDP 3102013lifemillion2847Încă nu există evaluări

- Home-Made Hydraulic Ram Pump 2005Document50 paginiHome-Made Hydraulic Ram Pump 2005Dlorah OalZepol100% (1)

- EPA Sewers Lift StationDocument8 paginiEPA Sewers Lift StationamarvinÎncă nu există evaluări

- Design Recommendations For Sump and PumpDocument8 paginiDesign Recommendations For Sump and PumpKatyayini Nelli100% (1)

- Home-Made Hydraulic Ram Pump: Click Here To See A Picture of An Assembled Ram PumpDocument54 paginiHome-Made Hydraulic Ram Pump: Click Here To See A Picture of An Assembled Ram PumpbracioÎncă nu există evaluări

- Low Pressure SewersDocument23 paginiLow Pressure SewersUlil A JaÎncă nu există evaluări

- SECTION 2 - Design Criteria For Water Distribution Systems - 201304251344365252Document8 paginiSECTION 2 - Design Criteria For Water Distribution Systems - 201304251344365252Harvey Jualo NancaÎncă nu există evaluări

- Piping AuxiliariesDocument12 paginiPiping AuxiliariesarchitÎncă nu există evaluări

- Two-Phase and Three-Phase SeparatorDocument40 paginiTwo-Phase and Three-Phase Separatormargaretramos100% (1)

- Axial Flow PumpsDocument3 paginiAxial Flow PumpsahadÎncă nu există evaluări

- Storm Water Drainage System PDFDocument14 paginiStorm Water Drainage System PDFRobert Nixon100% (1)

- Soil & Waste For High-RiseDocument6 paginiSoil & Waste For High-RiseSam Wing HongÎncă nu există evaluări

- Home-Made Hydraulic Ram PumpDocument87 paginiHome-Made Hydraulic Ram PumpZwq92y100% (3)

- Pump Clinic 33Document8 paginiPump Clinic 33fnahas_bhÎncă nu există evaluări

- Jabsco Flexible Impeller PumpsDocument46 paginiJabsco Flexible Impeller PumpsstratoschaÎncă nu există evaluări

- Ipe Plate 2 Fluid MachineriesDocument93 paginiIpe Plate 2 Fluid Machineriesjanuel borelaÎncă nu există evaluări

- Rig DesginDocument25 paginiRig DesginImam PranadipaÎncă nu există evaluări

- Chapuis and Chenaf, 2002: Test 3 6 Test Test 3Document1 paginăChapuis and Chenaf, 2002: Test 3 6 Test Test 3Sohail HanifÎncă nu există evaluări

- ASTM, 2013 Chapuis and Sabourin, 1989 Chesnaux Et Al., 2006 Hydro-Québec, 1990Document1 paginăASTM, 2013 Chapuis and Sabourin, 1989 Chesnaux Et Al., 2006 Hydro-Québec, 1990Sohail HanifÎncă nu există evaluări

- (Tested Soil) in M/S: 1 Test 1 5 4 1 3Document1 pagină(Tested Soil) in M/S: 1 Test 1 5 4 1 3Sohail HanifÎncă nu există evaluări

- Treet Corporation Is Aiming To Disrupt The Conventional Battery Market in Pakistan', Ali Aslam, COO Treet Battery ProjectDocument1 paginăTreet Corporation Is Aiming To Disrupt The Conventional Battery Market in Pakistan', Ali Aslam, COO Treet Battery ProjectSohail HanifÎncă nu există evaluări

- 114 N. Baptiste, R.P. Chapuis / Engineering Geology 184 (2015) 111 - 118Document1 pagină114 N. Baptiste, R.P. Chapuis / Engineering Geology 184 (2015) 111 - 118Sohail HanifÎncă nu există evaluări

- Cable Solutions To Ensure The Reliability of Your Energy NetworkDocument1 paginăCable Solutions To Ensure The Reliability of Your Energy NetworkSohail HanifÎncă nu există evaluări

- Plumbing DesignDocument2 paginiPlumbing DesignSohail HanifÎncă nu există evaluări

- RFP / TOR For Feasibility Study of ML-2 Pakistan RailwaysDocument1 paginăRFP / TOR For Feasibility Study of ML-2 Pakistan RailwaysSohail HanifÎncă nu există evaluări

- Engineering Geology: Nadège Baptiste, Robert P. ChapuisDocument1 paginăEngineering Geology: Nadège Baptiste, Robert P. ChapuisSohail HanifÎncă nu există evaluări

- Screen PDFDocument1 paginăScreen PDFSohail HanifÎncă nu există evaluări

- 6-36kV Medium Voltage Underground Power CablesDocument1 pagină6-36kV Medium Voltage Underground Power CablesSohail HanifÎncă nu există evaluări

- Viking+Johnson Design+data 2013Document1 paginăViking+Johnson Design+data 2013Sohail HanifÎncă nu există evaluări

- Cataloging-in-Publication Data Is On File With The Library of CongressDocument1 paginăCataloging-in-Publication Data Is On File With The Library of CongressSohail HanifÎncă nu există evaluări

- Why Air Valves? Types of Valves Valve Locations Sizing Valves Valve Specifications Installations QuestionsDocument1 paginăWhy Air Valves? Types of Valves Valve Locations Sizing Valves Valve Specifications Installations QuestionsSohail HanifÎncă nu există evaluări

- DLCJ/-ML - : Box Culvert Wingwall 800-111Document1 paginăDLCJ/-ML - : Box Culvert Wingwall 800-111Sohail HanifÎncă nu există evaluări

- 25 Simple Habits of Highly Successful PeopleDocument1 pagină25 Simple Habits of Highly Successful PeopleSohail HanifÎncă nu există evaluări

- Description Page No. Section - 1: Invitation For RFP .......................................................... 1Document1 paginăDescription Page No. Section - 1: Invitation For RFP .......................................................... 1Sohail HanifÎncă nu există evaluări

- RFP & TOR For ML-2Document1 paginăRFP & TOR For ML-2Sohail HanifÎncă nu există evaluări

- Engineering Drawing 4Document1 paginăEngineering Drawing 4Sohail HanifÎncă nu există evaluări

- Pakistan Railways: Chief Engineer / Survey & Construction Headquarters Office Lahore PakistanDocument1 paginăPakistan Railways: Chief Engineer / Survey & Construction Headquarters Office Lahore PakistanSohail HanifÎncă nu există evaluări

- Roads: Geometric Design and Layout PlanningDocument1 paginăRoads: Geometric Design and Layout PlanningSohail HanifÎncă nu există evaluări

- Exchange Rate: USD 1.00 PKR80.00: (2010 Prices)Document1 paginăExchange Rate: USD 1.00 PKR80.00: (2010 Prices)Sohail HanifÎncă nu există evaluări

- Engineering Drawing 3Document1 paginăEngineering Drawing 3Sohail HanifÎncă nu există evaluări

- Rs. 1 Crore Rs. 4.5 Crores: NAFA Stock FundDocument23 paginiRs. 1 Crore Rs. 4.5 Crores: NAFA Stock FundSohail HanifÎncă nu există evaluări

- Urban Development: Sub-Total: BDA Total: On-Going SchemesDocument1 paginăUrban Development: Sub-Total: BDA Total: On-Going SchemesSohail HanifÎncă nu există evaluări

- Chapter 2 - Current Transport Situation, Problems and IssuesDocument1 paginăChapter 2 - Current Transport Situation, Problems and IssuesSohail HanifÎncă nu există evaluări

- Glossary 1 2 Design Philosophy 3 Design Controls 4 Design Elements 5 Alignment Design 6 Intersections 7 Interchanges 8 Roadside Safety 9 RRR 10 Grade Separations 11 Toll Plazas Bibliography CoversDocument1 paginăGlossary 1 2 Design Philosophy 3 Design Controls 4 Design Elements 5 Alignment Design 6 Intersections 7 Interchanges 8 Roadside Safety 9 RRR 10 Grade Separations 11 Toll Plazas Bibliography CoversSohail HanifÎncă nu există evaluări

- Welding& Inspection WPS& WelderDocument112 paginiWelding& Inspection WPS& WelderNitesh Garg100% (7)

- Difference Between Austenitic, Ferritic, and MartensiticDocument3 paginiDifference Between Austenitic, Ferritic, and Martensitickihal zohirÎncă nu există evaluări

- CleaningDocument57 paginiCleaningmritsoudisÎncă nu există evaluări

- Baseplates OptionsDocument4 paginiBaseplates Optionsalexmuchmure2158Încă nu există evaluări

- 04-Rfittings.50 2002 200603Document44 pagini04-Rfittings.50 2002 200603mkpqÎncă nu există evaluări

- Phase Diagrams - 040823Document23 paginiPhase Diagrams - 040823Anthony MubangaÎncă nu există evaluări

- Akarshan Sood Graduate Marine Engineer Main Engine Bearing: Inserting Type Removable Shell BearingDocument7 paginiAkarshan Sood Graduate Marine Engineer Main Engine Bearing: Inserting Type Removable Shell Bearingakarshansood100% (4)

- Ansi 36.10Document11 paginiAnsi 36.10reyaaazÎncă nu există evaluări

- Asm Comp TT Stainless SteelDocument33 paginiAsm Comp TT Stainless SteelmarriolavÎncă nu există evaluări

- Assignment Engineering MaterialsDocument8 paginiAssignment Engineering MaterialsMirza HumzaÎncă nu există evaluări

- Bloques de DistribucionDocument12 paginiBloques de DistribucionJavier Arredondo IpiñaÎncă nu există evaluări

- Mini DredgeDocument12 paginiMini DredgeHans Hans SadzÎncă nu există evaluări

- Manning's Roughness CoefficientDocument2 paginiManning's Roughness Coefficientdjuka15Încă nu există evaluări

- 70 1911 Auto P94 149Document56 pagini70 1911 Auto P94 149Stan BrittsanÎncă nu există evaluări

- Moduflex FRL TechnicalDocument56 paginiModuflex FRL Technicalking4lifeÎncă nu există evaluări

- SteelMint Daily Report As On 27 Nov 2019Document13 paginiSteelMint Daily Report As On 27 Nov 2019Kyle ForemanÎncă nu există evaluări

- Cirp Annals - Manufacturing Technology: Tomoyoshi Maeno, Ken-Ichiro Mori (1), Masaki FujimotoDocument4 paginiCirp Annals - Manufacturing Technology: Tomoyoshi Maeno, Ken-Ichiro Mori (1), Masaki FujimotovinayakÎncă nu există evaluări

- Ptfe Coated Studs, Bolts and NutsDocument1 paginăPtfe Coated Studs, Bolts and Nutssabari ramasamyÎncă nu există evaluări

- Cold Rolled CR Structural S CM350-G® Steel: General Description Typical UsesDocument2 paginiCold Rolled CR Structural S CM350-G® Steel: General Description Typical UsesBaziÎncă nu există evaluări

- Design and Analysis of Connecting Rod For Different Material Using AnsysDocument7 paginiDesign and Analysis of Connecting Rod For Different Material Using AnsysGagan GaganÎncă nu există evaluări

- PQ IndexDocument2 paginiPQ IndexVíctor Miguel ClÎncă nu există evaluări

- BS3100 A2Document11 paginiBS3100 A2AlexÎncă nu există evaluări

- Iron and Steel IndustryDocument23 paginiIron and Steel IndustryArpan MÎncă nu există evaluări

- Nabl Scope TC 7876Document79 paginiNabl Scope TC 7876Kothiyal MukeshÎncă nu există evaluări

- The Axle Housing For A Skid-Steer Loader: A Design Study in Ductile Cast IronDocument28 paginiThe Axle Housing For A Skid-Steer Loader: A Design Study in Ductile Cast Ironbeibox100% (1)

- TR Stud Anchor: Features Material SpecificationsDocument2 paginiTR Stud Anchor: Features Material SpecificationsHauzhiÎncă nu există evaluări

- Foreword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BDocument4 paginiForeword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BMarcelo KleinÎncă nu există evaluări

- Maple Homes BrochureDocument6 paginiMaple Homes BrochurerajuwithualwaysÎncă nu există evaluări

- Ruukki Splicing of Steel Piles by WeldingDocument8 paginiRuukki Splicing of Steel Piles by Weldingyanickdouce1206100% (1)

- 9701 w14 QP 53Document12 pagini9701 w14 QP 53CindyVortexÎncă nu există evaluări

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionDe la EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionEvaluare: 4.5 din 5 stele4.5/5 (543)

- Well Integrity for Workovers and RecompletionsDe la EverandWell Integrity for Workovers and RecompletionsEvaluare: 5 din 5 stele5/5 (3)

- Electric Motor Control: DC, AC, and BLDC MotorsDe la EverandElectric Motor Control: DC, AC, and BLDC MotorsEvaluare: 4.5 din 5 stele4.5/5 (19)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDe la EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterÎncă nu există evaluări

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesDe la EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesEvaluare: 4.5 din 5 stele4.5/5 (21)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tDe la EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tEvaluare: 4.5 din 5 stele4.5/5 (27)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeDe la EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeEvaluare: 4.5 din 5 stele4.5/5 (10)

- Electric Motors and Drives: Fundamentals, Types and ApplicationsDe la EverandElectric Motors and Drives: Fundamentals, Types and ApplicationsEvaluare: 4.5 din 5 stele4.5/5 (12)

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonDe la EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonEvaluare: 5 din 5 stele5/5 (2)

- A Practical Handbook for Drilling Fluids ProcessingDe la EverandA Practical Handbook for Drilling Fluids ProcessingÎncă nu există evaluări

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDe la EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialÎncă nu există evaluări

- Building Energy Management Systems and Techniques: Principles, Methods, and ModellingDe la EverandBuilding Energy Management Systems and Techniques: Principles, Methods, and ModellingÎncă nu există evaluări

- The Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceDe la EverandThe Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceÎncă nu există evaluări

- Solar Energy: Survive Easily on Solar Power Off the GridDe la EverandSolar Energy: Survive Easily on Solar Power Off the GridÎncă nu există evaluări

- Multiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...De la EverandMultiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...Încă nu există evaluări

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ADe la EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AÎncă nu există evaluări

- Retro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsDe la EverandRetro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsÎncă nu există evaluări

- Introduction to Power System ProtectionDe la EverandIntroduction to Power System ProtectionEvaluare: 5 din 5 stele5/5 (1)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentDe la EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentEvaluare: 4.5 din 5 stele4.5/5 (21)

- Renewable Energy: Physics, Engineering, Environmental Impacts, Economics and PlanningDe la EverandRenewable Energy: Physics, Engineering, Environmental Impacts, Economics and PlanningEvaluare: 5 din 5 stele5/5 (4)

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesDe la EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesEvaluare: 5 din 5 stele5/5 (1)

- Power System Control and ProtectionDe la EverandPower System Control and ProtectionB. Don RussellEvaluare: 4 din 5 stele4/5 (11)