Documente Academic

Documente Profesional

Documente Cultură

Us 2735810

Încărcat de

cicerojoiasDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Us 2735810

Încărcat de

cicerojoiasDrepturi de autor:

Formate disponibile

Feb.

21, 1956

2,735,810

F. P. GAGL!ANO

RECOVERY OF COLO FROM SCRAP CONTAINING IT

Filed Feb. lO, 1954

ANODE CONDUCTOR

CATHODE-

f-/

r-CATHODE

1/l

== ---=-15

_t-_- - - =- - ----- ---=- -;-:-.::-=- -:- r-= -=--: :_-_

:_==. :::: ..:

- t..= _::: :._-=--=--=-= f=""-= :: .

r-.I{

--Ir- /IV')

1-

-- - - ;:: ---- -:. -:...:_:: .:- - - :P

.A ..no 13- :-.:--

17-

-.:: -

GOLO 5CRAP

17

-rr--

- - --- -- - ----- ---ELCTROLYTE CONTAINING

FERROCYANIOE

INVENTOR

banli.P.Gag/iafU)

BY

p

..;;ri

ORNEY

United States Patertt Office

1

2,735,810

RECOVERY OF GOLD FROM SCRAP

CONTAINING lT

Francis P. Gagliano, Jackson Heights, N. Y., assignor to

Secou Metais Corporation, White Plains, N. Y., a cor

poration of New York

Application February 10, 1954, Serial No. 409,475

8 Claims. (Cl. 204-110)

This invention relates to the recovery of gold from gold

plated or clad material, such, for example, as the scrap

produced in the manufacture of grids and other parts

of electronic- tubes and other sources of gold plated or

clad material.

Substantial amounts of scrap in the form of gold plated

or clad wire, ribbon, sheets, etc., which scrap contains

gold in amount of from 0.1% to 6%, copper or silver or

both in amounts of from less than 1% to as high as 90%

of copper and from less than 1% to as high as 10% of

silver, is produced in the manufacture of electronic

tubes. Such scrap may contain other metais including

one or more of the following-nickel, iron, tungsten,

molyb

denum

and

cadmium.

Ali percentages and parts herein are on a weight basis.

Attempts heretofore made to recover the gold content

of such scrap by electrolysis employing a cyanide as the

electrolyte have usually resulted in the copper or silver

plating out preferentially to the gold and otherwise inter

fering with the recovery of the gold to an extent render

ing such process uneconomical and ineffi.cient, particularly

in that the recovery process is very slow. It has been

found that, as the concentration of the copper or silver

builds up in the electrolytic bath, the effi.ciency of the bath

decreases until it reaches a point where it can no longer

be used practically to effect the recovery of the gold.

This invention is predicated on the surprising and un

expected discovery that the gold content of gold plated or

clad material containing copper or silver or both can

readily and effi.ciently be recovered electrolytically by em

ploying a bath containing from about 3% to about 16%

alkali metal or ammonium ferrocyanide, from about

0.25% to about 8% alkali metal or ammonium cyanide,

and maintaining the bath ata temperature of from 20 to

80 C., and ata pH of from about 7.5 to about 12. The

ratio of the ferrocyanide to the cyanide in the bath should

be within the range of from 2: 1to 60: 1.

Preferably, the bath contains from about 2% to 5%

alkali metal or ammonium ferrocyanide, from 0.5% to

2% alkali metal or ammonium cyanide, a ratio of fer

rocyanide to cyanide of 5:1. The bath, in use, is main

tained ata temperature ofJrom about 40 to 50 c. and

a pH of from 8 to 10. The ferrocyanide, cyanide and

salts or alkali hydroxides added for purposes of maintain

ing the desired pH, preferably have the same cation.

Thus, when employing potassium ferrocyanide as a con

stituent of the electrolytic bath, potassium cyanide is used

along with potassium carbonate, potassium phosphate

and/or potassium hydroxide, as will be explained more

fully hereinafter.

Particularly preferred is the use of a bath containing

4% potassium ferrocyanide, 0.8% potassium cyanide,

0.5% potassium carbonate ata temperature of about 45

C. and a pH of about 9. This pH is maintained by the

addition of monopotassium phosphate (KH2P04) and

potassium hydroxide as needed.

As the ferrocyanide employed in the bath, potassium

or sodium ferrocyanide is preferred, although other alkali

metal ferrocyanides, such as lithium, rubidium, caesium,

2,735,810

Patented Feb. 21, 1956

or francium ferrocyanide may be used. Ammonium fer

rocyanide may also be employed.

As the cyanide, sodium or potassium cyanide is pre

ferred, although the other above-mentioned alkali metal

5 or ammonium cyanides may be used. The cyanide is

added to the bath because it forms complexes with metais,

such as iron, copper, nickel, silver, chromium, etc., which

complexes are soluble and remain in solution. In the

absence of the cyanide, insoluble compounds, such as

10 Fe(CN)2, a brown precipitate, Fe2[Fe(CN) ]s, Fe(OH)a,

Fe(OH)2, Ni(CN)2, Cu2Fe(CN)s and Cu!!Fe(CN)s re

sult which contaminate the bath and reduce its effi.ciency.

As the electrolysis proceeds employing a bath having the

composition above noted the free CN concentration de15 creases due to the formation of complexes of the type

above noted. Accordingly, from time to time, as needed,

additional cyanide is added to replenish the cyanide thus

used up and maintain its cencentration within the range

above noted.

20

As above indicated, preferably, the cation of the ferrocyanide and the cyanide, as well as of any other salts

or bases incorporated in the bath, are the same.

In arder to maintain the pH within the range above

noted, alkali metal or ammonium carbonates, bicar25 bonates, hydroxides or phosphates, or mixtures of these

salts or bases may be added to the bath as neded. De

sidably, a mixture of alkali metal phosphate and carbon

ate is used. The alkali metal carbonate serves to main

tain the pH above 7.5, and the phosphate appears to have

30 a buffer action to maintain the pH at the desired value

substantially constant over relatively Iong periods of time.

A bath having the composition above noted has the

advantage of minimizing the effiuent disposal problem.

Spent baths employed in this invention can readily be

35 treated, for example, by chlorination, to condition them

to provide an effiuent which can be disposed of in the

usual sewage or other industrial drain

systems.

Moreover, a ferrocyanide-cyanide bath containing at

least 2 parts of ferrocyanide per part of cyanide is much

40 less toxic than the cyanide baths heretofore employed.

This is the case, because the ferrocyanides are much more

stable than the cyanides. Furthermore, in view of the

relatively small amounts of cyanide contained in the

baths employed in practicing this invention, there is ma45 terially less tendency for evolution of hydrogen cyanide

to take place than there is from the cyanide baths here

tofore used.

The cathode may be any desired electrical conductor,

preferably metallic, on which the gold will deposit.

50 Thus, gold plates or bars may be used as the cathode.

_ Alternatively, stainless steel may be used from which the

deposit of gold can be scraped or otherwise removed.

Cathodes may be employed, if desired, which are not

corrosion resistant, since the deposited gold will soon

55 form a protective layer; however, it is preferred to use

a cathode of gold, stainless steel, copper or other cor rosion

resistant metal.

As the anode any electrical conductor not attacked by

the bath may be used. Desirably, the anode is provided

60

-with contact rods on which the charge of scrap metal

is supported so that the electrical current is supplied ef

ficiently to the scrap metal. It will be understood the

anode simply serves as an electrical conductor for supply65 ing current to the scrap metal and that in effect the scrap

metal is the anode, once electrolysis has commenced.

The voltage and current density used will, of course,

depend on the particular equipment employed, the size

of the bath, the size of the cathodes, anodes, etc. In the

70 recovery of gold froin scrap employing a relatively small

bath for treating charges of from about 100 to about 500

grams, from 2 to 6 volts and a current density of ftom 1

2,736,810

to 6 amperes per square foot have been used with satis

factory results. However, as above noted, the-voltage and

current density may be varied within wide limits and

will depend on the equipment used.

Metal which may be treated in accordance with this 5

invention contains from 0.1% to 6% gold,an appreciable

amount of either silver or copper or both, the copper con

tent not exceeding 90% and the silver content not ex

ceeding 10%, from 0% to 90% nickel, from O% to 80%

iron, from 0% to 94% tungsten, from O% to 94% molyb- 10

denum, and from O% to 20% chromium. It will be

understood the process of this invention is applicable not

only to the recovery of gold from such scrap, but also

from any gold clad or plated material containing other

metais, particularly copper or silver or both in amounts 15

of from 1% to 90% copper, if copper is present, and

from 1% to 10% silver, if silver is present.

The charge is left in the bath as long as it is necessary to

remove or strip the gold. This usually will be evident

from a change in color of the charge. The charge should 20

not be left in the bath for an excess of time beyond that

necessary to strip substantially all of the gold, because

this will result in unnecessary contamination of the bath.

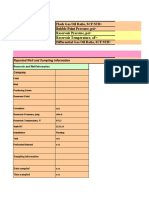

In the accompanying drawing is shown a vertical sec tion

through one form of an electrolytic bath which may 25 be

employed in practicing this invention. It will be under stocd

this showing is for purposes of illustration only and

other types of equipment may be used.

In the single figure of the drawing, 10 indicates a con

tainer provided with an acid resistant lining 11, desirably 30

of polyethylene, rubber, or other plastic. Cathodes 12,

which in the embodiment shown, are of stainless steel,

are immersed in the bath 13. Centrally disposed within

the container 10 is a perforated basket 14, desirably of

acid resistant plastic material, such as polyethylene. Bas- 35

ket 14 receives the charge of scrap 15 to be treated. An

ode conductor 16 of any electrically conducting material,

e. g., copper, steel, etc., is provided with contact rods 17

which extend through the pile of scrap 15 providing satis

factory electrical contact therewith.

40

The following examples are given for purposes of illus

trating the invention; it will be understood the invention

is not limited to these examples. In ali of these ex

amples the material treated was industrial scrap produced

in the production of grids for electronic tubes. It contained approximately 0.75% gold, 10% copper, 70% iron 45

and nickel and the rest molybdenum and tungsten. Ali

examples were carried out in equipment of the type shown

in the drawing employing a stainless steel cathode. Upon

the stripping of the gold from each charge or during each

run, the charge was removed and a fresh charge intro 50

duced.

EXAMPLE I

Analysis of the cathode plate showed it contained 40%

gold. The gold removed from the cathode could readily

be recovered in substantially pure form, for example, by

subjecting it to an acid refining to remove the other metal

chiefly copper.

!t is noted that in a comparative run using the same

scrap but in which the bath consisted of a solution of

potassium cyanide, the bath was soon fouled and it was

impossible to recover the gold content of even one charge

of about 200 grams.

EXAMPLE li

The composition of the bath was 500 grams of potas

sium ferrocyanide, 100 grams potassium cyanide to 1

gallon of water. Potassium hydroxide was added after the

second run to bring the pH of the bath up to 12. Addi

tional potassium hydroxide was added at the beginning

of Run 4 to maintain the pH of the bath at 12. Data

on these four runs is given in Table 2 which follows:

Table 2

Run

No.

Weight

of

Charge

in

Grams

Time in

Minutes

Taken to

Recover

Substantially

Allof

tbc Gold

Voltage

Used

---

--l_

275

306

292

31G

a

4

Amperage pHof Temperaturc of

Bath Bath,C.

Used

150

140

140

120

2.4

2.4

2.5

2.5

2.2

2.1

2.1

2.4

- --25

25

25

9

8

12

12

25

The cathode plate was heavy and showed a 60% gold

content corresponding approximately to an 80% gold re

covery from the gold content of the scrap.

EXAMPLElli

The composition of the bath used in this example

was 200 grams potassium ferrocyanide, 75 grams potassium cyanide, 40 grams potassium carbonate and 1 gal

lon of water. At the conclusion of Run 3 a small amount

of monopotassium phosphate was added, also small

amounts of potassium hydroxides were added to the bath

to maintain the pH at the values indicated. Data on

these runs are given in Table 3 whlch follows:

Table 3

Run

No.

Welght

of

Charge

in

Grams

Time in

Minutes

Taken to

Recover

Substantlally

Allof

the Gold

Voltage

Used

--- ----- -

--l_

Amperage pHof Temperature of

Bath Bath,C.

Used

245

235

180

298

373

320

534

165

125

90

50

40

70

50

2.0

2.5

2.5

2.0

2.0

2.0

2.0

2. 7

13

40

45

13

2.4

The bath used in this example was made by mixing 600

47

a

13

2.3

grams of potassium ferrocyanide K4Fe(CN)a3Hz0, 10 55 4

50

g

2.0

grams of potassium cyanide and 1 gallon of water. The

5

50

g

2.7

50

g

resultant solution was used as the electrolytic bath in

6

2.7

50

8

2.4

recovering the gold content of 6 successive charges of the

7------scrap. The data on these 6 charges (referred to as Run 1,

60

2, etc. in the table) is given in Table 1 which follows:

Analysis of the cathode plate showed approximately

100% gold recovery from the gold content of the scrap.

Table I

The expression "gold plated metal" is used in the

claims in a broad sense and is intended to include gold

Time in

Run

of

Welght

Minutes

'l'aken

Recover

No.

Ch_arge

Substantially

Ali of

the Gold

lU

Grams

---

Voltage Amperage pHof

Used

l_

34 .....

..

5,

6,

185

202

198

212

217

214

30

25

20

45

40

30

3.5

3.5

3. 5

3. 5

3.8

3.8

Used

Batb

Tempera

65 clad materiais as well as plated.

Since certain changes may be made in carrying out

ture of

the above process without departing from the scope

of the invention, it is intended that ali matter contained

in the above description shall be interpreted as illustra-------- 70 tive and not in a limiting sense.

What is claimed is:

1. An electrolytic process of recovering gold from

gold plated metais, which comprises _ subjecting

plated metal to electrolysis employing an electrolytic

75 containing a ferrocyanide from the group

10. o

10.0

10.0

10.0

11;512..0

10

10

10

9

9

9

Bath,C.

25

25

25

25

25

25

2,735,810

alkali metal and ammonium ferrocyanide and a cyanide

from the group consisting of alkali metal and ammonium

cyanides, the ratio of ferrocyanide to cyanide in the bath

being within the range of from 2: 1 to 5: 1 by weight.

2. The process as defined in claim 1, in which the bath

contains from 3% to 16% by weight of ferrocyanide

and from 0.25% to 8% by weight of cyanide.

3. A process of recovering gold from gold plated

metais, which comprises subjecting the gold plated metais

to electrolysis employing an electrolytic bath containing 10

from 3% to 16% by weight of a ferrocyanide from the

group consisting of the alkali metal and ammonium

ferrocyanides, from 0.25% to 8% by weight of a cyanide

from the group consisting of by weight, the alkali metal

taining approximately from 0.1% to 6% by weight of

gold and containing a metal from the group consisting of

copper and silver, which comprises subjecting the scrap

to electrolysis in an aqueous bath containing from 3%

to 16% by weight of ferrocyanide from the group con

sisting of alkali metal and ammonium ferrocyanides, and

from 0.25% to 8% by weight of a cyanide from the

group consisting of alkali metal and ammonium cyanides

at a pH of from 7.5 to 12 and a temperature of from

20e to soe c., the ratio of ferrocyanide to cyanide being

within the range of from 2: 1 to 5: 1 by

weight.

7. The process as defined in claim 6, in which the

bath contains from 2% to 4% by weight of potassium

ferrocyanide, from 0.5% to 2% by weight of potassium

and ammonium cyanides, the ratio of ferrocyanide to 15 cyanide, potassium carbonate and potassium phosphate

cyanide being within the range of from 2: 1 to 5: 1, the

in amount to maintain the bath at a pH of about 9

bath during the electrolytic decomposition being main

and the temperature of the bath is maintained at ap

proximately 45e C.

tained ata pH of from 7.5 to 12 and ata temperature of

from 20e to soe c.

8. An electrolytic process of recoverng gold from gold4. A process of recovering gold from gold plated 20 containing metais, which comprises introducing the goldmetais, which comprises subjecting the gold plated metais

containing metais into an electrolytic bath contain ing a

to electrolysis employing an electrolytic bath containing

ferrocyanide from the group consistng of alkali metal and

from 2% to 5% by weight of a ferrocyanide from the

ammonium ferrocyanides and a cyanide from the group

group consisting of the alkali metal and ammcnium

consisting of alkali metal and ammonium cyanides, the

ferrocyanides, from 0.5% to 2% by weight of a cyanide 25 gold-containing metal thus introduced being made the

from the group consisting of the alkali metal and am

anode, said bath a!so containing a cathode, the ratio of

monium cyanides, the ratio of ferrocyanide to cyanide

ferrocyanide to cyanide in the bath being within the range

being about 5: 1 by weight, the bath during the electro lytic of from 2: 1 to 5: 1 by weight, and passing current

decomposition being maintained at a pH of from

through said bath to effect deposition of the gold on said

8 to 10 and at a temperature of from 40e to 50e C.

30 cathode.

5. A process of recovering gold from gold plated

References Cited in the file of this patent

metais, which comprises subjecting the gold plated metais

Kern: "Transactions of the Electrochemical Society,"

to electrolysis employing an electrolytic bath containing

about 4% by weight of an alkali metal ferrocyanide ... vol. 24 (1913), pp. 241 to 270. Pages 260 to 265 and

and about 0.8% by weight of an alkali metal cyanide, "0 268 pertinent.

Kushner: "Products Finishing," January 1942, pages

the bath during the electrolytic decomposition being

maintained at a pH of about 9 and at a temperature of

46 to 56.

about 45e C.

Kushner: "Products Finishing," December 1941, pages

6. A process of recovering gold from gold scrap con26 and 28.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Gold Electroforms and Heavy Electrodeposits: Dirk WitheyDocument6 paginiGold Electroforms and Heavy Electrodeposits: Dirk WitheycicerojoiasÎncă nu există evaluări

- High Speed Selective Jet Electrodeposition of Gold and Gold Alloys Using Single Circular JetsDocument313 paginiHigh Speed Selective Jet Electrodeposition of Gold and Gold Alloys Using Single Circular Jetscicerojoias100% (1)

- United States Patent: Primary Examiner-G. L. Kaplan Attorney, Agent, or Firm-Wa!ter G. NilsenDocument5 paginiUnited States Patent: Primary Examiner-G. L. Kaplan Attorney, Agent, or Firm-Wa!ter G. NilsencicerojoiasÎncă nu există evaluări

- Us 2735810Document4 paginiUs 2735810cicerojoiasÎncă nu există evaluări

- High Speed Selective Jet Electrodeposition of Gold and Gold Alloys Using Single Circular JetsDocument313 paginiHigh Speed Selective Jet Electrodeposition of Gold and Gold Alloys Using Single Circular Jetscicerojoias100% (1)

- High Speed Selective Jet Electrodeposition of Gold and Gold Alloys Using Single Circular JetsDocument313 paginiHigh Speed Selective Jet Electrodeposition of Gold and Gold Alloys Using Single Circular Jetscicerojoias100% (1)

- Us 3856507 NBDocument4 paginiUs 3856507 NBcicerojoiasÎncă nu există evaluări

- Us 4377449Document5 paginiUs 4377449cicerojoiasÎncă nu există evaluări

- Refino D OurocDocument29 paginiRefino D OuroccicerojoiasÎncă nu există evaluări

- United States Patent: Primary Examiner-G. L. Kaplan Attorney, Agent, or Firm-Wa!ter G. NilsenDocument5 paginiUnited States Patent: Primary Examiner-G. L. Kaplan Attorney, Agent, or Firm-Wa!ter G. NilsencicerojoiasÎncă nu există evaluări

- Electrodeposition of Palladium-Silver Alloys From Ammoniacal ElectrolytesDocument10 paginiElectrodeposition of Palladium-Silver Alloys From Ammoniacal ElectrolytescicerojoiasÎncă nu există evaluări

- United States Patent (19) (11) Patent Number: 4,717,459: Nakazawa Et Al. (45) Date of Patent: Jan. 5, 1988Document6 paginiUnited States Patent (19) (11) Patent Number: 4,717,459: Nakazawa Et Al. (45) Date of Patent: Jan. 5, 1988cicerojoiasÎncă nu există evaluări

- Electrodeposition Palladium-Silver Alloys Arnrnoniacal ElectrolytesDocument8 paginiElectrodeposition Palladium-Silver Alloys Arnrnoniacal ElectrolytescicerojoiasÎncă nu există evaluări

- Determination of Gold (I) in Gold Plating Baths: VA Application Note V-199Document2 paginiDetermination of Gold (I) in Gold Plating Baths: VA Application Note V-199Linda GarzaÎncă nu există evaluări

- Us 3856507Document4 paginiUs 3856507cicerojoiasÎncă nu există evaluări

- 0831 Chapter15Document73 pagini0831 Chapter15Pedrin Cha OlivosÎncă nu există evaluări

- Art 10.1007 BF03214646Document7 paginiArt 10.1007 BF03214646cicerojoiasÎncă nu există evaluări

- EScholarship UC Item 2q71k3qkDocument132 paginiEScholarship UC Item 2q71k3qkcicerojoiasÎncă nu există evaluări

- 261Document6 pagini261cicerojoiasÎncă nu există evaluări

- Art 10.1007 BF03214617Document6 paginiArt 10.1007 BF03214617cicerojoiasÎncă nu există evaluări

- Refino D OuroDocument27 paginiRefino D OurocicerojoiasÎncă nu există evaluări

- V 104 N 10 P 563Document10 paginiV 104 N 10 P 563cicerojoiasÎncă nu există evaluări

- Us 2735810Document4 paginiUs 2735810cicerojoiasÎncă nu există evaluări

- Redken Shampoo Body Full... Ele - StrawberryNET PDFDocument2 paginiRedken Shampoo Body Full... Ele - StrawberryNET PDFcicerojoiasÎncă nu există evaluări

- Beschichtungstechnik e 29-05-2012Document12 paginiBeschichtungstechnik e 29-05-2012cicerojoiasÎncă nu există evaluări

- Namburi ThesisDocument50 paginiNamburi ThesiscicerojoiasÎncă nu există evaluări

- 2007 10 22 Guide Electroplating GuidanceDocument73 pagini2007 10 22 Guide Electroplating GuidancecicerojoiasÎncă nu există evaluări

- Feature: ⠙ญ⦽⦽ɡ⥥ಽəఉǍ⩥ PC ෝᔍᬊ⦹ᩍߑᯕ░ᱡᰆၰ b᳦☖ĥญ᮹šญᬊᯕ ↽ᗭ⊂ᱶᇥ⧕܆ 0.001༁ ⊂ᱶࠥɩ19᳦ඹ ↽ᗭ⊂ᱶ໕ᱢ1.7 mmDocument2 paginiFeature: ⠙ญ⦽⦽ɡ⥥ಽəఉǍ⩥ PC ෝᔍᬊ⦹ᩍߑᯕ░ᱡᰆၰ b᳦☖ĥญ᮹šญᬊᯕ ↽ᗭ⊂ᱶᇥ⧕܆ 0.001༁ ⊂ᱶࠥɩ19᳦ඹ ↽ᗭ⊂ᱶ໕ᱢ1.7 mmcicerojoiasÎncă nu există evaluări

- Metals 02 00450Document28 paginiMetals 02 00450cicerojoiasÎncă nu există evaluări

- Catalogo Compressores EmbracoDocument41 paginiCatalogo Compressores EmbracoTabulla GamesÎncă nu există evaluări

- Polymers For Advanced Techs - 2019 - Liu - Three Dimensional Printing of Poly Lactic Acid Bio Based Composites WithDocument13 paginiPolymers For Advanced Techs - 2019 - Liu - Three Dimensional Printing of Poly Lactic Acid Bio Based Composites WithTIop outÎncă nu există evaluări

- Validated HPLC MethodsDocument38 paginiValidated HPLC MethodsLaura GuarguatiÎncă nu există evaluări

- Shoe Sole Manufacturing TechDocument31 paginiShoe Sole Manufacturing TechDIPAK VINAYAK SHIRBHATE100% (6)

- MR - Bhushan Kharbadkar Project ReportDocument10 paginiMR - Bhushan Kharbadkar Project ReportPratik BhelondeÎncă nu există evaluări

- Vol. 5, Issue 2, February 2017, PharmaTutor, Paper-5Document9 paginiVol. 5, Issue 2, February 2017, PharmaTutor, Paper-5adnanakhan622Încă nu există evaluări

- Indion 414 As Superdisintegrant in Formulation ofDocument3 paginiIndion 414 As Superdisintegrant in Formulation ofsadafÎncă nu există evaluări

- Aoac 940.36 Medios de Cultivo CmaDocument1 paginăAoac 940.36 Medios de Cultivo CmaFernando MárquezÎncă nu există evaluări

- Depilatories: G. M. Howard, Perfumes, Cosmetics and Soaps © George M. Howard, W. A. Poucher 1974Document2 paginiDepilatories: G. M. Howard, Perfumes, Cosmetics and Soaps © George M. Howard, W. A. Poucher 1974chi nguyenÎncă nu există evaluări

- Nanotechnologies For Environmental Remediation-Giusy Lofrano, Giovanni Libralato, Jeanette Brown (Eds.)Document332 paginiNanotechnologies For Environmental Remediation-Giusy Lofrano, Giovanni Libralato, Jeanette Brown (Eds.)Matheus CiveiraÎncă nu există evaluări

- Gujarat Technological University: Semester - IV Subject Name: Fundamentals of Wastewater QualityDocument3 paginiGujarat Technological University: Semester - IV Subject Name: Fundamentals of Wastewater QualityshyamÎncă nu există evaluări

- 2.3 Control Valve ScheduleDocument13 pagini2.3 Control Valve Scheduleapi-19500842Încă nu există evaluări

- Aluminum Transmission Tower Bolts and Nuts: Standard Specification ForDocument4 paginiAluminum Transmission Tower Bolts and Nuts: Standard Specification ForMARCELO DOS SANTOS BARRETOSÎncă nu există evaluări

- Nanoparticle An Overview of Preparation CharacteriDocument12 paginiNanoparticle An Overview of Preparation CharacteriJordy ChandiaryÎncă nu există evaluări

- Lesson Presentation ChemistryDocument42 paginiLesson Presentation ChemistryTchr Ezra ChangÎncă nu există evaluări

- Xi-Che Revision SheetDocument14 paginiXi-Che Revision Sheetvedic computer labÎncă nu există evaluări

- Kseeb SSLC Class 10 Science Previous Year Paper 2019Document12 paginiKseeb SSLC Class 10 Science Previous Year Paper 2019ghs niduvani niduvaniÎncă nu există evaluări

- MSDS Sheets - Naphthalene - 476 - 00Document2 paginiMSDS Sheets - Naphthalene - 476 - 00ayamgoreng 123Încă nu există evaluări

- Examiners' Report/ Principal Examiner Feedback: IAL Chemistry WCH02/01Document10 paginiExaminers' Report/ Principal Examiner Feedback: IAL Chemistry WCH02/01JackÎncă nu există evaluări

- MDEADocument13 paginiMDEAAbdulla Alsowaidi100% (1)

- Sample To Answer LAMP On SmartPhoneDocument18 paginiSample To Answer LAMP On SmartPhonegvstempÎncă nu există evaluări

- Towards Dense Single-Atom Catalysts For Future Automotive ApplicationsDocument13 paginiTowards Dense Single-Atom Catalysts For Future Automotive ApplicationsAdriano Aj-formataçãoÎncă nu există evaluări

- FCJJ-16 Stoichiometry CH TeacherDocument7 paginiFCJJ-16 Stoichiometry CH TeacherHermes Polanco J.Încă nu există evaluări

- GFG Microtector Ii G460 7-Gas-Detector: Data SheetDocument5 paginiGFG Microtector Ii G460 7-Gas-Detector: Data SheetMiguel Angel López RamírezÎncă nu există evaluări

- Army Public School Dhaula Kuan Half Yearly Examination CHEMISTRY (2019)Document5 paginiArmy Public School Dhaula Kuan Half Yearly Examination CHEMISTRY (2019)YahooÎncă nu există evaluări

- Infineum Ilsa Gf-6 API SP e JasoDocument28 paginiInfineum Ilsa Gf-6 API SP e JasoDanielÎncă nu există evaluări

- Work Sheet Compounds 1Document11 paginiWork Sheet Compounds 1Jessa Bienel Biagtas OlescoÎncă nu există evaluări

- Flash Gas/Oil Ratio, SCF/STB Bubble Point Pressure, Psi Reservoir Pressure, Psi Reservoir Temperature, of Differential Gas/Oil Ratio, SCF/STBDocument52 paginiFlash Gas/Oil Ratio, SCF/STB Bubble Point Pressure, Psi Reservoir Pressure, Psi Reservoir Temperature, of Differential Gas/Oil Ratio, SCF/STBMario HuasasquicheÎncă nu există evaluări

- Chemical Bonding - 254 PDFDocument27 paginiChemical Bonding - 254 PDFJatin SinglaÎncă nu există evaluări

- Laetrile Amygdalinor Vitamin B17Document7 paginiLaetrile Amygdalinor Vitamin B17Isna NurhidayatiÎncă nu există evaluări