Documente Academic

Documente Profesional

Documente Cultură

Work Shop Manual GR 6 Matr 1-5302-387

Încărcat de

jepg83Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Work Shop Manual GR 6 Matr 1-5302-387

Încărcat de

jepg83Drepturi de autor:

Formate disponibile

SIGLA ET IDENTIFICATION Pag.

CARACTERISTIQUE 6-7

COURBES CARACTERISTIQUES DE PUISSANCE 8

ENTRETIEN-HUILE CONSEILLEE-CONTENANCES 9

ELIMINATION DES INCONVENIENTS 10

MESURES D’ENCOMBREMENT 11-12

COUPLES DES SERRAGE 13

COUPLES DES SERRAGE DES BOULLONS STANDARD 14

DISASSEMBLY/REASSEMBLY 15

Bringing fuel delivery limiter to its original position 36

Cam height 32

Cam timing 31

CAMSHAFT 31

Camshaft end play 33

Camshaft journals and bore 31

Camshaft timing 32

Choosing the head gasket thickness 25

Clearance between compression release cam and adjusting screw 17

CONNECTING ROD 26

Connecting rod alignment 27

Connecting rod dimensions 26

Conveyor plate for electric starting 18

CRANKSHAFT 29

Crankshaft end play 27

Crankshaft journal radius 29

Crankshaft lubrication ducts 29

CYLINDER 22

Cylinder characteristics in models 6LD260 and 6LD260/C 22

Cylinder classes 22

CYLINDER HEAD 19

Cylinder roughness 22

Dimensions and clearance between guides and valve stems (mm) 21

Dimensions of camshaft journal and bore 31

Dry air cleaner 16

Flywheel 18

Gear cover, timing side 28

Governor spring and leverage for small-size vehicles 35

Governor spring hooking position 34

Hand crank starting 37

Injector projection 19

Main bearing and connecting rod big end bearing inside diameter 30

Main bearing inside diameter 30

Main bearing support, flywheel side 27

Main journal and rod journal diameter 30

Manual droop adjustment 36

Muffler 16

Oil seal 28

Oil-bath air cleaner 15

Oil-bath air cleaner components 15

Oil-bath air cleaner components for de-noised engine 15

PISTON 23

Piston - Refitting 25

Piston classes and logo 23

Piston clearance 25

Piston pin 26

Piston rings - Clearance between grooves 24

Piston rings - End gaps 24

Piston rings - Fitting sequence 24

Pushrod tube 21

Re-coil starting 37

Rocker arm assembly 19

Rocker arm cover 16

Rocker arm cover with internal crankcase vapor recirculation system 17

Sound-insulating shroud with shroud plate and side plates 18

Speed governor 34

Speed governor and leverage for generating sets 35

Speed governor for engines meant for agricultural purposes 35

Speed governor setting 34

Speed governor with provision for external droop adjustment 36

Standard oil sump 25

Standard shroud and side plates 17

Tank 18

Thrust washer 30

Timing angles for checking purposes 33

Valve guide insertion 20

Valve guides and valve guide bores 20

Valve material 20

Valve seat lapping 21

Valve seats and valve seat bores 21

Valve spring 20

Valve timing check 33

Valve timing without considering timing marks 32

Valve/rocker arm clearance 17

Valves 19

LUBRICATION SYSTEM 38

Oil filter 39

Oil pressure check 40

Oil pressure curve at full speed 40

Oil pressure curve at idling speed 40

Oil pressure relief valve 40

Oil pump 39

Oil pump body and flange 39

FUEL SYSTEM 41

Fuel feeding pump drive rod protusion 42

Fuel feeding/injection system with feed pump and external fuel filter 41

Fuel filter inside tank 41

Fuel filter separate from the tank 42

Fuel transfer pump 42

Injec. pump type OLC for eng. fitted to small-size vehicles and agric. equip. 46

Injection pump 43

Injection pump delivery check at the test bed 48

Injection pump refitting 43

Injection timing checking device 48

Injection timing correction 50

Injection timing reference marks 49

INJECTOR 50

Injector type “P” 51

Nozzle 50

Nozzle for injector type “P” 51

OLC injection pump refitting 47

Plun. and deliv. valve for injec. pump type 6LD360, 6LD360N, 6LD400 and 6LD400/V 45

Plunger and deliv. valve for GDV for injec. pump type 6LD401/B1, 6LD435/B1 45

Plunger and deliv. valve for injec. pump type 6LD260 and 6LD260/C 44

Plunger and deliv. valve for injec. pump type 6LD325 and 6LD325/C 44

Plunger and deliv. valve for injec. pump type 6LD360 KAGR and 6LD400 KAGR 44

Plunger and deliv. valve for injec. pump type 6LD435 and 6LD435V 45

STATIC INJECTION TIMING 48

ELECTRIC SYSTEM 52

Alternator battery charger curve 53

Alternator, 12,5V 14A 53

Alternator, 12V 4A 53

Characteristic curves for starting motor type Valeo D6 RA 19 55

Check voltage regulator for proper operation 54

Electrical starting layout, 12V 4A 52

Injector setting 52

Key switch positions 56

Lighting system, 12V 14A 52

Starting motor type Bosch EF (L) 55

Voltage regulator 54

SETTINGS 57

Different types of injection pump delivery limiting device 58

Full speed setting in no-load conditions 57

Idle speed setting in no-load conditions 57

Injection pump delivery limiting device 57

Injection pump delivery setting 57

Injection pump delivery setting with engine on torque dynamometer 58

STORAGE 59

Permanent protection 59

Prepare the engine for operation 59

Temporary protection 59

S-ar putea să vă placă și

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorDe la EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorÎncă nu există evaluări

- Lombardini ManualDocument60 paginiLombardini ManualAndy Baldock80% (5)

- Donaldson WixDocument8 paginiDonaldson WixdionymackÎncă nu există evaluări

- Toyota Car StoriesDocument12 paginiToyota Car StoriesYudyChenÎncă nu există evaluări

- Dragon Days: The story of Miss Bardahl and the 1960s kids who loved hydros (2020 edition)De la EverandDragon Days: The story of Miss Bardahl and the 1960s kids who loved hydros (2020 edition)Încă nu există evaluări

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsDe la EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsÎncă nu există evaluări

- RP 2005 CatalogDocument434 paginiRP 2005 CatalogOleg100% (1)

- Alternator and Regulator NippondensoDocument16 paginiAlternator and Regulator NippondensoToua YajÎncă nu există evaluări

- TOYOTA060208Document9 paginiTOYOTA060208Pra YoudhaÎncă nu există evaluări

- CATMX1601Document1.234 paginiCATMX1601renatoÎncă nu există evaluări

- Ford 2.4, 2.8 and 2.9 Litre V6 EnginesDocument22 paginiFord 2.4, 2.8 and 2.9 Litre V6 Enginesjorge Angel LopeÎncă nu există evaluări

- 3s Engine - MechanicalDocument175 pagini3s Engine - MechanicalTiTi En GalaxyÎncă nu există evaluări

- Spare Parts For Engine Management: Extended Product Range KS Camshafts and AccessoriesDocument12 paginiSpare Parts For Engine Management: Extended Product Range KS Camshafts and Accessoriesartsarajevo100% (1)

- TGB Hde Blade 550 Efi FL WBC SloveniaDocument122 paginiTGB Hde Blade 550 Efi FL WBC SloveniaEnes Karagić100% (1)

- Aae New Catalog Web PDFDocument68 paginiAae New Catalog Web PDFRavi JadhavÎncă nu există evaluări

- The Alfa Romeo Spider Owners Work Manual: 1962 - 1978De la EverandThe Alfa Romeo Spider Owners Work Manual: 1962 - 1978Încă nu există evaluări

- A Guide to Motor-Cycle Design - A Collection of Vintage Articles on Motor Cycle ConstructionDe la EverandA Guide to Motor-Cycle Design - A Collection of Vintage Articles on Motor Cycle ConstructionÎncă nu există evaluări

- 013 Bombas CombsutivelDocument44 pagini013 Bombas Combsutiveljoao santosÎncă nu există evaluări

- How Mechanics Cheat Women: A Guide to Honest Car RepairDe la EverandHow Mechanics Cheat Women: A Guide to Honest Car RepairÎncă nu există evaluări

- CATAE902Document1.246 paginiCATAE902Desmond OeiÎncă nu există evaluări

- Sistem PengapianDocument16 paginiSistem PengapianArdianto BahtiarÎncă nu există evaluări

- Ignition, Engine Control (b4204t2 CVVT 2000)Document319 paginiIgnition, Engine Control (b4204t2 CVVT 2000)Jose PichinteÎncă nu există evaluări

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualDe la EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualÎncă nu există evaluări

- Building a WWII Jeep: Finding, Restoring, & Rebuilding a Wartime LegendDe la EverandBuilding a WWII Jeep: Finding, Restoring, & Rebuilding a Wartime LegendÎncă nu există evaluări

- Chassis Dynamometer Testing: Addressing the Challenges of New Global LegislationDe la EverandChassis Dynamometer Testing: Addressing the Challenges of New Global LegislationÎncă nu există evaluări

- Fuel InjectionDocument18 paginiFuel InjectionAshutoshSharmaÎncă nu există evaluări

- Catalogue John DeereDocument220 paginiCatalogue John DeereOussema HaddarÎncă nu există evaluări

- Acdelco Catalogue Spark PlugsDocument95 paginiAcdelco Catalogue Spark Plugscristian mininoÎncă nu există evaluări

- The Johnson Method: Guidebook For New Tractor-Trailer DriversDe la EverandThe Johnson Method: Guidebook For New Tractor-Trailer DriversÎncă nu există evaluări

- Land Rover Series III StageIDocument6 paginiLand Rover Series III StageIchristos390% (1)

- Steel WheelsDocument84 paginiSteel WheelsclopogaÎncă nu există evaluări

- Catalogo Fuel Pumps Air Flow 17122009135336Document88 paginiCatalogo Fuel Pumps Air Flow 17122009135336evailson2Încă nu există evaluări

- SteeringDocument122 paginiSteeringGreg HannaÎncă nu există evaluări

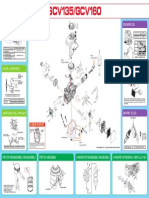

- GCV160 PDFDocument1 paginăGCV160 PDFClejeanu MihaelaÎncă nu există evaluări

- T25 2013 Catalogue 75dpi PDFDocument68 paginiT25 2013 Catalogue 75dpi PDFsinyoprimaÎncă nu există evaluări

- Toyota Nico PDFDocument33 paginiToyota Nico PDFDaniel GarciaÎncă nu există evaluări

- Emission Control PDFDocument63 paginiEmission Control PDFoz23100% (1)

- Honda Maintenance RevereDocument18 paginiHonda Maintenance ReverefrankkiniÎncă nu există evaluări

- 2011 GoodsonDocument147 pagini2011 GoodsonD.j. Kosa100% (1)

- Quincy Compressor Model 350Document33 paginiQuincy Compressor Model 350gonzalobovedaÎncă nu există evaluări

- CCW Two Cylinder ModelsDocument6 paginiCCW Two Cylinder ModelsPaul MartinÎncă nu există evaluări

- Haima S5 Service Manual-1Document133 paginiHaima S5 Service Manual-1roydez100% (1)

- Renr7167 02 01 All PDFDocument44 paginiRenr7167 02 01 All PDFИгорь СамоукинÎncă nu există evaluări

- Mitsubishi 6DB1 Engine PartsDocument5 paginiMitsubishi 6DB1 Engine PartsEngineParts250% (6)

- R9M ENGINE SPECSDocument7 paginiR9M ENGINE SPECSSabo Alex100% (2)

- c7 1 PDFDocument34 paginic7 1 PDFTASHKEELÎncă nu există evaluări

- mt09 1RCT&1RCU - 2015 PDFDocument75 paginimt09 1RCT&1RCU - 2015 PDFLa Casa del Motociclista-perùÎncă nu există evaluări

- Ic Engine and Turbo MachineryDocument25 paginiIc Engine and Turbo MachineryEyoÎncă nu există evaluări

- Automotive Fundamentals 2004-2005Document568 paginiAutomotive Fundamentals 2004-2005Adrian Ferrer84% (19)

- ISM Tier 3Document316 paginiISM Tier 3Ezequiel Zeta100% (1)

- Unit 1 Me8091 Automobile EngineeringDocument16 paginiUnit 1 Me8091 Automobile EngineeringRakeshkumarceg100% (3)

- Fiat 126 Owners Workshop ManualDocument131 paginiFiat 126 Owners Workshop ManualUmur GüngorÎncă nu există evaluări

- FZ6-S 2008 PDFDocument77 paginiFZ6-S 2008 PDFhectorÎncă nu există evaluări

- Chevrolet Tahoe 4.8L 5.3L & 6.0LDocument109 paginiChevrolet Tahoe 4.8L 5.3L & 6.0Lgabriel petitÎncă nu există evaluări

- DMM-2 Question BankDocument3 paginiDMM-2 Question BankrajuÎncă nu există evaluări

- Parts Catalog For Engine SeriesDocument72 paginiParts Catalog For Engine Seriesjuantalamera63299Încă nu există evaluări

- Tom-I Question Bank UpdatedDocument174 paginiTom-I Question Bank Updatedkiran_wakchaureÎncă nu există evaluări

- 4-Cylinder Direct Petrol Injection Engine 1.8L 2.0LDocument261 pagini4-Cylinder Direct Petrol Injection Engine 1.8L 2.0LdasomasoÎncă nu există evaluări

- F100B CDocument345 paginiF100B Cafpscribd0% (1)

- Components or Parts of IC Engine With Its Function PDFDocument9 paginiComponents or Parts of IC Engine With Its Function PDFMilbert Vaz AlfonsoÎncă nu există evaluări

- Subaru Robin's EX17 Service ManualDocument86 paginiSubaru Robin's EX17 Service ManualBilly HorshamÎncă nu există evaluări

- Linde Forklift Spare Parts ListDocument901 paginiLinde Forklift Spare Parts ListНиколай МозговÎncă nu există evaluări

- 480CK Wheel TractorDocument276 pagini480CK Wheel TractorAdam SeimÎncă nu există evaluări

- TBG 620 Work Shop Manual PDFDocument146 paginiTBG 620 Work Shop Manual PDFubaldo caraballoÎncă nu există evaluări

- LGA340Document36 paginiLGA340shansmartÎncă nu există evaluări

- (David Crolla - Behrooz Mashadi) Vehicle Powertrain Systems-Integration and Optimization - Solution ManualDocument256 pagini(David Crolla - Behrooz Mashadi) Vehicle Powertrain Systems-Integration and Optimization - Solution Manualsadegh_199067% (3)

- CD IK Tools v1.5 Plugin for C4D 9.6Document20 paginiCD IK Tools v1.5 Plugin for C4D 9.6Syed Aal-HussainÎncă nu există evaluări

- Bellcrank Mechanisms For Stirling EnginesDocument6 paginiBellcrank Mechanisms For Stirling Engineshmwong76Încă nu există evaluări