Documente Academic

Documente Profesional

Documente Cultură

Introducing The Adedge Ad26 Series Systems: Packaged Residential Arsenic Adsorption Systems

Încărcat de

mavillaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Introducing The Adedge Ad26 Series Systems: Packaged Residential Arsenic Adsorption Systems

Încărcat de

mavillaDrepturi de autor:

Formate disponibile

Introducing the AdEdge AD26 Series Systems

Packaged

Adsorption

Systemsfor Water Supplies

For Arsenic,

Iron, Residential

Manganese, Arsenic

and Sulfide

(AIMS) Reduction

The New Option for Effective Removal of Arsenic, Iron,

Manganese and Sulfide from Water Supplies.

Adedges new AD26 Systems for commercial and community water

systems are rapidly emerging as the preferred alternative for removing

AIMS. These systems are ideal for eliminating nuisance parameters

and improving overall water quality. The integrated oxidation and

filtration technology utilizes a proprietary, highly active, NSF 61 Certified

manganese dioxide media. It is packaged in a pre-engineered skid

mounted treatment system for simple installation and use. The targeted

contaminants are co-precipitated and filtered in the media bed, which is

periodically backwashed.

The systems have been designed by AdEdge specifically for well head

treatment. The Adedge AD26 systems are employed as stand alone

systems for the removal of iron, manganese, and sulfide, and arsenic if it

coexists with high levels of iron. Contact Adedge for specifics.

Whether you need to comply with the secondary contaminant rule or

simply want to improve the quality of your water, the AD26 system may

be the solution.

ADVANTAGES

AIMS are common in groundwater environments and can produce

unpleasant drinking water, undesirable health effects and produce

staining of household appliances and clothing. The Adedge AD26

Systems offer a more reliable and efficient way to remove AIMS. The

following are several advantages over conventional approaches using

traditional medias:

Much higher filtration rates in gpm/sq ft compared to manganese

greensand resulting in significantly smaller systems and footprint

Smaller systems and smaller footprints save you money on

equipment costs, building size and real estate.

Superior handling properties, stability, and NSF 61 certification

No permanganate or coagulant addition needed

Custom solutions to fit your site needs

Enhanced kinetics that allow short contact times

Long life typically over 5 years before replacement

Performance over wide range of incoming water quality

Ideal complement to arsenic adsorption systems that results in

longer arsenic media life and lower operating costs

High catalytic / oxidation activity for co-precipitation

Removal efficiencies 95% or better of iron and manganese

Q: How does the AD26 system remove iron

and manganese?

A: Through mechanisms of oxidation and coprecipitation, these contaminants are efficiently

removed in the AD26 media beds. Depending

on the specific water chemistry, the system can

achieve treatment efficiencies for these

contaminants to meet the secondary drinking

water standards (<0.3 mg/L Fe; <0.05 mg/L

Mn).

AdEdge 05-06

Q: How does the AD26 system

remove sulfide?

Operating Conditions

pH Range

6.5 9

Treatment Goals

< 0.3 mg/L Fe; < 0.05 mg/L Mn

< 0.010 mg/L As

Service Flow Rate

10-12 gpm / Sq Ft

Q: How does the AD26 system

remove arsenic?

Backwash Flow Rate

18-20 gpm / Sq Ft

Bed Expansion

20-30% typical

A: Arsenic is coprecipitated with iron

onto the media as ferric arsenate.

Contact Adedge for additional details.

Pressure Drop

< 5 psi typical across system

Oxidant

Hypochlorite feed for best results

Oxidant Contact Time

30 seconds

Typical Oxidant Dosage

0.5 2.0 ppm

Backwash Frequency

Site Specific (1-2X per week typical)

Media Life Expectancy

Site specific; typically 5+ years

A: The AD26 media converts H2S to

sulfur and than physically filters the

sulfur. The precipitated sulfur is

removed from the vessel during

backwash.

Q: How does it differ from other

processes such as Manganese

Greensand, Pyrolox, or Water

Conditioning?

A: The media is a NSF 61 certified

solid phase oxidation mineral. The

systems have a small footprint

compared to other technologies as

design flow rates are 10-12 gpm /

square foot of bed area. The

technology does not require a long

contact time, coagulants, or

permanganate addition /regeneration

like greensand and other oxidation

processes. No brine or salt is needed

and the process does not generate

hazardous waste.

Q: Is chlorine needed for the system

and does the media need

replacement?

A: A low Hypochlorite dose is

recommended for optimal performance

of the AD26 systems. It enhances the

removal process, improves longevity,

and keeps the surface of the media

oxidized to prevent buildup of solids.

Media life is typically 5+ years before

replacement.

Q: How do I determine the best way

to achieve my treatment goals for my

particular site?

A: Begin first by obtaining a complete

site specific water profile from a

qualified lab. This information can then

be submitted to AdEdge technical

support to discuss your application,

equipment sizing, and costs.

Q: What previous experience has AdEdge had using the

AD26 for iron removal?

A: Dozens of facilities in North America have utilized the

technology. One of the most notable project is the WWII

Memorial. The water is pumped from the groundwater feed

pumps and to the dual vessel AD26 system following in-line

hypochlorite (chlorine) injection. Hypochlorite solution is fed inline through a computer controlled metering and feed system

capable of real time chlorine residual measurement and control.

Iron and manganese are oxidized and filtered/adsorbed with the

proprietary AD26 catalytic media based system.

Manage the elements

Adedge Technologies, Inc.

5152 Belle Wood Ct, Suite A

Buford, GA 30518

1-866-8Adedge 678-352-0057 Fax

www.adedgetechnologies.com

support@adedgetechnologies.com

Notice: Information is believed to be reliable and is offered in good faith with no warranties or implied warranties or fitness for a particular use. Customer is responsible for determining whether use conditions and

information in this document are appropriate for specific applications and for ensuring compliance with applicable laws and regulations.

AdEdge 08-04

S-ar putea să vă placă și

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisDe la EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisEvaluare: 5 din 5 stele5/5 (1)

- Ion Exchange Resins and Adsorbents in Chemical Processing: Second EditionDe la EverandIon Exchange Resins and Adsorbents in Chemical Processing: Second EditionEvaluare: 5 din 5 stele5/5 (1)

- H2Zero Recycle BackwashDocument2 paginiH2Zero Recycle BackwashJaka PurnamaÎncă nu există evaluări

- Amine Degradation O2Document16 paginiAmine Degradation O2ZEN MAÎncă nu există evaluări

- How To Maximize Performance in The Amine Unit 2019Document4 paginiHow To Maximize Performance in The Amine Unit 2019Salman AbuzuhairaÎncă nu există evaluări

- Waterland Water Treatment Environmental TechnologiesDocument36 paginiWaterland Water Treatment Environmental TechnologiesSiraj AL sharifÎncă nu există evaluări

- H2 ZeroDocument2 paginiH2 ZeroJanzzen CrudaÎncă nu există evaluări

- Greensand Plus Narrative 2017Document6 paginiGreensand Plus Narrative 2017Cassy LimÎncă nu există evaluări

- Treatment GuideDocument13 paginiTreatment GuideLTE002Încă nu există evaluări

- Economical Chemical RecoveryDocument5 paginiEconomical Chemical Recoveryroohollah13Încă nu există evaluări

- Demineralization Systems - BrochureDocument4 paginiDemineralization Systems - BrochureLTE002Încă nu există evaluări

- Flue Gas DesulphurizationDocument12 paginiFlue Gas DesulphurizationFernanda Garrido SotoÎncă nu există evaluări

- Uop Separex Membrane Systems BrochureDocument2 paginiUop Separex Membrane Systems BrochureHamzaHashim100% (1)

- Chemco AMDDocument2 paginiChemco AMDimmanÎncă nu există evaluări

- Nayadic Design Manual PDFDocument24 paginiNayadic Design Manual PDFDavid QuirósÎncă nu există evaluări

- Conversion of SulfinolSM To BASF's aMDEADocument12 paginiConversion of SulfinolSM To BASF's aMDEAAna Carolina AbrantesÎncă nu există evaluări

- Aerobic Treatment PLDocument3 paginiAerobic Treatment PLbalakrishnagallaÎncă nu există evaluări

- Total Boiler SystemDocument11 paginiTotal Boiler SystemWaleed EmaraÎncă nu există evaluări

- h2s Scavenging BRDocument12 paginih2s Scavenging BROmid LarkiÎncă nu există evaluări

- Outstanding H S Removal: Reduce Risk. Increase ReturnDocument12 paginiOutstanding H S Removal: Reduce Risk. Increase ReturnQaiser HafeezÎncă nu există evaluări

- MdeaDocument28 paginiMdeahaarika1006100% (2)

- Jalamrut Water TreatmentDocument11 paginiJalamrut Water Treatmentamol patilÎncă nu există evaluări

- Efficiency Improvement and Trouble-Shooting: Separation SystemsDocument8 paginiEfficiency Improvement and Trouble-Shooting: Separation SystemsAlberto darianÎncă nu există evaluări

- Ion Exchange Vs Ultra Filtration SystemDocument12 paginiIon Exchange Vs Ultra Filtration SystemGauravÎncă nu există evaluări

- Cameron Water Injection BrochureDocument8 paginiCameron Water Injection Brochurelaleye_olumideÎncă nu există evaluări

- Water Injection BrochureDocument8 paginiWater Injection BrochuresegunoyesÎncă nu există evaluări

- Osiris BrochureDocument4 paginiOsiris BrochureJoy Das MahapatraÎncă nu există evaluări

- Osec B-Pak - Frequently Asked QuestionsDocument8 paginiOsec B-Pak - Frequently Asked Questionsalassy juyÎncă nu există evaluări

- Adnan Yahia 16109194 - Scrubber SystemDocument11 paginiAdnan Yahia 16109194 - Scrubber Systemadnan yhieÎncă nu există evaluări

- Environmental RestrictionsDocument2 paginiEnvironmental Restrictionsdebasish2000100% (1)

- Process - Desanding HydrocyclonesDocument4 paginiProcess - Desanding HydrocyclonesgshdavidÎncă nu există evaluări

- APU Aluminum 0411Document8 paginiAPU Aluminum 0411roohollah13Încă nu există evaluări

- Fe and MNDocument13 paginiFe and MNYuuki MaizakiÎncă nu există evaluări

- Boiler TreatmentDocument8 paginiBoiler Treatmentabhilibra14Încă nu există evaluări

- VPSA Oxygen PlantDocument4 paginiVPSA Oxygen PlantADJAHOUTONONÎncă nu există evaluări

- The Reclaimer Vol3 FinalDocument6 paginiThe Reclaimer Vol3 Finalhmudassir_1Încă nu există evaluări

- Ion Exchange TechDocument7 paginiIon Exchange TechclintoncÎncă nu există evaluări

- A Specifying Engineer's Guide To Water Treatment - IHS Engineering360Document3 paginiA Specifying Engineer's Guide To Water Treatment - IHS Engineering360PanosMitsopoulosÎncă nu există evaluări

- Steam Generator Chemical Cleaning: Head Office & FactoryDocument2 paginiSteam Generator Chemical Cleaning: Head Office & FactoryDilipÎncă nu există evaluări

- Remco EngineeringDocument20 paginiRemco Engineeringcrystalvoice12345Încă nu există evaluări

- Cooper Removal TechniqueDocument7 paginiCooper Removal TechniqueNoureddine MerahÎncă nu există evaluări

- Electroplating IndustryDocument5 paginiElectroplating IndustryRangasamyÎncă nu există evaluări

- Biogas Purification and Methane-Enrichment For Industrial Use - Mr. Sanjay Sharma, PSADocument15 paginiBiogas Purification and Methane-Enrichment For Industrial Use - Mr. Sanjay Sharma, PSASean HarshaÎncă nu există evaluări

- UOP Mercury Removal For Natural Gas Production BrochureDocument4 paginiUOP Mercury Removal For Natural Gas Production BrochurePherx Jhoss100% (1)

- Marine: Highest Level of International ApprovalDocument4 paginiMarine: Highest Level of International ApprovalddadaraÎncă nu există evaluări

- Alderley PWT BrochureDocument8 paginiAlderley PWT BrochurechirinoslaaÎncă nu există evaluări

- Water Treatment ProcessesDocument7 paginiWater Treatment ProcessesgondeathÎncă nu există evaluări

- The Challenge of Filtering Heavy Feed Stocks - Article From Filtration News - October 2011Document9 paginiThe Challenge of Filtering Heavy Feed Stocks - Article From Filtration News - October 2011Eaton FiltrationÎncă nu există evaluări

- Equipment Solutions That Fit: Water & Process TechnologiesDocument11 paginiEquipment Solutions That Fit: Water & Process Technologiesprocesspipingdesign100% (1)

- Christ Conesep MLDocument6 paginiChrist Conesep MLVijayakumar AndiÎncă nu există evaluări

- A New Way To Desalinate - Government Tested, Real-World ApprovedDocument0 paginiA New Way To Desalinate - Government Tested, Real-World ApprovedWONG TSÎncă nu există evaluări

- GasSweetening WorkshopDocument34 paginiGasSweetening Workshophrijucse100% (3)

- Water HyacinthDocument9 paginiWater HyacinthCzelsi Carlos NavarroÎncă nu există evaluări

- WTP ManualDocument248 paginiWTP ManualAldren Delina Rivera89% (9)

- Watts Premier INSTALLATION, OPERATION AND MAINTENANCE MANUAL WP5Document28 paginiWatts Premier INSTALLATION, OPERATION AND MAINTENANCE MANUAL WP5Jack AillonÎncă nu există evaluări

- LS 636 Industrial Process Fluids Application BrochureDocument12 paginiLS 636 Industrial Process Fluids Application BrochureJorge OcampoÎncă nu există evaluări

- CK WTC One Sep BrochureDocument4 paginiCK WTC One Sep BrochureVijayakumar AndiÎncă nu există evaluări

- MPR Technical Bulletin - Mobile ProcessesDocument5 paginiMPR Technical Bulletin - Mobile ProcessesELHAJBÎncă nu există evaluări

- Sewage Disposal Works: Their Design and ConstructionDe la EverandSewage Disposal Works: Their Design and ConstructionÎncă nu există evaluări

- Velocidad TuberiaDocument3 paginiVelocidad TuberiamavillaÎncă nu există evaluări

- Minimum Natural Bend RadiusDocument1 paginăMinimum Natural Bend RadiusmavillaÎncă nu există evaluări

- Washing Pump Layout1Document1 paginăWashing Pump Layout1mavillaÎncă nu există evaluări

- Safety Data Sheet According To Regulation (EC) No. 1907/2006/EC ECSO 8811Document11 paginiSafety Data Sheet According To Regulation (EC) No. 1907/2006/EC ECSO 8811mavilla100% (1)

- A-1828 Jaguar PumpDocument1 paginăA-1828 Jaguar PumpmavillaÎncă nu există evaluări

- Serial Keys - DAEMON Tools Lite 10Document2 paginiSerial Keys - DAEMON Tools Lite 10mavilla56% (18)

- Espesores TuberiaDocument1 paginăEspesores Tuberiahuguer1Încă nu există evaluări

- Introducing The Adedge Ad26 Series Systems: Packaged Residential Arsenic Adsorption SystemsDocument2 paginiIntroducing The Adedge Ad26 Series Systems: Packaged Residential Arsenic Adsorption SystemsmavillaÎncă nu există evaluări

- Web Diesel Fuel Oil (Canada)Document3 paginiWeb Diesel Fuel Oil (Canada)mavillaÎncă nu există evaluări

- PreFilter HousingDocument2 paginiPreFilter HousingmavillaÎncă nu există evaluări

- Filter Press PDFDocument9 paginiFilter Press PDFmavillaÎncă nu există evaluări

- Selecting The Proper Flare System PDFDocument6 paginiSelecting The Proper Flare System PDFjdgh1986100% (1)

- Diseño Sistema Tuberia PVCDocument21 paginiDiseño Sistema Tuberia PVCmavillaÎncă nu există evaluări

- Design Aerated Lagoons For Surface AeratorsDocument2 paginiDesign Aerated Lagoons For Surface AeratorsmavillaÎncă nu există evaluări

- Check Valve Inox PDFDocument3 paginiCheck Valve Inox PDFmavillaÎncă nu există evaluări

- Filter Nozzle Set Tech 19 PDFDocument1 paginăFilter Nozzle Set Tech 19 PDFmavillaÎncă nu există evaluări

- Blower Selection TableDocument3 paginiBlower Selection TableRabindranath Hendy TagoreÎncă nu există evaluări

- SanitaryTubeSpecs PDFDocument1 paginăSanitaryTubeSpecs PDFmavillaÎncă nu există evaluări

- Minimum Thermal FlowDocument4 paginiMinimum Thermal Flowdk4monjureÎncă nu există evaluări

- Pipe Fitting Dimensions: Od Tube: Asme Bpe-2002Document1 paginăPipe Fitting Dimensions: Od Tube: Asme Bpe-2002mavillaÎncă nu există evaluări

- Design Aerated Lagoons For Surface AeratorsDocument2 paginiDesign Aerated Lagoons For Surface AeratorsmavillaÎncă nu există evaluări

- HXY Methanol Water PDFDocument2 paginiHXY Methanol Water PDFmavillaÎncă nu există evaluări

- Tapas Tortuga YokeBoltDocument2 paginiTapas Tortuga YokeBoltmavillaÎncă nu există evaluări

- Adskpid Gs PDFDocument108 paginiAdskpid Gs PDFArini RizalÎncă nu există evaluări

- Fore3 ManualDocument48 paginiFore3 ManualMARIA FE GETALLAÎncă nu există evaluări

- 6.0 Biology Lab ManualDocument49 pagini6.0 Biology Lab ManualJacob SmithÎncă nu există evaluări

- Handling of Hygroscopic Products System-TechnikDocument4 paginiHandling of Hygroscopic Products System-TechnikMudassir FarooqÎncă nu există evaluări

- (MySchoolChildren) SKEMA Biologi Percubaan SPM 2012 SBP QDocument27 pagini(MySchoolChildren) SKEMA Biologi Percubaan SPM 2012 SBP QIsmaliza IshakÎncă nu există evaluări

- Drugdistributionfinal 151003021801 Lva1 App6891Document12 paginiDrugdistributionfinal 151003021801 Lva1 App6891Raju NiraulaÎncă nu există evaluări

- S.No. Type Medicine NameDocument6 paginiS.No. Type Medicine Namered petalsÎncă nu există evaluări

- Materials and Design: Ehab A. El-Danaf, Magdy M. El-Rayes, Mahmoud S. SolimanDocument6 paginiMaterials and Design: Ehab A. El-Danaf, Magdy M. El-Rayes, Mahmoud S. Solimankamal touilebÎncă nu există evaluări

- TM 10-4930-220-13PDocument133 paginiTM 10-4930-220-13PAdvocateÎncă nu există evaluări

- Worksheet2-Water QualityDocument4 paginiWorksheet2-Water QualityJoewellyn LimÎncă nu există evaluări

- G10 - Handout - Organic - Makeup Handout - First WeekDocument4 paginiG10 - Handout - Organic - Makeup Handout - First WeekSheela BatterywalaÎncă nu există evaluări

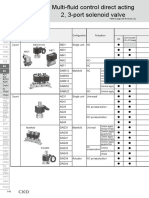

- General Purpose ValvesDocument46 paginiGeneral Purpose ValvesbataÎncă nu există evaluări

- Ipa18 202 SeDocument15 paginiIpa18 202 SeDimas Suryo WicaksonoÎncă nu există evaluări

- MK1977 CongressDocument173 paginiMK1977 CongressGodshalllaughÎncă nu există evaluări

- Table 1: Patient's Response On The Effectiveness of The Aratiles Leaves TeaDocument11 paginiTable 1: Patient's Response On The Effectiveness of The Aratiles Leaves TeaAlice Del Rosario CabanaÎncă nu există evaluări

- 4th Health2 For Demo Explicit TeachingDocument4 pagini4th Health2 For Demo Explicit TeachingLeony Cipriano100% (2)

- Gas Chromatography AmmoniaDocument10 paginiGas Chromatography AmmoniacurlychemÎncă nu există evaluări

- Bet MethodDocument16 paginiBet MethodG Nivetha100% (1)

- Models - Bfc.li Battery Thermal 2d AxiDocument16 paginiModels - Bfc.li Battery Thermal 2d AxijehadyamÎncă nu există evaluări

- ICSE Chemistry Board Paper19 PDFDocument9 paginiICSE Chemistry Board Paper19 PDFPrajakta DigheÎncă nu există evaluări

- Tensa Neoferma: Expansion JointsDocument4 paginiTensa Neoferma: Expansion JointsAlexandra SanduÎncă nu există evaluări

- A Brief Introduction To Pressure Vessels: (Clarification Needed)Document3 paginiA Brief Introduction To Pressure Vessels: (Clarification Needed)daniÎncă nu există evaluări

- Ohm's Law and Circuits: 2. Conductance, Insulators and ResistanceDocument29 paginiOhm's Law and Circuits: 2. Conductance, Insulators and ResistanceDita PramidaÎncă nu există evaluări

- Hydro Silk Fluid Englisch 06 2020Document1 paginăHydro Silk Fluid Englisch 06 2020Saman KhalidÎncă nu există evaluări

- Betadex Sulfobutyl Ether SodiumDocument11 paginiBetadex Sulfobutyl Ether SodiumLeidy GonzalezÎncă nu există evaluări

- Waste Minimization by Process Modification: Original ContributionDocument12 paginiWaste Minimization by Process Modification: Original ContributionVirginiaÎncă nu există evaluări

- Soda AshDocument10 paginiSoda Ashdr chatti hanumantha rao0% (1)

- NTSE Stage 1 State Level Model Paper 10Document30 paginiNTSE Stage 1 State Level Model Paper 10Om Prakash100% (1)

- DELTA-FC 1022 Tds - EngDocument2 paginiDELTA-FC 1022 Tds - EngAhmed HassanÎncă nu există evaluări

- Enviromental Toxicity and EvaluationDocument25 paginiEnviromental Toxicity and EvaluationSalma ShadÎncă nu există evaluări

- Data For Academic Report 2018-19 - MechanicalDocument42 paginiData For Academic Report 2018-19 - MechanicalVishvajit BhanavaseÎncă nu există evaluări