Documente Academic

Documente Profesional

Documente Cultură

The Behaviour of Elastomeric Bearings Under Load Combinations

Încărcat de

Mircea VenghiacDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

The Behaviour of Elastomeric Bearings Under Load Combinations

Încărcat de

Mircea VenghiacDrepturi de autor:

Formate disponibile

BULETINUL INSTITUTULUI POLITEHNIC DIN IAI

Publicat de

Universitatea Tehnic Gheorghe Asachi din Iai

Tomul LX (LXIV), Fasc. 3, 2014

Secia

CONSTRUCII. ARHITECTUR

THE BEHAVIOUR OF ELASTOMERIC BEARINGS UNDER

LOAD COMBINATIONS

BY

DANIELA OANEA FEDIUC*, MIHAI BUDESCU and

VASILE-MIRCEA VENGHIAC

Gheorghe Asachi Technical University of Iai

Faculty of Civil Engineering and Building Services

Received: June 19, 2014

Accepted for publication: July 14, 2014

Abstract. This paper presents experimental tests to determine the shear

modulus of elastomeric bearings at different values of the vertical force and

horizontal displacements.

The elastomeric bearings were designed for an experiment on scale models

for the shaking table tests. The elastomer had a hardness of 60 Sh A

Two sets of tests were carried out. The first was the application of a

compressive force on the elastomeric bearings with values between 10,...,60 kN

and the applied horizontal displacement with values of 14 mm and 17 mm. For

the second test, the compression force was 60 kN and the horizontal

displacements were equal to 17 mm, 34 mm and 43 mm.

Following the experimental tests, it resulted that the shear modulus of

elastomeric bearing has different values depending on the maximum applied

displacement. If the vertical force applied to the bearing increases, the shear

modulus decreases.

Key words: base isolation; shear modulus; hysteresis curves; experimental

tests.

*

Corresponding author: e-mail: oaneadaniela@yahoo.com

48

Daniela Oanea Fediuc, Mihai Budescu and Vasile-Mircea Venghiac

1. Introduction

An elastomeric bearing must fulfil the following characteristics: to have

high vertical flexibility, high vertical stiffness, to ensure the adherence of

elastomers for large displacements over the permissible limit and to withstand a

large number of alternating loads cycles.

The elastomers are materials which have similar mechanical

particularities with incompressible liquids, whose Poissons ratio is 0.5.

Therefore these bearings are made by reinforcing metal plates to prevent the

horizontal deformations of the material. The idea to introduce thin metal plates

in elastomeric bearings belongs to French engineer Eugne Freyssinet (Kelly et

al., 2011).

The Mullins effect is a phenomenon that occurs when the elastomer is

subjected to cyclic loadings and characterized by a decrease of the material

stiffness during charging (Fig. 1). The stabilization of hysteresis curve occurs

after several loading and unloading cycles.

1.6

1.4

Force [kN]

1.2

1

0.8

0.6

0.4

0.2

0

0

10

Strain [mm]

Fig. 1 The Mullins effect.

The Mullins effect is partially recoverable at ambient temperature in

long time (several days) or in a few hours at a temperature close to the

vulcanisation temperature (Ramier, 2004). The study of the Mullins effect is

important for understanding the behaviour of elastomeric bearings during shear

deformation.

The aim of this paper is to analyse the behaviour of elastomeric

bearings under vertical loads (compression) and horizontal loads (shear).

Bul. Inst. Polit. Iai, t. LX (LXIV), f. 3, 2014

49

2. Shear Test

2.1. Materials and Equipment

The tested elastomeric bearings had 100 100 mm plane dimensions

and consisted of 6 elastomer layers with 8 mm thickness interspersed with metal

plates with 95 95 mm plane dimensions and 3 mm thickness. The outer metal

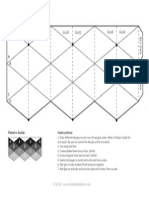

plates had a 8 mm thicknesses (Fig. 2). The elastomeric bearings have been

provided by the firm S.C. FREYROM S.A. The elastomer had a hardness of

60 Sh A and a bearing capacity of 80 kN.

Fig. 2 The elastomeric bearing.

Fig. 3 The test equipment.

An universal machine was used for test, having a capacity of 600 kN

that ensured the constant vertical force applied on the bearings, during the

50

Daniela Oanea Fediuc, Mihai Budescu and Vasile-Mircea Venghiac

application of the horizontal forces. A special installation that allows alternating

cycles in static regime was used for horizontal action (Fig. 3).

According to EN 1337-2006, the experimental test consisted in

measuring the shear deformation for a pair of bearings subject to progressive

shear forces; the shear modulus was determined and the bearing surfaces were

examined for defects after the maximum load. Thus, an average pressure of

6 MPa was applied and the bearings were subjected to shear at a constant speed,

to the maximum test deformation vxm (0.7Tq vxm 0.9Tq) which was then

reduced to zero. The compressive force has been removed and the bearings

were left for five minutes, then were tested again to shear at vxm. The vertical

force and the horizontal displacement were recorded continuously.

The secant shear modulus was determined by the relationship (ASRO,

2006):

G

( 2 1 )

,

( 2 1 )

(1)

where: 1,2 is the shear stress; 2 the shear strain at a displacement of 0.58 of

the elastomer layer thickness; 1 the shear strain at a displacement of 0.27 of

the elastomer layer thickness.

2.2. Results

The experimental tests were aimed to determine the influence of vertical

force on the horizontal stiffness of elastomeric bearings. In this regard, two sets

of tests were carried out.

The first consisted in the application of a compressive force on the

elastomeric bearings with values between 10,...,60 kN and the applied

horizontal displacements of 14 mm and 17 mm, that is 0.3 and 0.35 of the

elastomer layers thickness.

A number of six loading-unloading cycles were carried-out and the

force-displacement curves for the elastomeric bearings were plotted (Figs. 4 and

5).

The shear modulus values of elastomeric bearings were determined

using the force-displacement curves between 2 mm and 12 mm displacements.

The values are presented in Table 1.

Bul. Inst. Polit. Iai, t. LX (LXIV), f. 3, 2014

51

Fig. 4 Force-displacement curves for 14 mm displacement.

Fig. 5 Force-displacement curves for 17 mm displacement.

Table 1

The Shear Modulus Values for Elastomeric Bearings

Vertical force, [kN]

10

20

30

40

50

60

10

20

30

40

50

60

Horizontal displacement, [mm]

14

14

14

14

14

14

17

17

17

17

17

17

G, [MPa]

0.89

0.80

0.74

0.68

0.68

0.63

0.85

0.77

0.71

0.74

0.70

0.61

52

Daniela Oanea Fediuc, Mihai Budescu and Vasile-Mircea Venghiac

For the second test, the compression force was 60 kN and 17 mm,

34 mm and 43 mm horizontal displacements, that is 0.35, 0.7 and 0.9 of the

elastomer layers thickness (Fig. 6).

Fig. 6 The undeformed and deformed shape of the bearing at 34

mm displacement.

A number of six loading-unloading cycles were carried-out and the

force-displacement curves for the elastomeric bearings were plotted (Fig. 7).

Fig. 7 Force-displacement curves for elastomeric bearings.

The shear modulus values for the elastomeric bearings are presented in

Table 2.

Table 2

The Shear Modulus Values for Elastomeric Bearings

Test type

60 kN 17 mm

60 kN 34 mm

60 kN 43 mm

G, [MPa]

0.60

0.58

0.45

Bul. Inst. Polit. Iai, t. LX (LXIV), f. 3, 2014

53

After experimental research, the bearing surfaces were examined for

defects after the maximum load (Fig. 8).

Fig. 8 Elastomeric bearing degradation at 43 mm displacement.

3. Conclusions

Following experimental research, the effect of vertical forces variation

on the horizontal stiffness of elastomeric bearings was analysed.

If the vertical force applied to the bearing increases, the shear modulus

decreases. If the vertical force increases, the area of the hysteresis curve at

horizontal actions increases.

When the value of vertical force was 60 kN and the horizontal

displacement increased, the secant shear modulus decreased.

The shear modulus of the elastomeric bearing resulted 0.58 MPa at a 34

mm displacement and decreased to 0.45 MPa at a 43 mm displacement, which

means a 29% decrease. This phenomenon is explained by the rupture, at initial

elastomer displacements, of sulphur bridges which link the molecular chains

and the elastomer becomes more flexible in following cycles of deformation.

The shear modulus of the elastomeric bearing presents different values

depending on the maximum applied displacement, even to the horizontal

displacement limit, according to standards, that is 0.7 of the elastomer layers

thickness.

At 17 mm displacement (0.35 of the elastomer layers thickness),

detachments of the bearing from the outer metal plates have been observed.

At displacements greater than 24 mm (0.5 of the elastomer layers

thickness), bending tendency appeared (Fig. 8).

54

Daniela Oanea Fediuc, Mihai Budescu and Vasile-Mircea Venghiac

REFERENCES

Kelly J.M., Konstantinidis D.A., Mechanics of Rubber Bearings for Seismic and

Vibration Isolation. J. Wiley a. Sons, London, UK, 2011.

Ramier J., Thse: Comportement mcanique dlastomres chargs, Influence de

ladhsion charge polymre, Influence de la morphologie. LEcole Doctorale

Matriaux de Lyon, Paris, 2004.

*

*

* Aparate de reazem pentru structuri. Partea 3. Aparate de reazem din elastomeri.

Asociaia de Standardizare din Romnia, SR EN 1337-3-2006.

COMPORTAREA REAZEMELOR DIN ELASTOMERI SUB COMBINAII DE

NCRCRI

(Rezumat)

Se prezint ncercarea de laborator pentru determinarea modulului de

elasticitate transversal al reazemelor din elastomeri la diferite valori ale forei verticale

i ale deplasrilor orizontale.

Reazemele din elastomeri au fost concepute pentru un experiment pe modele la

scar pe platforma seismic. Elastomerul utilizat a avut duritatea de 60 Sh A.

S-au efectuat dou seturi de ncercri. Primul a constat n aplicarea unei fore

de compresiune asupra reazemului din elastomeri cu valori cuprinse ntre 10,,60 kN,

iar deplasarea orizontal aplicat a avut valori de 14 mm i 17 mm. Pentru al doilea set

fora de compresiune aplicat a fost de 60 kN i deplasarea orizontal de 17 mm, 34 mm

i 43 mm.

n urma ncercrilor experimentale a rezultat c modulul de elasticitate

transversal al reazemului din elastomer prezint valori diferite n funcie de deplasarea

maxim aplicat. n cazul n care fora vertical aplicat reazemului crete, modulul de

elasticitate transversal scade.

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Uponor PEX Plumbing Solutions GuideDocument73 paginiUponor PEX Plumbing Solutions GuideMaxmore Karumamupiyo100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- SWD Aci 530 11Document57 paginiSWD Aci 530 11Stephanie Miyata100% (2)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Technical Reference Guide Fastenal K Factor and MoreDocument62 paginiTechnical Reference Guide Fastenal K Factor and Moredlight0Încă nu există evaluări

- Project Report On Soil Stabilization Using Lime and Fly AshDocument35 paginiProject Report On Soil Stabilization Using Lime and Fly AshKUWIN MATHEW80% (100)

- EIFS performance standardsDocument40 paginiEIFS performance standardsRyan ClarkeÎncă nu există evaluări

- Composite Deck DesignDocument16 paginiComposite Deck Designvejanidb100% (1)

- Care of Children - KneippDocument294 paginiCare of Children - Kneippmmmattt100% (2)

- Physics of Radio Frequency Plasmas PDFDocument395 paginiPhysics of Radio Frequency Plasmas PDFdada12100% (1)

- Flextangles Template BABBLE DABBLE DODocument1 paginăFlextangles Template BABBLE DABBLE DOAnonymous rsL4gLÎncă nu există evaluări

- TezaDocument200 paginiTezaMircea VenghiacÎncă nu există evaluări

- FTS MainboardD2730ShortDescriptionENDE 10 1081195Document21 paginiFTS MainboardD2730ShortDescriptionENDE 10 1081195Mircea VenghiacÎncă nu există evaluări

- Harta Metrou LondraDocument2 paginiHarta Metrou LondraAle Bizdu100% (1)

- Conversion ChartsDocument10 paginiConversion ChartsLakshmi SurnilaÎncă nu există evaluări

- 220Document14 pagini220rts123Încă nu există evaluări

- Sew Beautiful Embroidery Stitch OrderDocument1 paginăSew Beautiful Embroidery Stitch OrderMircea VenghiacÎncă nu există evaluări

- Finishing Touch - A Denim RoseDocument2 paginiFinishing Touch - A Denim RoseMircea VenghiacÎncă nu există evaluări

- Creative Sewing RollDocument6 paginiCreative Sewing RollMircea Venghiac100% (1)

- Lungimi Suprapunere Pane Conform RUUKKI PDFDocument1 paginăLungimi Suprapunere Pane Conform RUUKKI PDFMircea VenghiacÎncă nu există evaluări

- Am QuakeDocument143 paginiAm QuakeMux MuxicÎncă nu există evaluări

- Structural Steelwork Design Brief 2011-2012Document20 paginiStructural Steelwork Design Brief 2011-2012Mircea VenghiacÎncă nu există evaluări

- The Effect of The Composite Floor Slab On The Behavior of Steel Moment-Resisting Frames in The North Ridge EarthquakeDocument16 paginiThe Effect of The Composite Floor Slab On The Behavior of Steel Moment-Resisting Frames in The North Ridge EarthquakeMircea VenghiacÎncă nu există evaluări

- Chemdur - 52Document3 paginiChemdur - 52ICPL-RWPÎncă nu există evaluări

- CVDocument2 paginiCVyadse100% (1)

- Ele541 Kje412 SJ 12Document13 paginiEle541 Kje412 SJ 12Mu'izz KaharÎncă nu există evaluări

- Deformation and Fracture Mechanics of Engineering MaterialsDocument44 paginiDeformation and Fracture Mechanics of Engineering MaterialsSyed Muhammad AliÎncă nu există evaluări

- Weco African Energy FlyerDocument7 paginiWeco African Energy FlyerNasiru BelloÎncă nu există evaluări

- Panduan Troli EmergencyDocument3 paginiPanduan Troli EmergencyTukiyemÎncă nu există evaluări

- 03 Trib OlogyDocument24 pagini03 Trib Ologyluis martinezÎncă nu există evaluări

- The Solar Still: Duncan KunzDocument5 paginiThe Solar Still: Duncan KunzNicu VisaÎncă nu există evaluări

- Swimming Pool BOQ - Water ProofingDocument2 paginiSwimming Pool BOQ - Water ProofingStephen RajÎncă nu există evaluări

- Ch11 CastingProcessesDocument102 paginiCh11 CastingProcessesFahmi PrayogiÎncă nu există evaluări

- Tempcore ProcessDocument4 paginiTempcore Processvikassolanki2010Încă nu există evaluări

- Completing The Puzzle:: 100% Plant-Derived PETDocument4 paginiCompleting The Puzzle:: 100% Plant-Derived PETAtif AzamÎncă nu există evaluări

- Welding: Dr. Sunil JhaDocument21 paginiWelding: Dr. Sunil JharassdriverÎncă nu există evaluări

- 02 Filtros de Ingreso A CompresorDocument6 pagini02 Filtros de Ingreso A CompresorLuis Alonso Dipaz ZeaÎncă nu există evaluări

- Pipe Support PDFDocument111 paginiPipe Support PDFm2110Încă nu există evaluări

- Straight Objective Type: Part-IDocument4 paginiStraight Objective Type: Part-Iaditya aryaÎncă nu există evaluări

- Proteins: The Diverse Macromolecules of LifeDocument54 paginiProteins: The Diverse Macromolecules of LifeMilimo JingsawÎncă nu există evaluări

- Biostimulation Treatments of Hydrocarbon-Contaminated SoilDocument6 paginiBiostimulation Treatments of Hydrocarbon-Contaminated SoilGeorgian-Răzvan CheșcaÎncă nu există evaluări

- T04: Mass Balance in Non Reacting System (Introduction Tu Multi Unit) A. Sugar Factory Activity (6 Min)Document2 paginiT04: Mass Balance in Non Reacting System (Introduction Tu Multi Unit) A. Sugar Factory Activity (6 Min)Dewi Mawaddatus SholekhahÎncă nu există evaluări

- HöglundDocument70 paginiHöglundIndri AuraliaÎncă nu există evaluări

- Satriana Et Al 2019 - European Journal of Lipid Science and TechnologyDocument1 paginăSatriana Et Al 2019 - European Journal of Lipid Science and TechnologyMuhammad Dani SupardanÎncă nu există evaluări

- B42 - Midterm10w CH 15-16-17-1Document7 paginiB42 - Midterm10w CH 15-16-17-1Siao Ryan YangÎncă nu există evaluări

- Water Cycle Questions AnwarDocument4 paginiWater Cycle Questions Anwarapi-124758305Încă nu există evaluări

- Zahid Husain M.Pharm (Pharmaceutics) Faculty of Pharmacy, IU, LucknowDocument24 paginiZahid Husain M.Pharm (Pharmaceutics) Faculty of Pharmacy, IU, LucknowQA Dhq OkaraÎncă nu există evaluări

- Convincing Worldwide: HERMETIC Pumps in The Refrigeration IndustryDocument28 paginiConvincing Worldwide: HERMETIC Pumps in The Refrigeration IndustryJose Ignacio Figueroa CortesÎncă nu există evaluări