Documente Academic

Documente Profesional

Documente Cultură

Statistics 2014 Cement

Încărcat de

Ali SeyediDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Statistics 2014 Cement

Încărcat de

Ali SeyediDrepturi de autor:

Formate disponibile

38

CEMENT

(Data in thousand metric tons unless otherwise noted)

Domestic Production and Use: In 2013, domestic production of cement totaled about 75.1 million tons of portland

cement and 2.1 million tons of masonry cement; output was from 98 plants in 34 States. Cement also was produced

at two plants in Puerto Rico. Production continued to be very low compared with the record level of 99 million tons in

2005, and reflected continued full-time idle status at several plants, underutilized capacity at many others, and plant

closures. Cement sales improved markedly in 2013, but were still about 44 million tons below the record volumes in

2005. The overall value of sales was about $7.6 billion. Most of the sales of cement were to make concrete, worth at

least $45 billion. As in recent years, about 70% of cement sales went to ready-mixed concrete producers, 11% to

concrete product manufacturers, 9% to contractors (mainly road paving), 4% each to oil and gas well drillers and to

building materials dealers, and 2% to other users. Texas, California, Missouri, Florida, and Michigan were, in

descending order, the five leading cement-producing States and accounted for 47% U.S. production.

1

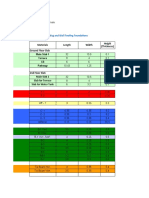

Salient StatisticsUnited States:

Production:

2

Portland and masonry cement

Clinker

Shipments to final customers, includes exports

Imports of hydraulic cement for consumption

Imports of clinker for consumption

Exports of hydraulic cement and clinker

3

Consumption, apparent

Price, average mill value, dollars per ton

Stocks, cement, yearend

e

Employment, mine and mill, number

4

Net import reliance as a percentage of

apparent consumption

2013

2009

2010

2011

2012

63,907

56,116

71,489

6,211

556

884

71,500

99.00

6,080

13,000

66,447

59,802

71,169

6,013

613

1,178

71,200

92.00

6,180

12,000

67,895

61,241

73,402

5,812

606

1,414

72,200

89.50

6,270

11,500

74,151

67,173

79,951

6,107

786

1,749

77,900

89.50

6,920

10,500

77,200

69,300

83,600

6,300

840

1,300

82,100

91.00

7,000

10,300

Recycling: Cement kiln dust is routinely recycled to the kilns, which also can burn a variety of waste fuels and

recycled raw materials such as slags and fly ash. Various secondary materials can be incorporated as supplementary

cementitious materials in blended cements and in the cement paste in concrete. Cement is not directly recycled, but

there is significant recycling of concrete for use as construction aggregate.

5

Import Sources (200912): Canada, 51%; Republic of Korea, 17%; China, 8%; Mexico, 5%; and other, 19%.

Tariff: Item

Cement clinker

White portland cement

Other portland cement

Aluminous cement

Other hydraulic cement

Number

2523.10.0000

2523.21.0000

2523.29.0000

2523.30.0000

2523.90.0000

Normal Trade Relations

123113

Free.

Free.

Free.

Free.

Free.

Depletion Allowance: Not applicable. Certain raw materials for cement production have depletion allowances.

Government Stockpile: None.

Events, Trends, and Issues: Sales of cement improved significantly in 2013 owing to higher spending levels for new

residential construction and for nonresidential buildings. Public sector construction remained below the already low

levels of 2012. Continued high numbers of home foreclosures and high levels of unemployment constrained spending

levels despite higher housing prices and assessments and associated improvements in property tax revenues to the

States. Imports of cement were slightly higher during the year. Although increasing, cement production remained well

below capacity at almost all plants, and most multikiln plants continued to operate only one kiln in 2013. Following the

2012 closure of one active integrated plant, one active grinding plant, and the announced closure of two already idle

integrated plants and one idle grinding plant, no plant closures were announced in 2013 and no new plants opened

during the year. Whereas three plants changed ownership in 2012, no such sales were announced in 2013.

Prepared by Hendrik G. van Oss [(703) 6487712, hvanoss@usgs.gov]

39

CEMENT

The manufacture of clinker for cement releases a great deal of carbon dioxide. The results of the second mandatory

reporting survey (2011) of the cement industrys greenhouse gas emissions were released by the U.S. Environmental

Protection Agency in early 2013 and revealed that most U.S. cement plants not already so equipped had installed

continuous emissions monitoring systems during the previous year. Carbon dioxide reduction strategies by the

cement industry mainly aim at reducing emissions per ton of cement product rather than by a plant overall.

Approaches include installation of more fuel-efficient kilns, partial substitution of noncarbonate sources of calcium

oxide in the kiln raw materials, and partial substitution of supplementary cementitious materials (SCM), such as

pozzolans, for portland cement in the finished cement products and in concrete. Because SCM do not require the

energy-intensive clinker manufacturing (kiln) phase of cement production, their use, or the use of inert additives or

extenders, reduces the unit monetary and environmental costs of the cement component of concrete. The ASTM C595 standard for blended cement was amended in 2012 to allow for the addition of up to 15% limestone in some

blends, but widespread use of limestone addition was not evident in 2013. Research continued toward developing

cements that require less energy to manufacture than portland cement, and (or) that use more benign raw materials.

The cement industry was granted a delay until 2015 in the implementation of the 2010 National Emissions Standards

for Hazardous Air Pollutants (NESHAP) protocol for cement plants. The protocol would significantly lower the

acceptable emissions levels of mercury and certain other pollutants. It was unclear how many plants would be able to

comply with the new limits; the mercury limits were expected to make it difficult for cement plants to continue to burn

fly ash as a raw material for clinker manufacture.

World Production and Capacity:

Cement production

e

2012

2013

United States (includes Puerto Rico)

74,900

77,800

Brazil

68,800

70,000

China

2,210,000

2,300,000

Egypt

46,100

46,000

Germany

32,400

34,000

India

270,000

280,000

Indonesia

32,000

35,000

Iran

70,000

75,000

Italy

33,000

29,000

Japan

51,300

53,000

Korea, Republic of

48,000

49,000

Mexico

35,400

36,000

Pakistan

32,000

32,000

Russia

61,500

65,000

Saudi Arabia

50,000

50,000

Thailand

37,000

35,000

Turkey

63,900

70,000

Vietnam

60,000

65,000

Other countries (rounded)

524,000

597,000

World total (rounded)

3,800,000

4,000,000

Clinker capacity

2012

2013

106,000

105,000

57,000

60,000

1,800,000

1,900,000

46,000

46,000

31,000

31,000

270,000

280,000

47,500

50,000

75,000

80,000

46,000

46,000

55,000

55,000

50,000

50,000

42,000

42,000

42,500

42,000

80,000

80,000

55,000

55,000

50,000

50,000

66,900

67,000

68,000

70,000

312,000

291,000

3,300,000

3,400,000

World Resources: Although individual plant reserves are subject to exhaustion, cement raw materials, especially

limestone, are geologically widespread and abundant, and overall shortages are unlikely in the future.

Substitutes: Most portland cement is used either in making concrete or mortars and, as such, competes in the

construction sector with concrete substitutes, such as aluminum, asphalt, clay brick, rammed earth, fiberglass, glass,

steel, stone, and wood. A number of materials, especially fly ash and ground granulated blast furnace slag, develop

good hydraulic cementitious properties by reacting with the lime released by the hydration of portland cement. Where

not constrained in supply, these SCM are increasingly being used as partial substitutes for portland cement in many

concrete applications.

e

Estimated.

Portland plus masonry cement unless otherwise noted; excludes Puerto Rico.

2

Includes cement made from imported clinker.

3

Production of cement (including from imported clinker) + imports (excluding clinker) exports + adjustments for stock changes.

4

Defined as imports (cement and clinker) exports.

5

Hydraulic cement and clinker.

1

U.S. Geological Survey, Mineral Commodity Summaries, February 2014

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Concrete Proportion and Concrete Mixture RatioDocument10 paginiConcrete Proportion and Concrete Mixture Ratiogarypaul95% (19)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- SSPC Guide11Document5 paginiSSPC Guide11vmonrroy7450Încă nu există evaluări

- Work Instruction Manual 2019Document203 paginiWork Instruction Manual 2019exam robot100% (1)

- Din 4030-1 - 1991Document6 paginiDin 4030-1 - 1991haK100% (2)

- Astm C157-14Document7 paginiAstm C157-14Fernando ChavarriaÎncă nu există evaluări

- Ree Buddha College of Engineering, Pattoor: ConcreteDocument9 paginiRee Buddha College of Engineering, Pattoor: ConcreteBala GopalÎncă nu există evaluări

- ACI351.1R 99 DigitalDocument18 paginiACI351.1R 99 DigitalAlejandro TrujilloÎncă nu există evaluări

- Sls 452 2019Document36 paginiSls 452 2019isuru samaranayake100% (1)

- Raw Mix DesignDocument8 paginiRaw Mix DesignkazamÎncă nu există evaluări

- 03 Strength Assessment of Recycled Aggregate Concrete by Ultrasonic Pulse Velocity Test PDFDocument5 pagini03 Strength Assessment of Recycled Aggregate Concrete by Ultrasonic Pulse Velocity Test PDFYati R. TankÎncă nu există evaluări

- Mini ProjectDocument45 paginiMini Projectmanohar manuÎncă nu există evaluări

- Excavation and Basement Construction: Backactor (Backhoe) Face Shoveling MachineDocument14 paginiExcavation and Basement Construction: Backactor (Backhoe) Face Shoveling MachineRajveer ThakurÎncă nu există evaluări

- Particle Packing TheoryDocument15 paginiParticle Packing Theorysrujan varma kaithojuÎncă nu există evaluări

- ADAA Technical Note 8Document3 paginiADAA Technical Note 8batquanÎncă nu există evaluări

- Column, Slab, Footing and Wall Footing Foundations: Class A MixingDocument47 paginiColumn, Slab, Footing and Wall Footing Foundations: Class A MixingGioharry Nul PanambulanÎncă nu există evaluări

- Sustainable Ways Sustainable Ways For Plastic Management For Plastic Management Sustainable Ways For Plastic ManagementDocument3 paginiSustainable Ways Sustainable Ways For Plastic Management For Plastic Management Sustainable Ways For Plastic ManagementEr Irfan BankaÎncă nu există evaluări

- 6015concrete Technology 1 & 2Document25 pagini6015concrete Technology 1 & 2rajitha shajiÎncă nu există evaluări

- Lab No. 9: To Determine The Dimension Tolerance Test of A Burnt Clay BrickDocument9 paginiLab No. 9: To Determine The Dimension Tolerance Test of A Burnt Clay BrickShehzad BachaniÎncă nu există evaluări

- Astm C 937-10Document3 paginiAstm C 937-10Rahul BhardwajÎncă nu există evaluări

- Metakaolin For High-Performance ConcreteDocument5 paginiMetakaolin For High-Performance ConcreteBekraoui KeltoumÎncă nu există evaluări

- List of Is Codes For Cement and ConcreteDocument7 paginiList of Is Codes For Cement and ConcreteShruti ShahÎncă nu există evaluări

- Vol-I - (Part - 2) THA Date - 08Document165 paginiVol-I - (Part - 2) THA Date - 08dox4useÎncă nu există evaluări

- The History of Concrete: From Prehistoric Rubble Mixes To Roman CementDocument3 paginiThe History of Concrete: From Prehistoric Rubble Mixes To Roman CementMadalena van ZellerÎncă nu există evaluări

- SoR 2016 17 PDFDocument16 paginiSoR 2016 17 PDFMallikarjuna SarmaÎncă nu există evaluări

- Construction and Building Materials Volume 23 Issue 1 2009 (Doi 10.1016 - J.conbuildmat.2007.12.004) D.A. Adesanya A.A. Raheem - A Study of The Workability and Compressive Strength Characteristics oDocument7 paginiConstruction and Building Materials Volume 23 Issue 1 2009 (Doi 10.1016 - J.conbuildmat.2007.12.004) D.A. Adesanya A.A. Raheem - A Study of The Workability and Compressive Strength Characteristics osubhansamuelsÎncă nu există evaluări

- Adisu FentawDocument138 paginiAdisu FentawnegisbabiÎncă nu există evaluări

- An Experimental Study On Recycled Aggregate Concrete by Partial Replacement For Cement y Areca-Nut AshDocument3 paginiAn Experimental Study On Recycled Aggregate Concrete by Partial Replacement For Cement y Areca-Nut AshVivek SenÎncă nu există evaluări

- 1 s2.0 S2211464522000690 MainDocument14 pagini1 s2.0 S2211464522000690 MainyasminÎncă nu există evaluări

- Carbocrete: The Future of ConcreteDocument9 paginiCarbocrete: The Future of Concretesiddharth gautamÎncă nu există evaluări

- EY Cement Industry in Customs Union Countries EngDocument28 paginiEY Cement Industry in Customs Union Countries Engabhi8554Încă nu există evaluări