Documente Academic

Documente Profesional

Documente Cultură

GasSealContamination TexasAnM Dresser Rand

Încărcat de

pest619Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

GasSealContamination TexasAnM Dresser Rand

Încărcat de

pest619Drepturi de autor:

Formate disponibile

146

Proceedings of the Fortieth Turbomachinery Symposium

September 12-15, 2011, Houston, Texas

GAS SEAL CONTAMINATION

Raphael Bridon

Components Focus Factory Manager

Dresser-Rand

Le Havre, France

rbridon@dresser-rand.com

Olivier Lebigre

Components Customer Support Manager

Dresser-Rand

Le Havre, France

olebigre@dresser-rand.com

ABSTRACT

Design of seals and sealing systems requires

multidisciplinary skills and deep understanding of

interactions between the seals and its environment.

This paper proposes to present typical gas seals

contaminants and corresponding consequences. It will

then describe the process typically used to perform the

root cause analysis and leading to a proposed fix.

INTRODUCTION

Dry gas seals are widely used in centrifugal

compressors to prevent process gas leakage to external

environment and bearing oil migration to the process.

Due to their operation under very tight running

tolerances, contamination of the dry gas seals can

result in catastrophic failures and make them one of

the most critical components of the centrifugal

compressors.

Below is a typical centrifugal compressor cutaway (figure 1) showing the location of the seals.

Their location is quite strategic as they are the

interface between the inside of the compressor (gas

process at high-pressure, high-temperature) and the

atmosphere (air and oil mist from the bearing cavity).

Due to the balance line, the gas seal only has

to deal with the intake pressure of the compressor.

As we will explain later, the gas seal requires a

high-quality gas to operate so instead of using the gas

present in the balance line, the seals are fed with a

clean and dry gas usually taken at the discharge of the

compressor.

This gas is dried, filtered, heated if necessary

and its pressure lowered to the intake pressure plus

epsilon before being injected at the primary port of the

seal.

Intake

Discharge

Pi

Pd

DRY GAS SEALS PRINCIPLE

Pi+

There is no means to have a totally leak free

sealing system between two parts in relative

movement (i.e., between a static and a rotating part;

between a housing and a shaft; in pumps, thermal

motors...).

There are more or less efficient devices able to

limit:

Leaks

Friction

Wear at the interface of the moving parts.

Gas seals are among the most efficient means to

reduce process gas leakage to the atmosphere and to

reduce wear and friction.

The gas seal is also a reliable means to route

effluent leaks to safe areas. The efficiency of the

whole process benefits from the gas seal system.

Pi+

Pi

Gas vein

Balance

line

Pi

Gas seal

Figure 1. Centrifugal compressor cut-away.

The gas seal principle is simple (figure 2).The

leakage (process gas) must be routed to a safe area;

therefore, the leakage is forced to pass between a static

and a rotating part. The rotating part is a grooved ring

driven by the compressor shaft. The static part is a ring

facing the rotating ring, but that only has light axial

movement.

When rotating, an aerodynamic effect generated

by the grooves creates a gap (from 4 to 10 microns)

between the rotating and stationary rings. The flow

Copyright 8 2011 by Turbomachinery Laboratory, Texas A&M University

147

generated by the pressure differential leaks between

the two faces, then the gas leakage is routed to the

venting system of the machine (flare) or vent.

Because of the gas film between the faces, a

constant gap between the faces prevents the parts from

rubbing against each other and makes the gas seal a

contact-free device.

Vent

(atmospheric

pressure+)

Dry and clean

gas

(Pi+)

Inner

labyrinth

with a buffer gas (generally nitrogen). This prevents

hazardous seal gas from leaking to the atmosphere.

Clean

gas

To

flare

Inert

gas

To

vent

Separation gas (Air or N2)

To process

Bearing vent

INBOARD

OUTBOARD

Figure 3. Tandem gas seal with intermediate labyrinth.

Process side

(Pi)

Figure 2. Cut away and cross section of a simplified

gas seal.

Typical gas seals arrangements

Tandem gas seal: Typically used for nonhazardous gases.

The sealing gas is injected at a pressure slightly

above the inboard pressure, so that a vast majority

(more than 80 percent) of it passes under the inner

labyrinth teeth. The remainder (less than 20 percent)

passes through the gap created by the lift off effect and

leaks to the flare (18 percent) and the last sealing gas

residues (2%) leaks through the secondary stage to the

vent.

The other important device in the compressor

seal is the tertiary seal. It can be a labyrinth or

segmented carbon rings. Its duty is to prevent bearing

oil mist migration to the seal and sealing gas migration

to the bearing oil. This separation is made by a gas

leak that prevents the oil from entering the gas seal

area on the inboard side and that prevents the sealing

gas coming from the secondary stage of the seal from

polluting the bearing oil.

So depending on the nature of the separation

gas, the gas seal vent may vent a mixture of sealing

gas (hydrocarbon) and nitrogen which is acceptable, or

a mixture of sealing gas and air.

Tandem gas seal with intermediate labyrinth:

Used when the process gas is hazardous: i.e., lethal

gas, flammable gas, or when condensates at primary

seal outlet (figure 3). A buffer gas is needed, such as

nitrogen, sweet gas, or fuel gas.

The principle is the same as in the tandem gas

seal with the addition of an intermediate labyrinth fed

Double opposed (back to back) gas seal: Used

when the process gas is dirty or the sealing pressure is

close to atmospheric pressure (figure 4). A sealing gas

(typically auxiliary gas) is needed, such as nitrogen,

sweet gas, or fuel gas.

The configuration consists of two sealing faces

(rotating ring and static seats) in a back-to-back

arrangement. The advantage is the lower number of

ports required: one for the sealing gas, one for the

vent, one for the separation gas, and one for the buffer

gas (optional).

Due to the pressure differential between the

inboard side of the gas seal and the sealing gas port

and between the vent and the sealing gas port, the flow

is not symmetrical (a majority of the sealing gas enters

the machine).

Generally in low-pressure applications, the

available process gas pressure that is not suitable to

feed the gas seal, so an alternate source must be

considered (i.e., nitrogen, fuel gas).

The nature of the sealing gas must also be

compatible with the nature of the process; nitrogen or

fuel gas can involve chemical reactions in the process

or damage the catalyst.

Inert

gas

To

vent

Separation gas (Air or N2)

Ref. Pressure

Bearing vent

INBOARD

OUTBOARD

Figure 4. Double opposed gas seal.

Copyright 8 2011 by Turbomachinery Laboratory, Texas A&M University

148

GAS SEAL CONTAMINANTS

Gas seal interfaces

Dry gas seals interface with the compressor

process inner labyrinth, compressor heads, and journal

bearings. Gas seals supply, vent and drain; ports are

then drilled in the compressor heads and connected to

seal support system.

All interfaces with the gas seal and its

environment are potential pollution paths. Black

arrows in Figure 5 are pollution paths. Pollution

occurs:

On the inboard side if the untreated process gas

leaks through the compressor inner labyrinth

when the seal gas pressure is lower than the

reference pressure

On the outboard side in the compressor bearing

oil when the separation seal is damaged or fails,

or there is insufficient separation gas (air or

nitrogen)

In the seal supply ports in the compressor head if

sealing gas is not adequately treated in the gas

seal system located upstream of the gas seal or if

piping is dirty

In the vent lines if dirt remains or if liquids can

be trapped or do not drain.

Nature of foreign particles

Foreign particles can be:

Particles from unclean piping (seal supply lines,

vent lines)

Particles from corroded piping, compressor or gas

seals components

Particles in the process gas (figure 6).

Figure 6. Black powder coming from compressor

inner labyrinth.

Pollution can occur because of:

Poor or non-existent filtration of sealing gas

Reverse pressurization of the gas seal

Insufficient flow under the compressor inner

labyrinth (figure 7).

Vent Separation

Seal Supply Flare

System System

Gas

Gas

Process

Gas

INBOARD

Bearing

Oil

OUTBOARD

Figure 5. Gas seal pollution paths.

Contaminant origins and consequences

To avoid gas seal pollution and because of the

very thin running gap between rotating and static

faces, it is necessary to properly treat sealing gas

upstream of the gas seal. Additionally, seal gas quality

must be ensured at all times, during all operating

sequences such as standby, start-up, running, and

shutdown.

Sealing gas is usually required to be free of

particles 3 microns (absolute) and larger and 99.97

percent free of liquids.

Contaminants can be either solids, liquids or

gaseous.

Figure 7. Salty deposit on gas seal housing.

Consequences

Because the running gap between static and rotating

faces is around 5 microns, any particle larger than the

gap will cause erosion of the faces (figures 8 and 9)

leading to an increase in the gas leakage and

eventually failure of the gas seal.

Where very thin particles are present, particle

accumulation and clogging of the rotating seat grooves

Copyright 8 2011 by Turbomachinery Laboratory, Texas A&M University

149

results in a loss of the lift-off effect and again failure

of the gas seal.

Another consequence can be damage of the

secondary sealing surfaces and more specifically of

the balance diameter.

static and rotating seats, heat generation, parts

deformation, O-rings extrusion, thermal shock on the

rotating seat and eventually failure of the rotating and /

or static rings. In addition static faces are commonly

made of carbon and are therefore subject to blistering

due to the porous nature of this material.

Gaseous pollution

Seal gas is not inherently a pollutant for the seal,

assuming it is adequately treated upstream of the gas

seal. However, some pollution could occur if a

chemical reaction develops:

Between the seal gas components themselves, for

instance polymerization of the seal gas

Between seal gas components and gas seal / gas

seal panel components materials, such as a reaction

between sulfur present in the seal gas stream and

nickel present in the rotating ring (figure 10).

Figure 8. Scratched static seat.

Clogged grooves by nickel

sulfide

Figure 10. Gaseous pollution of rotating ring.

Figure 9. Scratched dynamic seat.

Liquid pollution

Liquid pollution can:

Result from bearing oil leakage through the

separation seal or migration along the shaft line

Be present in the process gas stream if there is no,

or an inappropriately designed, coalescer in the

filtering system

Be due to the condensation of the sealing gas; seal

gas is most commonly taken from the compressor

discharge, filtered and then expands as it passes

through the gas seal system components, such as the

filter, valves, orifices and gas seal faces; as pressure

drops, temperature decreases and could result in the

seal gas entering in the liquid phase

Result from contamination by corrosion inhibitors

present in the process piping.

As a contact-free sealing device, the gas seal

does not require any maintenance of the cartridge

itself. However, in operation, some periodic

maintenance of the seal is preferred to check for any

pollution, check the condition of the carbon rings and

replacement of O-ring which have a limited life span.

This periodic maintenance is an opportunity to

control the condition of operation, the efficiency of the

panel and take corrective action if required.

As a consequence, providing both gas seal and

gas seal system are properly designed, a gas seal

failure is always an accident and shall not be

considered unavoidable. Thus, a root cause analysis

(RCA) of each seal failure shall be conducted. Due to

the nature of the gas seal (tight running tolerances,

multiple interfaces), such analysis is quite complex

and a rigorous methodology needs to be applied.

Process leading to damage

Condensates at the gas seal interface will lead to a

degradation of the lift-off effect, friction between

Copyright 8 2011 by Turbomachinery Laboratory, Texas A&M University

150

ROOT CAUSE ANALYSIS

The root cause of the failure is sometimes

obvious (seal gas supply failure, nitrogen supply

shortage, abnormal operating conditions). It may be

reported by the end user of the machine or be obvious

after a gas seal inspection.

The root cause would most likely be difficult to

identify, because it must be determined if observed

damages are a consequence of the failure or the cause.

Thus, a detailed gas seal failure root cause analysis

process has been developed in order to address all

potential contributing factors and fix the problem for

certain.

The process consists of:

Detailed inspection of the seals / lab analysis of

pollution if required

Collecting a maximum of gas seal environment

data / analysis

Elimination of failure scenario that do not

corroborates with data, collecting additional data

if required

Conclusion

visible on discharge gas seal and was instrumental in

the root cause identification.

b) The gas seal cartridge is inspected externally

(figure 12), pictures are taken to detect any external

pollution or damage to record areas of pollution and

check for any problem concerning the gas seal

assembly

c) Then the gas seal outboard housing is

removed. This makes it possible to check secondary

ring sealing surfaces (static seat and rotating seat).

Detailed inspection process

a) When a detailed inspection of a failed seal is

conducted, an inspection of the associated opposite gas

seal is recommended. Indeed, it is recommended to

dismantle the unit and inspect both seals in case of

failure for two reasons:

First, in the case of a gas seal failure, it is

very likely that the opposite gas seal has

encountered the same pollution/damages.

Second, it is helpful to have both seals

available for inspection because the second

gas seal provides clues depending on

whether it is not damaged or less damaged

than the failed one.

Figure 12. external and internal gas seal inspection.

The outboard side is most likely to be polluted

by oil. Location of lube oil should be checked to

identify whether lube oil was leaking through the

separation barrier or if the source is a gas seal /

compressor shaft O-ring problem.

Then the nature and location of any pollution is

identified (for example, on the rings, under spring

support, on buffer gas port, etc).

In the case of unidentified pollution, samples

are taken in order to conduct laboratory analysis.

These analyses give some indication on the origin of

the pollution. In figure 13, sulfur deposit is detected.

Figure 11. Two opposite seals inspection.

Figure 11 shows two primary rotating seats

from the same machine. Because the intake gas seal

has failed, it is very difficult to analyze any pollution

and draw out any conclusion. Pollution is much more

Copyright 8 2011 by Turbomachinery Laboratory, Texas A&M University

151

Figure 13. lab analysis of black deposit on rotating

seat.

design (flow control, pressure control, presence of

auxiliary seal gas supply, etc).

d) The tandem sleeve is extracted in order to

open inboard stage; primary ring sealing surfaces are

checked for pollution or damages.

e) Then, checking each stage, the condition of

the balance diameter is reviewed because it is a very

sensitive area that requires a perfect surface finish. At

that time, a thorough scrutiny of inboard and outboard

housings is also carried out.

f) Finally, the gas seal is fully dismantled in

order to check the condition of all O-rings, search for

any pollution under static seats and rotating seats and

look for any damage on all the parts.

Data collection

Investigation of gas seals direct environment is

mandatory in order to go further in the RCA.

Collecting gas seal environment data is a key phase

and is not an easy task because it involves different

actors such as:

End user of the compressor

Maintenance subcontractor

Field service representative of seal supplier

Compressor manufacturer.

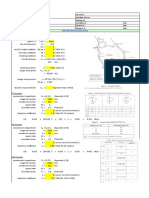

Figure 14. P&ID used for root cause analysis.

Compressor cross section and head drawings

(figure 15) are used to check if failure scenarios are

compatible with compressor design. Figure 15 shows

how water-washes lead to liquid accumulation on the

intake sides through the balance line and because of

the inlet side is cooler than the discharge.

A database of all manufactured gas seals has

been developed (each gas seal is identified by a serial

number). This makes available all original gas seals

data (operating conditions, gas analysis, arrangement)

for any gas seal.

This database is also used to record all

refurbishments or repairs performed on a gas seal after

original delivery. This makes it possible to have the

whole story of a specific gas seal or all seals of the

same service. This information is valuable to a root

cause analysis.

It is required to gather the following

information from different engineering disciplines:

Compressor design:

Compressor head: gas seal ports, draining

Journal bearing configuration

Process side: inner labyrinth, balance piston,

balance line

Gas seal system

Lube oil system.

Figure 15. Compressor cross section.

Information from installation site is necessary.

All available information from the site related to the

seal failure and the seal operation shall be collected.

This could include:

A field report from field service representative

recorded observations (visual for example) and

measurements taken may help in identifying the

failure scenario. On-site observations from client

personnel can also be important.

Trends of operating conditions and gas seal

parameters at the time of the failure are analyzed

(figure 16).

The sealing gas P&ID (figure 14) is analyzed to

check if failure scenarios are compatible with system

Copyright 8 2011 by Turbomachinery Laboratory, Texas A&M University

152

highlights only the root cause compatible with all

provided data.

As an alternative, formal root cause analysis

sessions involving compressor product engineers, gas

seal OEM representatives, and field representatives are

organized using commonly published root cause

analysis methods (Ishikawa diagram method, 5-Whys,

etc).

CONCLUSION

Figure 16. snapshots of trends of gas seal data at

failure period.

Up-to-date gas analysis and operating conditions

(inlet and discharge pressure / temperature, settle

out pressure, ambient conditions, number of

starts/stops, running hours, etc) and operating

sequence; these data provide the necessary

information for the actual phase map analysis and

can confirm if condensates and / or hydrates can

form in the gas seal system (figure 17).

Condensation / hydrate formation mostly occur

during transient phases: start-up / settle out, etc.

SOP

18C

36C = new temperature

switch from N2 to process

gas for cold startup or SOP

As can be seen from the above article,

performing a gas seal failure root cause analysis is a

difficult task involving several disciplines, several

actors and can be a lengthy process.

Root cause analysis can lead to gas seal or

system design adjustments such as:

Implementation of a conditioning skid: heater,

scrubber, filter, mercury trap, booster

Modification of operating sequences

Addition of heat tracing

Finally, it should be mentioned that these

design adjustments may help improving gas seal

system reliability but it can also be improved by:

Training the on-site operators to provide in-depth

knowledge of the seal and sealing systems

specificities

Ensuring gas seals installation and dismantling

from the compressor is done by trained personnel

Implementing periodic checks on the system, such

as weekly draining of low points, visual check of

vents.

REFERENCES

Stahley, J., 2001, Design, operation, and maintenance

considerations for improved dry gas seal performance

in centrifugal compressors, Proceedings of the 30th

Turbomachinery Symposium, Turbomachinery

Figure 17. Phase map analysis.

Failure scenario

As a result of the inspection, the analysis of gas

seal environment data, the failure root cause(s) can

usually be identified.

If this is not sufficient, an additional diagnostic

tool can be used. A failure mode and effect database

has been designed which links any observation

collected during gas seal inspection and all data

concerning gas seal environment with the potential

root causes. This database is used to generate the most

likely root cause because of an algorithm that

Laboratory, Texas A&M University, College Station,

Texas, pp. 203-207..

Stahley, J., 2005, Dry Gas Seals Handbook, Tulsa,

Oklahoma, Pennwell

ACKNOWLEDGEMENTS

The authors would like to thank all Dresser-Rand

parties involved in the root cause analysis process. We

also want to thank Dresser-Rand for permission to

publish this work.

Copyright 8 2011 by Turbomachinery Laboratory, Texas A&M University

S-ar putea să vă placă și

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- EnnnDocument9 paginiEnnnSajid AliÎncă nu există evaluări

- Pipes & Fittings: PlumbingDocument7 paginiPipes & Fittings: PlumbingShaik MunawarÎncă nu există evaluări

- Fire Protection Hydraulic CalculationsDocument25 paginiFire Protection Hydraulic CalculationsWillden100% (9)

- SPE-173598-MS A Simplified Approach To Sizing 2 and 3 Phase Separators PDFDocument21 paginiSPE-173598-MS A Simplified Approach To Sizing 2 and 3 Phase Separators PDFRicardo VargasÎncă nu există evaluări

- Che 15Document44 paginiChe 15Arnab DasÎncă nu există evaluări

- Wind Load CalculationDocument2 paginiWind Load CalculationWangTFÎncă nu există evaluări

- Turbulent Mixing and Transition Criteria of Flows Induced by Hydrodynamic InstabilitiesDocument69 paginiTurbulent Mixing and Transition Criteria of Flows Induced by Hydrodynamic InstabilitiesAndrei ChornyÎncă nu există evaluări

- Mckee Aqua Purified Refilling StationDocument3 paginiMckee Aqua Purified Refilling StationPaw LabadiaÎncă nu există evaluări

- Rotary Drum Vacuum FiltersDocument4 paginiRotary Drum Vacuum FiltersGilang Wahyu SejatiÎncă nu există evaluări

- Cañerias Del EnfriadorDocument4 paginiCañerias Del EnfriadorAlex BravoÎncă nu există evaluări

- Solution of Homework #4Document7 paginiSolution of Homework #4丁偉庭Încă nu există evaluări

- Refrigeration 2Document25 paginiRefrigeration 2krazylionÎncă nu există evaluări

- Air Handling Unit (AHU)Document6 paginiAir Handling Unit (AHU)bibombioÎncă nu există evaluări

- Chem 1-8Document43 paginiChem 1-8Cabacungan, John VinceÎncă nu există evaluări

- Problem Set #6: Name: Date: SectionDocument3 paginiProblem Set #6: Name: Date: SectionMatt DienteÎncă nu există evaluări

- Electronic Heat TransferDocument31 paginiElectronic Heat TransferShashank PansariÎncă nu există evaluări

- Control Valve ErosionDocument4 paginiControl Valve ErosionIbrahim HomosÎncă nu există evaluări

- Physics Project Class 11Document18 paginiPhysics Project Class 11Aarya Rajesh71% (55)

- Expansion Tank Design Guide, How To Size and Select An Expansion Tank For A Chilled Water System PDFDocument33 paginiExpansion Tank Design Guide, How To Size and Select An Expansion Tank For A Chilled Water System PDFOm Parkash SharmaÎncă nu există evaluări

- XĐ by Hot GasDocument71 paginiXĐ by Hot GasHoàngViệtAnhÎncă nu există evaluări

- Hydraulics - Chapter - 2 - Lecture - IIDocument30 paginiHydraulics - Chapter - 2 - Lecture - IIBikila LegesseÎncă nu există evaluări

- 3.3 Completion Equipment PDFDocument107 pagini3.3 Completion Equipment PDFJohn Cooper100% (1)

- Pump Start-Up Backpressure - Industrial Professionals - Cheresources - Com CommunityDocument7 paginiPump Start-Up Backpressure - Industrial Professionals - Cheresources - Com Communityjayrolling dollazÎncă nu există evaluări

- Diaphragm Valve How It WorksDocument3 paginiDiaphragm Valve How It Worksthouche007Încă nu există evaluări

- KWIGISHADocument93 paginiKWIGISHABernard PalmerÎncă nu există evaluări

- Homework 8 SolutionsDocument8 paginiHomework 8 SolutionsJack Tan100% (1)

- Mock Drill Report On IA Failure Dated 09.04.2023Document6 paginiMock Drill Report On IA Failure Dated 09.04.202300083583rfÎncă nu există evaluări

- Gas Turbine Engine Oil SystemsDocument2 paginiGas Turbine Engine Oil SystemsRodriguez ArthursÎncă nu există evaluări

- Boiler MannualDocument49 paginiBoiler MannualShailenderÎncă nu există evaluări

- Aerodynamics For StudentsDocument123 paginiAerodynamics For Studentsfilipbgd94100% (1)