Documente Academic

Documente Profesional

Documente Cultură

MAE 364 - Practice Exam

Încărcat de

huiqui1Descriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

MAE 364 - Practice Exam

Încărcat de

huiqui1Drepturi de autor:

Formate disponibile

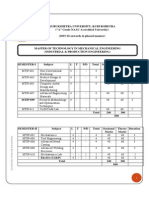

MAE 364: Manufacturing Processes

Practice Exam

Spring 2015

Sample Theory Questions

This section provides examples of how the theoretical content could be covered on the exam.

Exam questions will differ, both in structure and difficulty. Further, this set of problems is

intended to be representative, not exhaustive (i.e., it is likely that some exam questions will be

completely different).

Question 1

Identify and briefly describe the two stages of manufacturing.

Question 2

Identify two distinct uses of machining processes. Provide brief examples of each.

Question 3

Why are chip breakers used?

Question 4

Machining can generate significant heat. Where does this heat go? What is the preferred outlet for the

heat?

Question 5

What are the negative effects of a dull tool? For each effect identify the cause(s).

Question 6

Describe the general relationship between tool hardness and temperature.

Question 7

When selecting a cutting tool material, what tradeoffs might have to be made?

Question 8

Identify three subtractive techniques for creating holes. When would you use each technique?

Question 9

Identify two manufacturing processes that can only produce features with a constant cross-section.

Question 10

For a given machining process, know the potential problems and their probably causes.

Question 11

Discuss the range of geometry that can be produced with [Specific Subtractive] Process.

Question 12

Identify two distinct benefits of computer numerically controlled machines.

Question 13

What are the advantages of chemical machining, and when is it generally used?

MAE 364: Manufacturing Processes

Practice Exam

Spring 2015

Question 14

What is the basic mechanism that allows electrochemical machining to work? What restricts the

geometry of the features that can be created with the process?

Question 15

What are the advantages of electric discharge machining? When is the process used? Hint: consider

what influences the material removal rate.

Question 16

What are the advantages and disadvantages of laser beam machining processes?

Question 17

Describe the steps in the basic process of metal casting.

Question 18

Identify the two categories of mold type. Discuss the advantages and disadvantages of each.

Question 19

What cooling rates are desirable and why?

Question 20

What are the potential consequences of an incorrect flow rate when filling a mold?

Question 21

Describe the solidification process for a metal alloy?

Question 22

Given an image of a defect, identify the casting defect and its cause(s).

Question 23

Discuss the advantages and disadvantages of the [Modifier] Casting Process.

Question 24

What are the material requirements for die casting?

Question 25

What are the geometry requirements for permanent mold castings?

Question 26

Estimate the cost of a cast component.

Question 27

Identify the two main types of plastics. What is the primary difference that concerns manufacturing?

Question 28

Discuss the advantages and disadvantages of the [Specific Plastic Production] Process.

MAE 364: Manufacturing Processes

Practice Exam

Spring 2015

Question 29

Identify the two potential sources for melting plastic in an extruder.

Question 30

Discuss the range of geometry that can be produced with [Specific Plastic Production] Process.

Question 31

In blow molding, there are two methods to form the parison. What are they, and what are their repective

advantages and disadvantages?

Question 32

Identify one feature that cannot be created with a vacuum thermoforming process?

Question 33

Describe the range of component geometry and feature detail that can be created with vacuum

thermoforming.

Question 34

Given a defect in an injection molded part, identify the cause and suggest a possible remedy.

Question 35

Identify two techniques for creating undercuts.

Question 36

Given a component, identify the most like manufacturing process used to create it.

Sample Calculation Problems

This section provides examples of how the content covered could be turned into an exam

question where the theory is applied.

Exam questions will differ, both in structure and

difficulty. Further, this set of problems is intended to be representative, not exhaustive (i.e., it is

likely that some exam questions will be completely different).

Problem 1

Estimate the cost of machining a component.

Problem 2

Estimate the tool life for a machining operation.

Problem 3

Estimate the cost of a cast component.

Problem 4

Estimate solidification time for a cast component.

S-ar putea să vă placă și

- Me8351 MT1 Iq ND19 RejinpaulDocument1 paginăMe8351 MT1 Iq ND19 RejinpaulShrinath MPCBÎncă nu există evaluări

- Cutting Mechanics and ModelingDocument18 paginiCutting Mechanics and ModelingPercy RobertÎncă nu există evaluări

- Production Technology Question Bank Units 3-5Document2 paginiProduction Technology Question Bank Units 3-5Anonymous d9vzoSv9q2Încă nu există evaluări

- Cutting Mechanics and AnalyticalDocument18 paginiCutting Mechanics and AnalyticalOakmeÎncă nu există evaluări

- 068 - ME8351, ME6302 Manufacturing Technology I - Important QuestionsDocument1 pagină068 - ME8351, ME6302 Manufacturing Technology I - Important QuestionsMr. T. Anjaneyulu Mr. T. AnjaneyuluÎncă nu există evaluări

- Course OverviewDocument14 paginiCourse OverviewVinayaka G PÎncă nu există evaluări

- AssignmentDocument27 paginiAssignmentMitravanu MishraÎncă nu există evaluări

- Universiti Teknologi Mara Final Examination: Confidential EM/JAN 2012/MEM560Document5 paginiUniversiti Teknologi Mara Final Examination: Confidential EM/JAN 2012/MEM560Muhammad FirdawsÎncă nu există evaluări

- Universiti Teknologi Mara Final Examination: Confidential EM/JUN2012/MEM560Document5 paginiUniversiti Teknologi Mara Final Examination: Confidential EM/JUN2012/MEM560Muhammad FirdawsÎncă nu există evaluări

- DMX3206 - Tma 1Document2 paginiDMX3206 - Tma 1Thushith WithanageÎncă nu există evaluări

- MP 20Document2 paginiMP 20hkumarchauhan392Încă nu există evaluări

- Manufacturing Technology Question Bank on Pattern, Moulding, Casting and Welding ProcessesDocument1 paginăManufacturing Technology Question Bank on Pattern, Moulding, Casting and Welding ProcessesNumesh KumarÎncă nu există evaluări

- Universiti Teknologi Mara Final Examination: Confidential EM/JAN 2013/MEM560Document5 paginiUniversiti Teknologi Mara Final Examination: Confidential EM/JAN 2013/MEM560Shah GrungeÎncă nu există evaluări

- New Approach to Casting Defects Classification and Analysis Using SimulationDocument18 paginiNew Approach to Casting Defects Classification and Analysis Using SimulationkkamalakannaÎncă nu există evaluări

- Assignment For UNIT IDocument2 paginiAssignment For UNIT IParamasivam VeerappanÎncă nu există evaluări

- DOM S2022oDocument3 paginiDOM S2022oKhalit JamundeÎncă nu există evaluări

- Swansea University Exam on Manufacturing Technology IIDocument3 paginiSwansea University Exam on Manufacturing Technology IIVittor BenineÎncă nu există evaluări

- Robust Design Question Bank-3-8-2011Document15 paginiRobust Design Question Bank-3-8-2011Thamarai Kannan RamajayamÎncă nu există evaluări

- Pcme 109Document1 paginăPcme 109Mahin Samuel John 74Încă nu există evaluări

- Universiti Teknologi Mara Final Examination: Confidential EM/JAN 2012/MEM561/KJP516/470Document4 paginiUniversiti Teknologi Mara Final Examination: Confidential EM/JAN 2012/MEM561/KJP516/470Nasri JamaludinÎncă nu există evaluări

- Case Study DefectsDocument16 paginiCase Study DefectsmsudamÎncă nu există evaluări

- Manufacturing Process - LLDocument1 paginăManufacturing Process - LLNilesh Mistry (Nilesh Sharma)Încă nu există evaluări

- Rajalakshmi Engineering College Production Technology Question BankDocument2 paginiRajalakshmi Engineering College Production Technology Question BankGiridharan SharmaÎncă nu există evaluări

- Question Bank: Non Traditional Machining DE/PE-2.0 2 Marks QuestionDocument5 paginiQuestion Bank: Non Traditional Machining DE/PE-2.0 2 Marks QuestionpankajÎncă nu există evaluări

- High Pressure Die Casting Defects and Simulation Process by Computer Added Engineering-IrshadAliDocument19 paginiHigh Pressure Die Casting Defects and Simulation Process by Computer Added Engineering-IrshadAliKushagra Trivedi100% (1)

- 25 Mechanical Engineering Interview Questions and Answers - Freshers, ExperiencedDocument7 pagini25 Mechanical Engineering Interview Questions and Answers - Freshers, ExperiencedAnonymous RVO3O6zm0Încă nu există evaluări

- Week 1 - Introduction To Metal Forming ProcessesDocument80 paginiWeek 1 - Introduction To Metal Forming ProcessesSenura SeneviratneÎncă nu există evaluări

- EMM2512 AssignmentDocument4 paginiEMM2512 AssignmentVenkatesh GangadharÎncă nu există evaluări

- CH 22Document16 paginiCH 22onlydlonly100% (1)

- Simulation of Shrinkage - IJETT - International Journal of EngineeringDocument5 paginiSimulation of Shrinkage - IJETT - International Journal of EngineeringBasyirÎncă nu există evaluări

- Finite Element Modeling of Chip Formation in Orthogonal MachiningDocument45 paginiFinite Element Modeling of Chip Formation in Orthogonal MachiningSuresh ReddyÎncă nu există evaluări

- G.C.R.G.Memorial Trust'S Group of Institutions: Advanced Welding Technology EME-022Document1 paginăG.C.R.G.Memorial Trust'S Group of Institutions: Advanced Welding Technology EME-022Andrea DouglasÎncă nu există evaluări

- Emt 2512 Manufacturing Process PlanningDocument4 paginiEmt 2512 Manufacturing Process PlanningAlvin KiruiÎncă nu există evaluări

- Amity School of Engineering and Technology: Pankaj AgarwalDocument22 paginiAmity School of Engineering and Technology: Pankaj AgarwalPankaj AgarwalÎncă nu există evaluări

- Part B & Part C Questions: Me8392 Manufacturing TechnologyDocument1 paginăPart B & Part C Questions: Me8392 Manufacturing Technology26 MaheshkannanÎncă nu există evaluări

- M 057Document3 paginiM 057Nixon Joe EmmanuelÎncă nu există evaluări

- Manufacturing Tech SyllDocument4 paginiManufacturing Tech SyllJagjit SinghÎncă nu există evaluări

- Me Vtu DFM Syllabus CBCS SchemeDocument2 paginiMe Vtu DFM Syllabus CBCS SchemeNitheeshÎncă nu există evaluări

- Assignment Last SemDocument13 paginiAssignment Last SemLarry JamesÎncă nu există evaluări

- PDM Product Design & Manufacturing Subject Code 13ME413Document4 paginiPDM Product Design & Manufacturing Subject Code 13ME413NABIL HUSSAINÎncă nu există evaluări

- M.tech. (Mechanical Engineering) Part-Time (Semester System)Document37 paginiM.tech. (Mechanical Engineering) Part-Time (Semester System)Sarabjeet SinghÎncă nu există evaluări

- M.tech Mechanical Engg. (I &P)Document44 paginiM.tech Mechanical Engg. (I &P)Upender DhullÎncă nu există evaluări

- Casting SimulationDocument12 paginiCasting SimulationIshwar GuptaÎncă nu există evaluări

- Exam QuestionsDocument2 paginiExam QuestionsFalak VatsÎncă nu există evaluări

- Manufacturing Processes UTA026Document9 paginiManufacturing Processes UTA026Tania CEÎncă nu există evaluări

- Important Instructions To ExaminersDocument30 paginiImportant Instructions To ExaminersDiyaNegiÎncă nu există evaluări

- (WWW - Entrance-Exam - Net) - PTU M.Tech in Production Engineering Metal Cutting Sample Paper 3 PDFDocument2 pagini(WWW - Entrance-Exam - Net) - PTU M.Tech in Production Engineering Metal Cutting Sample Paper 3 PDFJagannath SahuÎncă nu există evaluări

- MET 204 Manufacturing ProcessDocument8 paginiMET 204 Manufacturing Processrejeesh_rajendranÎncă nu există evaluări

- Reliability and MaintenanceDocument2 paginiReliability and MaintenanceLakim Arsenal100% (1)

- Mce 653 Advanced Manufacturing TechnologyDocument1 paginăMce 653 Advanced Manufacturing TechnologypathakatulÎncă nu există evaluări

- Coursework Structural Integrity 2023-24Document7 paginiCoursework Structural Integrity 2023-24Yacine HalwaneÎncă nu există evaluări

- Manufacturing Technology SyllabusDocument4 paginiManufacturing Technology Syllabushrana287Încă nu există evaluări

- Class XII Technical Group Subjects Revision NotesDocument21 paginiClass XII Technical Group Subjects Revision Notesprabhjot singh1Încă nu există evaluări

- MA505-N-C Modern Manufacturing ProcessesDocument3 paginiMA505-N-C Modern Manufacturing Processeshrana287Încă nu există evaluări

- Manufacturing Technology-I - Department of Mechanical EngineeringDocument4 paginiManufacturing Technology-I - Department of Mechanical EngineeringSoma SundaramÎncă nu există evaluări

- Multiscale Modeling of Additively Manufactured Metals: Application to Laser Powder Bed Fusion ProcessDe la EverandMultiscale Modeling of Additively Manufactured Metals: Application to Laser Powder Bed Fusion ProcessÎncă nu există evaluări

- Engineering Applications: A Project Resource BookDe la EverandEngineering Applications: A Project Resource BookEvaluare: 2.5 din 5 stele2.5/5 (1)

- Practical Creativity and Innovation in Systems EngineeringDe la EverandPractical Creativity and Innovation in Systems EngineeringÎncă nu există evaluări

- PlotsDocument13 paginiPlotshuiqui1Încă nu există evaluări

- Assignment 3 MGQ 201Document1 paginăAssignment 3 MGQ 201huiqui1Încă nu există evaluări

- Ferrofluid - Properties and ApplicationsDocument10 paginiFerrofluid - Properties and ApplicationsfragmeÎncă nu există evaluări

- Assignment #0 Solution - Spring 2015Document6 paginiAssignment #0 Solution - Spring 2015huiqui1Încă nu există evaluări

- Lab 2: Data Acquisition and Signal SamplingDocument4 paginiLab 2: Data Acquisition and Signal Samplinghuiqui1Încă nu există evaluări

- Protective Paints For Heat Treatment of SteelsDocument4 paginiProtective Paints For Heat Treatment of SteelsMauricio Cesar DalzochioÎncă nu există evaluări

- Material ManagementDocument59 paginiMaterial Managementkenjisnack100% (1)

- Valvula Solenoide 8220 Vapor AscoDocument6 paginiValvula Solenoide 8220 Vapor AscoFerdinand Raul StoneÎncă nu există evaluări

- DEVELOP A BCG MATRIX FOR Engro Fertilizers: Horiz. Axis Division RMSP 0.4 0.9 0.2 0.8 0.8 0.6 0.7 0.5 1Document2 paginiDEVELOP A BCG MATRIX FOR Engro Fertilizers: Horiz. Axis Division RMSP 0.4 0.9 0.2 0.8 0.8 0.6 0.7 0.5 1UmarÎncă nu există evaluări

- High Street Shop CondominiumsDocument13 paginiHigh Street Shop CondominiumsbhativivekÎncă nu există evaluări

- WM TcodesDocument4 paginiWM TcodesjavedccÎncă nu există evaluări

- CLIA Cruise Industry 2012 PresentationDocument32 paginiCLIA Cruise Industry 2012 PresentationskiftnewsÎncă nu există evaluări

- Dyna BoltDocument4 paginiDyna BoltAnwar_Mohd_1401Încă nu există evaluări

- ACI-117 R-90-Standard SpecificationsDocument11 paginiACI-117 R-90-Standard Specificationsdox4use100% (1)

- Berwick (AD00009 A4)Document4 paginiBerwick (AD00009 A4)Su Chong GuangÎncă nu există evaluări

- Road Safety Audit Campus ReportDocument7 paginiRoad Safety Audit Campus Reportsiddharthsmp100% (3)

- 0096Document1 pagină0096buddhansamratÎncă nu există evaluări

- Data Seazip 12 Okt 2013Document2 paginiData Seazip 12 Okt 2013georgekc77Încă nu există evaluări

- Cutting & Jointing Copper PipesDocument3 paginiCutting & Jointing Copper Pipesamg007100% (1)

- A1010A1010M-13 Standard Specification For Higher-Strength Martensitic Stainless Steel Plate, Sheet, and StripDocument2 paginiA1010A1010M-13 Standard Specification For Higher-Strength Martensitic Stainless Steel Plate, Sheet, and Striptjt4779Încă nu există evaluări

- Hybrid Electric Vehicle: Ashley BuchananDocument9 paginiHybrid Electric Vehicle: Ashley BuchananSai Charan Sri HarshaÎncă nu există evaluări

- Evershine Modular KitchenDocument14 paginiEvershine Modular Kitchenwonders_24108631Încă nu există evaluări

- HSAC Jet Fuel Quality Control Procedures Inspection ChecklistDocument8 paginiHSAC Jet Fuel Quality Control Procedures Inspection ChecklistJhobana Ureña CasillasÎncă nu există evaluări

- OSU Ship Safety Manual SummaryDocument258 paginiOSU Ship Safety Manual Summaryyudiar2008100% (1)

- ArchitecturalDocument51 paginiArchitecturalShoukat Ali Shaikh0% (1)

- Astm A572Document4 paginiAstm A572udaykiranorange100% (2)

- Natsteel MeshDocument16 paginiNatsteel MeshsyafiqabangÎncă nu există evaluări

- 8989 PDFDocument12 pagini8989 PDFSathish KumarÎncă nu există evaluări

- Major Alberta ProjectsDocument71 paginiMajor Alberta Projectsthecolonel77Încă nu există evaluări

- Engineering and Fabrication of Ewt Module For Nautica MuarDocument40 paginiEngineering and Fabrication of Ewt Module For Nautica MuarengineeringyusufÎncă nu există evaluări

- Production Planning and Inventory ManagementDocument31 paginiProduction Planning and Inventory ManagementramakrishnaÎncă nu există evaluări

- Class 4 Safety Oral Solas & Marpol File (Full Permission)Document106 paginiClass 4 Safety Oral Solas & Marpol File (Full Permission)Pradeep Msc Shipping100% (2)

- Hdpe Fabricated Fittings: High Density Polyethylene FittingsDocument10 paginiHdpe Fabricated Fittings: High Density Polyethylene FittingsbakuhypnoÎncă nu există evaluări

- 8 - Mcma - Selection of Electric Cables - Risk of Sub-StandardDocument9 pagini8 - Mcma - Selection of Electric Cables - Risk of Sub-StandardmajorabsÎncă nu există evaluări

- AircraftFinanceReport2012 OnlineEditionDocument60 paginiAircraftFinanceReport2012 OnlineEditiontusharjetÎncă nu există evaluări