Documente Academic

Documente Profesional

Documente Cultură

NCC

Încărcat de

Deepika GuptaDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

NCC

Încărcat de

Deepika GuptaDrepturi de autor:

Formate disponibile

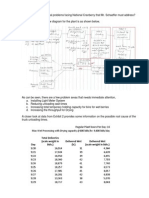

What are the major reasons for trucks waiting and excess worker overtime?

III.

MAJOR REASONS FOR DELIVERY TRUCK WAIT TIME & EXCESSIVE OVERTIME

When deliveries are processed at National Cranberry, truckloads of cranberries are initially weighed,

sampled and color-graded as they move through the front-end of the plant. The delivery truck

commences the process by backing up and tilting out its contents onto 5 conveyor belts, which moves

the cranberries up to the second floor to be held in temporary holding bins. From temporary bins, the

cranberries should move into later processes as long as there is no bottleneck issue and there is

space available for transfer. The full procedure of emptying the contents of these trucks onto the

conveyor belts should only take 7-8 minutes to drop-off and depart from the facility, but on occasion

the process is taking several hours.

Currently, the major reasons for excessive wait-times and overtime are the temporary holding bins are

becoming full because of a bottleneck at RP1. Specifically, the delivery trucks have to wait with the

cranberries if the temporary holding bins become full because no portion of the receiving plant is

dedicated to transition cranberries off the first floor if none of the holding bins are available on the

second floor. Thus, trucks are waiting several hours for the back-end of the facility to catch up with

the amount of cranberries already in the temporary holding bins. This type of bottleneck ultimately

holds up the delivery trucks and the entire process unless National Cranberry rethinks and augments

its existing system and strategy.

Assuming:

Input of 1,500 BBLS/hour

Transfer time between phases is negligible

1,500/75 = 20 trucks and 5 kiwanee dumpers. Wed need to unload 4 sequential sets of 5 trucks to

equal 1,500 BBLS.

Ratio of wet: dry of 70:30

Wet: 1050 BBLS/hour or 262.5/load

Dry: 450 BBLS/hour or 112.5/load

Cycle starting 7:00: Throughput: 131.625 minutes

Temp storage: 8 minutes (first transfer from trucks)

Wet track: 44.625 minutes

De-Chaffing: (262.5/3000)*60 minutes = 5.25 minutes

Drying: (262.5/600)*60 minutes = 26.25 minutes

Grading: (262.5/1200)*60 minutes = 13.125 minutes

Dry track: 14.625 minutes

De-Stoning: (112.5/1500)*60 minutes = 4.5 minutes

De-Chaffing: (112.5/1500)*60 minutes = 4.5 minutes

Grading: (112.5/1200)*60 minutes = 5.625 minutes

Temp storage: 8 minutes (Second transfer from trucks)

Wet track: 62.875 minutes

De-Chaffing: (262.5/3000)*60 minutes = 5.25 minutes

Idle: 18.25 (Drying process working on first load)

Drying: (262.5/600)*60 minutes = 26.25 minutes

Grading: (262.5/1200)*60 minutes = 13.125 minutes

Dry track: 14.625 minutes

De-Stoning: (112.5/1500)*60 minutes = 4.5 minutes

De-Chaffing: (112.5/1500)*60 minutes = 4.5 minutes

Grading: (112.5/1200)*60 minutes = 5.625 minutes

IV.

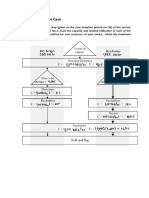

TRUCK WAIT TIME ON A BUSY WORKDAY

The following is applicable to calculate wait time for a busy workday:

Working Hours: from 7am to 11pm

Total working hours: 15 hours

Assume delivery per hour is 1,500 bbls

Wet berry: 70%

Weighted: 1,050 bbls

Capacity of bins for wet berry: 3,200 bbls

Because the capacity is 3,200 bbls, the trucks dont have to wait to load before 1pm.

The time that the trucks need to wait at 1pm is:

(filling + dechaffing + (drying*3))- delivery time = (0.5 +0.4+(1.8*3))-6 = 0.3

The time that the trucks need to wait after 12pm is:

1.8 (0.5 + 0.4) = 0.9 hour

The weighted average waiting time for wet berry is:

(0.3 + (0.9*9) )/16= 0.525

Dry berry: 30%

Weighted: 450 bbls

Capacity of bins for wet berry: 4,000 bbls

Time required processing the one hour delivery:

*hour

Because the high capacity, the trucks for dry berry dont need to wait if they deliver 450 bbls per hour.

The total weighted average waiting time for all trucks is: (0.525*0.7)=0.3675

hour or 22.05 minutes.

V.

BENEFITS OF SHIFTING PROCESS TIME

A significant issue facing the National Cranberry Co-operatives receiving plant #1 is the amount of

time that the trucks are sitting idle waiting to download their product. This issue is further magnified by

the fact that as a cooperative, the costs of the leased trucks and hired drivers increases as the trucks

sit idle which directly impacts the bottom line of our business partners. We need to keep the growers

happy.

Moving the processing time from 11:00 a.m. to 7:00 a.m. during the peak period is critical to

downloading trucks quickly and avoiding costly idle time. Based on the assumption that we receive

18000bbl on a single day during the peak season, 66% or 12,000bbl is wet and 33% or 6,000bbl is

dry equates to 240 truckloads of berries. Of these truckloads, 160 would be wet berries and 80 would

be dry. It takes trucks 8 minutes to back onto the dumper, empty its contents, and leave the platform.

With additional storage bins to hold berries added to the process, we could keep trucks moving. By

beginning the process at 7:00 a.m., the receiving plant would be able to end operations at 8:00 p.m.

More importantly, these improvements would benefit the growers.

Based on Exhibit 2 total barrels delivered from 9/1 through 12/10 is 610,185. From 9/20 through 10/9

RP#1 receives 327,596 or 54% of the production for the entire season. The 7:00 a.m. start time would

be most critical during these three weeks, but I feel the benefits of keeping the trucks moving makes

this start time a good idea for the entire season.

VI.

PROPOSED CHANGES: COST/BENEFIT ANALYSIS

In sum, we propose to start the process at 7:00 a.m., and install 2 dryers and an additional grading

line. This will cut the workday from 7:00 a.m. through 4:00 a.m. (under current capacity) to a workday

of 7:00 a.m. through 8:00 P.M.

Hourly cost of labor:

Length of season: 16 weeks

Workdays per week: 7

Average salary per employee: $10.5 (assuming no overtime)

Average number of employees: 40 (assuming equal time of heavy and light

volume days)

Total Cost per hour of having workforce: $47,040

Past 11 PM:

Total Cost per hour of workforce: $10,584 (only 9 employees are needed beyond

11 p.m.

If we only purchased one Dryer it would reduce the work hours from 4:00 a.m. to 11:00 p.m. This

would only produce savings of $52,920 and therefore not enough to cover the cost of one dryer.

If we purchased two Dryers it would reduce the work hours from 4:00 a.m. to 10:00 p.m. this would

produce savings of $99,960 again not enough to cost of this solution ($120,000).

However, if we purchased 2 dryers and added an additional separator line hours of operation would

be reduced from 4:00 a.m. to 8:00 p.m.

Savings due to reduced hours:

X = 5 * ($10,584) + 3* (47,040)

X = $52,920 + $141,120 = $194,040

Total Cost of implementing recommended solution:

Total cost of dryers: $120,000

Maximum cost of new separator line to maintain this option as viable: $74,040

VII.

CONCLUSION

In conclusion, National Cranberry Cooperative is facing a bottleneck in RP #1 that is causing several

hours of excessive overtime and delivery truck wait-time at the front-end of the facility. Our team

analyzed the data and offered alternative solutions towards correcting the problem that is upsetting

suppliers because of idle time and additional cost burdens. National Cranberry understands that it

must augment its processes to become more efficient or potentially lose business and overall profits.

As discussed in detail above, commencing the process at 7:00 am, installing 2 dryers, and an

additional grading line, will ultimately decrease the amount of hours worked by 8 hours, and National

Cranberry will achieve a savings of $194,040 because of these reduced hours and proposed

recommendations. Our team after reviewing the data believes this proposed solution is the most

proactive, and cost-effective way to reduce the bottleneck issue and excessive wait-times plaguing our

front line. Our team suggests we implement said changes immediately as they are critical to

effectively adjust the efficiency, and overall productivity of National Cranberry Cooperative in the

future.

S-ar putea să vă placă și

- Design For ReliabilityDocument32 paginiDesign For ReliabilityArman CustodioÎncă nu există evaluări

- Gitlab CICDDocument15 paginiGitlab CICDdeepak bansal100% (1)

- Assignment Nicmar / Sode Office: Name: Mr. Prabhakar Prakash Shingrut Course: GPCBM Reg. No. 217-04-22-50914-2183Document18 paginiAssignment Nicmar / Sode Office: Name: Mr. Prabhakar Prakash Shingrut Course: GPCBM Reg. No. 217-04-22-50914-2183Prabhakar Shingrut100% (1)

- Case - Grocery Gateway by Vineet Agrawal Vineetpgdme115Document4 paginiCase - Grocery Gateway by Vineet Agrawal Vineetpgdme115khushi kumariÎncă nu există evaluări

- ASTM 6365 - 99 - Spark TestDocument4 paginiASTM 6365 - 99 - Spark Testjudith_ayala_10Încă nu există evaluări

- Petroleum Refinery Relocation Projects: 5-Phases of Project ManagementDe la EverandPetroleum Refinery Relocation Projects: 5-Phases of Project ManagementÎncă nu există evaluări

- Xuanyao Zhu, Gao Chao, Anthony Leung, National Cranberry Case Write-UpDocument8 paginiXuanyao Zhu, Gao Chao, Anthony Leung, National Cranberry Case Write-UpJason zhuÎncă nu există evaluări

- Examples On Cycle TimeDocument27 paginiExamples On Cycle TimeNaty Griffin100% (1)

- Sany S800S ReviewDocument11 paginiSany S800S ReviewJuna PasaribuÎncă nu există evaluări

- Solutions To End of Chapter Problems 3Document4 paginiSolutions To End of Chapter Problems 3ArunSharmaÎncă nu există evaluări

- Answers NCCDocument2 paginiAnswers NCCAmara Khan0% (1)

- IA-NT-PWR-2.4-Reference GuideDocument110 paginiIA-NT-PWR-2.4-Reference GuideSamuel LeiteÎncă nu există evaluări

- National Cranberry Cooperative 1996-1 PDFDocument10 paginiNational Cranberry Cooperative 1996-1 PDFnephielive.cnÎncă nu există evaluări

- 14 Lect18 - Theory of Constraint (TOC) SchedulingDocument17 pagini14 Lect18 - Theory of Constraint (TOC) Schedulingpkj009Încă nu există evaluări

- NCC Awasthi 11BM60071Document8 paginiNCC Awasthi 11BM60071Abhishek AwasthiÎncă nu există evaluări

- Draft Tech Proposal NTB UtmDocument20 paginiDraft Tech Proposal NTB Utmdudi hidayatÎncă nu există evaluări

- NCC - Case StudyDocument3 paginiNCC - Case StudyDeepika GuptaÎncă nu există evaluări

- NationalCranberryCooperative CaseAnalysisDocument10 paginiNationalCranberryCooperative CaseAnalysisJishnu RoychaudhuriÎncă nu există evaluări

- National Cranberry Analysis - ScribdDocument9 paginiNational Cranberry Analysis - ScribdAudrey Tay100% (3)

- National Cranberry CooperativeDocument11 paginiNational Cranberry CooperativeFabiola SE100% (2)

- CranberryDocument5 paginiCranberrymaverick_659Încă nu există evaluări

- Sunwind AB Case StudyDocument6 paginiSunwind AB Case StudyTanmoy BoseÎncă nu există evaluări

- National Cranberry Part IDocument3 paginiNational Cranberry Part IPrateekRaj167% (3)

- IDS 532 - National Cranberry Case Study - AnswersDocument4 paginiIDS 532 - National Cranberry Case Study - AnswersVikas Mani TripathiÎncă nu există evaluări

- National Cranberry Cooperative CaseDocument7 paginiNational Cranberry Cooperative CaseMano Ranjani83% (12)

- Cybersecurity Essentials 1.0 Release Notes: PurposeDocument5 paginiCybersecurity Essentials 1.0 Release Notes: PurposeRonny Kimer Fiestas VargasÎncă nu există evaluări

- Manufacturing Wastes Stream: Toyota Production System Lean Principles and ValuesDe la EverandManufacturing Wastes Stream: Toyota Production System Lean Principles and ValuesEvaluare: 4.5 din 5 stele4.5/5 (3)

- National Cranberry Case Report Operations Management - IDocument9 paginiNational Cranberry Case Report Operations Management - IVikash KumarÎncă nu există evaluări

- CranberryDocument4 paginiCranberryharshkhambraÎncă nu există evaluări

- OM WordDocument3 paginiOM WordpulakitÎncă nu există evaluări

- ManufacturigCase StudyDocument19 paginiManufacturigCase Studyshruthicivil100% (1)

- National Cranberries CaseDocument7 paginiNational Cranberries CaseHyper Green MindÎncă nu există evaluări

- National Cranberry Case ReportDocument10 paginiNational Cranberry Case ReportCharles Van Hoorebeke75% (4)

- 11BM60008 Sec B National Cranberry CooperativeDocument9 pagini11BM60008 Sec B National Cranberry CooperativeKunal Verma100% (3)

- Littlefield Simulation ReportDocument7 paginiLittlefield Simulation ReportSidra SadafÎncă nu există evaluări

- Eco AmulDocument60 paginiEco AmulDeepika GuptaÎncă nu există evaluări

- Takt Time: A Guide to the Very Basic Lean CalculationDe la EverandTakt Time: A Guide to the Very Basic Lean CalculationEvaluare: 5 din 5 stele5/5 (2)

- Chapter 4 Process AnalysisDocument6 paginiChapter 4 Process Analysispbpotter43100% (1)

- National Cranberry Case SolutionDocument7 paginiNational Cranberry Case SolutionKarthik TirupatiÎncă nu există evaluări

- (OM - Group Assignment - Sunwind) (Group No. 3)Document6 pagini(OM - Group Assignment - Sunwind) (Group No. 3)Sambit Patra100% (2)

- Takt Time - Understanding the Core Principle of Lean Manufacturing: Toyota Production System ConceptsDe la EverandTakt Time - Understanding the Core Principle of Lean Manufacturing: Toyota Production System ConceptsEvaluare: 5 din 5 stele5/5 (1)

- OM - I National Cranberry CooperationDocument7 paginiOM - I National Cranberry Cooperationamritj100% (1)

- National Cranberry Cooperative: Revised Apr 09Document16 paginiNational Cranberry Cooperative: Revised Apr 09Varun ChandÎncă nu există evaluări

- National Cranberry HBS Case SolutionDocument9 paginiNational Cranberry HBS Case SolutionSandhya Patil100% (1)

- Case 1 - National Cranberry CooperativeDocument7 paginiCase 1 - National Cranberry Cooperativewhitney100% (1)

- National Cranberry Cooperative: Operations Management-SCH-MGMT-670Document8 paginiNational Cranberry Cooperative: Operations Management-SCH-MGMT-670Shreyas SatardekarÎncă nu există evaluări

- Appli ChemDocument14 paginiAppli ChemAayushiJhaÎncă nu există evaluări

- National Cranberry - Section 4 Group 16Document8 paginiNational Cranberry - Section 4 Group 16milwandaÎncă nu există evaluări

- Bacchus, Safraz LE1 - NCCDocument6 paginiBacchus, Safraz LE1 - NCCshaf33zaÎncă nu există evaluări

- National Cranberry Case SubmissionDocument3 paginiNational Cranberry Case SubmissionHardik SemlaniÎncă nu există evaluări

- Essay ReviewDocument11 paginiEssay ReviewMilagros AzparrentÎncă nu există evaluări

- Assignment #1: Merton Truck Company Question 1: What Is The Contribution Toward Fixed Costs If Only Model 101 Is Built?Document9 paginiAssignment #1: Merton Truck Company Question 1: What Is The Contribution Toward Fixed Costs If Only Model 101 Is Built?TerryÎncă nu există evaluări

- National Cranberry Cooperative Case StudyDocument7 paginiNational Cranberry Cooperative Case StudyAkhil Krishna GuptaÎncă nu există evaluări

- MT 4 - Process AnalysisDocument31 paginiMT 4 - Process AnalysisRuíz Figueroa, Jean E.Încă nu există evaluări

- Name: Syed Wajahat Abbas Reg#: 10466 Operation ManagementDocument4 paginiName: Syed Wajahat Abbas Reg#: 10466 Operation Managementammar abbas100% (1)

- BZAN 505 Quiz 2 - SolutionDocument6 paginiBZAN 505 Quiz 2 - SolutionJahedulHoqÎncă nu există evaluări

- Batch Processing & Scheduling EDITED 19-3-2019Document47 paginiBatch Processing & Scheduling EDITED 19-3-2019Engr Muhammad IrfanÎncă nu există evaluări

- Capacity Planning Chapter5 Feb 11Document44 paginiCapacity Planning Chapter5 Feb 11JOANNECHUÎncă nu există evaluări

- Implementation of Kaizen and 5S in Plastic PipeDocument6 paginiImplementation of Kaizen and 5S in Plastic Pipeaman tembhekarÎncă nu există evaluări

- Implementation of Kaizen and 5S in Plastic PipeDocument6 paginiImplementation of Kaizen and 5S in Plastic Pipeaman tembhekarÎncă nu există evaluări

- Merloni Elettrodomestici SpADocument5 paginiMerloni Elettrodomestici SpAAmit ShiraliÎncă nu există evaluări

- CASE 28 PEAS Stuart Chambers and Tammy HelanderDocument5 paginiCASE 28 PEAS Stuart Chambers and Tammy HelanderKit MalapitanÎncă nu există evaluări

- Group 5 - Section C - NCCDocument16 paginiGroup 5 - Section C - NCCNitish Raj SubarnoÎncă nu există evaluări

- StarbucksDocument19 paginiStarbucksNimah SaeedÎncă nu există evaluări

- 3.1 Case Exercises For ClassDocument2 pagini3.1 Case Exercises For ClassSanthosh Kumar RaoÎncă nu există evaluări

- Case Study On Productivity Improvement by Work Study: Yogesh KumarDocument6 paginiCase Study On Productivity Improvement by Work Study: Yogesh KumarYogesh SharmaÎncă nu există evaluări

- Illustrated Catalogue of Cotton MachineryDe la EverandIllustrated Catalogue of Cotton MachineryÎncă nu există evaluări

- Michigan-Supp CHN MGMTDocument16 paginiMichigan-Supp CHN MGMTDeepika GuptaÎncă nu există evaluări

- KM Tigers-Employee InitiativesDocument11 paginiKM Tigers-Employee InitiativesDeepika GuptaÎncă nu există evaluări

- Risk and Sensitivity in CapitalDocument8 paginiRisk and Sensitivity in CapitalDeepika GuptaÎncă nu există evaluări

- Venture Capital - 6 Pgs - PariDocument6 paginiVenture Capital - 6 Pgs - PariDeepika GuptaÎncă nu există evaluări

- List of Colleges 11111111111Document3 paginiList of Colleges 11111111111Deepika GuptaÎncă nu există evaluări

- Final ProjectDocument21 paginiFinal ProjectDeepika GuptaÎncă nu există evaluări

- EmfsDocument28 paginiEmfsDeepika GuptaÎncă nu există evaluări

- The Power Behind.: Rectifier DPR 2900B-48 (ESR48/56C F)Document2 paginiThe Power Behind.: Rectifier DPR 2900B-48 (ESR48/56C F)Charmer JiaÎncă nu există evaluări

- Savitha S. Panikar, PH.DDocument4 paginiSavitha S. Panikar, PH.Diboorose7Încă nu există evaluări

- Computer Reviewer For Grade 6Document4 paginiComputer Reviewer For Grade 6Cyril DaguilÎncă nu există evaluări

- 3 SuperjunctionDocument5 pagini3 SuperjunctionharibadriÎncă nu există evaluări

- Necco BondDocument1 paginăNecco BondZdenko SemanÎncă nu există evaluări

- Color CCD Imaging With Luminance Layering: by Robert GendlerDocument4 paginiColor CCD Imaging With Luminance Layering: by Robert GendlerbirbiburbiÎncă nu există evaluări

- No More FTP White PaperDocument11 paginiNo More FTP White PaperrlogieÎncă nu există evaluări

- The Power of Slope SpectrosDocument2 paginiThe Power of Slope SpectrosJohn SiricoÎncă nu există evaluări

- Trafo Manual ABBDocument104 paginiTrafo Manual ABBMarcos SebastianÎncă nu există evaluări

- Air Force Qualification TrainingDocument51 paginiAir Force Qualification TrainingJanJanLuÎncă nu există evaluări

- Philips New Pricelist July 2022Document3 paginiPhilips New Pricelist July 2022PravinÎncă nu există evaluări

- Presented by Name: Kanu Ikechukwu Department:Chemistry MATRIC NO:DE:2014/2707 REG NO:ITA/2015/122568Document13 paginiPresented by Name: Kanu Ikechukwu Department:Chemistry MATRIC NO:DE:2014/2707 REG NO:ITA/2015/122568chdiÎncă nu există evaluări

- Python Setup and Usage: Release 2.7.8Document57 paginiPython Setup and Usage: Release 2.7.8dingko_34Încă nu există evaluări

- Module 4-STS Espinas Bsat 1-1Document2 paginiModule 4-STS Espinas Bsat 1-1Joseph Daniel EspinasÎncă nu există evaluări

- Logitech Mouse M505 ManualDocument2 paginiLogitech Mouse M505 ManualbmmanualsÎncă nu există evaluări

- Ficha Tecnica Talesun 410WDocument2 paginiFicha Tecnica Talesun 410WIes IngenieriaÎncă nu există evaluări

- What Is Marketing MixDocument12 paginiWhat Is Marketing Mixmansi mehtaÎncă nu există evaluări

- Massey Ferguson 8570 COMBINE Parts Catalogue ManualDocument22 paginiMassey Ferguson 8570 COMBINE Parts Catalogue ManualdidkskmdmdmÎncă nu există evaluări

- WWW - Manaresults.Co - In: Set No. 1Document1 paginăWWW - Manaresults.Co - In: Set No. 1My Technical videosÎncă nu există evaluări

- Sample Maths Exam PDFDocument11 paginiSample Maths Exam PDFAnonymous oJ0Dl7rWÎncă nu există evaluări

- Presented To:prof. Rashmi Menon & Class Prepared By: Valay Chaya (07) Nikul Maheshwari (28) Anis Vohra (56) Ravi Vyas (57) Nilesh JainDocument57 paginiPresented To:prof. Rashmi Menon & Class Prepared By: Valay Chaya (07) Nikul Maheshwari (28) Anis Vohra (56) Ravi Vyas (57) Nilesh JainAnis VohraÎncă nu există evaluări

- Appexchange Publishing GuideDocument29 paginiAppexchange Publishing GuideHeatherÎncă nu există evaluări

- AeroDocument27 paginiAeroBALAKRISHNANÎncă nu există evaluări