Documente Academic

Documente Profesional

Documente Cultură

TIMBER (Design Specs)

Încărcat de

John Darwin SabioDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

TIMBER (Design Specs)

Încărcat de

John Darwin SabioDrepturi de autor:

Formate disponibile

Technological Institute of the Philippines Quezon City

938 Aurora blvd., Cubao, Quezon City

January 16, 2011

Timber Design

Submitted by;

Dela Cerna, Rena Jimenez

CE-5TH Year-2nd Semester

Submitted to;

Engr. Rhonnie Estores

1|Page

Page |2

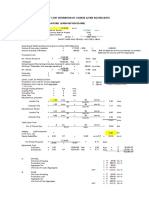

Design Load Specification

Dead Load

Gypsum

Board

(12mm

thickness)

________0.096kPa

Gypsum

Board

(20mm

thickness)

________0.16kPa

Sub-flooring

(19mm)

__________________0.14kPa

Ceramic Tile (20mm Rest Room)

On 25mm mortar bed _________________

1.10kPa

Mechanical

Load

______________________0.1kPa

Plumbing

____________________________

0.1kPa

Live Load

Basic

Floor

Area

______________________1.9kPa

Library

______________________________2.9kPa

Storage

_____________________________1.9kPa

Balcony

(Exterior)

_____________________2.9kPa

Ceiling (0ver 60 m2 in tributary area)

______ 0.60kPa

2|Page

Page |3

Design of Ceiling joist 3

VIII Ceiling Joist Observation

If we try to look at the roof ceiling

plan, we can observe that the longest

span can be found in Ceiling Joist 3D (CJ3D). From here, we can already say that

among the Ceiling Joist schedule CJ-3D

will govern in maximum dimension since

the dead load and live load carrying by

these members are constant.

Because of this reason, I the

designer decided not to show all the

computation of ceiling joist design.

NOTE:

The designer have computed all

floor joist schedule but because of the

repeatable solution, I decided not to show

all the solution, instead only those

members with the most critical loading

and span.

I Wood Data

Species ____________________Yakal

____________________50 % Stress

Grade

Bending and Tension

Parallel to grain ____________15.5MPa

Modulus of Elasticity _________3110MPa

Compression Parallel to grain __9.55Mpa

Compression

Perpendicular to grain ________3.92MPa

Shear parallel to grain ________1.55MPa

Relative Density _____________0.76 Kg/m3

Span ______________________2.70m

Allowable Deflection _________L/360

II Compute the Total Load

W total = DL+LL

= 0.378 + 3

= 3.378kPa

II.A Uniformly Distributed Load

W total = 3.378kPa(S)

= 3.378kPa (0.40)

= 1.351KN/m

III Design by Bending

M

= Wtotal(L)2/8

= 1.351KN/m (12)/8

3|Page

Page |4

= 0.169kN-m

= 168875N-mm

Assume

dimension

for

(B=50mm)

fb= 6M/bd^2

15.5 = (6*168875)/(50*d^2)

d

= 36.158mm

Use d

= 75mm

Le

breadth

III.A Compute the dead load of the

floor joist

Breadth = 50mm

Depth = 75mm

Relative Density = 0.76kg/m3

= 7600N/m3

Wwood

= ybd

= 7600(.05*.075)

= 28.5N/m

Add this dead weight to the weight

carried by the floor joist

III.B Check the adequacy of the floor

joist

III.C Uniformly Distributed Load

Wtotal = 1.351KN/m

= 1.351KN/m+ .0285

= 1.380KN/m

III.D Compute the slenderness factor

and flexural stress

Lu

= 1000mm

= 1.92(1000)

= 1920mm

Cs

= ((Le*d)/(b^2))1/2

= ((1920*75)/ (50^2))1/2

= 7.589 < 10

Ck

= 0.811((E/fb)) 1/2

= 0.811((3110/15.5)) 1/2

= 11.488

10>Cs<Ck

fb = 15.5MPa

III.E Check the actual bending stress

and compare to the allowable

fb = 15.5MPa

Fb = 6M/bd2

M= Wtotal(Lu2)/8

= 1.380 (12)/8

= 172500N-mm

Fb = (172500*6)/(50*752)

= 3.68MPa

The 50x75mm floor joist is safe in

bending stress

IV Design by Shear

IV.A Compute the maximum shear

Since the floor joist is simply supported

the maximum shear will occur at the

support.

Vmax = Wtotal(L)/2

4|Page

Page |5

= 1.351 (1)/2

= 0.676KN

IV.B Compute the design Depth

Assume

dimension

for

breadth

(B=50mm)

Fv

= 1.55MPa

1.55 = 3Vmax/(2bd)

= 3(0.676*1000)/(2*50*d)

d

= 13.084mm

Use d = 75mm

IV.C Compute the dead load of the

floor joist

Breadth

= 50mm

Depth

= 75mm

Relative Density = 0.76kg/m3

= 7600N/m3

Wwood = ybd

= 7600(.05*.075)

= 28.5N/m

Add this dead weight to the weight

carried by the floor joist

IV.D Check the adequacy of the floor

joist

IV.E Uniformly Distributed Load

Wtotal = 1.351KN/m

= 1.351+ .0285

= 1.380KN/m

IV.G Check the actual Shear stress

and compare to the allowable shear

stress

Vmax = Wtotal(Lu)/2

= 1.380(1)/2

= 0.690KN

fv

= 1.55MPa

Fv

= 3Vmax/(2bd)

= 3(0.690*1000)/(2*50*75)

= 0.276MPa<1.55MPa

The 50x100mm floor joist is safe for

shear

V Design by Deflection

Wtotal = DL+LL

= 0.378 + 3

= 3.378kPa

V.A Uniformly Distributed Load

Wtotal = 3.378(S)

= 3.378(0.40)

= 1.351KN/m

Allowable Deflection _____________ L/360

Modulus

of

Elasticity

_____________

3110MPa

V.B Compute the design depth by

assuming

bredth

= 100mm

I

= bd3/12

5|Page

Page |6

Lu/360

= (5WtLu4)/(384EI)

d

= 78.768mm

use d

= 100mm

V.C Compute the dead load of the

floor joist

Breadth

= 05mm

Depth

= 100mm

Relative Density = 0.76kg/m3

= 7600N/m^3

Wwood = ybd

= 7600(.05*.100)

= 38N/m

Add this dead weight to the weight

carried by the floor joist

Check the adequacy of the floor joist

IV.D Uniformly Distributed Load

Wtotal

= 1.351KN/m

= 1.351KN/m+ 0.038

= 1.389KN/m

IV.E Check the actual deflection and

compare it to the allowable

I

actual

allowable = L/360

= 1000/360

= 2.778mm>1.387 Safe

The 50x100mm ceiling joist is safe in

deflection

V Compute the required depth of

notch at support

fv

= 3Vmax(d)/(2bdd)

1.55 = 3(0.690*1000)(100)/(2*50*d2)

D

= 36.544

Use d

= 30mm

VI Observation and Conclusion

In the preceding computation we have

found the following dimensions of ceiling

joist according to their area of analysis.

For bending we have computed a safe

ceiling joist dimension of 50x75mm,

50x75mm for shear and finally a safe

value of 50x100mm for deflection. We

can then observe that the safest value to

be applied in our ceiling joist 3 is

50x100mm with a notch depth of 30mm

= bd3/12

= (5WtLu4)/(384EI)

=1.387mm

6|Page

Page |7

Design of Ceiling joist 3B

I Wood Data

Species ____________________Yakal

___________________________50 % Stress

Grade

Bending and Tension

Parallel to grain ____________15.5MPa

Modulus of Elasticity _________3110MPa

Compression Parallel to grain __9.55Mpa

Compression

Perpendicular to grain ________3.92MPa

Shear parallel to grain ________1.55MPa

Relative Density _____________0.76kg/ m3

Span ______________________2.70m

Allowable Deflection _________L/360

II Compute the Total Load

Wtotal = DL+LL

= 0.378 + 3

= 3.378kPa

II.A Uniformly Distributed Load

Wtotal = 3.378kPa(S)

= 3.378kPa (0.40)

= 1.351KN/m

III Design by Bending

M

= Wtotal(L)^2/8

= 1.351KN/m (1.1252)/8

= 0.214kN-m

= 214000N-mm

Assume

dimension

for

(B=50mm)

fb= 6M/bd^2

15.5 = (6*214000)/ 50*d2)

d

= 40.703mm

Use d = 75mm

breadth

III.A Compute the dead load of the

floor joist

Breadth

= 50mm

Depth

= 75mm

Relative Density = 0.76kg/ m3

= 7600N/ m3

Wwood = ybd

= 7600(.05*.075)

= 28.5N/m

Add this dead weight to the weight

carried by the floor joist

III.B Check the adequacy of the floor

joist

III.C Uniformly Distributed Load

Wtotal = 1.351KN/m

= 1.351KN/m+ .0285

= 1.380KN/m

III.D Compute the slenderness factor

and flexural stress

Lu

= 1125mm

7|Page

Page |8

Le

= 1.92(1125)

= 2160mm

Cs

= ((Le*d)/(b^2)) 1/2

= ((2160*75)/(50^2)) 1/2

= 8.05 < 10

Ck

= 0.811((E/fb)) 1/2

= 0.811((3110/15.5)) 1/2

= 11.488

10>Cs<Ck

fb

= 15.5MPa

III.E Check the actual bending stress

and compare to the allowable

Fb

= 15.5MPa

Fb

= 6M/bd^2

Vmax

M= Wtotal(Lu^2)/8

= 1.380(1.1252)/8

= 218000N-mm

Fb = (218000*6)/(50*752)

= 4.651MPa

The 50x75mm floor joist is safe in

bending stress

= Wtotal(L)/2

= 1.351 (1.125)/2

= 0.76KN

IV.B Compute the design Depth

Assume

dimension

for

breadth

(B=50mm)

Fv

= 1.55MPa

1.55 = 3Vmax/(2bd)

1.55 = 3(0.76*1000)/(2*50*d)

D

= 14.701mm

Use d

= 75mm

IV.C Compute the dead load of the

floor joist

Breadth = 50mm

Depth

= 75mm

Relative Density = 0.76kg/m3

= 7600N/m3

Wwood = ybd

= 7600(.05*.075)

= 28.5N/m

Add this dead weight to the weight

carried by the floor joist

IV Design by Shear

IV.A Compute the maximum shear

Since the floor joist is simply supported

the maximum shear will occur at the

support.

IV.D Check the adequacy of the floor

joist

IV.E Uniformly Distributed Load

Wtotal = 1.351KN/m

= 1.351+ .0285

= 1.380KN/m

8|Page

Page |9

IV.G Check the actual Shear stress and

compare to the allowable shear stress

Vmax = Wtotal(Lu)/2

= 1.380(1)/2

= 0.690KN

fv

= 1.55MPa

Fv

= 3Vmax/(2bd)

= 3(0.690*1000)/(2*50*75)

= 0.276MPa<1.55MPa

The 50x100mm floor joist is safe

from shear failure

V Design by Deflection

Wtotal = DL+LL

= 0.378 + 3

= 3.378kPa

V.A Uniformly Distributed Load

Wtotal = 3.378(S)

= 3.378(0.40)

= 1.351KN/m

Allowable Deflection _____________ L/360

Modulus

of

Elasticity

_____________

3110MPa

V.B Compute the design depth by

assuming

bredth = 100mm

I

= bd3/12

Lu/360

= (5WtLu4)/(384EI)

d

= 88.614mm

use d

= 100mm

V.C Compute the dead load of the

floor joist

Breadth = 05mm

Depth = 100mm

Relative Density = 0.76kg/m3

= 7600N/m^3

Wwood = ybd

= 7600(.05*.100)

= 38N/m

Add this dead weight to the weight

carried by the floor joist

Check the adequacy of the floor joist

V.D Uniformly Distributed Load

Wtotal = 1.351KN/m

= 1.351KN/m+ 0.038

= 1.389KN/m

V.E Check the actual deflection and

compare it to the allowable

I

= bd3/12

= (5WtLu4)/(384EI)

actual=2.236mm

allowable= L/360

= 1125/360

= 3.125mm>1.387mm Safe

9|Page

P a g e | 10

The 50x100mm ceiling joist is safe

from deflection failure

VI Compute the required depth of

notch at support

fv

= 3Vmax(d)/(2bdd)

1.55 = 3(0.690*1000)(100)/(2*50*d2)

D

= 36.544mm

Use d

= 30mm

VII Observation and Conclusion

In the preceding computation we have

found the following dimensions of ceiling

joist according to their area of analysis.

For bending we have computed a safe

ceiling joist dimension of 50x75mm,

50x75mm for shear and finally a safe

value of 50x100mm for deflection. We

can then observe that the safest value to

be applied in our ceiling joist 3B is

50x100mm with a notch depth of 30mm

Design of Ceiling joist 3C

I Wood Data

Species ____________________Yakal

___________________________50 %

Grade

Bending and Tension

Stress

Parallel to grain ____________15.5MPa

Modulus of Elasticity _________3110MPa

Compression Parallel to grain __9.55Mpa

Compression

Perpendicular to grain ________3.92MPa

Shear parallel to grain ________1.55MPa

Relative Density _____________0.76kg/m3

Span ______________________1.875m

Allowable Deflection _________L/360

II Compute the Total Load

Wtotal = DL+LL

= 0.378 + 3

= 3.378kPa

II.A Uniformly Distributed Load

Wtotal = 3.378kPa(S)

= 3.378kPa (0.40)

= 1.351KN/m

III Design by Bending

M

= Wtotal(L) 2/8

= 1.351KN/m (1.8752)/8

= 0.594kN-m

= 594000N-mm

Assume

dimension

for

breadth

(B=50mm)

fb= 6M/bd^2

15.5 = (6*594000)/ 50*d2)

D

= 67.814mm

Use d

= 100mm

10 | P a g e

P a g e | 11

III.A Compute the dead load of the

floor joist

Breadth = 50mm

Depth = 100mm

Relative Density = 0.76kg/m3

= 7600N/m3

Wwood = ybd

= 7600(.05*0.1)

= 38N/m

Add this dead weight to the weight

carried by the floor joist

III.B Check the adequacy of the floor

joist

III.C Uniformly Distributed Load

Wtotal = 1.351KN/m

= 1.351KN/m+ .038KN

= 1.389KN/m

III.D Compute the slenderness factor

and flexural stress

Lu

= 1875mm

Le

= 1.92(1875)

= 3600mm

Cs = ((

Le*d)/(b^2)) 1/2

= ((3600*75)/(50^2)) 1/2

= 10.392 > 10

Ck = 0.811((E/fb)) 1/2

= 0.811((3110/15.5)) 1/2

= 11.488 > Cs

10<Cs<Ck

Fb

= Fb((1-(1/3)(Cs/Ck)^4)

=15.5((1-(1/3)(10.392/11.488)^4)

=

12.040MPa_________________

allowable

III.E Check the actual bending stress

and compare to the allowable

Fb

= 12.040MPa

Fb

= 6M/bd^2

= Wtotal(Lu2)/8

= 1.389(1.8752)/8

= 0.610KN-m

= 610000N-mm

Fb

= (610000*6)/(50*752)

= 7.325MPa < 12.040MPa Safe

The 50x100mm floor joist is safe in

bending stress

M

IV Design by Shear

IV.A Compute the maximum shear

Since the floor joist is simply supported

the maximum shear will occur at the

support.

Vmax = Wtotal(L)/2

= 1.351 (1.875)/2

= 1.266KN

IV.B Compute the design Depth

Assume

dimension

for

breadth

(B=50mm)

11 | P a g e

P a g e | 12

Fv

= 1.55MPa

1.55 = 3Vmax/(2bd)

1.55 = 3(1.266*1000)/(2*50*d)

D

= 24.503mm

Use d = 75mm

IV.C Compute the dead load of the

floor joist

Breadth = 50mm

Depth = 75mm

Relative Density = 0.76kg/m3

= 7600N/m3

Wwood = ybd

= 7600(.05*.075)

= 28.5N/m

Add this dead weight to the weight

carried by the floor joist

IV.D Check the adequacy of the floor

joist

IV.E Uniformly Distributed Load

Wtotal = 1.351KN/m

= 1.351+ .0285

= 1.380KN/m

IV.F Check the actual Shear stress

and compare to the allowable shear

stress

Vmax = Wtotal(Lu)/2

= 1.380(1.875)/2

= 1.294KN

fv

= 1.55MPa

Fv

= 3Vmax/(2bd)

= 3(1.294*1000)/(2*50*75)

= 0.518MPa<1.55MPa

The 50x100mm floor joist is safe

from shear failure

V Design by Deflection

Wtotal = DL+LL

= 0.378 + 3

= 3.378kPa

V.A Uniformly Distributed Load

Wtotal = 3.378(S)

= 3.378(0.40)

= 1.351KN/m

Allowable Deflection _____________ L/360

Modulus

of

Elasticity

_____________

3110MPa

V.B Compute the design depth by

assuming

bredth = 100mm

I

= bd^3/12

Lu/360

= (5WtLu4)/(384EI)

d

= 147.690mm

Use d

= 150mm

V.C Compute the dead load of the

floor joist

Breadth = 50mm

Depth = 150mm

12 | P a g e

P a g e | 13

Relative Density = 0.76kg/m3

= 7600N/m3

Wwood = ybd

= 7600(.05*.150)

= 57N/m

Add this dead weight to the weight

carried by the floor joist

VI Compute the required depth of

notch at support

fv

= 3Vmax(d)/(2bdd)

1.55 = 3(1.294*1000)(150)/(2*50*d2)

D

= 61.293mm

Use d

= 50mm

VII Observation

Check the adequacy of the floor joist

V.C Uniformly Distributed Load

Wtotal = 1.351KN/m

= 1.351KN/m+ 0.057

= 1.408KN/m

V.E Check the actual deflection and

compare it to the allowable

I

= bd3/12

= (5WtLu4)/(384EI)

actual=5.181mm

allowable= L/360

= 1875/360

= 5.208mm>5.181mm Safe

The 50x150mm ceiling joist is safe in

deflection

In the preceding computation we have

found the following dimensions of ceiling

joist according to their area of analysis.

For bending we have computed a safe

ceiling joist dimension of 50x75mm,

50x75mm for shear and finally a safe

value of 50x100mm for deflection. We

can then observe that the safest value to

be applied in our ceiling joist 3C is

50x150mm with a notch depth of 50mm

Design of Ceiling Joist 3D

I Wood Data

Species

Bending and Tension Parallel to

grain MPa

Compression Parallel to Grain Mpa

Compression Perpendicular to

Grain Mpa

Yakal 50% Stress

Grade

=

=

15.5

9.55

3.92

13 | P a g e

P a g e | 14

Shear Parallel to Grain Mpa

Modulus of Elasticity Mpa

Relative Density Kg/m3

Allowable Deflection mm

Span (mm)

Spacing (mm)

DL (kPa)

LL (kPa)

=

=

=

=

=

Load

Wtotal (KN/m)

II.A Uniformly Distributed Load

Wtotal (KN/m)

1.3512

III Design by Bending

Mmax (N-mm)

Assummed Breadth (mm)

Depth (mm)

Use Depth (mm)

=

=

=

=

1055625

III.B Check the Adequacy of

the Joist

III.C Uniformly Distributed

Le (mm)

Cs

Ck

fb (Mpa)

fb (Mpa)

Use fb (MPa)

=

=

4800

8.2623

64

11.487

76

14.117

43

10.322

01

15.5

III.E Check the actual

BeNDING Stress

73.81319053

Mmax (N-mm)

fb

fb

actual

=

=

10912

50

13.640

63

15.5

Safe

The 75x100mm Ceiling joist is safe from

bending stress failure

III.A Compute the dead looad

of the wood

Wwood (KN/m3)

1.3968

III.D Compute the Slenderness

Factor

II Compute the Total Load

Wtotal (kPa)

Allowable

0.0456

IV Design by Shear

IV.A Compute the Maximum

shear

Vmax (N)

1689

14 | P a g e

P a g e | 15

IV.B Compute the design

depth

Assumed Breadth (mm)

Fv (MPa)

=

=

depth (mm)

Use depth (mm)

=

=

IV.C Compute the dead load of

the joist

Wwood (N/m)

IV.D Check the Adequacy of the

joist

IV.E Uniformly Distributed Load

Wtotal (N/m)

IV.G Check the actual Shear

Vmax (N)

Fv

Fv

actual

(Mpa)

Allowable

(Mpa)

=

=

=

50

1.55

32.690

32

75

Wtotal (kPa)

3.378

V.A Uniformly Distributed Load

Wtotal (KN/m)

Allowable Deflection

E (MPa)

=

=

=

1.3512

6.944444444

3110

V.B Compute the Depth

Depth (mm)

Use Depth (mm)

=

=

156.3029831

175

V.C Compute the dead weight

of the Joist

Wwood (N/m)

1379.7 V.D Uniformly Distributed

Load

Wtotal (KN/m)

actual (mm)

allowable(mm)

=

=

The 50x75mm ceiling joist is safe from shear failure

VI Compute the required d of

notch

=

133

1.4842

1724.625 V.E Check the actual

deflection

0.68985

Use dimension

V Design by Deflection

Assumed breadth (mm)

Vmax (N)

=

=

5.4349

8

6.9444

44

Safe

1855.2

5

15 | P a g e

P a g e | 16

d' (mm)

Use d' (mm)

=

=

56.053

15

115

If we try to look at the second floor

framing plan, we can observe that the

longest span can be found in second floor

The 50x100mm ceiling joist is safe from

Joist 2F with a span of 2500mm (FJ-2D).

deflection failure

However our schedule of loading varies

depending upon the type of area inside

VII Observation

the dwellings. From here, we cannot say

immediately what schedule of joist will

govern. From this reason we will then try

In the preceding computation we have found the

to compute FJ-2B, FJ-2D, and FJ-2F.

following

Dimensions of ceiling joist according to their area of

analysis.

NOTE:

For bending we have computed a safe ceiling joist

The designer have computed all

dimension

floor joist schedule but because of the

of 75x100mm, 50x75mm for shear and finally a safe

repeatable solution, I decided not to show

value of

all the solution, instead only those

100x175mm for deflection. We can then observe that the

members with the most critical loading

safest

and span.

value to be applied in our ceiling joist 3 is 100x175mm

with a

notch depth of 115mm.

Design of Floor Joist 2B

I Wood Data

Floor Joist Observation

Species

Bending and Tension Parallel to

grain MPa

Compression Parallel to Grain Mpa

Compression Perpendicular to

Grain Mpa

Yakal 50% Stress

Grade

=

=

15.5

9.55

3.92

16 | P a g e

P a g e | 17

Shear Parallel to Grain Mpa

Modulus of Elasticity Mpa

Relative Density Kg/m3

Allowable Deflection mm

Span (mm)

Spacing (mm)

DL (kPa)

LL (kPa)

=

=

=

=

=

Load

Wtotal (KN/m)

1.9689

Le (mm)

2160

Cs

8.049844719

Ck

fb (Mpa)

fb (Mpa)

Use fb (MPa)

=

=

=

=

11.48775592

14.25428224

10.32200584

15.5

III.E Check the actual Bending

Stress

Mmax (N-mm)

311486.1328

actual

6.6450375

Allowable

15.5

Safe

1091.475

50

III.D Compute the Slenderness

Factor

II Compute the Total Load

Wtotal (kPa)

II.A Uniformly Distributed Load

Wtotal (KN/m)

III Design by Bending

Mmax (N-mm)

Assummed Breadth (mm)

Depth (mm)

Use Depth (mm)

fb

=

=

=

=

III.A Compute the dead looad

of the wood

Wwood (KN/m3)

III.B Check the Adequacy of

the Joist

III.C Uniformly Distributed

306977.3438

fb

The 50x75mm floor joist is

48.75037221

safe from

bending stress failure

IV Design by Shear

IV.A Compute the Maximum

shear

Vmax (N)

IV.B Compute the design depth

Assumed Breadth (mm)

17 | P a g e

P a g e | 18

Fv (MPa)

depth (mm)

Use depth (mm)

=

=

IV.C Compute the dead load of

the joist

Wwood (N/m)

IV.D Check the Adequacy of the

joist

IV.E Uniformly Distributed Load

Wtotal (N/m)

Fv

Fv

actual

(Mpa)

=

=

(Mpa)

Use dimension

=

=

Allowable

The 50x75mm floor joist is

safefailure

from shear

V Design by Deflection

Assumed breadth (mm)

Wtotal (kPa)

V.A Uniformly Distributed Load

=

=

=

1.9404

3.125

3110

V.B Compute the Depth

Depth (mm)

Use Depth (mm)

=

=

87.34068008

100

V.C Compute the dead weight

of the Joist

Wwood (N/m)

57

V.D Uniformly Distributed Load

Wtotal (KN/m)

1.9974

actual (mm)

2.143253339

allowable(mm)

3.125

IV.G Check the actual Shear

Vmax (N)

21.12532258

Wtotal (KN/m)

Allowable Deflection

E (MPa)

=

=

1107.50625

V.E Check the actual deflection

Safe

VI Compute the required d of

notch

Vmax (N)

d' (mm)

Use d' (mm)

=

=

=

1123.5375

38.07526502

60

The 75x100mm floor joist is

safe from

deflection failure

VII Observation

18 | P a g e

P a g e | 19

In the preceding computation we have found the

following

Spacing (mm)

DL (kPa)

LL (kPa)

Dimensions of floor joist according to their area of

analysis.

II Compute the Total Load

For bending, we have computed a safe floor joist

Wtotal (kPa)

dimension

of 50x75mm, 50x75mm for shear and finally a safe value

of

II.A Uniformly Distributed Load

75x100mm for deflection. We can then observe that the

Wtotal (KN/m)

safest

value to be applied in our floor joist 2B is 75x100mm

with a

III Design by Bending

notch depth of 60mm.

Mmax (N-mm)

Assummed Breadth (mm)

Depth (mm)

Design of Floor Joist 2D

Use Depth (mm)

I Wood Data

Species

Bending and Tension Parallel to grain

MPa

Compression Parallel to Grain Mpa

Compression Perpendicular to Grain

Mpa

Shear Parallel to Grain Mpa

Modulus of Elasticity Mpa

Relative Density Kg/m

Allowable Deflection mm

Span (mm)

=

=

=

=

=

300

2.568

4

6.568

1.9704

=

=

=

=

311723.4375

50

49.1257849

75

0.0285

III.A

Compute the dead looad of

Yakal 50%

Stress

the wood

Wwood (KN/m3)

=

=

=

=

=

19 | P a g e

P a g e | 20

Error! Not a valid link.

Error! Not a valid link.

Floor Joist Observation

If we try to look at the ground floor

framing plan, we can observe that the

longest span can be found in ground floor

Joist 1C with a span of 2500mm (GJ-1C).

However our schedule of loading varies

depending upon the type of area inside

the dwellings. From here, we cannot say

immediately what schedule of joist will

govern. From this reason we will then try

to compute GJ-1B, GJ-1C.

NOTE:

The designer have computed all

floor joist schedule but because of the

repeatable solution, I decided not to show

all the solution, instead only those

members with the most critical loading

and span.

Error! Not a valid link.

VI Compute the required d of

notch

Vmax (N)

d' (mm)

Use d' (mm)

=

=

6029.25

170.80336

74

75

The 50x100mm Ground joist is

safe from

deflection failure

VII Observation

In the preceding computation we have found the

following

dimensions of Ground joist according to their area of

analysis.

For bending, we have computed a safe Ground joist

dimension

of 50x100mm, 50x100mm for shear and finally a

safe value of

50x100mm for deflection. We can then observe that

the safest

value to be applied in our Ground joist 1B is

50x100mm with a

20 | P a g e

P a g e | 21

notch depth of 60mm.

21 | P a g e

S-ar putea să vă placă și

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresDe la EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresEvaluare: 4 din 5 stele4/5 (1)

- TIMBERFINALDocument42 paginiTIMBERFINALmanuel alburoÎncă nu există evaluări

- Toaz - Info Timber Design PRDocument13 paginiToaz - Info Timber Design PRJose Josua GaleraÎncă nu există evaluări

- (Estimation of Dead Load) in A 2-Storey Residential House: Ce 115 - Structural Theory IiDocument31 pagini(Estimation of Dead Load) in A 2-Storey Residential House: Ce 115 - Structural Theory Iishinichi falcoÎncă nu există evaluări

- Uc Structural AnalysisDocument75 paginiUc Structural AnalysisAngelo AmarÎncă nu există evaluări

- Earthquake Computation Lets GoDocument33 paginiEarthquake Computation Lets GoAngie BitesÎncă nu există evaluări

- Portal MethodDocument14 paginiPortal MethodSadiri Roy D Aragon100% (1)

- Chapter3 (Page 6 To 21)Document16 paginiChapter3 (Page 6 To 21)bikramÎncă nu există evaluări

- 003 Direct ShearDocument29 pagini003 Direct ShearMatthewzki FerrerasÎncă nu există evaluări

- Truss Analysis and DesignDocument16 paginiTruss Analysis and DesignAldrin LeyteÎncă nu există evaluări

- DSS Lecture Note 2 - Gravity LoadsDocument92 paginiDSS Lecture Note 2 - Gravity LoadsMrSamspartÎncă nu există evaluări

- Sem 7 FinalDocument15 paginiSem 7 FinalParth Patel0% (1)

- 1 Seismic AnalysisDocument13 pagini1 Seismic Analysiskenneth nobleÎncă nu există evaluări

- Tributary Area For Second Floor: Chapter V-Load Computation and AnalysisDocument7 paginiTributary Area For Second Floor: Chapter V-Load Computation and AnalysisNeneng Acog BisasÎncă nu există evaluări

- Chapter 3: Computation: ND THDocument9 paginiChapter 3: Computation: ND THpeachÎncă nu există evaluări

- Tourism Office Building Computations: Truss 2Document32 paginiTourism Office Building Computations: Truss 2Jesselle CelestialÎncă nu există evaluări

- Design of Purlins and Load Calc.Document2 paginiDesign of Purlins and Load Calc.Anabelle Olimba SantillanÎncă nu există evaluări

- Preliminary Sizing: Panel L, M L, M L /L Slab Design Min.h, M Min.h, MMDocument23 paginiPreliminary Sizing: Panel L, M L, M L /L Slab Design Min.h, M Min.h, MMTrol O'lolÎncă nu există evaluări

- Structural Computation: Phase 7-A Block 17 Lot 04 Orchard & Residential Estate, Salitran, Dasmariñas, CaviteDocument9 paginiStructural Computation: Phase 7-A Block 17 Lot 04 Orchard & Residential Estate, Salitran, Dasmariñas, CaviteEdward Jade EmolagaÎncă nu există evaluări

- CE 181 ProjectDocument55 paginiCE 181 ProjectErniel YansonÎncă nu există evaluări

- Example - Seismic Force by Static Analysis MethodDocument3 paginiExample - Seismic Force by Static Analysis MethodJosé Henrique Delabio100% (1)

- Design of Floor JoistDocument5 paginiDesign of Floor JoistXDXDXDÎncă nu există evaluări

- Truss-and-Purlins-Design Alternative DesignDocument8 paginiTruss-and-Purlins-Design Alternative DesignAiron Kaye SameloÎncă nu există evaluări

- Abra-Kalinga (454-456 & 409-412)Document188 paginiAbra-Kalinga (454-456 & 409-412)Ernest BelmesÎncă nu există evaluări

- Design ProjectDocument54 paginiDesign ProjectGiemhel GeleraÎncă nu există evaluări

- Staad Pro-Modeling of A Grid BeamDocument7 paginiStaad Pro-Modeling of A Grid BeamV.m. Rajan0% (1)

- Two Way Slab ExcelDocument16 paginiTwo Way Slab ExcelGing LimjocoÎncă nu există evaluări

- Section Analysis-LC 150x50x18x3.0mmDocument2 paginiSection Analysis-LC 150x50x18x3.0mmRachelle Quilala0% (1)

- Mech 1201D Statics: Tutorial 5Document4 paginiMech 1201D Statics: Tutorial 5Vivek RaoÎncă nu există evaluări

- Fire Code Estimate PDFDocument2 paginiFire Code Estimate PDFMark Christian EsguerraÎncă nu există evaluări

- TOS 2 - 3 Moment EquationDocument5 paginiTOS 2 - 3 Moment EquationAndrei AlidoÎncă nu există evaluări

- Computation of LoadsDocument30 paginiComputation of Loadspablo naragÎncă nu există evaluări

- Two Story Residential Design ComputationDocument8 paginiTwo Story Residential Design ComputationNick OperarioÎncă nu există evaluări

- Earthquake LoadingsDocument22 paginiEarthquake Loadingspablo naragÎncă nu există evaluări

- NEW - Structural Design & Analysis (Pt. 1)Document23 paginiNEW - Structural Design & Analysis (Pt. 1)Rein Aira OrdanezÎncă nu există evaluări

- Breakdown of Cost Estimate: Beverly Hills Subd., Antipolo CityDocument4 paginiBreakdown of Cost Estimate: Beverly Hills Subd., Antipolo CityjologscresenciaÎncă nu există evaluări

- Seismic AnalysisDocument13 paginiSeismic AnalysisJea Manguing-YubalÎncă nu există evaluări

- ANALYSIS AND DESIGN OF Sadddddddddddddd - v4 - 6-5-21Document43 paginiANALYSIS AND DESIGN OF Sadddddddddddddd - v4 - 6-5-21bok1221Încă nu există evaluări

- Statics Chapter 8 Tutorial 13th October 2015Document5 paginiStatics Chapter 8 Tutorial 13th October 2015Qawi Roslee0% (1)

- Compiled Computations - 3 Storey PDFDocument117 paginiCompiled Computations - 3 Storey PDFAlbert Martin ReyesÎncă nu există evaluări

- Copy - DESIGN-LOADS-FOR-COVERED-COURTDocument39 paginiCopy - DESIGN-LOADS-FOR-COVERED-COURTLouise CarleyÎncă nu există evaluări

- Dead Loads: Roof: Unit 3.54 Kpa Roof DeckDocument52 paginiDead Loads: Roof: Unit 3.54 Kpa Roof DeckJohn Paul Hilary Espejo100% (1)

- Earthquake Lateral Forces Calculations According To UBC97: InputDocument10 paginiEarthquake Lateral Forces Calculations According To UBC97: InputOnurUmanÎncă nu există evaluări

- Design of Columns: I.Determination If Long Column or Short ColumnDocument26 paginiDesign of Columns: I.Determination If Long Column or Short ColumnJohn Paul Hilary EspejoÎncă nu există evaluări

- STAAD - Pro & STAAD Advanced Concrete Designer RCDC: (Beams, Slabs, Columns and Footings)Document49 paginiSTAAD - Pro & STAAD Advanced Concrete Designer RCDC: (Beams, Slabs, Columns and Footings)Arnold VercelesÎncă nu există evaluări

- Concrete Design PlateDocument26 paginiConcrete Design PlateLauro PaniergoÎncă nu există evaluări

- Computation Fink TrussDocument62 paginiComputation Fink TrussJorge Christian BeldiaÎncă nu există evaluări

- Truss Analysis and Design For Half Truss 3Document13 paginiTruss Analysis and Design For Half Truss 3Bevelyn ManaloÎncă nu există evaluări

- Wall FootingDocument4 paginiWall FootingMunthir NumanÎncă nu există evaluări

- Column Design/Analysis Software: (Based On The NSCP 2015 Code)Document2 paginiColumn Design/Analysis Software: (Based On The NSCP 2015 Code)Gelbert SilotÎncă nu există evaluări

- LC1 - LC3 - LC2 - LC4 - LC5 - at The Base: Based On Section 203.3 of NSCP 2015 7th EditionDocument1 paginăLC1 - LC3 - LC2 - LC4 - LC5 - at The Base: Based On Section 203.3 of NSCP 2015 7th EditionAly Arquillano JrÎncă nu există evaluări

- Roof Truss DesignDocument36 paginiRoof Truss DesignTaufiq PrihantoroÎncă nu există evaluări

- Steel NewDocument19 paginiSteel NewMark Jendel TomoÎncă nu există evaluări

- 1 - Introduction To Steel Design PDFDocument9 pagini1 - Introduction To Steel Design PDFNadine PascualÎncă nu există evaluări

- STRUCTURAL ANALYSIS AND DESIGN AutosavedDocument29 paginiSTRUCTURAL ANALYSIS AND DESIGN AutosavedJeremy Mark SorianoÎncă nu există evaluări

- Two Way SlabDocument19 paginiTwo Way SlabAllysa Joy MoralesÎncă nu există evaluări

- ECS448 - Topic 5 (Deformation - Virtual Work For Frame & Truss)Document33 paginiECS448 - Topic 5 (Deformation - Virtual Work For Frame & Truss)darwishshahrir__Încă nu există evaluări

- KANDING Loadings - NSCP 2015 - 2 Storey Residential Concrete StructureDocument23 paginiKANDING Loadings - NSCP 2015 - 2 Storey Residential Concrete StructureNikka FerrerÎncă nu există evaluări

- Preliminary Design: Area of Steel Required Area of Steel ProvidedDocument10 paginiPreliminary Design: Area of Steel Required Area of Steel ProvidedArchana Poudel100% (1)

- Algimar Construction: Structural Soundness CertificateDocument2 paginiAlgimar Construction: Structural Soundness CertificateJohn Darwin Sabio100% (1)

- Seminar GREEN PLUMBING AND MECHANICAL CODE IAPMO PDFDocument9 paginiSeminar GREEN PLUMBING AND MECHANICAL CODE IAPMO PDFJohn Darwin SabioÎncă nu există evaluări

- Plumbing ToolsDocument24 paginiPlumbing ToolsHarold Abubo Haber100% (4)

- Especially For YouDocument8 paginiEspecially For YouJohn Darwin SabioÎncă nu există evaluări

- (Basil Valdez) - You - Arrange by Mark Sagum-1Document5 pagini(Basil Valdez) - You - Arrange by Mark Sagum-1John Darwin SabioÎncă nu există evaluări

- Simplified Design Equation of Lap Splice Length in CompressionDocument6 paginiSimplified Design Equation of Lap Splice Length in CompressionJohn Darwin SabioÎncă nu există evaluări

- Traverse CalculationsDocument18 paginiTraverse CalculationsJosé María Durán50% (2)

- Church of God. Chosen People Sing Your Praise To God. He Has Called You Out of Darkness Into His Marvelous LightDocument1 paginăChurch of God. Chosen People Sing Your Praise To God. He Has Called You Out of Darkness Into His Marvelous LightJohn Darwin SabioÎncă nu există evaluări

- Rebar Detailing StandardsDocument12 paginiRebar Detailing StandardsDang-dang Siggaoat-CopiacoÎncă nu există evaluări

- Fixing A Broken HeartDocument5 paginiFixing A Broken HeartJohn Darwin Sabio0% (1)

- Doraemon Played in The Key of DDocument2 paginiDoraemon Played in The Key of DJohn Darwin SabioÎncă nu există evaluări

- D2487 Clasificacion SUCS PDFDocument12 paginiD2487 Clasificacion SUCS PDFAlejandro OrtegaÎncă nu există evaluări

- Can You Feel The Love TonightDocument6 paginiCan You Feel The Love TonightJohn Darwin SabioÎncă nu există evaluări

- Geotextile Research Option 1Document5 paginiGeotextile Research Option 1John Darwin SabioÎncă nu există evaluări

- 4 Load CalculationDocument4 pagini4 Load CalculationJohn Darwin SabioÎncă nu există evaluări

- TimberDocument9 paginiTimberJohn Presly Ilarde100% (2)

- SymbolsDocument12 paginiSymbolsJohn Darwin SabioÎncă nu există evaluări

- Timber Truss Design ProcedureDocument15 paginiTimber Truss Design ProcedureTony Lee Jones87% (15)

- Related StudiesDocument3 paginiRelated StudiesJohn Darwin SabioÎncă nu există evaluări

- Truss Design:: For Dead LoadDocument6 paginiTruss Design:: For Dead LoadJohn Darwin SabioÎncă nu există evaluări

- Reinforced Concrete CourseDocument25 paginiReinforced Concrete CourseAbdissa BekeleÎncă nu există evaluări

- Technological Institute of The Philippines Manila Civil EngineeringDocument2 paginiTechnological Institute of The Philippines Manila Civil EngineeringJohn Darwin SabioÎncă nu există evaluări

- Chem 2990 Specific Gravity ReadingsDocument5 paginiChem 2990 Specific Gravity ReadingsJohn Darwin SabioÎncă nu există evaluări

- Final LLLLLDocument3 paginiFinal LLLLLJohn Darwin SabioÎncă nu există evaluări

- Elements of ConstructionDocument56 paginiElements of ConstructionDanja PantelićÎncă nu există evaluări

- Ust NSTP Cwts and Lts HandbookDocument9 paginiUst NSTP Cwts and Lts HandbookJia Chu ChuaÎncă nu există evaluări

- Catholic ChurchDocument6 paginiCatholic ChurchJohn Darwin SabioÎncă nu există evaluări

- Case Medical WardDocument20 paginiCase Medical WardJohn Darwin SabioÎncă nu există evaluări

- We Made It Through: F BB BB GM CDocument2 paginiWe Made It Through: F BB BB GM CJohn Darwin SabioÎncă nu există evaluări

- Chapter 3Document53 paginiChapter 3yohannes lemiÎncă nu există evaluări

- Physics Project Final1Document15 paginiPhysics Project Final1sohamÎncă nu există evaluări

- Materijali I Konstrukcije Materials and Structures: GRA ĐevinskiDocument204 paginiMaterijali I Konstrukcije Materials and Structures: GRA ĐevinskiAnonymous FJG4UKm5HÎncă nu există evaluări

- A New Deformable Catenary Element For The Analysis of Cable Net Structures - 2006Document9 paginiA New Deformable Catenary Element For The Analysis of Cable Net Structures - 2006Truong Viet HungÎncă nu există evaluări

- Coriolis Meter Sizing CalculationDocument3 paginiCoriolis Meter Sizing CalculationJeyhan M DonavistaÎncă nu există evaluări

- Modeling of Low Voltage Switchgear and Controlgear Assemblies Using Computational Fluid Dynamics - 465-147668798701-06Document6 paginiModeling of Low Voltage Switchgear and Controlgear Assemblies Using Computational Fluid Dynamics - 465-147668798701-06Bao LamÎncă nu există evaluări

- HFSS-High Frequency Structure SimulatorDocument38 paginiHFSS-High Frequency Structure SimulatorSanchita BasakÎncă nu există evaluări

- Working Stresses of Philippine WoodsDocument4 paginiWorking Stresses of Philippine WoodsErwin Ronald CalmaÎncă nu există evaluări

- HT Practice Problems PDFDocument2 paginiHT Practice Problems PDFChinnarao PulapaÎncă nu există evaluări

- 12th Physics Full Book MCQs PDFDocument43 pagini12th Physics Full Book MCQs PDFshahid abbas82% (11)

- The High Strength Friction GripDocument10 paginiThe High Strength Friction GripfiarÎncă nu există evaluări

- May Thuy Khi Cau Hoi On Tap NewDocument29 paginiMay Thuy Khi Cau Hoi On Tap NewKhang DangÎncă nu există evaluări

- Straw Rocket LabDocument4 paginiStraw Rocket Labaaguiar1Încă nu există evaluări

- Distillation Columns Containing Structured Packings. A Comprehensive Model For Their Performance. 1. Hydraulic ModelsDocument11 paginiDistillation Columns Containing Structured Packings. A Comprehensive Model For Their Performance. 1. Hydraulic ModelsJohan Sebastian Moreno LaraÎncă nu există evaluări

- Analysis of G+20 RC Building in Different Zones Using Etabs: Narla Mohan, A.Mounika VardhanDocument14 paginiAnalysis of G+20 RC Building in Different Zones Using Etabs: Narla Mohan, A.Mounika VardhanRohan ChauguleÎncă nu există evaluări

- E103 - Moment of InertiaDocument5 paginiE103 - Moment of InertiaStephh LouisÎncă nu există evaluări

- Seismic Design of Steel StructuresDocument55 paginiSeismic Design of Steel StructuresAndrea LitzÎncă nu există evaluări

- How To Predict CavitationDocument7 paginiHow To Predict CavitationrkssÎncă nu există evaluări

- Theory and Modeling of Electronic Excitations in NanoscienceookDocument52 paginiTheory and Modeling of Electronic Excitations in NanoscienceookahmedkhidryagoubÎncă nu există evaluări

- 1st Year IPE Important QuestionsDocument2 pagini1st Year IPE Important QuestionsNAVEEN PAUL UNDIÎncă nu există evaluări

- Radiation Heat Transfer in Combustion Systems - Viskanta - Menguc - 1987Document64 paginiRadiation Heat Transfer in Combustion Systems - Viskanta - Menguc - 1987Martin Martin MartinÎncă nu există evaluări

- GuideDocument770 paginiGuidepavankumar001Încă nu există evaluări

- A Vortex Model of The Darrieus Turbine: An Analytical and Experimental StudyDocument6 paginiA Vortex Model of The Darrieus Turbine: An Analytical and Experimental Studyjohn arbuckleÎncă nu există evaluări

- Lab Report Ratio ControlDocument15 paginiLab Report Ratio Controlnaneesa_1100% (8)

- Notes On Q M C Delta TDocument2 paginiNotes On Q M C Delta TDing30180Încă nu există evaluări

- AvcDocument18 paginiAvcgulshanÎncă nu există evaluări

- Problem Set A: Electrostatic FieldsDocument2 paginiProblem Set A: Electrostatic FieldsfsfsfsÎncă nu există evaluări

- Ansys PZTDocument28 paginiAnsys PZTQuoc LeÎncă nu există evaluări

- Peperiksaan Percubaan SBP Fizik 2011 Marking Scheme For Physics Paper 2Document8 paginiPeperiksaan Percubaan SBP Fizik 2011 Marking Scheme For Physics Paper 2Lee Li JieÎncă nu există evaluări

- Prestree Bridge Design 20200316 PDFDocument47 paginiPrestree Bridge Design 20200316 PDFsantosh yevvariÎncă nu există evaluări