Documente Academic

Documente Profesional

Documente Cultură

RA 002 - D.O. Tank Inspection and Cleaning

Încărcat de

dassi99Descriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

RA 002 - D.O. Tank Inspection and Cleaning

Încărcat de

dassi99Drepturi de autor:

Formate disponibile

MARAN GAS MARITIME INC.

RA 002

CHAPTER 13

RISK ASSESSMENT FORM

RISK MANAGEMENT

Operation / Work activity being assessed:

Generated by: Vessel

RA Code number:

D.O TANK INSPECTION/ CLEANING (ENCLOSED SPACE ENTRY)

Routine

Non-routine

Office

(record the name)

ALTERNATIVE WAYS TO CONDUCT THE WORK (Prior to deciding to proceed with the work always ensure that all other alternatives methods

for carrying out the job have been identified and documented )

No alternative ways available for this task.

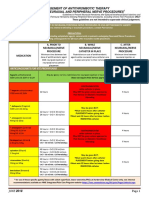

FREQUENCY CATEGORY

CONSEQUENCE CATEGORY

Frequent - Possibility of

repeated incidents

Probable - Possibility of

isolated incidents

More often than

once per voyage

Once per year

Occasional- Possibility of

occurring sometime

Once per 5 years

Remote- Not likely to occur

Once per 10 years

Very unlikely- Practically

impossible

Once per 30 years

or more

CECONSEQUEN

1

2

3

4

Human losses / fatalities

Major pollution /

Full scale response

Serious injury to

personnel

Moderate pollution/

Significant resources commitment

Number of minor

injuries / Medical

treatment for personnel

Little pollution /

Limited response of short duration

Little cost or damage

($10000 $ 100000)

Slight impact

Few minor injuries

Minimum pollution /

Little or no response needed

Minimum cost /

damage

< $10000

Zero impact

1

L (1)

L (2)

RISK MATRIX

FREQUENCY

2

3

L (2)

L (3)

M(4)

M(6)

4

M (4)

H(8)

5

M (5)

H(10)

L(3)

M(6)

H(9)

H(12)

H(15)

M(4)

H(8)

H(12)

H(16)

H(20)

Excessive/ high cost

damage >$1000000

Moderate cost or

damage

(100000 1000000$)

Major national &

international impact

Considerable

impact

High=Intolerable Risk Medium=Tolerable Risk Low=Negligible Risk

Risk Assessment

Risk Identification

No

Hazard

Inadequate work planning

Issue No. / Date: 1 / 02.07

Risk Analysis

Potential

hazardous event

Delays/

confusion/ crew

injury / property

damage

Initial risk

evaluation

Existing control measures

a. Working plan will be

communicated prior the job

commencement to the participants,

as defined in SMS Ch. 7.9.2.

b. A pre-job toolbox meeting will be

carried out among all personnel

involved with the job, in order to

discuss and analyze the identified

hazards. All people involved in the

job should countersign the RA.

c. Form P-001 for entry in

enclosed space should also be

issued. The Permit must be

completed/ signed by the Master,

Revision No. / Date: 2 / 05.14

Page 1 of 6

MARAN GAS MARITIME INC.

RA 002

CHAPTER 13

RISK ASSESSMENT FORM

Risk Assessment

Risk Identification

No

Hazard

Risk Analysis

Potential

hazardous event

Crew fatigue/ Lack of experience of the

personnel carrying out the job

Crew injury,

delays

Slips, trips, falls

Crew injury

Issue No. / Date: 1 / 02.07

Existing control measures

the Responsible Officer and the

person entering the space or

authorized team leader.

d. After the work break, the job will

be resumed only when the

supervisor is ensured that the

control measures are still valid.

a. Only well-rested personnel will

participate in the job.

b. Experienced personnel will

participate in the job.

a. PPE will be used throughout the

whole job execution. Head torches

to be worn on the helmets, if

applicable. See SMS Ch. 7.9.17.

b. Any hazards assessed through

the JHA and RA will be eliminated

prior the job commencement.

c. Stby personnel will be available

in order to replace anyone

indicating signs of fatigue. Rest

hours will be observed.

d. Team leader to inspect the

surfaces and to warn the rest of

the team members for any hazards

while he passes from the enclosed

space. The team leader will decide

if the team will proceed by doing

an on scene hazard assessment,

and decide whether the job should

be ceased. As a general rule,

stepping on inclined surfaces

such as hoppers and stringers

must be avoided.

e. Team leader to visually inspect

the access means of tank, and to

confirm the proper condition of the

following: (a) permanent attached

ladders, (b) hinged grating

platforms in position and pin

locked (if fitted), (c) open deck

access manholes and openings

(securing and protection means,

such as rails, warning tapes etc.)

Revision No. / Date: 2 / 05.14

Initial risk

evaluation

F

Page 2 of 6

MARAN GAS MARITIME INC.

RA 002

CHAPTER 13

RISK ASSESSMENT FORM

Risk Assessment

Risk Identification

No

Hazard

Risk Analysis

Potential

hazardous event

Lack of communication between vessels

departments.

Equipment

damage/

operational

problem

Inadequate ventilation, increased numbers of

O2, hydrocarbons and toxic gases.

Asphyxiation

Issue No. / Date: 1 / 02.07

Existing control measures

Initial risk

evaluation

F

f. Entry team to familiarize with the

space and the arrangements

within, by reviewing the relevant

tank plan.

Prior work commences, it should

1

be ensured that communication

between all head departments is

established and same channel will

be maintained throughout job

execution. All UHF batteries to be

fully charged.

In case of UHF malfunction or

dead battery:

- Replace the UHF with

another.

- Change the battery in a

gas proof area.

Each team member should carry a

walkie talkie, fully charged and

tested. Person standing in the

entrance should also carry a

walkie talkie.

a. Before entry, thorough

2

examination and atmosphere tests

should be performed in various

heights of the tank/space, in order

to ensure that levels of O2,

hydrocarbons and toxic gases are

within the acceptable entry limits.

b. At least 2 members of the entry

team will carry personal

atmosphere test equipment.

c. The ventilation of the space will

remain turned on until the work

has been completed and the space

has been evacuated.

d. Additional and frequent

atmosphere tests will be performed

by portable equipment in a

predefined period. It should be

noted that the predefined periods

should not exceed the duration of

2 hours.

e. In case of ventilation failure,

Revision No. / Date: 2 / 05.14

Page 3 of 6

MARAN GAS MARITIME INC.

RA 002

CHAPTER 13

RISK ASSESSMENT FORM

Risk Assessment

Risk Identification

No

Hazard

Risk Analysis

Potential

hazardous event

Inadequate illumination

Crew injury

Adverse sea/ weather conditions

Crew injury

Heat and humidity in the enclosed space

Delays,

confusion,

fatigue

Issue No. / Date: 1 / 02.07

Existing control measures

portable atmosphere test

equipment failure or of any

indication of possible gas or lack of

oxygen exists, entry will be ceased

and the team will abandon the

space at once.

f. Requirements for entry in an

enclosed space are defined in the

SMS Chapter 7.9.2. Circular no.

04-2010 gives guidance on the

measures to be followed for each

confined space. The following are

the requirements that need to be

fulfilled before entry in an enclosed

space:

Spaces having a risk factor

above 375:

Inspection: JHA/ RA (Office

approval), Gas free certificate,

Entry permit P-001

Before entry, responsible person to

confirm that the space illumination

is adequate. Each team member

will carry a safe and filly charged

torch with them, in order to

illuminate any obscured parts of

the space that cant be covered by

the main means of illumination.

Test and confirm the lighting

equipment operation condition.

The inspection/ work to be

performed under favorable

weather conditions and minimums

sea motions (pitching/ rolling).

Bridge OOW to monitor weather

reports and sea conditions, in

order to inform team when weather

deterioration if expected. Entry

should be ceased if deemed

necessary.

Dehydration measures should be

taken before entry. In case the

heat and humid conditions of the

space are extreme (40 C), entry

Revision No. / Date: 2 / 05.14

Initial risk

evaluation

F

Page 4 of 6

MARAN GAS MARITIME INC.

RA 002

CHAPTER 13

RISK ASSESSMENT FORM

Risk Assessment

Risk Identification

No

Risk Analysis

Potential

hazardous event

Hazard

Use of tools/ electrical equipment

Crew injury

10

Presence of flammable liquid

Fire/ Crew injury

11

Exposure to hazardous material

Crew injury

Initial risk

evaluation

Existing control measures

should be abandoned.

a. The tools should be lowered in a

proper safe manner (plastic bucket

etc.) in order to avoid the

possibility of being dropped.

b. The good condition of the

equipment will be checked prior

each use.

Tanks/ spaces to dry as much as

possible before entry, by extend

ventilation.

A portable fire extinguisher will be

standby/ready for immediate use.

a. MSDS of the chemicals to be

used, to be reviewed prior the oil

waste collection

b. Adequate ventilation should be

ensured.

c. Relevant PPE will be used in

order to avoid skin contact with oil

residues.

Note F: Frequency, C: Consequence, R: Risk

Notes: (1) This Form should be filed onboard in File M27 & E5.

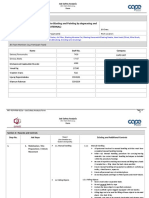

Risk Treatment

Hazard

No.

Additional Risk Control Measures

Residual risk

evaluation

Responsible

*Action

Timeline

Note F: Frequency, C: Consequence, R: Risk

Contingency plans (to facilitate safe management and recovery of the situation in case of any unplanned occurrences)

Emergency case

Contingency Plans

Personnel Injury

SMS/Ch. 8(A) Emergency Case #12

Fire

SMS/Ch. 8(A) Emergency Case #7

Risk Assessment reviewed/approved by:

Name

Issue No. / Date: 1 / 02.07

Rank / Title

Signature

Revision No. / Date: 2 / 05.14

Date

Page 5 of 6

MARAN GAS MARITIME INC.

RA 002

CHAPTER 13

RISK ASSESSMENT FORM

Please enter below the persons who will be

involved in the job:

Remarks:

*Action timeline : Ensure the close out of the preventive actions prior to commencement of work.

Verification (Master and the Officer in Charge) that all control measure are fully implemented prior work commencing.

Name

Rank / Title

Signature

Date

Office verification reviewed/approved by:

Name

Issue No. / Date: 1 / 02.07

Rank / Title

Signature

Revision No. / Date: 2 / 05.14

Date

Page 6 of 6

S-ar putea să vă placă și

- RA 002 - BunkeringDocument5 paginiRA 002 - Bunkeringdassi99Încă nu există evaluări

- RA 002 - BunkeringDocument5 paginiRA 002 - Bunkeringdassi99Încă nu există evaluări

- Perkins 1104D (Mech) EngineDocument140 paginiPerkins 1104D (Mech) EngineAnonymous yjK3peI787% (15)

- Astm A 240-18Document12 paginiAstm A 240-18Giann' Andreh'xd100% (2)

- 95-0120 Cometence Assurance For HSE Critical ActivitiesDocument48 pagini95-0120 Cometence Assurance For HSE Critical ActivitiesClive Nicli100% (2)

- 4.10.1 Ramp Up-Ramp Down Plan-AsclepiusDocument1 pagină4.10.1 Ramp Up-Ramp Down Plan-Asclepiusdassi99100% (1)

- RA 002 - Engine Casing Exhaust Funnel - Hot WorkDocument6 paginiRA 002 - Engine Casing Exhaust Funnel - Hot Workdassi99Încă nu există evaluări

- RISK ASSE 110 - Fire Fighting System - F03Document8 paginiRISK ASSE 110 - Fire Fighting System - F03Rochdi BahiriÎncă nu există evaluări

- Marine Safety Management Plan: Kendall Bay Sediment Remediation ProjectDocument37 paginiMarine Safety Management Plan: Kendall Bay Sediment Remediation Projectkhabiran100% (1)

- Hydro Blasting 3Document6 paginiHydro Blasting 3Robinson Ysasis100% (1)

- Risk Assessment No 25 PAINTING in GENERAL Rev 02 20 03 09Document2 paginiRisk Assessment No 25 PAINTING in GENERAL Rev 02 20 03 09sizwe0% (1)

- Paper 1Document295 paginiPaper 1Shreyas TiwariÎncă nu există evaluări

- Planar MetalsDocument11 paginiPlanar MetalsSilvano Prado0% (1)

- Stop Anticoagulation Neuraxial AnesthesiaDocument3 paginiStop Anticoagulation Neuraxial AnesthesiaGihan NakhlehÎncă nu există evaluări

- RA 002 - HFO Line Pressure TestDocument4 paginiRA 002 - HFO Line Pressure Testdassi99100% (1)

- RA For High Pressure Cleaning Using HPCE 520-330Document3 paginiRA For High Pressure Cleaning Using HPCE 520-330George CristianÎncă nu există evaluări

- RA 002 - LPSG Steam Pipe Hot Work in ERDocument6 paginiRA 002 - LPSG Steam Pipe Hot Work in ERdassi99Încă nu există evaluări

- PTSB (Jsa Form)Document5 paginiPTSB (Jsa Form)hanujaÎncă nu există evaluări

- Confined Space Entry For Painting Inside PontoonDocument4 paginiConfined Space Entry For Painting Inside PontoonAchalere Shekhar KashinathÎncă nu există evaluări

- Loto Implementation Procedure Plan PDFDocument18 paginiLoto Implementation Procedure Plan PDFgilÎncă nu există evaluări

- Cold Cutting PDFDocument9 paginiCold Cutting PDFAshraf BottaniÎncă nu există evaluări

- 3S HSE MS Docs ContentDocument85 pagini3S HSE MS Docs Contentrashid zamanÎncă nu există evaluări

- Chemical Manifest and Hazardous Chemical Substance List KathuDocument13 paginiChemical Manifest and Hazardous Chemical Substance List KathuVictorÎncă nu există evaluări

- Photo Taking JHADocument4 paginiPhoto Taking JHAMohd Hakiem Zazali100% (2)

- 9.0 HSSE Risk ManagementDocument10 pagini9.0 HSSE Risk Managementsinghal.ns4497Încă nu există evaluări

- Risk Assessment No. 48 USE OF ELECTRICITY Rev. 02 28.12.09Document1 paginăRisk Assessment No. 48 USE OF ELECTRICITY Rev. 02 28.12.09Devi Ratna Pratiwi0% (1)

- 6 - 2.emergency Drill Record Form - ExampleDocument1 pagină6 - 2.emergency Drill Record Form - ExampleJaijeev PaliÎncă nu există evaluări

- JSA Formet New Structural Steel FabricationDocument7 paginiJSA Formet New Structural Steel Fabricationsakthi venkatÎncă nu există evaluări

- STC5 Risk Management and Safe Work ProcedureDocument36 paginiSTC5 Risk Management and Safe Work ProcedureDenise Isebella LeeÎncă nu există evaluări

- Cold Work Permit New PDFDocument2 paginiCold Work Permit New PDFNazzta allezÎncă nu există evaluări

- HSE Exception Request Form Rev.1Document1 paginăHSE Exception Request Form Rev.1Dhimaz YudiÎncă nu există evaluări

- Job Hazard Analysis (Jha) Worksheet: Installation/Facility Job Activity Location Description of Activity NoteDocument3 paginiJob Hazard Analysis (Jha) Worksheet: Installation/Facility Job Activity Location Description of Activity NoteganeshkanthÎncă nu există evaluări

- Jsa Welding & Gas CuttingDocument3 paginiJsa Welding & Gas CuttingM M PRADHANÎncă nu există evaluări

- Visible Safety and Induction: Hse Management Visit ChecklistDocument6 paginiVisible Safety and Induction: Hse Management Visit ChecklistHARSHALÎncă nu există evaluări

- Ra02 - Container OffloadingDocument3 paginiRa02 - Container OffloadingSamÎncă nu există evaluări

- 6.2 - Hsse Risk ManagementDocument27 pagini6.2 - Hsse Risk ManagementNwekeNwokomaAugustineÎncă nu există evaluări

- Tanker ChecklistDocument3 paginiTanker ChecklistRoshan PandeyÎncă nu există evaluări

- RA Folder Jan 12Document83 paginiRA Folder Jan 12mouben100% (2)

- Jsa For Piping and Erection RevisedDocument1 paginăJsa For Piping and Erection RevisedDr AnwarÎncă nu există evaluări

- Risk Ass - ProcessDocument4 paginiRisk Ass - ProcessBalakrishnan Sivagnanam SÎncă nu există evaluări

- RA Templates ElectricalDocument17 paginiRA Templates ElectricalAbid MujtabaÎncă nu există evaluări

- JSA - Blasting - EXTERNALDocument13 paginiJSA - Blasting - EXTERNALAzad pravesh khanÎncă nu există evaluări

- 20070301-30 Safe Use of Oxygen Fuel Gas Equipment PDFDocument4 pagini20070301-30 Safe Use of Oxygen Fuel Gas Equipment PDFkalyan1990Încă nu există evaluări

- 03.JSA - Confined Space EntryDocument1 pagină03.JSA - Confined Space Entryr0shÎncă nu există evaluări

- JSA Chemicals CleaningDocument2 paginiJSA Chemicals CleaningVijay RajaindranÎncă nu există evaluări

- Safe Work Procedure BulletinDocument2 paginiSafe Work Procedure BulletinAndreas 'gondez' Siallagan100% (1)

- Job Hazard Analysis (Jha) Worksheet: Body Injury 2 2 4 1 1 1 AcceptableDocument2 paginiJob Hazard Analysis (Jha) Worksheet: Body Injury 2 2 4 1 1 1 Acceptableganeshkanth0% (1)

- JHA Vessel EntryDocument2 paginiJHA Vessel EntryRiyadh SalehÎncă nu există evaluări

- JSA For Hydrojetting (Gun With Rigid Lance) at Jetting YardDocument23 paginiJSA For Hydrojetting (Gun With Rigid Lance) at Jetting YardSHAH NAWAZ SAEEDÎncă nu există evaluări

- Risk Assess - 98-Installation Fuel Oil ConditioniDocument4 paginiRisk Assess - 98-Installation Fuel Oil ConditioniRochdi BahiriÎncă nu există evaluări

- Risk Assessment For Sand Blasting PDFDocument8 paginiRisk Assessment For Sand Blasting PDFOvais FarooqÎncă nu există evaluări

- Cold Work PermitDocument11 paginiCold Work PermitMuneeb Ur Rehman100% (1)

- Hot WorkDocument20 paginiHot WorkmarceloÎncă nu există evaluări

- JSA #34 - N2 PurgingDocument1 paginăJSA #34 - N2 PurgingHelza RahmanniaÎncă nu există evaluări

- Jsa FormDocument3 paginiJsa Formmiaicarba100% (1)

- R1937-JSA-003 Job Safety Analysis For TrenchingDocument5 paginiR1937-JSA-003 Job Safety Analysis For TrenchingVineet AgrawalÎncă nu există evaluări

- JSA M36 Hydro Testing Spool Pieces & PipeworkDocument4 paginiJSA M36 Hydro Testing Spool Pieces & PipeworkMianÎncă nu există evaluări

- Lifting Hoisting Hazard HuntDocument1 paginăLifting Hoisting Hazard Hunt曹庆园100% (1)

- Adverse Weather PolicyDocument10 paginiAdverse Weather Policyvlad100% (1)

- JSA-Site Acceptance Test of 33 KV Feeders After Replacing Existing Relay by IEC61850 Facility RelayDocument9 paginiJSA-Site Acceptance Test of 33 KV Feeders After Replacing Existing Relay by IEC61850 Facility Relayfrancis_e_tan100% (2)

- Mid West Ports Authority 4.6 Working On, Over or Near WaterDocument9 paginiMid West Ports Authority 4.6 Working On, Over or Near Waterqualiman1Încă nu există evaluări

- High H2S Content in Bunker Risk AssessmentDocument5 paginiHigh H2S Content in Bunker Risk AssessmentCharalampos ChatzivasileiouÎncă nu există evaluări

- RA For Hydrostatic Pneumatic-Test and Flushing of Pipeline and Equipment - 17Document9 paginiRA For Hydrostatic Pneumatic-Test and Flushing of Pipeline and Equipment - 17alla malik100% (1)

- Lifting Equipment PDFDocument2 paginiLifting Equipment PDFcityofdarwingisÎncă nu există evaluări

- Risk AssessmentDocument3 paginiRisk Assessmentkamil100% (1)

- Conversion Table For PressureDocument4 paginiConversion Table For Pressuredassi99Încă nu există evaluări

- Conversion Table For PressureDocument4 paginiConversion Table For Pressuredassi99Încă nu există evaluări

- Piezoelectricity:: Principle Knock SensorsDocument1 paginăPiezoelectricity:: Principle Knock Sensorsdassi99Încă nu există evaluări

- JAN 701B HandoutsDocument22 paginiJAN 701B Handoutsdassi990% (1)

- Owners' Damages For Repudiation by CharterersDocument16 paginiOwners' Damages For Repudiation by Charterersdassi99Încă nu există evaluări

- 06 - Major Alarm& Safety of 50DF With UNIC (DNV)Document16 pagini06 - Major Alarm& Safety of 50DF With UNIC (DNV)dassi99100% (1)

- WISE Cargo User Manual - Ver 6 (A4)Document36 paginiWISE Cargo User Manual - Ver 6 (A4)dassi9950% (2)

- Calculating Damages by Clive AstonDocument10 paginiCalculating Damages by Clive Astondassi99100% (1)

- The Law of Shipbuilding Contracts - PART 1 The Nature of The Shipbuilding ContractDocument3 paginiThe Law of Shipbuilding Contracts - PART 1 The Nature of The Shipbuilding Contractdassi99Încă nu există evaluări

- College of Nursing: Cebu Normal UniversityDocument5 paginiCollege of Nursing: Cebu Normal UniversityChelsea WuÎncă nu există evaluări

- SigmazincDocument8 paginiSigmazincHaresh BhavnaniÎncă nu există evaluări

- Anti-Aromatase Activity of Phytochemicals in White Button Mushrooms (Agaricus Bisporus)Document10 paginiAnti-Aromatase Activity of Phytochemicals in White Button Mushrooms (Agaricus Bisporus)Nimra Naveed ShaikhÎncă nu există evaluări

- Bab 4 ObjektifDocument9 paginiBab 4 ObjektifFida NordinÎncă nu există evaluări

- GATE-2018 - Mechanical Engineering Online Test Series ENGINEERING THERMODYNAMICSDocument10 paginiGATE-2018 - Mechanical Engineering Online Test Series ENGINEERING THERMODYNAMICSDebashis NayakÎncă nu există evaluări

- CE4105 Surface Production Operations: Operasi Produksi Permukaan Hidrokarbon / Operasi Hulu Minyak Dan GasDocument41 paginiCE4105 Surface Production Operations: Operasi Produksi Permukaan Hidrokarbon / Operasi Hulu Minyak Dan GasRickyWisaksonoÎncă nu există evaluări

- National Core Manual - Chapter 5 Pesticide Hazards and First AidDocument55 paginiNational Core Manual - Chapter 5 Pesticide Hazards and First AidMarvinGarciaÎncă nu există evaluări

- RNA Structure, Functions WebDocument25 paginiRNA Structure, Functions WebEmad ManniÎncă nu există evaluări

- Pe Fir Handbook 1 2Document237 paginiPe Fir Handbook 1 2Salman JoÎncă nu există evaluări

- HTT 45 CableDocument1 paginăHTT 45 CableKoel DeyÎncă nu există evaluări

- Drill String Checklist 1 - IPMDocument3 paginiDrill String Checklist 1 - IPMEmre CengizÎncă nu există evaluări

- Biodegradable Wastes: Hospital WasteDocument4 paginiBiodegradable Wastes: Hospital WasteFAIZA A PASCUALÎncă nu există evaluări

- 1 - Toxic GasesDocument19 pagini1 - Toxic GasesxIRONxWOLFxÎncă nu există evaluări

- SERVO Cut S - PDSDocument1 paginăSERVO Cut S - PDSVENKATÎncă nu există evaluări

- Ramabulana Et Al. 2021 MN and MetPA - Chemical Space of Four Momordica Plant SpeciesDocument15 paginiRamabulana Et Al. 2021 MN and MetPA - Chemical Space of Four Momordica Plant SpeciesFernanda SantosÎncă nu există evaluări

- The Birth of The Lithium-Ion BatteryDocument4 paginiThe Birth of The Lithium-Ion Batterytamilmuthu100% (1)

- Finals ReviewerDocument5 paginiFinals ReviewerARIAR, Jyllianne Kyla C.Încă nu există evaluări

- 0653 - w12 - QP - 11 (Combined)Document20 pagini0653 - w12 - QP - 11 (Combined)MCHÎncă nu există evaluări

- Experilab Breinwave: Bubble BlowersDocument4 paginiExperilab Breinwave: Bubble BlowersHirenkumarÎncă nu există evaluări

- Energy Brochure 26-04-2012Document6 paginiEnergy Brochure 26-04-2012michaelvillameÎncă nu există evaluări

- Identification of CarbohydratesDocument2 paginiIdentification of CarbohydratesChristine Pearl Po0% (2)

- Brochures WSM2-Y PDFDocument16 paginiBrochures WSM2-Y PDFkunkzÎncă nu există evaluări

- High Risk Medication PolicyDocument44 paginiHigh Risk Medication PolicyDewi Ratna SariÎncă nu există evaluări

- For NAT Review Earth and Life ScienceDocument2 paginiFor NAT Review Earth and Life ScienceKier CorbitaÎncă nu există evaluări

- Solutios, Solutions of Non Electrolyte - 2019-2020 v2Document80 paginiSolutios, Solutions of Non Electrolyte - 2019-2020 v2hazo hazÎncă nu există evaluări