Documente Academic

Documente Profesional

Documente Cultură

Section 4 - Masonry Works PDF

Încărcat de

ادزسر بانديكو هادولهDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Section 4 - Masonry Works PDF

Încărcat de

ادزسر بانديكو هادولهDrepturi de autor:

Formate disponibile

QIP Under the CCDP-B

Technical Specifications

SECTION 4.0: MASONRY

4.1

Scope of Work

The work includes furnishing and placing of concrete masonry units in conformity

with the lines, grades and cross-sections shown on the drawings and in

accordance with the specifications.

4.2

Applicable Documents

The latest edition of the following specifications and standards shall form part of

this specification to the extent required by the references thereto.

4.3

ASTM

America Society for Testing Materials

C144

Standard Specifications for Aggregate for Masonry Mortar

PSA

Product Standards Agency Publications (Philippines)

PNS 16

Specification for Concrete Hollow Blocks

Materials Requirements

4.3.1

Concrete Hollow Blocks

Concrete hollow blocks shall be a standard product of recognized

manufacturer to PNS 16, as indicated on the drawings. Exterior and

interior masonry units shall be non load-bearing units. However, loadbearing units maybe provided in lieu of non-load bearing units. For load

bearing units, the required compressive strength, shall be

Be 25 kg/cm2 or 2.48 Mpa.

4.3.2

Louver Decorative Blocks

Louver decorative blocks shall be of a standard product of recognized

manufacturer subject to the approval of the Project manager as qualify,

design, dimension and finish.

4.3.3

Cement, Reinforcing Steel, and Water

Cement, reinforcing steel, and water shall be as specified in Section

3.0.

4.4

Construction Requirements

4.4.1

Workmanship

1 of 5

QIP Under the CCDP-B

Technical Specifications

Masonry walls shall be placed level and plumb all around. One section

of the walls shall not be placed in advance of the others, unless

specifically approved. Unfinished work shall be stepped back for

joining with new work; tooting shall not be permitted. Heights of

masonry shall be checked with an instrument at sills and heads of

openings to maintain the level of the walls. Door and window frames,

louvered openings, anchors, pipes, and conduits shall be installed in

carefully and neatly as the masonry work progresses. Spaces around

doorframes shall be filled solidly with mortar. Drilling, cutting fitting and

patching, to accommodate the work of others, shall be performed by

skilled workers. Bolts, anchors, inserts, plugs, ties, and miscellaneous

metal work specified elsewhere shall be placed in position as the work

progress. Chases of approved dimensions for pipes and other

purposes shall be provided, where indicated or necessary. Top of

exposed walls and partitions, not being worked on, shall be covered

with a waterproof membrane, well secured in place. Walls and

partitions shall be structurally bonded or anchored to each and to

concrete wall beams, and columns.

4.4.2

Mortar Mixing

Mortar materials shall be measured in approved containers to insure

that the specified proportions of materials are controlled and accurately

maintained during the progress of the work. Unless specified otherwise,

mortar shall be mixed in proportions by volume. The aggregates shall

be introduced and mixed in such a manner that the materials will be

distributed uniformly throughout the mass. A sufficient amount of water

shall be added gradually and the mass further mixed, not less than 3

minutes, until a mortar of the plasticity required for the purpose intended

shall obtained. The mortar shall be mixed in a manner such that the

quality of water can be controlled accurately and uniformly. Mortar

boxes, pans of mixing drums shall be kept clean and free of debris or

dried mortar. The mortar shall be used before the initial setting of the

cement has taken place; retempering of mortar in which cement has

started to set shall not be permitted.

4.4.3

Proportion of Mortar Grout

Fine mortar grout shall be mixed in the volumetric proportion of one part

Portland cement part hydrated lime and 3 parts sand. Coarse grout

shall be mixed in proportion of one part Portland cement, part

hydrated lime, 3 parts sand and 3 parts pea gravel 3/8 inch sieve.

4.4.4

Use of Fine Coarse Grout

Fine grout shall be used in grout spaces less than 50 mm in any

horizontal dimension or when clearance between reinforcement and

masonry unit is less than 17 mm. Coarse grout shall be used in grout

spaces more than 50 mm in all horizontal dimensions or where

clearance between the reinforcement and masonry is more than 17 mm.

2 of 5

QIP Under the CCDP-B

4.4.5

Technical Specifications

Mortar Joints

Mortar joints shall be uniform in thickness, and the average thickness of

any three consecutive joints shall be 9.50 mm. Gage rods shall be

made and approved prior to starting the work and shall be used

throughout the work. Changes in coursing or bonding after the work

has started shall no be permitted. The jointer shall be slightly larger

than the width of the joints, so that complete contact is made along the

edge of the units, compressing and sealing the surface of the joint.

Joints in masonry, which will not be exposed, shall be struck flush.

Joints shall be brushed to remove all loose and excess mortar, All

horizontal joints shall be on level and vertical joints shall be plumbed

and aligned from the top to the bottom of the wall with a tolerance of

plus or minus 12 mm.

4.4.6

Concrete Masonry Unit

The first course of concrete masonry unit shall be laid in full bed of

mortar, for the full width of the unit; the succeeding courses shall be laid

with broken joints. Concrete masonry units with the cells verticals shall

have bed-joints formed by applying the mortar of a width of about 25

mm to the ends of the adjoining units laid previously. The mortar for

joints shall be smooth, not furrowed, and shall be of such thickness that

it will be forced out of joints as the units are being placed in position.

Where anchors, bolts, ties and reinforcing bars occur within the cell of

the units, such cells shall be solidly filled with mortar or grout as the

work progresses.

4.4.7

Reinforcement

Horizontal tie reinforcement shall be provided where indicated.

Reinforcement shall be continuous and provided in the longest available

lengths. Reinforcement shall be continuous and provided in the longest

available lengths. Reinforcement above and below openings shall

extend and be embedded into the columns, unless otherwise shown on

the drawings.

Splices shall overlap not less than 150 mm.

Reinforcement shall be embedded in the mortar joints in the manner

that all parts shall be protected by mortar. The two top courses of filler

block walls shall have their cores filled with grout when placed in

position.

Unless otherwise shown on the drawings, the size and spacing of bars

shall be as follows:

For Vertical Bars:

150 mm (6) CHB

12mm (1/2) dia. at 600 mm

(24) on centers

3 of 5

QIP Under the CCDP-B

Technical Specifications

100 mm (4) CHB

10 mm (3/8) dia. at 600 mm

For Horizontal bars:

12mm (1/2) dia. At 600 mm

(24) on center (every third

Course) for 150 mm

(6) and 100 m (4) CHBs.

4.4.8

Bounding and anchoring

Masonry walls and partitions shall be accurately anchored or bonded at

points where they intersect, and they about or adjoin the concrete frame

of building. All anchors shall be completely embedded in mortar.

4.4.9

Grout Placement

Grout shall be performed on the interior side of wall, except as

approved otherwise, Sills, ledges, offsets and other surfaces to be left

exposed shall be protected form grout falling on such surfaces and be

and shall be removed immediately. Grout shall be stirred before placing

to avoid segregation of the aggregate and shall be sufficiently fluid to

flow into joints and around the reinforcement without leaving any voids.

Grout shall be placed by pumping or pouring from buckets equipped

with spouts, in lifts not exceeding 1.2 meters high. Grout shall be

puddle thoroughly to eliminate voids without displacing the masonry

units from its original position. Masonry units displaced by the grouting

operation shall be removed and relaid to its proper alignment using

fresh mortar grout.

4.4.10

Tests and Test Reports

The testing requirements stated herein or incorporated in referenced

contract documents may be waived provided certified copies of report of

tests from approved laboratories performed on previously manufactured

materials are submitted and approved.

Test reports shall be

accompanied by notarized copies from the manufacturer certifying that

the previously tested material is of the same type, quality manufacture,

and make as those proposed of this project.

4.5

Method of Measurement and Basis of Payment

4.5.1

Method of Measurement

In measuring the quality of masonry units for payments, the

dimensions to be used shall be as shown on the plans or as directed

by the Procuring Entitys Representatves in writing. Projections

extended beyond the faces of the wall shall not be included. The area

to be paid for under this section shall be the number of square meters

4 of 5

QIP Under the CCDP-B

Technical Specifications

of concrete masonry wall and partition placed and accepted in

accordance with the plans and specifications.

Payment of accomplished work, shall be deemed to include the cost of

mortar grout, reinforcing steel, tie wires, false work and other

necessary works to complete this item.

4.5.2

Basis of Payment

The quantity of concrete masonry wall and partition determined as

provided in Sub-Section 4.5.1, Measurements, shall be paid for at the

contract unit price shown in the bid schedule, which payment shall be

full compensation for furnishing and placing all materials, labor,

equipment, tools and incidentals necessary to complete work.

5 of 5

S-ar putea să vă placă și

- Lecture Notes on Reinforced Concrete DesignDe la EverandLecture Notes on Reinforced Concrete DesignÎncă nu există evaluări

- Design Criteria 02Document1 paginăDesign Criteria 02cindy_dlpÎncă nu există evaluări

- CE 552 Lecture 9 Reinforced Concrete Column DesignDocument29 paginiCE 552 Lecture 9 Reinforced Concrete Column DesignKeyvin dela CruzÎncă nu există evaluări

- Lec 6 Analysis of PrecipitationDocument43 paginiLec 6 Analysis of PrecipitationumairÎncă nu există evaluări

- Review of Related LiteratureDocument10 paginiReview of Related LiteratureRhea MunozÎncă nu există evaluări

- Summary of Punchlist Need To Closed OutDocument7 paginiSummary of Punchlist Need To Closed OutJan Lawrence Alberto100% (1)

- Construction cost estimate for grouted riprap projectDocument5 paginiConstruction cost estimate for grouted riprap projectcarlomaderazoÎncă nu există evaluări

- Textbook For CMT (Asphalt, Wood, & Steel)Document15 paginiTextbook For CMT (Asphalt, Wood, & Steel)vincelordÎncă nu există evaluări

- Gaddani Covered CourtDocument136 paginiGaddani Covered CourtErnestÎncă nu există evaluări

- Mvuc Revised Final 02Document7 paginiMvuc Revised Final 02Dexter G. BatalaoÎncă nu există evaluări

- DO 037 s2016 PDFDocument13 paginiDO 037 s2016 PDFKaren Balisacan Segundo RuizÎncă nu există evaluări

- Preparation of POWs and Estimates for Engineering Equipment Rental RatesDocument1 paginăPreparation of POWs and Estimates for Engineering Equipment Rental RatesreynoldÎncă nu există evaluări

- Hauling & Disposal of Unsuitable Materials EstimateDocument2 paginiHauling & Disposal of Unsuitable Materials EstimatereynoldÎncă nu există evaluări

- DPWH Standard Specifications for Non-Structural Metal FramingDocument8 paginiDPWH Standard Specifications for Non-Structural Metal FramingleovorigÎncă nu există evaluări

- Sampling Aggregates Lab ManualDocument8 paginiSampling Aggregates Lab ManualJoshua CalaÎncă nu există evaluări

- Worksheet For Design of Concrete Mix: Type 1 Portland CementDocument2 paginiWorksheet For Design of Concrete Mix: Type 1 Portland CementLuis PacquiaoÎncă nu există evaluări

- 18PO0040 CCS and DUPADocument37 pagini18PO0040 CCS and DUPARheyJun Paguinto AnchetaÎncă nu există evaluări

- Araldite PW 1036 Hardener HW 1036: Product Data SheetDocument4 paginiAraldite PW 1036 Hardener HW 1036: Product Data SheetAhmed HusseinÎncă nu există evaluări

- Megawide Precast PlantDocument21 paginiMegawide Precast PlantPaolo ManansalaÎncă nu există evaluări

- Column Design/Analysis Software: (Based On The NSCP 2015 Code)Document2 paginiColumn Design/Analysis Software: (Based On The NSCP 2015 Code)Gelbert SilotÎncă nu există evaluări

- Two Storey Structural DesignDocument9 paginiTwo Storey Structural Designking taugÎncă nu există evaluări

- Rehabilitation of Alegria - Mabuhay FTMRDocument3 paginiRehabilitation of Alegria - Mabuhay FTMRKerwin Jay CondorÎncă nu există evaluări

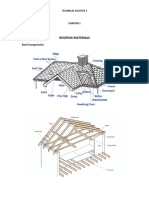

- Roofing Materials: Roof ComponentsDocument17 paginiRoofing Materials: Roof ComponentsMero Mero100% (1)

- DPWH Standard Specification For Carbon Fiber, Item 416.Document8 paginiDPWH Standard Specification For Carbon Fiber, Item 416.jay_medrano_1Încă nu există evaluări

- Code of Ethics for Civil EngineersDocument38 paginiCode of Ethics for Civil EngineersJEAN KATHLEEN SORIANOÎncă nu există evaluări

- Design of TerminalDocument77 paginiDesign of TerminalJohn Cedric SatojetoÎncă nu există evaluări

- DPWH Do - 044 - S2012Document12 paginiDPWH Do - 044 - S2012theengineer3Încă nu există evaluări

- Timber and Metal Formworks and Scaffolds Materials Price List - PHILCON PRICESDocument4 paginiTimber and Metal Formworks and Scaffolds Materials Price List - PHILCON PRICESjohn reyesÎncă nu există evaluări

- DPWH Standard Specification On:: Compaction and StabilizationDocument30 paginiDPWH Standard Specification On:: Compaction and StabilizationAldever BretanaÎncă nu există evaluări

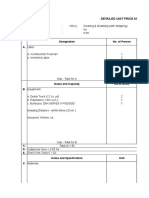

- Unit Price AnalysisDocument5 paginiUnit Price AnalysisSasanka T WijesingheÎncă nu există evaluări

- Residential Building Project Gantt ChartDocument3 paginiResidential Building Project Gantt ChartJoe Mark AvilaÎncă nu există evaluări

- Bsge Feati PDFDocument5 paginiBsge Feati PDFkupaloidÎncă nu există evaluări

- 05 Hollow Core Ferrocement ProjectDocument19 pagini05 Hollow Core Ferrocement ProjectDeo NievesÎncă nu există evaluări

- Mock Quiz Solution Key PDFDocument20 paginiMock Quiz Solution Key PDFLong Live TauÎncă nu există evaluări

- Mdterm Comprehensive QuizDocument2 paginiMdterm Comprehensive QuizMac KYÎncă nu există evaluări

- List of Bridge Completed by DPWH From 2014 - 2018Document87 paginiList of Bridge Completed by DPWH From 2014 - 2018Rappler100% (1)

- Item 1018Document5 paginiItem 1018Ester MarianÎncă nu există evaluări

- Road Construction 2015Document928 paginiRoad Construction 2015Karen Balisacan Segundo RuizÎncă nu există evaluări

- Civil Engineer Fee ScheduleDocument7 paginiCivil Engineer Fee Schedulefranz anthonyÎncă nu există evaluări

- 02 - DILG - Salintubig - Components of Water Supply SystemDocument43 pagini02 - DILG - Salintubig - Components of Water Supply SystemTarhata KalimÎncă nu există evaluări

- DPWH Standard Specification for Coconut Bio-Engineering SolutionsDocument8 paginiDPWH Standard Specification for Coconut Bio-Engineering SolutionsWilliamÎncă nu există evaluări

- Bridge Construction Methodology DPWH TARLAC 1ST DEODocument19 paginiBridge Construction Methodology DPWH TARLAC 1ST DEOSam100% (1)

- 02 PDFDocument319 pagini02 PDFHarot StyleshÎncă nu există evaluări

- Overview+Soil Quiz 1Document241 paginiOverview+Soil Quiz 1Elmer Cabulisan JrÎncă nu există evaluări

- Proposed Two (2) Storey, Three (3) Units Residential: Lot 1, Block 277, Lilac Cor. Kilyawan, Rizal, Makati City: Bonifacio RectoDocument2 paginiProposed Two (2) Storey, Three (3) Units Residential: Lot 1, Block 277, Lilac Cor. Kilyawan, Rizal, Makati City: Bonifacio RectoJonathanEncisa100% (1)

- CHB 125mmDocument2 paginiCHB 125mmKatrina NanoÎncă nu există evaluări

- X'WELL Company Profile 2017Document35 paginiX'WELL Company Profile 2017francis pacaigueÎncă nu există evaluări

- P'R 1 Dp"Jt-I : Republic of The PhilippinesDocument5 paginiP'R 1 Dp"Jt-I : Republic of The PhilippinesjrsiaseÎncă nu există evaluări

- Review of Agricultural Waste Utilization As Improvement Additives For Residual Tropical SoilsDocument17 paginiReview of Agricultural Waste Utilization As Improvement Additives For Residual Tropical SoilsAZOJETE UNIMAIDÎncă nu există evaluări

- Tile Works Reyes EstimatesDocument4 paginiTile Works Reyes EstimatesVicent John ParedesÎncă nu există evaluări

- Soil InvestigationDocument45 paginiSoil InvestigationMelano ArjayÎncă nu există evaluări

- Bid Documents PDFDocument133 paginiBid Documents PDFCaitlin Elise O. CornelÎncă nu există evaluări

- REVISED PERT/CPM TIME-SCALED NETWORK DIAGRAM FOR MARCOS BRIDGE REHABILITATION PHASE IIDocument1 paginăREVISED PERT/CPM TIME-SCALED NETWORK DIAGRAM FOR MARCOS BRIDGE REHABILITATION PHASE IIThortheGreayÎncă nu există evaluări

- DPWH PPP PresentationDocument18 paginiDPWH PPP PresentationPPPnewsÎncă nu există evaluări

- Philippines timber design standards overviewDocument4 paginiPhilippines timber design standards overviewKhale Kyrzhal RamirezÎncă nu există evaluări

- SLAB DESIGN FOR M25 CONCRETE AND FE415 STEELDocument3 paginiSLAB DESIGN FOR M25 CONCRETE AND FE415 STEELuttamÎncă nu există evaluări

- 6 6-PurlinsDocument12 pagini6 6-PurlinsRyan Bacus BautistaÎncă nu există evaluări

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985De la EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985Încă nu există evaluări

- Foundation: It Includes Cast-In Place Concrete FoundationsDocument11 paginiFoundation: It Includes Cast-In Place Concrete FoundationsAnonymous ze9ag1Încă nu există evaluări

- Method Statement for Concrete WorksDocument7 paginiMethod Statement for Concrete WorksJeffrey WeyÎncă nu există evaluări

- Office Lease: Premises: Office NO.: Landlord: TenantDocument6 paginiOffice Lease: Premises: Office NO.: Landlord: Tenantادزسر بانديكو هادولهÎncă nu există evaluări

- Office Space Lease ContractDocument1 paginăOffice Space Lease Contractادزسر بانديكو هادولهÎncă nu există evaluări

- PlumbingDocument34 paginiPlumbingادزسر بانديكو هادولهÎncă nu există evaluări

- Basic Plumbing SymbolsDocument1 paginăBasic Plumbing SymbolsBrandon Borromeo75% (4)

- Plumbing Questionnaire 2Document51 paginiPlumbing Questionnaire 2mcpayod100% (1)

- Plumbing Continuing Education TestDocument14 paginiPlumbing Continuing Education TestCarlito PantalunanÎncă nu există evaluări

- Sizing of Water HeatersDocument40 paginiSizing of Water Heatersادزسر بانديكو هادوله100% (1)

- Plumbing Test Guides - Sample QuestionsDocument10 paginiPlumbing Test Guides - Sample QuestionsJeff D. AgustinÎncă nu există evaluări

- What Is A Fire ExtinguisherDocument1 paginăWhat Is A Fire ExtinguisherAsith KashyapÎncă nu există evaluări

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Plumbing ToolsDocument24 paginiPlumbing ToolsHarold Abubo Haber100% (4)

- Plumbing & SanitaryDocument25 paginiPlumbing & SanitaryRap PinedaÎncă nu există evaluări

- Pipe SizingDocument8 paginiPipe SizingJer Si100% (3)

- SANITARY SCIENCE BUILDINGSDocument12 paginiSANITARY SCIENCE BUILDINGSVholts Villa Vitug71% (7)

- Plumbing ReviewerDocument17 paginiPlumbing Reviewerادزسر بانديكو هادولهÎncă nu există evaluări

- Preboard 4 Practical Problem PDFDocument8 paginiPreboard 4 Practical Problem PDFادزسر بانديكو هادولهÎncă nu există evaluări

- Plumbing Practice QuestionsDocument9 paginiPlumbing Practice QuestionsJacky Lynne Regis Agustin100% (2)

- Plumbing ExamDocument218 paginiPlumbing ExamJhobs BesmonteÎncă nu există evaluări

- Master Plumbing Reviewer 2010-2012Document144 paginiMaster Plumbing Reviewer 2010-2012Ysai92% (12)

- PLUMBING CODE QuestionDocument20 paginiPLUMBING CODE Questionادزسر بانديكو هادولهÎncă nu există evaluări

- Master PlumberDocument47 paginiMaster PlumberMark Anthony Olinares83% (18)

- Plumbing 2Document35 paginiPlumbing 2Daryl Gomez TimatimÎncă nu există evaluări

- Plumbing-CodeDocument33 paginiPlumbing-CodeTon Ton Bonda100% (3)

- Module 1 - Water & Human NeedsDocument30 paginiModule 1 - Water & Human NeedsTon Ton BondaÎncă nu există evaluări

- Module 2 - Public Water SupplyDocument26 paginiModule 2 - Public Water SupplyTon Ton Bonda100% (1)

- Preboard - 2 - Sanitation, DesignDocument7 paginiPreboard - 2 - Sanitation, Designimanolkio88% (8)

- RMP Sample QuestionsDocument14 paginiRMP Sample QuestionsJenny-Rose Olaer CabayacruzÎncă nu există evaluări

- Preboard - 1 - Plumbing ArithmeticDocument8 paginiPreboard - 1 - Plumbing Arithmeticimanolkio92% (26)

- Preboard - 3 - Plumbing CodeDocument8 paginiPreboard - 3 - Plumbing Codeimanolkio67% (6)

- Master Plumbing Review NotesDocument29 paginiMaster Plumbing Review Notesmcpayod100% (3)

- App B3-DEWA Tech & STD SpecsDocument2 paginiApp B3-DEWA Tech & STD SpecsanooppattazhyÎncă nu există evaluări

- Grouting On Sandy SoilDocument48 paginiGrouting On Sandy SoilSabari PrasanthÎncă nu există evaluări

- CEMLATEX GIUNTI TDS English Rev03Document2 paginiCEMLATEX GIUNTI TDS English Rev03Sunny RohillaÎncă nu există evaluări

- Masterinject - 1333-Asean-V3-1115Document2 paginiMasterinject - 1333-Asean-V3-1115Sunny RohillaÎncă nu există evaluări

- Handbook On Retrofitting of Existing BuildingDocument38 paginiHandbook On Retrofitting of Existing BuildingRahish RaviÎncă nu există evaluări

- Product DescriptionDocument8 paginiProduct DescriptionPatrisha SantosÎncă nu există evaluări

- Helifix Crack StitchingDocument2 paginiHelifix Crack Stitchingneel12321Încă nu există evaluări

- 09 30 00 TilingDocument4 pagini09 30 00 TilingshajbabyÎncă nu există evaluări

- High Early Strength Non-Metallic Non-Shrink Grout Data SheetDocument1 paginăHigh Early Strength Non-Metallic Non-Shrink Grout Data SheetvasantsunerkarÎncă nu există evaluări

- Grouting FundamentalsDocument66 paginiGrouting FundamentalsNurali MamenÎncă nu există evaluări

- Thinset and Grout Coverage GuideDocument2 paginiThinset and Grout Coverage GuidemichelleÎncă nu există evaluări

- Chemrite Tile Grout YC 802Document3 paginiChemrite Tile Grout YC 802ICPL-RWPÎncă nu există evaluări

- Appendix 2 - Arch'l Specs 20220810 (MSL-00086) To LRMC (F1, F2, F8, & W5) PDFDocument14 paginiAppendix 2 - Arch'l Specs 20220810 (MSL-00086) To LRMC (F1, F2, F8, & W5) PDFJpbÎncă nu există evaluări

- Vol - I (Hippo)Document29 paginiVol - I (Hippo)jeevanÎncă nu există evaluări

- RF Buildings SOR 2009-10-CIVIL PDFDocument93 paginiRF Buildings SOR 2009-10-CIVIL PDFdoosanapudi mounika naidu dmonÎncă nu există evaluări

- Mapei - 141-Kerapoxy-G9 PDFDocument6 paginiMapei - 141-Kerapoxy-G9 PDFLee WenjianÎncă nu există evaluări

- 0012-wms For Wall & Floor TilesDocument7 pagini0012-wms For Wall & Floor TilesRaman Bhadouria100% (1)

- BNBC Part 05 - Building MaterialsDocument91 paginiBNBC Part 05 - Building MaterialsPranoy Barua50% (4)

- Construction of Multi-Purpose Building Tambo, Ayungon, Negros OrientalDocument15 paginiConstruction of Multi-Purpose Building Tambo, Ayungon, Negros OrientalAna Bella RosarioÎncă nu există evaluări

- Non-Shrink Grout Mix PDFDocument4 paginiNon-Shrink Grout Mix PDFAnonymous AJYdboÎncă nu există evaluări

- Sika Top 77Document3 paginiSika Top 77Sushanta Kumar RoyÎncă nu există evaluări

- Compresssive Strength Test Concrete Hollow Block PDFDocument8 paginiCompresssive Strength Test Concrete Hollow Block PDFMohammad Tarequl AlamÎncă nu există evaluări

- Laticrete 252 TDSDocument5 paginiLaticrete 252 TDSDilon FernandoÎncă nu există evaluări

- Cementitious Grout for Ceramic TilesDocument2 paginiCementitious Grout for Ceramic TilesVenkata RaoÎncă nu există evaluări

- Sample Guide Specs - O-CellDocument9 paginiSample Guide Specs - O-CellNaomi PurbaÎncă nu există evaluări

- Recommendations for Structural GroutingDocument6 paginiRecommendations for Structural GroutingwahbiaÎncă nu există evaluări

- Construction of Earth DamDocument53 paginiConstruction of Earth DamMehdi Mir100% (3)

- BOQ - Gurgaon - 25.06.23Document3 paginiBOQ - Gurgaon - 25.06.23Anurag ZullurwarÎncă nu există evaluări

- Guide To Epoxy Grouting: Foundation Preparation FormingDocument2 paginiGuide To Epoxy Grouting: Foundation Preparation FormingerleosÎncă nu există evaluări