Documente Academic

Documente Profesional

Documente Cultură

Gas Suppression System Calculations PDF

Încărcat de

engNorTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Gas Suppression System Calculations PDF

Încărcat de

engNorDrepturi de autor:

Formate disponibile

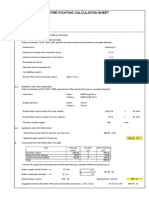

GAS SUPPRESSION SYSTEM CALCULATIONS

The Novec 1230 system is installed in Library and Store & Pharmacy of a hospital.

It provides continued fire protection of the costly medicines and irreplaceable

photographs, books, documents. The contents of the library are protected by this fire

suppression system that does not cause damage while still being environment friendly.

Design calculations for Library area

Step 01: Determine hazard volume

Library volume = 46 (l) x 325 (b) x 10 (h) = 14950 ft

Step 02: Determine Volume of solid, permanent structures, or equipment.

2

Area of each column = 2.42ft

Volume = 2.42 x 10

= 24.2ft

No. of pillars occupying room area = 7

Total Volume = 24.2 x 7 = 169.4 say 170 ft

Step 03: Calculate reduced volume

Reduced volume = Step 1 ans. step 2 ans.

3

= 14950 - 170 = 14780 ft ~ 418.52m

Step 04: Determination of NOVEC 1230 Quantity

Q = V x CF x C Alt

Where

Q = Agent quantity required [kg]

V = Hazard volume [m]

CF = Flooding factor [kg/m]

C Alt = Altitude correction factor

Therefore,

Q = 418.52x 0.5875x 0.90

= 221.29

Hence required agent quantity = say 225Kg

To check the concentration C reached in the hazard the following formula can be

used:

=

+(

100

)

Where,

Q = agent quantity supplied from the system [kg] (at sea level)

V = hazard volume [m]

s = specific vapor volume [m/kg] = 0.0664 + 0.000274 x T (at sea level)

T = max. Hazard temperature [C]

Altitude = 542m

A quantity of 225 kg Novec 1230 has been calculated at an altitude of 542 m.

At sea level this would result in 225 kg / 0.943 = 250 kg Novec

Specific vapour volume(s) for Novec 1230:

Formula:

= 0.0664 + 0.000274

=

40 = 0.077

250 0.0773 100

= 4.41%

418.52 + ( 250 0.0773 )

(Concentration is less than NOAEL* (10%) okay for occupied space)

*No Observed Adverse Effect Level

Step 06: Determination of number and size of tanks required

Nominal

Cylinder

Size

600 lb

900 lb

1000 lb

P/N

20508

20509

20510

Fill Capacity

Minimum

Maximum

lb

Kg

lb

304

137.9

609

455

206.4

910

561

254.5

1000

Empty Weight

Kg

276.2

412.7

453.6

* 75% of max. filling

Tank fill level = actual filling (kg)/max. filling (kg)

1 x 412.7 kg tanks required - filled with 250kg Novec 1230

lb

346

471

766

Kg

157.0

213.6

346.5

Step 07: Determination of number

Number of nozzles:

Total Volume of hazard area / coverage area of each nozzle

360 Pattern: 418.52/ 292 = 1.43 say 2

o

180 Pattern: 418.52/ 146 = 2.86 say 3

Step 08: Pipe Size Estimation

Pipe Type

Pipe Diameter Internal Diameter

Min Flow

(kg/sec)

Max Flow

(kg/sec)

40T

1 mm

15.8

0.454

1.361

40T

20mm

20.93

0.907

2.495

40T

25mm

26.64

1.59

3.855

40T

32mm

35.05

2.72

5.67

40T

40mm

40.89

4.08

9.072

40T

50mm

52.5

6.35

13.61

40T

65mm

62.71

9.072

24.95

40T

80mm

77.93

13.61

40.82

40T

100mm

102.25

24.95

56.7

40T

125mm

128.2

40.82

90.72

40T

150mm

154.05

54.43

136.1

Total quantity = 250 kg Novec 1230 (in 10 s) from 2 nozzles

12.5 kg/s

Find the next higher value in "Max. Flow" column

Estimated Pipe size = 50 mm (2)

Step 09: Pressure Venting

=

Where, A

required free venting area (m)

Novec 1230 flow (kg/s)

specific volume of agent (m/kg)*

max. Allowable pressure increase (Pa) **

VHOM

specific volume of the homogeneous air / Novec

1230 mixture***

c2

resistance coefficient for the opening****

* Use 0.072 m/kg for Novec 1230.

** A value between 100 and 300 Pascals should be used if there is no other value

offered by the client or clients representative.

*** 0.42 is a good average value for 4.2% Novec 1230 concentration.

**** 0.5<c2<1; to simplify the formula, use c2=1

250 kg Novec 1230 to be discharged (within 10 seconds).

Maximum overpressure allowed = 300 Pa.

=

25

0.072

300

4.2

1 = 0.05

Therefore, 0.05 m free venting area is required.

S-ar putea să vă placă și

- NOVEC 1230 Total Flooding System - EGEC Calculations SheetDocument14 paginiNOVEC 1230 Total Flooding System - EGEC Calculations SheetDesigner Forever100% (2)

- Manual - FM 200 Flow CalcDocument102 paginiManual - FM 200 Flow CalcIvan Chan80% (10)

- Fire Sprinkler Design Comparison (R5)Document24 paginiFire Sprinkler Design Comparison (R5)ruzla100% (1)

- Ig-541 Clean Agent (Flooding Quantity Volume Calculation)Document1 paginăIg-541 Clean Agent (Flooding Quantity Volume Calculation)Imran Aziz100% (1)

- Guideline For TSP FM200 Systems Rev8Document12 paginiGuideline For TSP FM200 Systems Rev8binhhnÎncă nu există evaluări

- FM-200 and CO2 Calculation SheetDocument4 paginiFM-200 and CO2 Calculation SheetAMMH100% (1)

- FM200Document6 paginiFM200zshehadehÎncă nu există evaluări

- When Sizing A Water Storage Tank For Exclusive Fire Protection UseDocument4 paginiWhen Sizing A Water Storage Tank For Exclusive Fire Protection UsemengineeringÎncă nu există evaluări

- Hydraulic Calculations ExplainedDocument38 paginiHydraulic Calculations ExplainedJovani G. Ballon100% (4)

- Ig 100Document16 paginiIg 100Rhoderic Radomes JrÎncă nu există evaluări

- Hydraulic sprinkler calculation using Hazen-Williams formulaDocument3 paginiHydraulic sprinkler calculation using Hazen-Williams formulaMiguel Angel Carcamo Ordaz100% (1)

- Simplex 4100ES Operating InstructionsDocument2 paginiSimplex 4100ES Operating InstructionsRaviÎncă nu există evaluări

- Fire Sprinklers Hydraulic CalculationsDocument38 paginiFire Sprinklers Hydraulic CalculationsVerlin Ann LacastesantosÎncă nu există evaluări

- Fire Sprinklers Hydraulic CalculationsDocument38 paginiFire Sprinklers Hydraulic CalculationsMohamed Albana100% (3)

- Fire Sprinkler Hydraulic Calculation SheetDocument2 paginiFire Sprinkler Hydraulic Calculation SheetSameera Lakmal50% (2)

- A Tutorial To Getting Started With FHC: Hydraulic Calculation Software For Water Based Fire Protection SystemsDocument7 paginiA Tutorial To Getting Started With FHC: Hydraulic Calculation Software For Water Based Fire Protection SystemsZaw Moe Khine100% (1)

- SprinkCalc TutorialsDocument170 paginiSprinkCalc Tutorialsmancas500% (1)

- Fm200 CalculationDocument2 paginiFm200 CalculationAlper Türk100% (1)

- Sample Calculation For FM 200 Clean Agent: STEP 1: Determined Room VolumeDocument6 paginiSample Calculation For FM 200 Clean Agent: STEP 1: Determined Room VolumeMohd Zulhairi Mohd Noor100% (8)

- Fire Sprinkler System NFPA 13 Plan Review ChecklistDocument10 paginiFire Sprinkler System NFPA 13 Plan Review ChecklistTanveer Aziz100% (2)

- Battery Load Calculation For 2 Zones Fm200 Panel at TNB Sub Station 2 & Trans 3 & 4Document3 paginiBattery Load Calculation For 2 Zones Fm200 Panel at TNB Sub Station 2 & Trans 3 & 4MFaiz RHamiraÎncă nu există evaluări

- Fire Protection Hydraulic CalculationDocument25 paginiFire Protection Hydraulic CalculationGianKarloSicat100% (5)

- Fire Pump Pressure SettingsDocument2 paginiFire Pump Pressure SettingsJhe Inibam100% (1)

- Design Fire Fighting Systems CO2 CalculationDocument3 paginiDesign Fire Fighting Systems CO2 Calculationantonalmeida100% (1)

- Sprinkler Design ChecklistDocument3 paginiSprinkler Design ChecklistVigneshÎncă nu există evaluări

- Guideline For Ansul Low Pressure Carbon Dioxide Fire Suppression SystemsDocument32 paginiGuideline For Ansul Low Pressure Carbon Dioxide Fire Suppression SystemsAob AprilÎncă nu există evaluări

- FM200 - Technical SpecificationDocument14 paginiFM200 - Technical SpecificationSubharajkÎncă nu există evaluări

- FM200 SpecificationDocument13 paginiFM200 Specificationsechoo100% (2)

- 6special Protection SystemDocument59 pagini6special Protection SystemGurusumiÎncă nu există evaluări

- Hydraulic Calculation FOR Automatic Wet Sprinkler Systems: Design of Plumbing SystemsDocument18 paginiHydraulic Calculation FOR Automatic Wet Sprinkler Systems: Design of Plumbing Systemshrstga100% (1)

- Novec 1230 All CalculationsDocument5 paginiNovec 1230 All CalculationsKhyle Laurenz DuroÎncă nu există evaluări

- NOVEC 1230 Total Flooding System EGEC Calculations SheetDocument4 paginiNOVEC 1230 Total Flooding System EGEC Calculations SheetAbdulqader MousaÎncă nu există evaluări

- Kidde WHDR™ Wet ChemicalFire Suppression SystemDocument292 paginiKidde WHDR™ Wet ChemicalFire Suppression SystemJORGE ENRIQUE ARANGOÎncă nu există evaluări

- Guide For Fire Protection and Detection SystemDocument50 paginiGuide For Fire Protection and Detection SystemGreenbuild ZM-JV100% (1)

- Fire Alarm System Design Guide PDFDocument5 paginiFire Alarm System Design Guide PDFBen MusimaneÎncă nu există evaluări

- FM 200 Datasheet and DesignDocument174 paginiFM 200 Datasheet and DesignRichard Rajkumar0% (1)

- System Design: Total Flooding Extinguishing SystemDocument45 paginiSystem Design: Total Flooding Extinguishing SystemJose Antonio LaraÎncă nu există evaluări

- Water Pressure and Flow FundamentalsDocument46 paginiWater Pressure and Flow FundamentalsBanang Mulia Permana100% (10)

- Foam System CalculationsDocument4 paginiFoam System CalculationsDesigner Forever100% (1)

- Fire Fighting Calculation En-20150403 - NutrecoDocument6 paginiFire Fighting Calculation En-20150403 - NutrecoTrang Ngo100% (3)

- FHC User ManualDocument43 paginiFHC User ManualJosé Carlos Mairena Zumbado0% (1)

- Fire Pump Schedule and Head CalculationsDocument7 paginiFire Pump Schedule and Head CalculationsAry TubagusÎncă nu există evaluări

- FM-200 and CO2 calculation sheet for typical floorsDocument4 paginiFM-200 and CO2 calculation sheet for typical floorsDesigner ForeverÎncă nu există evaluări

- Fully Calculated Firefighting Systems With EN 12845 StandardDocument21 paginiFully Calculated Firefighting Systems With EN 12845 StandardIsidoros Siderakis100% (1)

- Fire Water Curtain DesignDocument2 paginiFire Water Curtain Designkb_pramod89% (9)

- 1 - Test Procedure For FM200 SystemDocument1 pagină1 - Test Procedure For FM200 SystemAli Salman100% (2)

- Calculating fire water requirements and reservoir capacityDocument1 paginăCalculating fire water requirements and reservoir capacityclique67% (6)

- How FPE Determines Sprinkler Flow for BuildingsDocument12 paginiHow FPE Determines Sprinkler Flow for BuildingsArt James100% (1)

- Manual SprinkCADDocument51 paginiManual SprinkCADDiego EscalanteÎncă nu există evaluări

- Design Basis For Fire-Fighting SystemDocument10 paginiDesign Basis For Fire-Fighting Systemsohail1985100% (2)

- Minimum Fire Sprinkler Design CriteriaDocument14 paginiMinimum Fire Sprinkler Design Criteriajun005100% (3)

- Novec 1230 DesignDocument8 paginiNovec 1230 Designnandeesh100% (1)

- Distillation Column Design ReportDocument20 paginiDistillation Column Design Reportkausshal28Încă nu există evaluări

- Gas - Sup.sys Co2Document10 paginiGas - Sup.sys Co2omarrgb97Încă nu există evaluări

- Numerical Question Part 6 (Q71 80)Document4 paginiNumerical Question Part 6 (Q71 80)ramkrishna100% (4)

- Rotary Drier DesignDocument29 paginiRotary Drier DesignDharamvir Singh80% (5)

- ProjectDocument26 paginiProjectsiddharthkharat123Încă nu există evaluări

- Distillation Column DesignDocument67 paginiDistillation Column Designrajindo1Încă nu există evaluări

- Design of Shell and Tube Heat ExchangerDocument42 paginiDesign of Shell and Tube Heat Exchanger3004 Divya Dharshini. MÎncă nu există evaluări

- Sewage Treatment PlantDocument9 paginiSewage Treatment PlantRohit NegiÎncă nu există evaluări

- BOnd Strength ASTM-F904-98Document1 paginăBOnd Strength ASTM-F904-98akash.biradarÎncă nu există evaluări

- Column and Wall Load Take Down Spreadsheet v1.0 - CLDocument28 paginiColumn and Wall Load Take Down Spreadsheet v1.0 - CLBilal KhattabÎncă nu există evaluări

- Gaspardo MAESTRA 2004-02 (19530520)Document78 paginiGaspardo MAESTRA 2004-02 (19530520)costelchelariuÎncă nu există evaluări

- VP R&D/VP QualityDocument3 paginiVP R&D/VP Qualityapi-79326007Încă nu există evaluări

- Solar Desalination PlantDocument28 paginiSolar Desalination PlantAnonymous TETH310% (1)

- Military Standard for Circular Connector Insert ArrangementsDocument59 paginiMilitary Standard for Circular Connector Insert ArrangementsVadim RiabovÎncă nu există evaluări

- Autocad 2010 Tutorial Series Autocad Mechanical 2010 Tutorial SeriesDocument4 paginiAutocad 2010 Tutorial Series Autocad Mechanical 2010 Tutorial Seriesbdi_roÎncă nu există evaluări

- PTH Crusher GBDocument16 paginiPTH Crusher GBElvis Eberth Huanca MachacaÎncă nu există evaluări

- Contact-Molded Reinforced Thermosetting Plastic (RTP) Laminates For Corrosion-Resistant EquipmentDocument8 paginiContact-Molded Reinforced Thermosetting Plastic (RTP) Laminates For Corrosion-Resistant EquipmentQUALITY MAYURÎncă nu există evaluări

- Iec 62097-2009Document170 paginiIec 62097-2009luis.alvaradoÎncă nu există evaluări

- Fitter ToolsDocument7 paginiFitter ToolsSainadhReddy100% (1)

- Pfaff 360 Sewing Machine Instruction ManualDocument55 paginiPfaff 360 Sewing Machine Instruction ManualiliiexpugnansÎncă nu există evaluări

- Electrical Power Transmission & DistributionDocument18 paginiElectrical Power Transmission & DistributionMd Saif KhanÎncă nu există evaluări

- Interfacing Electrification and System ReliabilityDocument29 paginiInterfacing Electrification and System Reliabilityพี่จิน ยศเนืองนิตย์Încă nu există evaluări

- Bondek Design & Construct ManualDocument131 paginiBondek Design & Construct ManualAkuma.Gokai7328100% (12)

- Cava v6 1x Install enDocument29 paginiCava v6 1x Install enWael SalahÎncă nu există evaluări

- MIT OCW Principles of Inorganic Chemistry II Lecture on Octahedral ML6 Sigma ComplexesDocument7 paginiMIT OCW Principles of Inorganic Chemistry II Lecture on Octahedral ML6 Sigma Complexessanskarid94Încă nu există evaluări

- Xtrons - TD609 User ManualDocument16 paginiXtrons - TD609 User ManualadrianÎncă nu există evaluări

- Difference Between Industrial Revolution & French, Russian Revolution?Document10 paginiDifference Between Industrial Revolution & French, Russian Revolution?Anonymous 3owUL0ksVÎncă nu există evaluări

- Ibm Lenovo Whistler Rev s1.3 SCHDocument52 paginiIbm Lenovo Whistler Rev s1.3 SCH1cvbnmÎncă nu există evaluări

- Vapor Pressure Experiment Data AnalysisDocument3 paginiVapor Pressure Experiment Data AnalysisRanaÎncă nu există evaluări

- Jolywood-JW-HD144N-545-570 Bifacial 2285x1134x30Document2 paginiJolywood-JW-HD144N-545-570 Bifacial 2285x1134x30Agata GuzikÎncă nu există evaluări

- VP Director Finance Controller in Washington DC Resume Brenda LittleDocument2 paginiVP Director Finance Controller in Washington DC Resume Brenda LittleBrendaLittleÎncă nu există evaluări

- Tivizen Iplug Greek GuideDocument13 paginiTivizen Iplug Greek GuideDenexoÎncă nu există evaluări

- Tds G. Beslux Tribopaste L-2-3 S (26.03.09)Document1 paginăTds G. Beslux Tribopaste L-2-3 S (26.03.09)Iulian BarbuÎncă nu există evaluări

- Regional Contest Package in EIM NC IIDocument3 paginiRegional Contest Package in EIM NC IIAlÎncă nu există evaluări

- ATHENAEUMDocument4 paginiATHENAEUMShubhra PatraÎncă nu există evaluări

- Coverage of Quiz 1Document24 paginiCoverage of Quiz 1Ben RileyÎncă nu există evaluări

- 03-2ezii (Ex-Lx-Dx) Codde 3 QRH1 V1Document352 pagini03-2ezii (Ex-Lx-Dx) Codde 3 QRH1 V1sadh94Încă nu există evaluări

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeDe la EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeEvaluare: 4.5 din 5 stele4.5/5 (3)

- Asset Integrity Management for Offshore and Onshore StructuresDe la EverandAsset Integrity Management for Offshore and Onshore StructuresÎncă nu există evaluări

- Science Goes Viral: Captivating Accounts of Science in Everyday LifeDe la EverandScience Goes Viral: Captivating Accounts of Science in Everyday LifeEvaluare: 5 din 5 stele5/5 (1)

- Guidelines for Asset Integrity ManagementDe la EverandGuidelines for Asset Integrity ManagementEvaluare: 5 din 5 stele5/5 (1)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsDe la EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsEvaluare: 4 din 5 stele4/5 (146)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionDe la EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionEvaluare: 4.5 din 5 stele4.5/5 (542)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksDe la EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksEvaluare: 5 din 5 stele5/5 (1)

- Coating and Drying Defects: Troubleshooting Operating ProblemsDe la EverandCoating and Drying Defects: Troubleshooting Operating ProblemsEvaluare: 5 din 5 stele5/5 (1)

- High Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsDe la EverandHigh Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsEvaluare: 4 din 5 stele4/5 (1)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolDe la EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolÎncă nu există evaluări

- Stuff Matters: Exploring the Marvelous Materials That Shape Our Man-Made WorldDe la EverandStuff Matters: Exploring the Marvelous Materials That Shape Our Man-Made WorldEvaluare: 4 din 5 stele4/5 (289)

- Essential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilDe la EverandEssential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilEvaluare: 5 din 5 stele5/5 (1)

- The Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026De la EverandThe Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026Evaluare: 5 din 5 stele5/5 (1)

- Guidelines for Defining Process Safety Competency RequirementsDe la EverandGuidelines for Defining Process Safety Competency RequirementsEvaluare: 3 din 5 stele3/5 (1)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeDe la EverandChemistry for Breakfast: The Amazing Science of Everyday LifeEvaluare: 4.5 din 5 stele4.5/5 (14)

- Off-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemDe la EverandOff-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemÎncă nu există evaluări

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsDe la EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsEvaluare: 5 din 5 stele5/5 (3)

- Napoleon's Buttons: 17 Molecules That Changed HistoryDe la EverandNapoleon's Buttons: 17 Molecules That Changed HistoryEvaluare: 4 din 5 stele4/5 (25)

- Ramblings of a Mad Scientist: 100 Ideas for a Stranger TomorrowDe la EverandRamblings of a Mad Scientist: 100 Ideas for a Stranger TomorrowÎncă nu există evaluări

- Monkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifeDe la EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifeEvaluare: 4 din 5 stele4/5 (9)

- It's Elemental: The Hidden Chemistry in EverythingDe la EverandIt's Elemental: The Hidden Chemistry in EverythingEvaluare: 4 din 5 stele4/5 (10)

- Beginner's Guide to Reading Schematics, Third EditionDe la EverandBeginner's Guide to Reading Schematics, Third EditionÎncă nu există evaluări

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionDe la EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionEvaluare: 4 din 5 stele4/5 (331)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersDe la Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersEvaluare: 5 din 5 stele5/5 (1)