Documente Academic

Documente Profesional

Documente Cultură

Steel Beam Analysis & Design (AISC360) - Beam Supporting Wall - Ted

Încărcat de

Roberto CatalaniTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Steel Beam Analysis & Design (AISC360) - Beam Supporting Wall - Ted

Încărcat de

Roberto CatalaniDrepturi de autor:

Formate disponibile

POAGE

Project

Job Ref.

Section

Sheet no./rev.

1

Calc. by

Date

3/19/2015

Chk'd by

Date

App'd by

Date

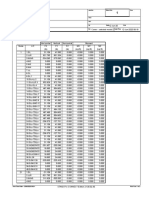

STEEL BEAM ANALYSIS & DESIGN (AISC360-10)

In accordance with AISC360 14th Edition published 2010 using the ASD method

Tedds calculation version 3.0.08

Load Envelope - Com bination 1

1.135

0.0

ft

15

1

14

2

18

3

Bending Mom ent Envelope

kip_ft

-33.228

-33.2

-21.9

0.0

0.5

21.9

30.854

30.9

ft

A

15

1

14

2

18

3

Shear Force Envelope

kips

12.061

12.1

7.1

7.1

0.0

-9.973

A

Support conditions

Support A

15

1

14

2

Vertically restrained

Rotationally free

Support B

Vertically restrained

Rotationally free

Support C

Vertically restrained

Rotationally free

Support D

Vertically restrained

Rotationally free

Applied loading

Beam loads

-8.4

-8.8

-10.0

ft

Dead self weight of beam 1

Dead full UDL 0.5 kips/ft

Dead full UDL 0.57 kips/ft

18

3

POAGE

Project

Job Ref.

Section

Sheet no./rev.

2

Calc. by

Date

3/19/2015

Chk'd by

Date

App'd by

Load combinations

Load combination 1

Support A

Dead 1.00

Live 1.00

Roof live 1.00

Snow 1.00

Span 1

Dead 1.00

Live 1.00

Roof live 1.00

Snow 1.00

Support B

Dead 1.00

Live 1.00

Roof live 1.00

Snow 1.00

Span 2

Dead 1.00

Live 1.00

Roof live 1.00

Snow 1.00

Support C

Dead 1.00

Live 1.00

Roof live 1.00

Snow 1.00

Span 3

Dead 1.00

Live 1.00

Roof live 1.00

Snow 1.00

Support D

Dead 1.00

Live 1.00

Roof live 1.00

Snow 1.00

Analysis results

Maximum moment;

Mmax = 30.9 kips_ft;

Mmin = -33.2 kips_ft

Maximum moment span 1;

Ms1_max = 21.9 kips_ft;

Ms1_min = -21.9 kips_ft

Maximum moment span 2;

Ms2_max = 0.5 kips_ft;

Ms2_min = -33.2 kips_ft

Maximum moment span 3;

Ms3_max = 30.9 kips_ft;

Ms3_min = -33.2 kips_ft

Maximum shear;

Vmax = 12.1 kips;

Vmin = -10 kips

Maximum shear span 1;

Vs1_max = 7.1 kips;

Vs1_min = -10 kips

Maximum shear span 2;

Vs2_max = 7.1 kips;

Vs2_min = -8.8 kips

Maximum shear span 3;

Vs3_max = 12.1 kips;

Vs3_min = -8.4 kips

Deflection;

max = 0 in;

min = 0 in

Deflection span 1;

s1_max = 0 in;

s1_min = 0 in

Deflection span 2;

s2_max = 0 in;

s2_min = 0 in

Deflection span 3;

s3_max = 0 in;

s3_min = 0 in

Date

POAGE

Project

Job Ref.

Section

Sheet no./rev.

3

Calc. by

Date

3/19/2015

Chk'd by

Maximum reaction at support A;

RA_max = 7.1 kips;

Unfactored dead load reaction at support A;

RA_Dead = 7.1 kips

Maximum reaction at support B;

RB_max = 17.1 kips;

Unfactored dead load reaction at support B;

RB_Dead = 17.1 kips

Maximum reaction at support C;

RC_max = 20.8 kips;

Unfactored dead load reaction at support C;

RC_Dead = 20.8 kips

Maximum reaction at support D;

RD_max = 8.4 kips;

Unfactored dead load reaction at support D;

RD_Dead = 8.4 kips

Date

App'd by

RA_min = 7.1 kips

RB_min = 17.1 kips

RC_min = 20.8 kips

RD_min = 8.4 kips

Section details

W 18x65

A992

Steel yield stress;

Fy = 50 ksi

Steel tensile stress;

Fu = 65 ksi

Modulus of elasticity;

E = 29000 ksi

18.4"

0.75"

Section type;

ASTM steel designation;

0.75"

0.45"

7.59"

Safety factors

Safety factor for tensile yielding;

ty = 1.67

Safety factor for tensile rupture;

tr = 2.00

Safety factor for compression;

c = 1.67

Safety factor for flexure;

b = 1.67

Safety factor for shear;

v = 1.50

Lateral bracing

Span 1 has continuous lateral bracing

Span 2 has continuous lateral bracing

Span 3 has continuous lateral bracing

Classification of sections for local bending - Section B4

Classification of flanges in flexure - Table B4.1b (case 10)

Width to thickness ratio;

bf / (2 tf) = 5.06

Limiting ratio for compact section;

pff = 0.38 [E / Fy] = 9.15

Date

POAGE

Project

Job Ref.

Section

Sheet no./rev.

4

Calc. by

Date

3/19/2015

Limiting ratio for non-compact section;

Chk'd by

rff = 1.0 [E / Fy] = 24.08;

Date

App'd by

Date

Compact

Classification of web in flexure - Table B4.1b (case 15)

Width to thickness ratio;

(d - 2 k) / tw = 35.78

Limiting ratio for compact section;

pwf = 3.76 [E / Fy] = 90.55

Limiting ratio for non-compact section;

rwf = 5.70 [E / Fy] = 137.27;

Compact

Section is compact in flexure

Design of members for shear - Chapter G

Required shear strength;

Vr = max(abs(Vmax), abs(Vmin)) = 12.061 kips

Web area;

Aw = d tw = 8.28 in2

Web plate buckling coefficient;

kv = 5

Web shear coefficient - eq G2-2;

Cv = 1.000

Nominal shear strength - eq G2-1;

Vn = 0.6 Fy Aw Cv = 248.400 kips

Allowable shear strength;

Vc = Vn / v = 165.600 kips

PASS - Allowable shear strength exceeds required shear strength

Design of members for flexure in the major axis at span 2 - Chapter F

Required flexural strength;

Mr = max(abs(Ms2_max), abs(Ms2_min)) = 33.228 kips_ft

Yielding - Section F2.1

Nominal flexural strength for yielding - eq F2-1;

Mnyld = Mp = Fy Zx = 554.167 kips_ft

Nominal flexural strength;

Mn = Mnyld = 554.167 kips_ft

Allowable flexural strength;

Mc = Mn / b = 331.836 kips_ft

PASS - Allowable flexural strength exceeds required flexural strength

Design of members for vertical deflection

Consider deflection due to dead, live, roof live and snow loads

Limiting deflection;;

lim = Ls3 / 360 = 0.6 in

Maximum deflection span 3;

= max(abs(max), abs(min)) = 0.05 in

PASS - Maximum deflection does not exceed deflection limit

S-ar putea să vă placă și

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionDe la EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionÎncă nu există evaluări

- Timber Examples - TeddsDocument19 paginiTimber Examples - TeddsTom KwoÎncă nu există evaluări

- Cant SlabDocument4 paginiCant Slabinsane88Încă nu există evaluări

- EC2 Continuous Beam DesignDocument14 paginiEC2 Continuous Beam Designikanyu79Încă nu există evaluări

- Production and Maintenance Optimization Problems: Logistic Constraints and Leasing Warranty ServicesDe la EverandProduction and Maintenance Optimization Problems: Logistic Constraints and Leasing Warranty ServicesÎncă nu există evaluări

- RC Beam Analysis & Design (En1992-1) in Accordance With UK National AnnexDocument7 paginiRC Beam Analysis & Design (En1992-1) in Accordance With UK National Annexmishu_cojoÎncă nu există evaluări

- ACI-350 Concrete Beam Design 1.1Document6 paginiACI-350 Concrete Beam Design 1.1nhulugalla33% (3)

- Pressuremeter Testing: Methods and InterpretationDe la EverandPressuremeter Testing: Methods and InterpretationEvaluare: 5 din 5 stele5/5 (2)

- DG Bim Consulting: RC Beam Analysis & Design Bs8110Document8 paginiDG Bim Consulting: RC Beam Analysis & Design Bs8110cheligp1981Încă nu există evaluări

- Transmission Tower Foundation DesignDocument26 paginiTransmission Tower Foundation DesignSara Nuon86% (7)

- Continuous Beam DesignDocument20 paginiContinuous Beam DesignUa AnyanhunÎncă nu există evaluări

- Design of Buildings for Wind: A Guide for ASCE 7-10 Standard Users and Designers of Special StructuresDe la EverandDesign of Buildings for Wind: A Guide for ASCE 7-10 Standard Users and Designers of Special StructuresEvaluare: 3.5 din 5 stele3.5/5 (2)

- Anchor Embedment - Pa2Document8 paginiAnchor Embedment - Pa2joeilaganÎncă nu există evaluări

- Pressure Vessel and Stacks Field Repair ManualDe la EverandPressure Vessel and Stacks Field Repair ManualEvaluare: 4 din 5 stele4/5 (4)

- Case-1 (Actual Load+tension With Anchor Bar)Document16 paginiCase-1 (Actual Load+tension With Anchor Bar)userhieÎncă nu există evaluări

- Aw-01-07 ColumnDocument14 paginiAw-01-07 ColumnalexanderÎncă nu există evaluări

- Design of Piles Under Cyclic Loading: SOLCYP RecommendationsDe la EverandDesign of Piles Under Cyclic Loading: SOLCYP RecommendationsAlain PuechÎncă nu există evaluări

- 132/11Kv Al Sadd 3 Substation: Updated Structural Stair DesignDocument4 pagini132/11Kv Al Sadd 3 Substation: Updated Structural Stair Designmuhammed sabir v aÎncă nu există evaluări

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesDe la Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesÎncă nu există evaluări

- FOOTING DESIGNDocument9 paginiFOOTING DESIGNMitra RampersadÎncă nu există evaluări

- Process Intensification for Sustainable Energy ConversionDe la EverandProcess Intensification for Sustainable Energy ConversionÎncă nu există evaluări

- Design of Corriguteed Sheet PDFDocument41 paginiDesign of Corriguteed Sheet PDFflorinelvvÎncă nu există evaluări

- Slab DesignDocument7 paginiSlab Designnhulugalla0% (1)

- 110 Waveform Generator Projects for the Home ConstructorDe la Everand110 Waveform Generator Projects for the Home ConstructorEvaluare: 4 din 5 stele4/5 (1)

- Example Beam Column Design IS800Document3 paginiExample Beam Column Design IS800Goutam Chakraborty100% (4)

- 35 KL DesignDocument10 pagini35 KL DesigneduardoambientalÎncă nu există evaluări

- Topographical Tools for Filtering and Segmentation 2: Flooding and Marker-based Segmentation on Node- or Edge-weighted GraphsDe la EverandTopographical Tools for Filtering and Segmentation 2: Flooding and Marker-based Segmentation on Node- or Edge-weighted GraphsÎncă nu există evaluări

- Mathcad - Spreader Beam Design Calculations As Per DNV 5th VerDocument29 paginiMathcad - Spreader Beam Design Calculations As Per DNV 5th VerAbderraoufAffes100% (3)

- Bridge 3exampleDocument84 paginiBridge 3exampletrabajosicÎncă nu există evaluări

- Power Systems-On-Chip: Practical Aspects of DesignDe la EverandPower Systems-On-Chip: Practical Aspects of DesignBruno AllardÎncă nu există evaluări

- Gantry CraneDocument18 paginiGantry Craneamirthraj7494% (16)

- Marine Electrical Practice: Marine Engineering SeriesDe la EverandMarine Electrical Practice: Marine Engineering SeriesEvaluare: 4 din 5 stele4/5 (8)

- Anchor Bolt Design (ACI318)Document5 paginiAnchor Bolt Design (ACI318)Ashraful AlamÎncă nu există evaluări

- Economics of Climate Change Mitigation in Central and West AsiaDe la EverandEconomics of Climate Change Mitigation in Central and West AsiaÎncă nu există evaluări

- ACI Pad Foundation ExampleDocument7 paginiACI Pad Foundation ExampleEm MarÎncă nu există evaluări

- Solution Manual for 100 Genesys Design Examples: Second EditionDe la EverandSolution Manual for 100 Genesys Design Examples: Second EditionÎncă nu există evaluări

- Column Skirt Support Design CalculationDocument5 paginiColumn Skirt Support Design CalculationRitesh VishambhariÎncă nu există evaluări

- API 650 Rafter DesignDocument12 paginiAPI 650 Rafter Designrongweius100% (1)

- Rafter DesignDocument12 paginiRafter DesignsetakÎncă nu există evaluări

- FOUNDATION ANALYSIS TITLEDocument7 paginiFOUNDATION ANALYSIS TITLERoberto Catalani100% (1)

- Ce591plategirders F13Document67 paginiCe591plategirders F13cocococo1100% (1)

- Secondary Beam ExampleDocument5 paginiSecondary Beam ExampleAboalmaail AlaminÎncă nu există evaluări

- Owner:-North Eastern Owner: - North Eastern: Electric Power Corporation Ltd. Electric Power Corporation LTDDocument13 paginiOwner:-North Eastern Owner: - North Eastern: Electric Power Corporation Ltd. Electric Power Corporation LTDIrshad KhanÎncă nu există evaluări

- Member Check 60x60x5 RSA (Top & Bottom Boom)Document10 paginiMember Check 60x60x5 RSA (Top & Bottom Boom)Bobor Emmanuel OfovweÎncă nu există evaluări

- Warehouse Roof Design and AnalysisDocument51 paginiWarehouse Roof Design and AnalysisAnonymous q0irDXlWAm100% (2)

- Design of Steel I Section BS5950Document6 paginiDesign of Steel I Section BS5950amachmouchi100% (1)

- Design of Beam to Column ConnectionDocument13 paginiDesign of Beam to Column ConnectionGautam SharmaÎncă nu există evaluări

- 17 TonsDocument8 pagini17 Tonsabuzahrau100% (3)

- Lifting Lug CalculationDocument5 paginiLifting Lug CalculationEm Mar100% (2)

- Crane Gantry Girder (BS5950 - Part1 - 2000)Document6 paginiCrane Gantry Girder (BS5950 - Part1 - 2000)sayed100% (1)

- RC Corbel Design (ACI318)Document2 paginiRC Corbel Design (ACI318)Emad KhanÎncă nu există evaluări

- Lightweight Insulating Concrete For Floors and Roof DecksDocument6 paginiLightweight Insulating Concrete For Floors and Roof DecksPeter BussellÎncă nu există evaluări

- Analysis and Design of Shipping Container SupportDocument23 paginiAnalysis and Design of Shipping Container SupportRoberto CatalaniÎncă nu există evaluări

- ValueEngineering Practical PDFDocument416 paginiValueEngineering Practical PDFjhoward2012npÎncă nu există evaluări

- Failure of Spread FootingsDocument7 paginiFailure of Spread FootingsRoberto CatalaniÎncă nu există evaluări

- Beam GraphsDocument11 paginiBeam GraphsRoberto CatalaniÎncă nu există evaluări

- Typical Jack and King Stud Load Calculation TemplateDocument7 paginiTypical Jack and King Stud Load Calculation TemplateRoberto CatalaniÎncă nu există evaluări

- Pe Rules TexasDocument74 paginiPe Rules TexasRoberto CatalaniÎncă nu există evaluări

- Stemwall Reinforcement For PipesDocument1 paginăStemwall Reinforcement For PipesRoberto CatalaniÎncă nu există evaluări

- Staad Reaction For Overturning Moments in Connex StructureDocument2 paginiStaad Reaction For Overturning Moments in Connex StructureRoberto CatalaniÎncă nu există evaluări

- Design of Steel Canopy NotesDocument1 paginăDesign of Steel Canopy NotesRoberto CatalaniÎncă nu există evaluări

- Tedds Calculation of ASCE 7-10 Wind Loads For A Pole BarnDocument7 paginiTedds Calculation of ASCE 7-10 Wind Loads For A Pole BarnRoberto CatalaniÎncă nu există evaluări

- BLM Cost Estimating HDBK Dec2002Document158 paginiBLM Cost Estimating HDBK Dec2002osvald97Încă nu există evaluări

- Spmats PDFDocument72 paginiSpmats PDFRoberto CatalaniÎncă nu există evaluări

- Shearwall Overturning Calculation TemplateDocument3 paginiShearwall Overturning Calculation TemplateRoberto CatalaniÎncă nu există evaluări

- Structural Deisgn - Elevator SectionDocument1 paginăStructural Deisgn - Elevator SectionRoberto CatalaniÎncă nu există evaluări

- Z725 Performance Rated I-JoistsDocument28 paginiZ725 Performance Rated I-JoistsbabshuagÎncă nu există evaluări

- Diaphragm CalculatorDocument4 paginiDiaphragm CalculatorRoberto CatalaniÎncă nu există evaluări

- Spmats PDFDocument72 paginiSpmats PDFRoberto CatalaniÎncă nu există evaluări

- Joke Elections MexicoDocument1 paginăJoke Elections MexicoRoberto CatalaniÎncă nu există evaluări

- Seismic Load AnalysisDocument99 paginiSeismic Load AnalysisMANDARAW100% (1)

- National Building Code Recommended NY 1913Document337 paginiNational Building Code Recommended NY 1913Roberto CatalaniÎncă nu există evaluări

- Stair Shop Drawing ExampleDocument1 paginăStair Shop Drawing ExampleRoberto CatalaniÎncă nu există evaluări

- Typical Structural Joint DetailDocument1 paginăTypical Structural Joint DetailRoberto CatalaniÎncă nu există evaluări

- Historical Live Loads NFPU NY 2015Document1 paginăHistorical Live Loads NFPU NY 2015Roberto CatalaniÎncă nu există evaluări

- Slab On Ground (ACI360R)Document2 paginiSlab On Ground (ACI360R)Roberto Catalani100% (2)

- Typical Base Plate DetailsDocument1 paginăTypical Base Plate DetailsRoberto CatalaniÎncă nu există evaluări

- Seismic Load AnalysisDocument99 paginiSeismic Load AnalysisMANDARAW100% (1)

- Architectural Plan of Pizza JointDocument1 paginăArchitectural Plan of Pizza JointRoberto CatalaniÎncă nu există evaluări

- Typical Structural HatchesDocument1 paginăTypical Structural HatchesRoberto CatalaniÎncă nu există evaluări

- Typical Structural NotesDocument1 paginăTypical Structural NotesRoberto CatalaniÎncă nu există evaluări

- 5348 Chapter7 10Document46 pagini5348 Chapter7 10Nihir PatelÎncă nu există evaluări

- Optimum Strength Ratio of Hysteretic DamperDocument12 paginiOptimum Strength Ratio of Hysteretic DamperÁngelDeJesúsLópezPérezÎncă nu există evaluări

- Physical Geology 2nd Edition Chapter 11 EarthquakesDocument35 paginiPhysical Geology 2nd Edition Chapter 11 EarthquakesJenny Rose OliverosÎncă nu există evaluări

- NSCP 2010 Seismic ProvisionsDocument67 paginiNSCP 2010 Seismic ProvisionsJule LobresÎncă nu există evaluări

- Development of Aluminum Honeycomb Cored Carbon FibDocument29 paginiDevelopment of Aluminum Honeycomb Cored Carbon FibRahulÎncă nu există evaluări

- Problem Sheet - Design of KeysDocument2 paginiProblem Sheet - Design of KeysAbdul Rasheed GhaziÎncă nu există evaluări

- Simply supported beam bending and shear verificationDocument7 paginiSimply supported beam bending and shear verificationmn4webÎncă nu există evaluări

- Timoshenko CoefficientDocument6 paginiTimoshenko CoefficientwarterflyÎncă nu există evaluări

- Scalar and vector quantities, equations of motion, and Newton's lawsDocument7 paginiScalar and vector quantities, equations of motion, and Newton's lawsApollo Wong100% (1)

- Design of Pile Cap and Abutment WallDocument20 paginiDesign of Pile Cap and Abutment Wallshashibhushan singh100% (1)

- Vibroreplacement PDFDocument9 paginiVibroreplacement PDFthadikkaranÎncă nu există evaluări

- MAE 343 - Strain Energy and Castigliano's TheoremDocument17 paginiMAE 343 - Strain Energy and Castigliano's Theoremjohnvchristy7Încă nu există evaluări

- DS482Document3 paginiDS482mariomatoÎncă nu există evaluări

- Mechanics of Composite MaterialsDocument2 paginiMechanics of Composite MaterialsGopinath GangadhariÎncă nu există evaluări

- Slope StabilityDocument44 paginiSlope StabilitySUNDEEP KUMAR.BÎncă nu există evaluări

- Analytical Behavior of Concrete-Filled Aluminum Tubular Stub Columns Under Axial Compression, 2019 (Fa-Cheng Wang) PDFDocument10 paginiAnalytical Behavior of Concrete-Filled Aluminum Tubular Stub Columns Under Axial Compression, 2019 (Fa-Cheng Wang) PDFPhan Đào Hoàng HiệpÎncă nu există evaluări

- Design and Construction of Anchored and Strutted Sheet Pile WallsDocument37 paginiDesign and Construction of Anchored and Strutted Sheet Pile WallsJaime Morales BazalduaÎncă nu există evaluări

- Chemical Composition % of Steel C40 (1.0511) : EN 10277-2-2008Document1 paginăChemical Composition % of Steel C40 (1.0511) : EN 10277-2-2008CorneÎncă nu există evaluări

- Structural steel design guide contentsDocument1 paginăStructural steel design guide contentsNeeraj DubeyÎncă nu există evaluări

- (W. H. Mosley, R. Hulse, J. H. Bungey (Auth.) ) Rei (B-Ok - Xyz) PDFDocument441 pagini(W. H. Mosley, R. Hulse, J. H. Bungey (Auth.) ) Rei (B-Ok - Xyz) PDFHamidullah Afghan100% (1)

- Wood Compression Test ResultsDocument10 paginiWood Compression Test ResultsianzkieeÎncă nu există evaluări

- Calculation For Wall Anchor Bracket Project Phase 1A &1B: Data - 08 11 2020 REV 00Document9 paginiCalculation For Wall Anchor Bracket Project Phase 1A &1B: Data - 08 11 2020 REV 00Antonysamy SanthanamÎncă nu există evaluări

- Eval 2 FinalDocument4 paginiEval 2 FinalGreg Rasco, REE, RMPÎncă nu există evaluări

- 10 1 1 703 8121 PDFDocument41 pagini10 1 1 703 8121 PDFFrans van der MerweÎncă nu există evaluări

- Direct Shear Test S 30 1Document10 paginiDirect Shear Test S 30 1jems patel0% (1)

- Critical State Soil Mechanics LectureDocument30 paginiCritical State Soil Mechanics LecturevariablespiceÎncă nu există evaluări

- Combined Shear and TensionDocument16 paginiCombined Shear and TensionDAN MARK OPONDAÎncă nu există evaluări

- COLUMN BASE PLATE DESIGN CALCULATIONS (BS5950-1:2000Document7 paginiCOLUMN BASE PLATE DESIGN CALCULATIONS (BS5950-1:2000Shakil Akhter100% (1)

- Velloso - Piles Subjected To Horizontal Loads Due To Asymmetrical Surcharges On The SurfaceDocument5 paginiVelloso - Piles Subjected To Horizontal Loads Due To Asymmetrical Surcharges On The SurfaceMarcelaMarquesÎncă nu există evaluări