Documente Academic

Documente Profesional

Documente Cultură

Thesis 001

Încărcat de

James Harrill Torres LaydeaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Thesis 001

Încărcat de

James Harrill Torres LaydeaDrepturi de autor:

Formate disponibile

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

Application ofEvaporative Air Coolant

InPurok 6,Brgy. BigaaCabuyao, Laguna

Group Member

Go, Mark Anthony B.

Saunar, Arvin Y.

Velasco, Jezreel A.

Hamor, Michael Angelo E.

Engr. Joel M. Aviso

Professor

0|Page

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

Copyright 2015 Mark Anthony Go, Arvin Saunar, Jezreel Velasco, & Michael Angelo

Hamor

All Rights Reserved

1|Page

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

CHAPTER 1

INTRODUCTION

Background of the study

The City of Cabuyao is located about 43 kilometres (27 mi) southeast of Metro

Manila, at the western portion of Laguna. It is bordered by the Laguna de Bay, the

country's largest lake, to the north (N), Calamba City to the east (E) with Barangays

Uwisan (NE), Banlic& San Cristobal (E) and Mapagong& Canlubang (SE), some portion

of Silang, Cavite (Brgy. PutingKahoy) to the south (S) and by the Santa Rosa City to the

west (W) with the Barangays Malitlit (SW), Dita (W) and Caingin (NW) respectively.

Cabuyao is approximately 54 kilometres (34 mi) away from Santa Cruz, the provincial

capital, and 9 kilometres (5.6 mi) from the city center of Calamba City, the chartered city

and regional center of CALABARZON region.

The rainfall regime of Cabuyao is characterized by two pronounced season, the

wet and the dry seasons. The wet season is from June to November and the relatively dry

season runs from December to May. The average annual rainfall is about 2,000mm. There

are 150 rainy days in average per year for the wet season.

2|Page

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

The seasonal variation of the temperature field is uneventful. The coldest months

start from November up to January and the warmest month on record is the month of May.

On the average, a 12- degree centigrade temperature difference exists between the

warmest and the coldest months. The mean annual temperature is a warm 27.5 degree

centigrade.

The Annual relative humidity is 76%. The most humid months are June, July,

August and September with the normal relative humidity registered at 84% while April

and May are driest at 70%.

During the dry seasons, most of the households in Cabuyao make use of standard

fans so as to cool the air inside the house. One of their selections is the use of air

conditioning unit however it can lead to a high power usage of electricity leading to higher

electrical bills.

Air cooling is a method of dissipating heat. It works by making the object to be

cooled have a larger surface area or have an increased flow of air over its surface, or both.

An example of the former is to add cooling fins to the surface of the object, either by

making them integral or by attaching them tightly to the object's surface (to ensure

efficient heat transfer). In the case of the latter it is done by using a fan blowing air into or

onto the object one wants to cool. The addition of fins to a heat sink increases its total

surface area, resulting in greater cooling effectiveness.

3|Page

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

Free cooling is an economical method of using low external air temperatures to

assist in chilling water, which can then be used for industrial processes, or air conditioning

systems. The chilled water can either be used immediately or be stored for the short- or

long-term. When outdoor temperatures are lower relative to indoor temperatures, this

system utilizes the cool outdoor air as a free cooling source. In this manner, the system

replaces the chiller in traditional air conditioning systems while achieving the same

cooling result. Such systems can be made for single buildings or district cooling networks.

Evaporative cooling differs from typical air conditioning systems which use vaporcompression or absorption refrigeration cycles. Evaporative cooling works by employing

water's large enthalpy of vaporization. The temperature of dry air can be dropped

significantly through the phase transition of liquid water to water vapor (evaporation),

which can cool the air using lesser energy than refrigeration. In extremely dry climates,

evaporative cooling of air has the added benefit of conditioning the air with more moisture

for the comfort of building occupants.

The cooling potential for evaporative cooling is dependent on the wet bulb

depression, the difference between dry-bulb temperature and wet-bulb temperature. In arid

climates, evaporative cooling can reduce energy consumption and total equipment for

conditioning as an alternative to compressor-based cooling. In climates not considered

arid, indirect evaporative cooling can still take advantage of theevaporative cooling

4|Page

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

process without increasing humidity. Passive evaporative cooling strategies offer the same

benefits of mechanical evaporative cooling systems without the complexity of equipment

and ductwork.

STATEMENTOF PROBLEM

In every typical household in Purok 6, Brgy. Bigaa, Cabuyao, Laguna, houses have

2-3 windows, 2-3 rooms, 1 door, 4-6 light bulbs or florescent lights, 6-10 appliances and

the houses are just wall-separated.

In these house distances, the people living inside feel inconvenient due to the

blockage of fresh air coming from different direction. Installing an air-conditioning unit

was a great idea but it is too expensive for a typical family, putting a ventilator or electric

fanmay help but it is still not enough to improve convenience to the residents living in

Purok 6, brgy. Bigaa, cabuyao, Laguna.Due to this difficulty, the researcher believes that

putting an advanced cooler inside the house will improve the ventilation of air.

OBJECTIVES

As a researcher we aim to achieve the following in doing this research:

To validate the temperature inside and outside of the house in Brgy. Bigaa,

Cabuyao, Laguna.

5|Page

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

To design innovative equipment that can decrease the temperature of a room or

space in the house in brgy. Bigaa, Cabuyao, Laguna.

To evaluate the effectiveness of the designed coolant.

SIGNIFICANCE OF THE STUDY

This section will provide brief description on the various significances of the study.

For the people, the proposed study will serve them a guide how to simply reduce

the high temperature to 3-5 degree Celsius inside the house especially on a hot

season.

For students, the proposed study will help them have a deeper understanding in the

air-conditioning system. Furthermore, this study will give them knowledge how to

come up with this innovative and useful project.

To future researchers, the proposed study will serve them a guide for more future

innovations and works.

SCOPE AND LIMITATION

1. The researchers have focused on lowering the temperature in a certain room or

space of a house located in Purok 6, brgy. Bigaa, Cabuya Laguna.

2. The researchers have used ice with a maximum volume of 4 liters and a

minimum of 2 liter.

6|Page

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

DEFINITION OF TERMS

Axial - Relating to or forming an axis

Boiling point Temperature at which liquid boils: the temperature at which a heated

liquid turns too gas, e.g. 100 or 212 for water at sea level.

Chilling To cool specially without freezing.

Chlorofluorocarbon (CFC) - is an organic compound that contains only carbon,

chlorine, and fluorine, produced as a volatile derivative of methane, ethane, and

propane. They are also commonly known by the DuPont brand name Freon.

Heat - is energy in transfer other than as work or by transfer of matter. When there is a

suitable physical pathway, heat flows from a hotter body to a colder one. It results in a

net increase in entropy. The pathway can be direct, as in conduction and radiation, or

indirect, as in convective circulation.

Humidifier -Is a device that increases humidity (moisture) in a single room or an entire

7|Page

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

building. In the home, point-of-use humidifiers are commonly used to humidify a

single room, while whole-house or furnace humidifiers, which connect to a home's

HVAC system, provide humidity to the entire house.

Hygrometer - is a device used for measuring the humidity content in the atmosphere.

Thermal insulation - is the reduction of heat transfer (the transfer of thermal energy

between objects of differing temperature) between objects in thermal contact or in

range of radioactive influence.

Latent heat - is the energy released or absorbed by a body or a thermodynamic system

during a constant-temperature process. A typical example is a change of state of

matter, meaning a phase transition such as the melting of ice or the boiling of water.

Metrological is the interdisciplinary scientific study of the atmosphere that focuses

on weather processes and forecasting.

Mist a fine spray produced by a vaporizer to add moisture to the air for breathing.

Nozzle - is a device designed to control the direction or characteristics of a fluid flow

(especially to increase velocity) as it exits (or enters) an enclosed chamber or pipe.

Orifice - is any opening, mouth, hole or vent, as of a pipe, plate, or a body.

8|Page

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

Relative Humidity - (abbreviated RH) is the ratio of the partial pressure of water vapor

to the equilibrium vapor pressure of water at the same temperature. Relative humidity

depends on temperature and the pressure of the system of interest.

Enthalpy - is the preferred expression of system energy changes in many chemical,

biological, and physical measurements, because it simplifies certain descriptions of

energy transfer.

CHAPTER 2

STUDY OF RELATIVE LITERATURE

Thermal Comfort

If temperature and humidity levels in the office are too high or too low, occupants

can be dissatisfied with the environment, uncomfortable and less effective in their tasks.

Comfortable conditions in mechanically ventilated buildings depend on six variables:

air temperature, air velocity, relative humidity, radiant temperature, occupants clothing

insulation and occupants activity level. American Society of Heating, Refrigerating, and

Air-Conditioning Engineers (ASHRAE) Standard -55 defines a comfort zone based on

9|Page

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

these variables, where the majority of occupants are likely to feel comfortable.

The higher density of occupants and equipment in most open-plan offices increases

the amount of heat released (and thereby the cooling requirements) in the space. Thus the

heating/cooling system must have the capacity to handle the occupant density, and be

operated appropriately to meet thermal requirements.

According to the comfort zone diagram, comfortable temperatures are almost

impossible to achieve when the relative humidity is high. High humidity also supports

mould and bacterial growth, so ASHRAE recommends that relative humidity be

maintained below 60%. There is no recommended lower level of humidity for achieving

thermal comfort, but as dry conditions can lead to increased static electricity and health

problems, such as skin irritation, the relative humidity should be greater than 30%.

ASHRAEs acceptable ranges of operative temperature (a combination of air and radiant

temperatures) for relative humidity levels of 30% and 60% are shown in Table 1.

Conditions

Acceptable operative temperatures

Relative humidity 30%

24.528

7682

Relative humidity 60%

2325.5

7478

Summer (clothing insulation = 0.5 clo)

Table 1

Occupants vary their clothing with the seasons, so recommendations for summer

10 | P a g e

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

and winter are given, to reflect the amount of clothing insulation (clo) that clothes

provide. These ranges are valid for typical office activities and for air velocities less than

0.2 m/s (40 ft./min.). For acceptable operative temperatures for different levels of air

velocity, relative humidity, clothing insulation and activity level, refer to ASHRAEs

comfort zone diagrams.1 Findings from an the International Residential Code (IRC) field

study supported what are considered by ASHRAE to be acceptable temperature ranges.

Occupants in open-plan offices typically have to share one thermostat setting,

reducing the control they can exert over the thermal environment. A flexible dress policy

gives occupants one means to fine-tune their thermal comfort, but should not be provided

as an alternative to appropriate building temperature control.

While occupants can be thermally comfortable overall, they may still experience

discomfort on a specific part of their body, most commonly from drafts. Their experience

of draft depends on air temperature, air velocity, and turbulence intensity (the amount of

fluctuation in the air flow).

ASHRAE recommends that conditions be configured so that less than 20% of

occupants are dissatisfied due to draft. In general, air temperature within the comfort zone

and air velocities below 0.2 m/s meet this recommendation, although (IRC) found that a

velocity of 0.1 m/s or less could lead to a further increase in satisfaction.

ASHRAE allows for higher air velocities in warm, humid conditions, as some research

suggests that occupants welcome the cooling effect these higher velocities provide.3 The

11 | P a g e

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

proviso is that occupants have control over the local air speed.

IRC researchers found the alignment of supply air diffusers relative to

workstations sometimes led to an increased risk of draft. This is most likely to be a

problem with smaller workstations, where there is less opportunity for occupants to move

out of the path of supply air, and where the total airflow is also likely to be higher (to cope

with the greater occupant density and higher cooling load).

As well, there is a greater likelihood of draft when the diffusers are angled to

supply large amounts of air directly toward the occupant. When the office is reconfigured,

it is important to change diffuser placement and ventilation volume to help minimize these

problems.

Occupants seated next to a window tend to be less satisfied with thermal

conditions. Although workstations located next to windows benefit from natural lighting

and a view, their occupants often experience a wider range of temperatures because of the

warm or cool radiant temperatures from the window. Blinds, perimeter heating and

cooling, and well-insulated windows can help minimize these problems.

Room temperature (also referred to as ambient temperature) is a common term to

denote a certain temperature within enclosed space to which human beings are

accustomed. Room temperature is thus often indicated by general human comfort, with

the common range of 18C (64F) to 23C (73F), though differences in climate may

acclimate people to higher or lower temperaturesfor instance, 78F could be a common

12 | P a g e

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

temperature for some people.

The term may also refer to the temperature of food to be consumed (such as red

wine), which is placed in a particular room for a given time. In addition, it may refer to a

certain temperature within settings of scientific experiments and calculations.

For human comfort, desirable room temperature greatly depends on individual

needs and various other factors. According to the West Midlands Public Health

Observatory (UK), 21 C (70 F) is the recommended living room temperature, whereas

18 C (64 F) for bedroom temperature. A study carried out at the University of Uppsala

(Sweden), on indoor air quality and subjective indoor air quality (SIAQ) in primary

schools, states that perception of high room temperature was related to a poor climate of

cooperation. To achieve a good SIAQ, it recommends room temperature should be at a

maximum of 22.0 C (71.6 F).

Typically staff and student concerns about indoor thermal comfort occur in areas

that are poorly ventilated and/or inadequately shaded from sunlight. Individual thermal

comfort can also be affected by physical exertion, crowded working areas and some

medical conditions.

The optimal conditions for indoor work environments are outlined below.

Temperature optimum summer temperature range 21-24 degrees Celsius

Temperature range 20-26 degrees Celsius (depending on the time of year)

Humidity range 40-60%

13 | P a g e

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

Minimum recommended fresh air rate 10 Litres per second (L/s) per person or 10

L/s per 10 m2 for mechanical ventilation systems

Optimum air movement 0.1-0.2 m/s (air-conditioned space).

Poor indoor air quality can lead to a number of physical symptoms and complaints.

The most common include:

Headaches

Fatigue

Shortness of breath

Sinus congestion

Coughs

Sneezing

Eye, nose, and throat irritation

Skin irritation

Dizziness

Nausea

Although these physical symptoms and complaints are often attributed to indoor

air quality, it is important to note that indoor air quality is not always responsible. Noise,

overcrowding, improper lighting, poor ergonomic conditions, and job stress can also lead

to these symptoms and complaints. Frequently, a combination of factors is to blame.

Indoor air contaminants affect some people more seriously, including:

14 | P a g e

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

People with allergies or asthma

People with respiratory disease

People whose immune system is suppressed as a result of disease or treatment

People who wear contact lenses

Air Quality - 6 - Factors affecting indoor air quality A number of factors can affect

the indoor air quality of a building or facility, including:

The physical layout of the building

The buildings heating, ventilation, and air conditioning (HVAC) system

The outdoor climate

The people who occupy the building

Contaminants inside and outside the building

The physical layout of the building and of the buildings HVAC system determines

how air moves throughout the building and how much fresh air enters the building from

outside. For example, changing the layout of a building by erecting walls or dividers

inside can change the air circulation patterns and lead to poor air circulation or a

concentration of contaminants in certain areas. The buildings HVAC system is designed

to distribute outdoor air throughout the building, remove contaminants and odours, and

control the indoor temperature and humidity. A poorly designed or poorly maintained

system can cause indoor air quality problems. The outdoor climate can also affect indoor

15 | P a g e

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

air quality, especially in colder regions. For example, to reduce heating costs many HVAC

systems reduce the amount of fresh air brought into the building when the outside air is

cold. Also, the humidity level outside the building can make it difficult to control the

relative humidity inside the building. The people who occupy a building also affect indoor

air quality. Occupants may affect air quality by smoking, cooking, wearing cosmetics or

scents, or producing body odours.

When conditions differ from those listed above, productivity and efficiency are

likely to be adversely affected. Lowered concentration due to discomfort can lead to an

increased risk of accidents.

Hot and humid conditions can lead to dehydration.

Insufficient ventilation (supply of fresh air) can result in a build-up of carbon

dioxide levels that can result in occupants feeling tired and complaining of stuffiness.

Too much ventilation, e.g. air movement faster than 0.2 m/s, may result in some

staff complaining of the cold due to noticeable draughts.

Low humidity can cause dryness of the eyes, nose and throat.

High humidity results in rapid fatigue.

The Maintenance of the unit as follows:

After using the unit fill out the water inside the cylindrical bucket. Clean the inside

and outside of the cylindrical bucket with clean cloth. Clean the air filter with water or use

detergent (Depends on the user) then dry out the water on it. Wipe the fan blade with clean

16 | P a g e

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

cloth to remove the dust. Last then keep the unit in a safe place when not using.

CHAPTER 3

METHODOLOGY

This chapter contains the principles and methodologies of the research design, and

considered materials used and purposed.

There are different sources/ references were considered in developing this air

coolant which includes the data and information from the different links of the World

Wide Web, books and journals specifically on the topics about air cooling, evaporative

cooling and free cooling. Important contribution was made by a family resident in Purok 6

Brgy. Bigaa, Cabuyao, Laguna as our experimental respondent.

This study uses the concept of direct evaporative air cooling. Evaporative cooling

17 | P a g e

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

is a process of heat and mass transfer based on the transformation of sensible heat into

latent heat. The non-saturated air reduces it temperature, providing the sensible heat that

transforms into latent heat to evaporate the water. If the process develops in ideal adiabatic

conditions, the dry bulb air temperature decreases as this transformation develops,

increasing the humidity. The heat exchange continues until the air reaches the saturated

state when the air and water temperature reach the same value or adiabatic saturation

temperature. As applied directly in our study, cold water mixed with ice evaporates

directly in the stream of air, producing an adiabatic process of heat exchange in which the

air dry bulb temperature decreases as its humidity increases.Thus, the amount of heat

transferred from the air to the water is the same as the one employed in the evaporation of

the water.

The Researcher measured the inside space, considered the appliances of the chosen

house and conducted a temperature reading experiment inside and outside of the house in

brgy. Bigaa, Cabuyao, Laguna. The researcher measured the temperature at 12: 00 NN to

3:00 PM because it is the hottest time in our country have. These data will be serve as a

basis

to

the

design

and

the

gathered

data

are

Area:

___,

People:___,

Height:___Lights:___,Quantities:___, Window:___, Appliances:___

Table2. Location assessment

Temperature

Time

Outside

18 | P a g e

Inside

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

12: 00 NN

1:30 PM

3:00 PM

The system was composed of different materials, the researcher choose the

materials that has a low thermal conductivity for less heat transfer inside the system.

Thecircular bucketmade out ofpolypropylenethat will served as a body of the

system,Styrofoam will be glued circularly inside the bucket and will be worked as the

insulator to resist the flow of heat.The bucket and Styrofoam is will be pierced three times

using a hole saw which is a saw blade of ring shaped, with a separation distance of 50.8

mm each and having a hole diameter of 50 mm.then three pieces of hallow pipe having a

50mm outside diameter and 76.2 length is will be fixed on the hole by silicon sealant.The

cover of the system is also made up of polypropylene and will be cut based on the frame

diameter of fan.

The fan is 35 watts, 220 volts, 60 Hz and having frame diameter of 200 mm. the

air produced by the fan is coming from the surroundings. This is placed at the top of the

bucket and pushes the air downward throughout the filter.The filter is placed before the

fan to remove any impurities that will make contact to the ice inside.

As the results of that interconnection of the unit when fan blew the air, the ice

worked as a cooling instrument that gives an air development inside the room. When the

warm air made contact through the ice it will start to evaporate as cooled steam and it will

19 | P a g e

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

go around the roomto enhance the temperature.

This part contains the computation of materials specification based on the design.

CENTRIFUGAL FAN

Power Input: 220V- 60 Hz 35watts

Diameter of Blade: 106mm

RPM: 3600

For finding the total head (ht)

P = Q x aht

(source: Primess Industrial Power Plant Engineering, pp. IV-2)

P Power, Kw

a density of air, 0.01251 kN/m3

Q fan capacity, m3

ht total head, m

Q = Velocity x Area

V = DN = x 0.106 m x

3600 rpm

=19.99 m/s

60 sec .

A=

D2 ( 0.106 m)

=

=8.8247 x 103 m2

4

4

Q = 19.99

20 | P a g e

m

m3

x 8.8243 x 103 m2=0.1763

s

s

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

m3

kN

0.035 kW =0.0882

x 0.01251 3 x ht

s

m

t= 15.87 m

h

Styrofoam

Height: 356mm

Thickness: 12.7mm

Thermal Conductivity: 0.033 W/(mK) (foam, 0.05 g/cm3)

Bucket(Polypropylene)

Diameter (Inside and outside): 285mm, 305mm

Inside: 285mm

Outside: 305mm

Height: 395mm

Thermal Conductivity: 0.17 0.22 W/m K

Pipe

Diameter: 50.8mm

Length: 89mm

21 | P a g e

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

Filter

Diameter: 270 mm

HEAT TRANSFER INSIDE THE SYSTEM

Q=

A ( T )

xb xs

+

kb k s

(Source: Primess Industrial Power Plant Engineering, pp. I-2)

Where:

Q heat transmitted, W

A heat transfer area, m2

T change in temperature inside to outside, K

x b thickness of bucket, 0.010 m

x s Thickness of Styrofoam, 0.0127 m

k s Thermal conductivity of Styrofoam, 0.17

k b Thermal conductivity of bucket, 0.033

W

m K

W

m K

A=H x L

(Source: Plane and Solid Mensuration by Earnhart and Bejasa, 2007, pp. 94)

Where:

22 | P a g e

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

H Height of bucket/Styrofoam,0.356 m

L Length of bucket/Styrofoam ( L = C)

C=2 r

(Source: Plane and Solid Mensuration by Earnhart and Bejasa, 2007, pp. 94)

C Circumference of the bucket/Styrofoam

r Radius of bucket/Styrofoam, 0.1525m

C=2 ( 0.1525 m )

C=0.95818 m

A=L x C

A=0.95818 m x 0356 m

A=0.341114 m2

Q

0.341114 m

=

(T)

0.0127 m

0.010 m

+

W

W

0.033

0.17

m K

mK

Q

W

=10. 4628

K

(T)

The different parameters on how we come up with the materials that used in the

23 | P a g e

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

study.

Centrifugal Fan

Power

Volts

Ampere

Size

RPM

35 Watts

220

0.16

20 cm

3600

Total

Head

15.87m

Styrofoam

Height

35.6 cm

Thickness

1.27 cm

Thermal Conductivity

0.033 W/(mK) (foam, 0.05 g/cm3)

Bucket (Polypropylene)

Diameter

Inside

Outside

28.5 cm 30.5 cm

Height

Thermal Conductivity

39.5 cm

0.17 0.22 W/m K

Total Heat Transfer in the system

Heat Transmitted

10.4628 W/K

Pipes

Diamete

r

24 | P a g e

Length

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

5.08 cm

8.9 cm

Filter

Filter it removes particles from the air stream to both keep the air coolers clean and

to remove particles from the air.

Figure 1

Centrifugal Fan

The use of this is to push the cold air inside from the inside to the outside of the

bucket.

25 | P a g e

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

(Figure 2)

Bucket Cover

The use of this are cover and handle of rotating fan.

Figure 3

Styrofoam

The use of this is thermal insulation for the bucket.

Figure 4

26 | P a g e

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

Hollow Pipes

The use of this is to convey the cold air from the inside of the cylindrical bucket to

the outside of the cylindrical bucket.

(Figure 5)

Cylindrical bucket

The use of this is a case for the Styrofoam.

(Figure 6)

27 | P a g e

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

System specification

(Figure 7

28 | P a g e

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

1. Centrifugal Fan

2. Cylindrical Bucket Cover

3. Styrofoam

4. Hollow Pipes

5. Cylindrical Bucket

ACTUAL PROCEDURE:

PROCEDURE

(Figure 8)

29 | P a g e

Figure 9

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

Apply the shell wood glue on

the Styrofoam

Then Place the styrofoam inside the

bucket

(Figure 10)

After putting the styrofoam inside the

bucket, make sure it is firmly fitted on it

sides, then use the 50.8 mm hole saw to

make a hole for the pipes

(Figure 12)

30 | P a g e

(Figure 11)

Then Cut the pipes in to

3 pcs with a length of 89 mm then place it

on the signify holes.

(Figure 13)

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

Apply silicon sealant

Cut the cover circularly to

make a hole, where the fan will

be place

toprevent leakage inside the bucket

After applying dry it first then

prepare the cover

(Figure 15)

(Figure 14)

RESULT

Then after applying all the

needed materials of the

unit. Paint it for better

appearance

(figure 16)

31 | P a g e

Air Cooling System

(Figure 17)

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

Fix the fan with the cover of the bucket

Use Tie wire to connect it with each other.

Then last place it on the top of the bucket to

complete the unit

Operational Procedures

Steps on how to operate the air cooler

1. Prepare the air cooler and the pack of ice

2. Place the air cooler 1 meter above the ground

3. Get the outdoor air temperature

4. Get the initial dry bulb temperature and wet bulb temperature of the room

5. Measure the initial volume of ice pack

6. Put the ice inside the air cooler unit

7. Turn on the fan, set it to the highest stage

8. Measure the air temperature coming out from the air cooler

9. Record the running time of the air cooler

10. Measure the final dry bulb temperature and wet bulb temperature of the room.

32 | P a g e

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

11. Check the properties of the ice pack

12. Compute the effectiveness of the air cooler inside the room

Experimentation and handling of data

In order to prove/test the cooling effect of the system, series of experiments was

performed.

The Researcher measured the inside space, considered the appliances of the chosen

house and conducted a temperature reading experiment in brgy. Bigaa, Cabuyao, Laguna.

That has been measured in different time. The researcher tabulated the data such as area,

height, people, lights, quantities of window, doors and appliances

(Table3) Location assessment

Temperature

Time

Outside

1pm

2pm

3pm

Cooling unit

33 | P a g e

Inside

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

This experiment was performed by running the unit with specific volume of ice

and measured the temperature of the discharge air in different running time. The

researcher assumed the following volume: 2, 3, 4 litters of ice in each trial. Three trials

were conducted.

Pure ice, slightly melted, nearly melted, almost water. Pure ice, the water is at its

solid form, zero percent water. Slightly melted, the content of water is thirty percent.

Nearly melted, the content of water is sixty percent. Almost water, the content of water is

eighty percent. Water form meaning the there no more ice content.

(Table 4)condition of the ice and the air temperature coming out

Running Time: 15 minutes

Temperature of air coming

Volume of

Trial

Property of Ice

from the unit(C)

the Ice

(Litter/s)

Before

After

Before

1

2

3

(Table 5)condition of the ice and the air temperature coming out

Running Time: 30 minutes

34 | P a g e

After

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

Temperature of air coming

Volume of

Trial

Property of Ice

from the unit(C)

the Ice

Before

(Litter/s)

After

Before

After

1

2

3

(Table 6)condition of the ice and the air temperature coming out

Running Time: 1 Hour

Volume of

Trial

Temperature of air coming

Property of Ice

from the unit(C)

the Ice

(Litter/s)

Before

After

Before

After

1

2

3

After getting all the experimented data, the researcher chooses the most effective

volume of ice in each different running time.

35 | P a g e

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

Determination of the effect of using an ice cooled air cooler.

This experiment was performed by comparing the air cooler versus electric fan and

selecting time at which the temperature is considered hot. The experiment will be

performed at 12:00 NN to 3:00 PM, the researcher will acquired the dry bulb temperature

and wet bulb temperature of the room by using digital thermometer.

The researcherwill choosethe volume of iced based on the result in previous

experiment and used it with a running time of 1 hour and 30 minutes break to restart the

temperature inside the room.

(Table 7)The effect inside the room

Trial

1

2

3

Starting Time

12:00 NN

1:30 PM

3:00PM

CHAPTER 4

DATA AND RESULT

Location assessment

Area: 277cm x 242 cm = 67034 cm2

People: 3

Height: 238cm

Lights: LED lights

Quantities: 1

36 | P a g e

Condition of Room

Using electric fan

Using air cooler

Tdb

Twb

Tdb

Twb

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

Window: 1

Appliances: Television

Cell phone/Charger

Laptop

Standard Temperature of the area

(TABLE 8)

Temperature

Time

Outside

Inside

1pm

30

34

2pm

31

35

3pm

32

34

The Cooling UnitTrials

(TABLE 9)Running Time: 15 minutes

Volume of

Trial

Property of Ice

the Ice

Temperature of air coming

from the unit(C)

(Litter/s)

Before

After

Before

After

Pure Ice

Slightly Melted

25

27

Pure Ice

Slightly Melted

21

23

Pure Ice

Slightly Melted

19

20

(TABLE 10)Running Time: 30 minutes

37 | P a g e

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

Trial

Volume of the

Ice (Litter/s)

Property of Ice

Temperature of air coming

from the unit(C)

Before

After

Before

After

Pure Ice

Nearly Melted

25

27

Pure Ice

Nearly Melted

21

27

Pure Ice

Slightly Melted

19

24

(TABLE 11)Running Time: 1 Hour

Temperature of air coming

Volume of the

Property of Ice

from the unit(C)

Trial

Ice (Litter/s)

Before

After

Before

After

Pure Ice

Water

25

30

Pure Ice

Almost Water

21

28

Pure Ice

Nearly Melted

19

27

Ice properties

38 | P a g e

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

(Figure 18)

In figure 18 it shows that after 1 hour the property of ice turns pure Ice to water

(Figure 19)

In figure 19 it shows that after 1 hour the property of ice turns pure Ice to slightly

water.

(Figure 20)

In figure 20 in the final test it shows that after 1 hour the property of ice turns pure

39 | P a g e

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

Ice

to

slightly water.

Determination of the effect inside room.

Eff. = (Tdb-Te) / (Tdb-Tw) * 100%

Eff. = Efficiency of air cooler as a Percentage

Tdb= Temperature air entering air cooler

Te = Temperature of room after 1 hour

Twb = Wet bulb temperature (entering the air cooler)

Initial temperature

Starting

Trial

Time

1

2

3

12:00 PM

1:30 PM

3:00PM

40 | P a g e

Condition of Room

of the room

Using electric

Tdb

34

35

34

Using evaporative air cooler

Twb

26.1

27.4

26.3

fan

Tdb

32

33

32

Twb

25.9

26.5

26.5

Tdb

31

32

31

Twb

27.4

28.1

27.3

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

(Table 12)

Using Electric fan

At 1:00 PM

Eff. = [(34 32)/(32 25.9)]*100

Eff = 28.17%

At 2:30 PM

Eff. = [(35 32)/(35 26.1)]*100

Eff. = 28.99%

At 4:00 PM

Eff. = [(34 32)/(34 26.3)]*100

Eff = 26.66%

Average eff. = [(28.17 + 28.99 + 26.66)/3]*100

Average eff. = 27.94%

Using Evaporative air cooler

41 | P a g e

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

At 1:00 PM

Eff. = [(34 31)/(34 26.1)]*100

Eff = 37.97%

At 2:00 PM

Eff. = [(35 32)/(35 27.4)]*100

Eff. = 39.47%

At 3:00 PM

Eff. = [(34 31)/(34 26.3)]*100

Eff = 34.48%

Average eff. = [(37.97 + 39.47 + 34.48)/3]*100

Average eff. = 37.31%

Room improvement = Average eff. Of evaporative air cooler Average eff. Of electric fan

= 37.31 27.94

= 9.37 % improvement vs. ordinary electric fan

Data Analysis

(Figure 21)

This is the gathered data for the overall trials that has been conducted in different

time frame.

42 | P a g e

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

SUMMARY OF FINDINGS

This Study was to develop an evaporative air cooler system and its adverse

effectiveness on the extent of our research. The following are the findings after conducting

the experiments:

1. After 15 minutes, the temperature difference for 2L of ice was 2C while for 3L

and 4L, the difference was 3C.

2. At 30 minutes running time, there was an ambient temperature rise for 2L from

31C to 32C making the temperature difference of 1C from the initial

temperature. The same observation was seen for 3L of ice however its temperature

difference was 2C from initial temperature. The same result was observed for 4L

of ice from the 15mins running time.

3. After 1 hour, as based from 30mins running time, the same results were observed

for 2L, 3L, and 4L having a temperature drops of 1C, 2C, and 3C respectively.

43 | P a g e

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

4. Based from the three different time frames, the 4L of ice showed a consistency in

the temperature difference from its initial temperature. The ambient temperature

after the operation of the air cooler settled at 31C having a temperature drop of

3C.

5. Taking into account on the volume of the ice, 30% has melted for 4L, 60% for 3L

and 80% for 2L. The results also show a reasonable outcome hence the surface

area of the ice is also an account for the heat exchange.

6. The improvement of room while using Evaporative air Cooler increased to 9.37 %.

BILS OF MATERIALS FOR THE PROTOTYPE

(figure 22)

Name Of Materials

Price (Php)

Nylon wire

25

Hole Saw Set

400

Glue

55

Styrofoam

63.75

Red paint metallic 2pcs

178

Gold paint metallic 2pcs

178

Sealant White

130

Devcon epoxy

150

Water Base paint

40

Pipe

70

Rotation fan

400

44 | P a g e

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

Bucket sets

150

Amazing roller stand

150

Filter free/donation

Total Expenses

1989.75

CHAPTER 5

CONCLUSION AND RECOMMENDATION

Conclusion

The following conclusions are being deduced from the findings of the experiment:

1. The evaporative water cooler is an effective cooling device as it shows a 3-degree

Centigrade difference in the room temperature from its initial temperature reading.

2. The larger the volume of the ice used, the longer is the running time for the cooling

device to operate.

3. The speed of the fan and the initial ambient temperature (temperature before the

application of air cooler) also affects the time limit or the melting time of the ice inside the

air cooler.

4. The tolerable or enough room size would correspond to a best result of the evaporative

water cooler.

Recommendation

Based on the results and inferences of the study, the following are recommendations for

45 | P a g e

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

the improvement of the study:

1. With a blower in the cooling system, one disadvantage is that it is expected that the

ice would melt quicker but not enough to improve the temperature of the

room.However for future studies, we suggest adding a suction or exhaust

systemwill enhance the flow of air through the area.

2. On the other side, if the availability of ice is sufficient, we suggest to add salt on

ice for faster room cooling. Adding salt to water lowers the freezing point, thus

preventing the formation of ice. In the effect when salt is added to water, the salt

and water molecules stick together removing the additional heat that is required to

freeze the salt-water combination making the ice melts faster.

3. For future innovations, the researchers would also like to recommend the use of a

desiccant for the air blown by the air cooling system. A desiccant would sustain the

dryness of the air in the vicinity of the cooler.

4. We would also like to suggest the usage of the air-cooling system on the exact

room area or size for the cooling system for it to be well functional in respond to

the needs of the people. A smaller area is highly suggested.

5. We further recommend trying the air-cooling system to other space area having a

different construction, like wood, so as to experiment on the efficiency of our

innovation.

46 | P a g e

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

Reference

Francisco ,Jose R (2006). Air-conditioning and Analysis and Design hand book,

Quezon City:C&E Pub., 2006.

Mandawe, J.A and Capote, R.s (2007). Industrial Plant Engineering hand book [s.l.]:

Benchmark Publishers, c2005. ISBN9718060227

Sta. Maria, Hipolito B.(1993) Air-conditioning 2nd edition handbook. Publisher:

Manila: National Bookstore, 1989

Sta.Maria ,Hipolito B. (1990). Thermodynamics 1 published by Ser Nas FErnandez

on Oct 04, 2013

Sta. Maria, Hipolito B., Melegnito, Raymund M., Pasamontes, Nelson M., Sapano,

Renato M. (1991). Thermodynamics 2, Published by Unified Mechanical

Engineering and Technology Society on Apr 04, 2010

Wang, S. K., Lavan, Z., & Kreith, F. (1999). Air-conditioning and refrigeration,

47 | P a g e

University of Perpetual Help System Laguna

Sto. Nio, Bian City, Laguna

College of Engineering & Tech-Voc

(02) 520-8290 local 3006 / CELL# 09228900917`

mechanical engineering handbook. CRC Press LL. Frank Kreith Boca Raton.

Zubair, S. M., Yaqub, M., & Khan, S. H. (1996). Second-law-based thermodynamic

analysis of two-stage and mechanical-subcooling refrigeration

cycles. International journal of refrigeration, 19(8), 506-516.

Blumberg, Mark S. 2004. Body Heat: Temperature and Life on Earth. New Ed Edition.

Cambridge, MA: Harvard University Press. ISBN 0674013697

Fendrich, J. (2009). Chemistry in Action-Triple Delight. Science Scope, 33(2), 46.

Charles, K. E., Reardon, J. T., & Magee, R. J. (2005). Indoor air quality and thermal

comfort in open-plan offices. Institute for Research in Construction, National

Research Council of Canada.

Raj, V. A. A., & Velraj, R. (2010). Review on free cooling of buildings using phase

change materials. Renewable and Sustainable Energy Reviews, 14(9), 2819-2829.

Voss, Matt , Andrew Skipor, Ph.D., (2006), The salt does in fact melt the ice, Science

K-12 Educators, sponsored and operated by Argonne National Laboratory's

Educational Programs, Andrew Skipor, Ph.D., Head of Educational Programs.

Zalba, B., Marn, J. M., Cabeza, L. F., & Mehling, H. (2004). Free-cooling of

buildings with phase change materials. International Journal of Refrigeration,

27(8), 839-849

48 | P a g e

S-ar putea să vă placă și

- Comfort Requirements and Sustainability in Housing Construction in AngolaDocument6 paginiComfort Requirements and Sustainability in Housing Construction in AngolaJoao MoreiraÎncă nu există evaluări

- Motion Activated Temperature Controlled Matc Electric FanDocument5 paginiMotion Activated Temperature Controlled Matc Electric FanBuena QuintinÎncă nu există evaluări

- 2010 Envisci Paper GSHPDocument16 pagini2010 Envisci Paper GSHPHector Miguel Hernandez TurrubiatesÎncă nu există evaluări

- SANTOS Midterm Major Requirement Research ProposalDocument8 paginiSANTOS Midterm Major Requirement Research Proposalefraim lemuel santosÎncă nu există evaluări

- Maglasang - Report On Research Paper Review #1Document23 paginiMaglasang - Report On Research Paper Review #1Jude Philip MaglasangÎncă nu există evaluări

- Cost and Return Analysis To Upgrade Existing Homes To Be Sustainable and EfficientDocument8 paginiCost and Return Analysis To Upgrade Existing Homes To Be Sustainable and EfficientmrstewardÎncă nu există evaluări

- Hvac DesignDocument8 paginiHvac DesignSuan, Mike E.Încă nu există evaluări

- Building Science 1: Thermal Comfort ReportDocument60 paginiBuilding Science 1: Thermal Comfort ReportChristopher Ng Man KingÎncă nu există evaluări

- CarbonDocument300 paginiCarbonJashwin Ullal100% (1)

- Adapting Zero Carbon Houses For Tropical Climates - Passive Cooling Design in The PhilippinesDocument8 paginiAdapting Zero Carbon Houses For Tropical Climates - Passive Cooling Design in The PhilippinesLouise BayÎncă nu există evaluări

- Write Up For The DIY TechnologyDocument6 paginiWrite Up For The DIY TechnologySheena LaniogÎncă nu există evaluări

- In-Situ Evolution of Heat and Mass Transfer Phenomena and Evaporative Water Losses of Three Agro-Waste Evaporative Cooling Pads: An Experimental and Modeling StudyDocument11 paginiIn-Situ Evolution of Heat and Mass Transfer Phenomena and Evaporative Water Losses of Three Agro-Waste Evaporative Cooling Pads: An Experimental and Modeling StudySanaan AhmadiÎncă nu există evaluări

- Energy Savings That Can Be Achieved by Installation of Solar Water HeaterDocument11 paginiEnergy Savings That Can Be Achieved by Installation of Solar Water HeaterARUN 007Încă nu există evaluări

- Energy Conservation in Air Conditioning and Refrigeration SystemsDocument3 paginiEnergy Conservation in Air Conditioning and Refrigeration Systemssuresh vÎncă nu există evaluări

- Development of Spray Type Condenser Cooling System Attachment For Window Type Air Conditioning UnitDocument37 paginiDevelopment of Spray Type Condenser Cooling System Attachment For Window Type Air Conditioning UnitJustineMarieSegoviaBuenaflorÎncă nu există evaluări

- Esl Report BethDocument4 paginiEsl Report BethFatima PaqueteÎncă nu există evaluări

- Conservation Measures of Water and ElectDocument11 paginiConservation Measures of Water and ElectfreeretdocsÎncă nu există evaluări

- CTZ 040Document16 paginiCTZ 040Pl TorrÎncă nu există evaluări

- Sakib 2021 IOP Conf. Ser. Mater. Sci. Eng. 1078 012035Document10 paginiSakib 2021 IOP Conf. Ser. Mater. Sci. Eng. 1078 012035Ernest Rael RoqueÎncă nu există evaluări

- An Effective Combined Cooling With Power Reduction For Refrigeration Cum Air Conditioner, Air Cooler and Water Cooler: A ReviewDocument7 paginiAn Effective Combined Cooling With Power Reduction For Refrigeration Cum Air Conditioner, Air Cooler and Water Cooler: A ReviewShubham SharmaÎncă nu există evaluări

- SamsungDocument5 paginiSamsungzondombalenhle453Încă nu există evaluări

- Solar Water Heating ThesisDocument6 paginiSolar Water Heating Thesisfc5wsq30100% (1)

- Cib DC28305Document8 paginiCib DC28305olajumokekvÎncă nu există evaluări

- Geothermal in GreenhousesDocument9 paginiGeothermal in Greenhousesa-christÎncă nu există evaluări

- ELECONDocument17 paginiELECONA.keerthana A.keerthanaÎncă nu există evaluări

- 1366 LongPaperSubmissionDocument5 pagini1366 LongPaperSubmissionRenata MansueloÎncă nu există evaluări

- SANTOS Research Proposal in Journal Format (Draft)Document5 paginiSANTOS Research Proposal in Journal Format (Draft)efraim lemuel santosÎncă nu există evaluări

- Mobile Thermoelectric Cooling Jacket For Philippine ClimateDocument14 paginiMobile Thermoelectric Cooling Jacket For Philippine ClimateJohn CarlÎncă nu există evaluări

- Chapter OneDocument9 paginiChapter OneHope Consolacion AparicioÎncă nu există evaluări

- Sustainable Community Planning: Co2 Free HotelDocument12 paginiSustainable Community Planning: Co2 Free HotelDiana ZhumabaevaÎncă nu există evaluări

- Sustainability 05 01680Document20 paginiSustainability 05 01680Rami SaeedÎncă nu există evaluări

- Depita, Velarde, Rondina, Malagamba, Solana: Homemade Aircon Made of Foam Box and Plastic BottlesDocument7 paginiDepita, Velarde, Rondina, Malagamba, Solana: Homemade Aircon Made of Foam Box and Plastic BottlesJacie TupasÎncă nu există evaluări

- Chapter 1Document8 paginiChapter 1Jay UmaliÎncă nu există evaluări

- A Small Geothermal Project of Low Enthalpy in B o B o SandDocument7 paginiA Small Geothermal Project of Low Enthalpy in B o B o SandMARCOSÎncă nu există evaluări

- Closed Greenhouse Cooling JH 2009Document7 paginiClosed Greenhouse Cooling JH 2009Javiercm10Încă nu există evaluări

- Temperature GuidedDocument36 paginiTemperature Guidedqfmn8tcp2zÎncă nu există evaluări

- 2009 - The Use of Deep Water Cooling Systems - Two Canadian ExamplesDocument4 pagini2009 - The Use of Deep Water Cooling Systems - Two Canadian ExamplesJeffÎncă nu există evaluări

- Actual Usage Conditions and Energy Consumption of Refrigerator-FreezersDocument22 paginiActual Usage Conditions and Energy Consumption of Refrigerator-FreezersMoeP - KYYÎncă nu există evaluări

- Ceylan 2016Document23 paginiCeylan 2016MichelÎncă nu există evaluări

- Investigation Study of Solar Peltier Referigerator: Dept of Mechanical Engg, Nhce Banglore 1Document31 paginiInvestigation Study of Solar Peltier Referigerator: Dept of Mechanical Engg, Nhce Banglore 1Akash BiradarÎncă nu există evaluări

- Modelling and Fabrication of Solar Powered Air Cooler With Coolingcabin For Household Food ItemsDocument2 paginiModelling and Fabrication of Solar Powered Air Cooler With Coolingcabin For Household Food ItemsSoumyodeep MukherjeeÎncă nu există evaluări

- 75.your Detailed Guide To Energy Efficient Housing PDFDocument206 pagini75.your Detailed Guide To Energy Efficient Housing PDFKVRamanan100% (1)

- New Solar Water Heating System Safety Design and IDocument7 paginiNew Solar Water Heating System Safety Design and Ihari karanÎncă nu există evaluări

- Building and Environment: A. Franco, R. Fernández-Cañero, L. Pérez-Urrestarazu, D.L. ValeraDocument9 paginiBuilding and Environment: A. Franco, R. Fernández-Cañero, L. Pérez-Urrestarazu, D.L. Valerafrank_luna_43Încă nu există evaluări

- PID5196785Document7 paginiPID5196785danyalÎncă nu există evaluări

- Optimization of Air Conditioning System: D. Y. Patil College of Engg. & Tech., Kolhapur - Page 1 of 19Document19 paginiOptimization of Air Conditioning System: D. Y. Patil College of Engg. & Tech., Kolhapur - Page 1 of 19OmkarÎncă nu există evaluări

- Portable Water Cooler With Water Heater Using TherDocument10 paginiPortable Water Cooler With Water Heater Using Thersai jagatheeswaranÎncă nu există evaluări

- Group 4 - Heat TransferDocument22 paginiGroup 4 - Heat TransferKolokoy KasinÎncă nu există evaluări

- Report On Sustanability: About SiteDocument14 paginiReport On Sustanability: About SiteRia GurbaniÎncă nu există evaluări

- Enhancing The Efficiency of Industrial Airconditioning System Using Nano ParticleDocument10 paginiEnhancing The Efficiency of Industrial Airconditioning System Using Nano ParticleIJRASETPublicationsÎncă nu există evaluări

- SANTOS 6.3.1 Project Design Study DraftDocument3 paginiSANTOS 6.3.1 Project Design Study Draftefraim lemuel santosÎncă nu există evaluări

- IntroductionDocument3 paginiIntroductionGab OdonioÎncă nu există evaluări

- LCCC, Energy Efficiency and Renewable Energy Site. Ministry of Communication, Works, Transport and Public Utilities, St. Lucia, 12-2010Document34 paginiLCCC, Energy Efficiency and Renewable Energy Site. Ministry of Communication, Works, Transport and Public Utilities, St. Lucia, 12-2010Detlef LoyÎncă nu există evaluări

- Importance of Energy ConservationDocument5 paginiImportance of Energy ConservationShradda VkkÎncă nu există evaluări

- Solar Air Conditioner Research PaperDocument6 paginiSolar Air Conditioner Research Papergz8zw71w100% (1)

- Advances in Air Conditioning Technologies: Improving Energy EfficiencyDe la EverandAdvances in Air Conditioning Technologies: Improving Energy EfficiencyÎncă nu există evaluări

- Research Papers Renewable Energy SourcesDocument6 paginiResearch Papers Renewable Energy Sourcesgz7y9w0s100% (1)

- Climatizacion Sostenible en Zonas Calidas de ColombiaDocument9 paginiClimatizacion Sostenible en Zonas Calidas de ColombiaJuan Pablo CdlmÎncă nu există evaluări

- Energy Harvesting From Road Pavements Using Thermoelectric Generators at Tuguegarao City, PhilippinesDocument47 paginiEnergy Harvesting From Road Pavements Using Thermoelectric Generators at Tuguegarao City, PhilippinesSofia Delos SantosÎncă nu există evaluări

- Act - No.3 - Summary ReportDocument2 paginiAct - No.3 - Summary ReportJeriza AquinoÎncă nu există evaluări

- Petrochemical ProcessDocument20 paginiPetrochemical Processsanjeevs01Încă nu există evaluări

- C-H Activation CyclopalladationDocument22 paginiC-H Activation CyclopalladationQifeng WangÎncă nu există evaluări

- Theory of Coprecipitation MethodDocument22 paginiTheory of Coprecipitation MethodSebastian PalaÎncă nu există evaluări

- Bimbel 2Document6 paginiBimbel 2Wibowo Sugandi, S.T.Încă nu există evaluări

- Aromatic Substi-Wps OfficeDocument54 paginiAromatic Substi-Wps OfficeTariq ZiaÎncă nu există evaluări

- Supercritical PlantDocument71 paginiSupercritical PlantNitish KumarÎncă nu există evaluări

- CHE 156a REDOX ReactionsDocument62 paginiCHE 156a REDOX ReactionsJosephÎncă nu există evaluări

- Journal of Chemical Education Volume 74 Issue 1 1997Document2 paginiJournal of Chemical Education Volume 74 Issue 1 1997Hector LeytonÎncă nu există evaluări

- 25008Document13 pagini25008AdyÎncă nu există evaluări

- Metallization, Back-End Technology (BEOL)Document65 paginiMetallization, Back-End Technology (BEOL)Celia ThomasÎncă nu există evaluări

- Reactions of Aliphatic Alcohols and PhenolDocument9 paginiReactions of Aliphatic Alcohols and Phenolmoon star angelÎncă nu există evaluări

- 5 Lesson Plan On HeatDocument4 pagini5 Lesson Plan On HeatJustine Collamar GanabÎncă nu există evaluări

- PPE Problem Set 1Document128 paginiPPE Problem Set 1Gracee86% (14)

- BASF Alumina Catalysts Broschuere UpdateDocument13 paginiBASF Alumina Catalysts Broschuere Updatevibage2942Încă nu există evaluări

- Exp 3Document6 paginiExp 3ohhiÎncă nu există evaluări

- HVAC 02 Heat ExchangerDocument28 paginiHVAC 02 Heat ExchangerRyanmizar Satrio NeoÎncă nu există evaluări

- Sevilv22.10.2012 21.35.18sciDocument6 paginiSevilv22.10.2012 21.35.18sciBayu Pramana PutraÎncă nu există evaluări

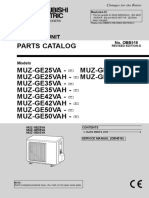

- Manual Técnico de Despiece A.A. Serie MUZ-GEDocument12 paginiManual Técnico de Despiece A.A. Serie MUZ-GEesteban andres olivaÎncă nu există evaluări

- Hydrothermal MethodDocument16 paginiHydrothermal Methodavni vatsÎncă nu există evaluări

- Final05 PDFDocument7 paginiFinal05 PDFRam chandraÎncă nu există evaluări

- Pub - Solid State Physics PDFDocument299 paginiPub - Solid State Physics PDFMohit PandeyÎncă nu există evaluări

- Jamb-chemistry-syllabus-by-Studentmajor.com-convertedDocument4 paginiJamb-chemistry-syllabus-by-Studentmajor.com-convertedEtefia EtefiaÎncă nu există evaluări

- HVAC Training - Updated PDFDocument80 paginiHVAC Training - Updated PDFmohamed sharief100% (1)

- GCSE Science Double Award (2017) - Advance-Information-2023Document24 paginiGCSE Science Double Award (2017) - Advance-Information-2023David McFaulÎncă nu există evaluări

- Fenske Underwood Gilliland (FUG)Document8 paginiFenske Underwood Gilliland (FUG)HariKrishnaBushiÎncă nu există evaluări

- SreejithDocument23 paginiSreejithAkn SÎncă nu există evaluări

- Scha021 Schb021 Practical Guide 2023Document70 paginiScha021 Schb021 Practical Guide 2023Tsebang BeholdÎncă nu există evaluări

- Binary ORC (Organic Rankine Cycles) Power Plants For The Exploitation of Medium-Low Temperature Geothermal Sources - Part B Techno-Economic OptimizationDocument12 paginiBinary ORC (Organic Rankine Cycles) Power Plants For The Exploitation of Medium-Low Temperature Geothermal Sources - Part B Techno-Economic OptimizationJoao Minho100% (1)

- BS 5422 2001 Method For Specifying Thermal Insulating Materials For Pipes, Tanks, Vessels, DuctDocument60 paginiBS 5422 2001 Method For Specifying Thermal Insulating Materials For Pipes, Tanks, Vessels, DuctRamiAl-fuqahaÎncă nu există evaluări

- Gr12 WorksheetDocument3 paginiGr12 WorksheetDGGØDÎncă nu există evaluări