Documente Academic

Documente Profesional

Documente Cultură

API 5L PRACTICE QUESTIONS - Doc r2

Încărcat de

Mhd EbalTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

API 5L PRACTICE QUESTIONS - Doc r2

Încărcat de

Mhd EbalDrepturi de autor:

Formate disponibile

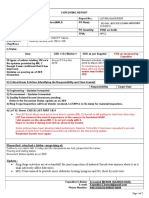

OPEN BOOK EXAMINATION

API 5L STANDARD (2007) PRACTICE QUESTIONS

Name :

Examination :

Date of

Please answer all the questions as below.

1.

What edition ISO standards are added to API 5L?

ISO 3183 -1/2/3(1996)

2.

How many specification levels in API 5L and what are they?

Two (PS1 & PS2)

3. What is the PSL stand for?

Product Specification Level

4. Which is more stringent PSL 1 or PSL 2?

PSL2

5. What additional mandatory requirements for PSL 2?

Chemical composition, notch toughness and strength properties and

additional NDE

6.

What kind of welding process is EW? Electric Welding

7.

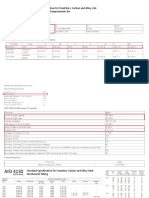

What is the formula for carbon equivalent for PSL 2 pipe with a product

analysis carbon mass fraction equal to or less than 0.12% ?

CE =C+Si/30+Mn/20+ Cu/20 +Ni/60+Cr/20+Mo/15+V/10+5B

8.

What is the formula for carbon equivalent for PSL 2 pipe with a product

analysis carbon mass fraction greater than 0.12% ?

CW = C + Mn/6 + (Cr+ Mo +V) / 5 + (Ni + Cu)/15

9.

The seams of double-seam pipe shall be approximately 180?

(True/False) True

10.

Internal metal separation that creates layers, generally parallel to the

pipe surface is called lamination? (True/False) True

11.

What kind of general information to be supplied by the purchaser to the

manufacturer which shall be included in the purchase order when

ordering pipes?

Quantity, PSL level, type of pipe, reference to ISO 3183, steel grade,

outside diameter and wall thickness, Length and type of length,

comfirmation of applicability of individual annexes.

12.

The yield strength of API pipe grade B (seamless) is 35 500psi?

(True/False) True

13.

The tensile strength of API pipe grade L485 or X 70 is 82 700psi?

(True/False) True

14.

What is the minimum average (of a set of three test pieces) absorbed

energy for each pipe weld and HAZ test, based upon full size test pieces

and a test temperature of 0 C for diameter less than 56.000 in. in

grades L555 or X80 ? 27J

15.

For Drop-Weight Tear (DWT) for PSL 2 welded pipe, what is the average

shear fracture for each test based upon a test temperature of 0 C if

thickness is less than 25.4mm? 85%

16.

All pipes shall be free from defects in the finished condition? (True/False)

True

17.

All pipes shall be free from cracks, sweats and leaks? (True/False) True

18.

The acceptance criteria for imperfections found by non-destructive

inspection shall be in accordance with Annex?

E

19.

Undercuts -0.4mm depth and regardless in SAW and COW pipes found

by visual inspection is acceptable? acceptable

20.

Is arc burns classified as defects? True or False. True

21.

Laminations or inclusions extending into the face or bevel of the pipe and

having a visually determined length in the circumferential direction>

6.4mm shall be classified as defects? True or False. True

22.

For other than dents, geometric deviations from the normal cylindrical

contour of the pipe(flat spots and peaks) that occur as a result of the pipe

forming process or manufacturing operations and that exceeds 3.2mm in

depth, measured as the gap between the extreme point of the deviation

and the prolongation of the normal contour of the pipe, shall be

considered defects? True or False. True

22.

What is the maximum depth for sharp bottom gouges dent if the length of

the dent is equal or less than 0.5D? 3.2mm

23.

What is the maximum depth for other dents if the length of

the dent is equal or less than 0.5D? 6.4mm

24.

Any hard spot larger than 50mm in any direction shall be classified as a

defect if its hardness exceeds 35HRC,345HV10 or 327HBW, based upon

individual indentations. True or False. True

26.

Based on the defects, is it true that, the sections of the pipe containing the

surface defects shall be cut off, within the limits on length? True or False.

True

27.

What is the diameter tolerance on end pipe for pipe diameter greater than

168.3mm.? +/- 0.005D but maximum of =/- 1.6mm

28.

What is the out-of-roundness tolerances for pipe end for pipe diameter

greater than 168.3mm ? 0.015D

29.

What is the tolerance for wall thickness for 8mm seamless pipe (SMLS)?

+0.150t/-0.125t.

30.

The total deviation from a straight line (straightness), over the entire pipe

length, shall be 0.2% of the pipe length? True or False. True

31.

The local deviation from a straight line (straightness) in the 1000mm

portion at each pipe end shall be 4.0mm ? True or False. True

32.

PSL pipe shall be furnished with plain ends? True or False. True

33.

The out of squareness, measured for finish of plain ends shall be

1.6mm? True or False. True

34.

Unless otherwise agreed, the end faces of plain-end pipe with t> 3.2mm

shall be beveled for welding (bevel angle 30 +5 / - and width of the root

face of the bevel shall be 1.6mm with a tolerance of +/- 0.8mm)? True or

False. True

35.

The outside flash shall be trimmed to an essentially flush condition for EW

& LW pipes. True or False. True

36.

The inside flash shall not extend above the contour of the pipe by more

than 1.5mm EW & LW pipes. True or False. True

37.

What is the tolerances for mass for pipe grade L175,L175P,A25 and A25P

? +10% -5.0%

38.

What is the holding time for hydrostatic test for welded pipe D> 457mm?

not less than 10sec.

39.

The hydrostatic test pressure for plain end pipe shall using what equation

formula with results rounded to the nearest 10psi?

P =2St/D

40.

Name the requirements of pipe markings found on completed pipe.

a) Name or mark of manufacturer of the pipe.

b) Specified outside diameter.

c) Number designation of ISO 3183 plus, or alternatively, an identical

national adoption of ISO if agreed.

d) Specified wall thickness.

e) Pipe steel grade

f) Product specification level designation

g) Type of pipe

h) Mark of the customers inspection representative

i) An identification number which permits the correlation of the product or

delivery unit with the related inspection document, if applicable.

S-ar putea să vă placă și

- Painting Inspector: Passbooks Study GuideDe la EverandPainting Inspector: Passbooks Study GuideÎncă nu există evaluări

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryDe la EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryÎncă nu există evaluări

- Octg (Casing & Tubing) - API 5ct Tubing LDocument4 paginiOctg (Casing & Tubing) - API 5ct Tubing LalizareiforoushÎncă nu există evaluări

- API 5l Practice Questions Doc r2Document4 paginiAPI 5l Practice Questions Doc r2Anonymous SLI4aGÎncă nu există evaluări

- API 5L Welded PipeDocument2 paginiAPI 5L Welded Pipereliant pipesÎncă nu există evaluări

- Valves & Fittings PDFDocument24 paginiValves & Fittings PDFFahad AhmadÎncă nu există evaluări

- Line Pipe API 5lDocument3 paginiLine Pipe API 5lJithuJohnÎncă nu există evaluări

- API 5L QuesDocument33 paginiAPI 5L QuesRavindra S. Jivani100% (1)

- Api 5LDocument22 paginiApi 5Lmullanji50% (2)

- TK®-236 Physical Properties: 1. HardnessDocument2 paginiTK®-236 Physical Properties: 1. HardnessSaradhi MedapureddyÎncă nu există evaluări

- Training Session On Api Specification 5L 46 EditionDocument32 paginiTraining Session On Api Specification 5L 46 EditionVenkatesh Naidu100% (1)

- BSEN1092 16 DimensionsDocument2 paginiBSEN1092 16 DimensionsalfonscarlÎncă nu există evaluări

- Insulating JointDocument17 paginiInsulating Jointreza329329100% (1)

- BS 4504 FlangeDocument11 paginiBS 4504 FlangeAlon BalonÎncă nu există evaluări

- Heat Treatment Requirement As Per ASME B31.3Document2 paginiHeat Treatment Requirement As Per ASME B31.3Siddiqui Abdul Khaliq67% (3)

- API 5L 46th-Edition Update 20180424 PDFDocument1 paginăAPI 5L 46th-Edition Update 20180424 PDFIshtiaq Ishi100% (1)

- 2019 ASME Section IX SynopsisDocument31 pagini2019 ASME Section IX SynopsisFaiez GhrabÎncă nu există evaluări

- Asme Section Ii A Sa-29 Sa-29m PDFDocument26 paginiAsme Section Ii A Sa-29 Sa-29m PDFHyunjong MoonÎncă nu există evaluări

- WPS SummaryDocument33 paginiWPS SummaryMidhun K ChandraboseÎncă nu există evaluări

- Astm A860Document5 paginiAstm A860julian2282254Încă nu există evaluări

- Iso 8502-06Document18 paginiIso 8502-06Alex OliveiraÎncă nu există evaluări

- Telebrineller System BrochureDocument15 paginiTelebrineller System BrochureITTSA S.A DE C.VÎncă nu există evaluări

- Vijay CV Cswip Nace 1Document3 paginiVijay CV Cswip Nace 1Vijay RajputÎncă nu există evaluări

- Scope: PurposeDocument5 paginiScope: Purposezahid_497100% (1)

- Conduct Ultrasonic Testing and Magnetic Particle Inspection On Rig Mast and Structure As Per API RP4G CATDocument18 paginiConduct Ultrasonic Testing and Magnetic Particle Inspection On Rig Mast and Structure As Per API RP4G CATMurugananthamParamasivam100% (2)

- STD 1104 - Welding of Pipelines and Related FacilitiesDocument38 paginiSTD 1104 - Welding of Pipelines and Related FacilitiesGishnu SunilÎncă nu există evaluări

- Catalogo GASKET General Measurement TablesDocument20 paginiCatalogo GASKET General Measurement TablescastibraÎncă nu există evaluări

- Asme B16.34 Valves - Flanged, Threaded, and Welding EndDocument77 paginiAsme B16.34 Valves - Flanged, Threaded, and Welding EndWilfredo Saavedra50% (2)

- Final Inspection Release NoteDocument2 paginiFinal Inspection Release NoteMark ThrelfallÎncă nu există evaluări

- Electric-Fusion-Welded Steel Pipe For Atmospheric and Lower TemperaturesDocument7 paginiElectric-Fusion-Welded Steel Pipe For Atmospheric and Lower Temperaturesrgi178Încă nu există evaluări

- A Process Engineer'S Guide To The Pressure Equipment DirectiveDocument25 paginiA Process Engineer'S Guide To The Pressure Equipment DirectiveadrianioantomaÎncă nu există evaluări

- 5 CTDocument5 pagini5 CTDileep KumarÎncă nu există evaluări

- Aluminum-Bronze Sand Castings: Standard Specification ForDocument5 paginiAluminum-Bronze Sand Castings: Standard Specification Forpablo_stzÎncă nu există evaluări

- API 1104 Acceptance CriteriaDocument2 paginiAPI 1104 Acceptance CriteriaEngr Arfan Ali Dhamraho79% (14)

- Essential VariablesDocument6 paginiEssential VariablesVikas LkÎncă nu există evaluări

- Technical Inquiries To API 1104Document20 paginiTechnical Inquiries To API 1104Rey Fiedacan92% (12)

- Difference ASTM A106 and A333 Grade 6.Document2 paginiDifference ASTM A106 and A333 Grade 6.Qaisir MehmoodÎncă nu există evaluări

- Pqr-152 - Run SheetDocument38 paginiPqr-152 - Run SheetMAT-LIONÎncă nu există evaluări

- API 6A 21 Edition WG: API Subcommittee SC-6 DiscussionsDocument9 paginiAPI 6A 21 Edition WG: API Subcommittee SC-6 DiscussionsMinhaj AkbarÎncă nu există evaluări

- En 10253-4 - Butt-Welding Pipe Fitting-Stainless SteelDocument100 paginiEn 10253-4 - Butt-Welding Pipe Fitting-Stainless Steelนพโชติ เสนาพิทักษ์Încă nu există evaluări

- Expediting Report MIL-30Sept FINALDocument2 paginiExpediting Report MIL-30Sept FINALjasmineamma100% (1)

- API 5CT Casing MaterialDocument6 paginiAPI 5CT Casing Materialkaveh-bahiraee100% (2)

- Hydrotesting of PipelineDocument14 paginiHydrotesting of PipelineJWC Sales & Services :100% (1)

- Asme Section Ii A Sa-179 Sa-179m PDFDocument4 paginiAsme Section Ii A Sa-179 Sa-179m PDFHyunjong MoonÎncă nu există evaluări

- API 6A Pressure EquipmentDocument13 paginiAPI 6A Pressure EquipmentLee Sweningson100% (1)

- LG5003 OpsDocument20 paginiLG5003 Opstamilmalar08Încă nu există evaluări

- Two Step Spiral Pipe ManufacturingDocument4 paginiTwo Step Spiral Pipe ManufacturingEagle SpiritÎncă nu există evaluări

- Especificacion API 5lDocument44 paginiEspecificacion API 5ljpcc1986100% (1)

- Steel Pipes Tubes Eng PDFDocument21 paginiSteel Pipes Tubes Eng PDFsintaprisilliaÎncă nu există evaluări

- Sa 450/sa 450MDocument13 paginiSa 450/sa 450MSaravana VelÎncă nu există evaluări

- Fluid Service CategoriesDocument5 paginiFluid Service CategoriesKodali Naveen Kumar100% (1)

- API 1104 WQTRDocument2 paginiAPI 1104 WQTRalisyalalaÎncă nu există evaluări

- AISI 4130: Standard Specification For Steel Bars, Carbon and Alloy, Hot-Wrought, General Requirements ForDocument3 paginiAISI 4130: Standard Specification For Steel Bars, Carbon and Alloy, Hot-Wrought, General Requirements ForAndy SaputroÎncă nu există evaluări

- Ruukki Hot Rolled Steels Inspection DocumentsDocument17 paginiRuukki Hot Rolled Steels Inspection Documentsfranz_passariniÎncă nu există evaluări

- Api 6a 21 Ed Summary of ChangesDocument2 paginiApi 6a 21 Ed Summary of ChangesQuality controller100% (3)

- Q & A 2023Document10 paginiQ & A 2023Ehab AhmedÎncă nu există evaluări

- Aramco Exam QusDocument23 paginiAramco Exam Qussarath100% (3)

- Piping QuizDocument20 paginiPiping QuizMuhammad Tamanna ButhaÎncă nu există evaluări

- Piping QuizDocument20 paginiPiping QuizAlex CarreraÎncă nu există evaluări

- Question For InterviewDocument4 paginiQuestion For InterviewJlkKumar100% (2)

- Chemflake SpecialDocument5 paginiChemflake Specialmajmor-1Încă nu există evaluări

- Baltoflake S2000Document5 paginiBaltoflake S2000Mhd EbalÎncă nu există evaluări

- Chapter 1 Innovation ManagementDocument31 paginiChapter 1 Innovation ManagementMhd EbalÎncă nu există evaluări

- Repair PatchDocument1 paginăRepair PatchMhd EbalÎncă nu există evaluări

- Equilibrium in Rigid BodiesDocument3 paginiEquilibrium in Rigid BodiesMhd EbalÎncă nu există evaluări

- Car CoolDocument6 paginiCar CoolMhd EbalÎncă nu există evaluări

- Radiographic Interpretation Graphs GuidelineDocument15 paginiRadiographic Interpretation Graphs GuidelineMhd Ebal100% (1)

- Welding SubpartEDocument71 paginiWelding SubpartEsumedheilÎncă nu există evaluări

- Osma Osmadrain BG Pim Od107 Feb 2017pdfDocument58 paginiOsma Osmadrain BG Pim Od107 Feb 2017pdfDeepakkumarÎncă nu există evaluări

- Science Form 3 2020 (Notes, PBD, Exercise) : Chapter: 8 RadioactivityDocument19 paginiScience Form 3 2020 (Notes, PBD, Exercise) : Chapter: 8 Radioactivitysakinah100% (1)

- Hubungan Faktor Lokal, Faktor Sistemik Dan Faktor Perilaku Terhadap Kejadian Penyakit Periodontal Di Indonesia (Analisis Riskesdas)Document10 paginiHubungan Faktor Lokal, Faktor Sistemik Dan Faktor Perilaku Terhadap Kejadian Penyakit Periodontal Di Indonesia (Analisis Riskesdas)lidyaÎncă nu există evaluări

- Bio1 11 - 12 Q1 0501 FDDocument23 paginiBio1 11 - 12 Q1 0501 FDIsabelle SchollardÎncă nu există evaluări

- Learnership AgreementDocument10 paginiLearnership Agreementkarl0% (1)

- Employee Leave PolicyDocument3 paginiEmployee Leave Policyladdu30Încă nu există evaluări

- Case Study of Flixborough UK DisasterDocument52 paginiCase Study of Flixborough UK Disasteraman shaikhÎncă nu există evaluări

- Ceilcote 222HT Flakeline+ds+engDocument4 paginiCeilcote 222HT Flakeline+ds+englivefreakÎncă nu există evaluări

- Physical Activity and Weight ControlDocument6 paginiPhysical Activity and Weight Controlapi-288926491Încă nu există evaluări

- The Mystique of The Dominant WomanDocument8 paginiThe Mystique of The Dominant WomanDorothy HaydenÎncă nu există evaluări

- Guarantor Indemnity For Illness or DeathDocument2 paginiGuarantor Indemnity For Illness or Deathlajaun hindsÎncă nu există evaluări

- Inversor Abb 3 8kwDocument2 paginiInversor Abb 3 8kwapi-290643326Încă nu există evaluări

- Big Elephants Are Useful Mnemonics & IdiomsDocument144 paginiBig Elephants Are Useful Mnemonics & IdiomsNachoAndrésLlorente100% (1)

- Fora Active Plus P 30 ManualDocument32 paginiFora Active Plus P 30 ManualBvcÎncă nu există evaluări

- 27nov12 PA Task Force On Child Protection ReportDocument445 pagini27nov12 PA Task Force On Child Protection ReportDefendAChildÎncă nu există evaluări

- CASE 1. Non-Cash Assets Are Sold For P 580,000Document3 paginiCASE 1. Non-Cash Assets Are Sold For P 580,000Riza Mae AlceÎncă nu există evaluări

- Red Bank Squadron - 01/22/1942Document28 paginiRed Bank Squadron - 01/22/1942CAP History LibraryÎncă nu există evaluări

- Mcdes 1Document7 paginiMcdes 1JerdÎncă nu există evaluări

- 9 - 1 H Wood Cabinet Spec Options NelDocument8 pagini9 - 1 H Wood Cabinet Spec Options NelinformalitybyusÎncă nu există evaluări

- JAR Part 66 Examination Mod 03Document126 paginiJAR Part 66 Examination Mod 03Shreyas PingeÎncă nu există evaluări

- HOME (2021) - Fransivan MacKenzieDocument21 paginiHOME (2021) - Fransivan MacKenzieFransivan MacKenzie100% (1)

- Fire BehaviourDocument4 paginiFire BehaviourFirezky CuÎncă nu există evaluări

- Simple CASC StationsDocument74 paginiSimple CASC Stationssherief marouf100% (2)

- PC110R 1 S N 2265000001 Up PDFDocument330 paginiPC110R 1 S N 2265000001 Up PDFLuis Gustavo Escobar MachadoÎncă nu există evaluări

- Maternal and Child Health Nursing 7 BulletsDocument4 paginiMaternal and Child Health Nursing 7 BulletsHoneylie PatricioÎncă nu există evaluări

- Factors Associated With Early Pregnancies Among Adolescent Girls Attending Selected Health Facilities in Bushenyi District, UgandaDocument12 paginiFactors Associated With Early Pregnancies Among Adolescent Girls Attending Selected Health Facilities in Bushenyi District, UgandaKIU PUBLICATION AND EXTENSIONÎncă nu există evaluări

- BrainPOP Nutrition Quiz242342Document1 paginăBrainPOP Nutrition Quiz242342MathableÎncă nu există evaluări

- Schools Division of Roxas CityDocument4 paginiSchools Division of Roxas CityHuge Propalde EstolanoÎncă nu există evaluări

- Building Technology (CE1303) : Window: Lecturer: Madam FatinDocument19 paginiBuilding Technology (CE1303) : Window: Lecturer: Madam FatinRazif AjibÎncă nu există evaluări

- Julie Trimarco: A Licensed Speech-Language PathologistDocument5 paginiJulie Trimarco: A Licensed Speech-Language PathologistJulie TrimarcoÎncă nu există evaluări