Documente Academic

Documente Profesional

Documente Cultură

High Pressure Processing of Orange Juice

Încărcat de

alimarufDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

High Pressure Processing of Orange Juice

Încărcat de

alimarufDrepturi de autor:

Formate disponibile

JFS:

Food Engineering and Physical Properties

High-Pressure Processing of Orange Juice:

Combination Treatments and a Shelf Life Study

U. NIENABER AND T.H. SHELLHAMMER

ABSTRACT: Several process alternatives for the stabilization of fresh orange juice at pressures between 500 MPa and

800 MPa and temperatures between 25 and 50 8C were evaluated. Processing at 800 MPa and 25 8C for 1 min and use

of thermally pasteurized pulp yielded the lowest level of residual pectinmethylesterase activity (3.9%) and good

cloud stability at 4 and 37 8C over a period of more than 2 mo. Ascorbic acid loss was less than 20% after storage for

3 mo at 4 8C or 2 mo at 15 8C. Color values were stable during storage at 4, 15, and 26 8C.

Key Words: high pressure, orange juice, pectinmethylesterase, cloud, shelf life

Introduction

HE SHELF LIFE OF FRESHLY SQUEEZED ORANGE JUICE CAN BE

Food Engineering and Physical Properties

greatly extended through the application of high hydrostatic pressure. Similar to thermal treatment, high pressure

processing (HPP) inactivates most of the pectinmethylesterase (PME) isoenzymes responsible for pectin degradation and subsequent cloud loss in citrus juices. As a nonthermal processing technology HPP results in minimal product quality loss, thereby retaining fresh-like flavor. In addition high pressure also eliminates or reduces the spoilage

microflora of yeasts, molds, and lactic acid bacteria commonly found in citrus juice (Ogawa and others 1990; Ogawa

and others 1992; Takahashi and others 1993; Dons and others 1996; Parish 1998a; Goodner and others 1999). Parish

(1998a) reported a D-value of 4 s for Saccharomyces cerevisiae ascospores at 500 MPa. Goodner and others (1999) estimated plate counts on orange serum agar of 5 to 10 colonies

per mL orange juice processed at 800 MPa for 1 min. Yeasts,

molds, lactobacilli, and streptococci were not detected in orange juice after pressure treatment at 350 MPa and 30 C for

1 min (Dons and others 1996). Hold times of 1 to 2 min at

500 MPa or 2 to 5 min at 400 MPa were sufficient to eliminate

yeasts and molds in Sudachi (Citrus sudachi) juice (Iuchi and

others 1996). Inoculation studies with pressure-resistant

strains of Escherichia coli O157:H7 in orange juice showed at

least a 6-log reduction after treatment at 550 MPa for 5 min

at 20 or 30 C (Linton and others 1999a). High pressure also

significantly increased the susceptibility of E. coli O157:H7 to

acidity, resulting in accelerated cell death rates during subsequent refrigerated storage (Linton and others 1999b).

The enzyme pectinmethylesterase (PME), which causes

the breakdown of citrus juice cloud, is found in all tissues of

the fruit, but primarily in the juice sacs (75% of total activity)

(Rouse 1953). Some of several PME isoenzymes in orange

juice are thermostable (Cameron and others 1994; Cameron

and Grohmann 1996; Snir and others 1996; Cameron and

others 1997; Cameron and others 1998) and appear to be

pressure-resistant as well (Goodner and others 1998). A

study on treatment of orange juice at pressures of up to 600

MPa combined with temperatures between 20 and 60 C

concluded that processing at 600 MPa and 20 C or 400 MPa

with additional heating reduced PME activity to less than

10% (Irwe and Olsson 1994). Parish (1998b) found that or-

332 JOURNAL OF FOOD SCIENCEVol. 66, No. 2, 2001

jfsv66n2p0332-0336ms20001527.p65

Black

332

ange juice stabilized with high pressure received significantly

higher sensory scores than heat-pasteurized juice after up

the 16 wk storage at 4 C. The costs associated with pressure

processing are directly related to the treatment pressure and

dwell time necessary to achieve the desired effect. Pressures

lower than 400 MPa are of no commercial interest because

of excessively long processing times. At pressures higher

than 600 MPa, kinetic studies are practically impossible because of nearly instantaneous PME inactivation during the

pressure come-up time. Improvements in HPP efficacy will

result in a reduction of processing costs through optimized

operating pressures and dwell times. At the same time residual PME activity needs to be minimized to extend the shelf

life of HPP orange juice. The first objective of this study was

to investigate several processing alternatives within a pressure range of 500 to 800 MPa and hold times between 1 and 5

min. The second objective was to conduct a shelf-life study

to monitor a number of quality parameters to assess the feasibility of high pressure pasteurization of orange juice.

Materials and Methods

Juice sample preparation

Freshly squeezed orange juice and pulp were produced at

a citrus processing plant in Florida, rapidly frozen, and

shipped overnight to Columbus, Ohio. Orange juice and pulp

were stored at 25 C until use. Thawed pulp was milled in a

Fitz mill to reduce particle size. Some of the pulp was heatpasteurized in Nylon-EVA pouches by submersion in a 90 C

waterbath for 2 min. Under these conditions PME was found

to be completely inactivated. Samples of 30 mL juice with or

without additional pulp (85 g per kg juice) were vacuumpacked in Nylon-EVA pouches (Winpak Ltd., Winnipeg, Manitoba, Canada) and stored at 25 C until use. For the shelflife study, orange juice with added pasteurized pulp (85 g per

kg juice) was filled into 8-oz PET bottles with screw-cap closures (Novapak Corp., Hazelton, Pa., U.S.A.).

High pressure processing

Pressure treatment was achieved using an ABB Quintus

Food Processor QFP-6 Cold Isostatic Press (ABB Flow Pressure Systems, Kent, Washington, U.S.A.). The pressure fluid

was a mixture of 1 part distilled water and 1 part Houghto 2001 Institute of Food Technologists

5/1/2001, 3:02 PM

High Pressure Processing of Orange Juice . . .

Pectinmethylesterase assay

PME activity was determined titrimetrically at pH 8.0 and

30 C using the method of Rouse and Atkins (1955) with

modifications. The pH was maintained using a ComputerAided Titrimeter (CAT) titration system (Fisher-Scientific,

Pittsburgh, Pa., U.S.A.) by addition of 0.05 N NaOH from an

automatic buret. The reaction mixture consisted of 10 mL of

juice and 40 mL of substrate solution containing 10 g/L of

pectin and 0.1 M of NaCl. The rate of NaOH consumption

over time was linear and proportional to PME activity, expressed as microequivalents (meq) per min and mL juice.

Each sample was analyzed in duplicate. Analysis run times

ranged from 5 min to 30 min, depending on the level of PME

activity.

Ascorbic acid

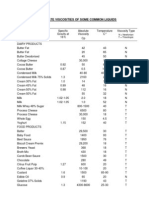

Table 1Residual PME activities in orange juice with added

pulp under different process conditions

Process conditions

T (C)

p(MPa)

t (min)

Juice +

unpasteurized

pulp

25

25

50

unprocessed

800

600

500

1

5

5

100.0%

6.4%

11.4%

19.9%

Juice +

pasteurized

pulp

64.8%

3.9%

7.5%

11.3%

traScan spectrophotometer (Hunter Associates Laboratory,

Reston, Va., U.S.A.). Samples were filled into glass cuvets with

a 2-cm path length. The following settings were used: reflectance mode, illuminant C, 10 observer. Total color differences (DE values) were calculated as

DE ((L1 - L2)2 (a1 a2)2 (b1 b2)2 )0.5

Shelf life study design

For the shelf-life study, orange juice with added heat-pasteurized pulp (85 g per kg juice) in PET bottles was processed

at 800 MPa with a 1-min hold time at 25 C. Samples were

stored at 4 temperature levels (4, 15, 26, 37 C). Samples

stored at 26 and 37 C were analyzed at time 0 and every wk

for a total of 7 wk; samples stored at 4 and 15 C at time 0

and every 2 wk for a total of 14 wk. Untreated juice stored at

4 C was used as a control and sampled every week for a total

of 5 wk, at which time it had clearly spoiled. All experiments

were performed in triplicate.

Statistical Analyses

The ascorbic acid concentration was analyzed by a titriAnalysis of variance, correlation analysis, and general linmetric method using 2,6-dichloroindophenol (AOAC Official

ear

modeling were performed with the SAS system for WinMethod 967.21). Samples of 50 mL of juice were extracted

dows,

release 6.12 (SAS Institute Inc., Cary, N.C., U.S.A.) and

with equal volumes of metaphosphoric acid-acetic acid soluTM

tion and filtered. Aliquots of 5 mL of filtrate were used for data analysis functions in Microsoft Excel 97.

quantitative determination of ascorbic acid.

Results and Discussion

Cloud loss

Cloud loss was determined according to an industrial

quality control method (Redd and others 1986). Samples of

50 mL juice were centrifuged at 360 g for 10 min using a

tabletop centrifuge (Dynac II, Becton Dickinson, Sparks, Md.,

U.S.A.). Transmission at 650 nm was measured in the supernatant. Light transmission values are interpreted as follows:

0% to 24% - no cloud loss; 25% to 35% - slight cloud loss;

36% to 60% - definite cloud loss; 61% to 100% - extreme

cloud loss.

Process alternatives

A number of process conditions were selected for their

commercial feasibility. Since PME is attached to the cell walls

of the juice sacs, total PME activity increases with the pulp

level. This means that commercial juices with high pulp levels

pose a special challenge to achieving sufficient PME inactivation. For these experiments orange juice with 8.5% added

unpasteurized or pasteurized pulp was used. This pulp level

is found in commercial not-from-concentrate orange juices

with high pulp levels.

Processing of juice with unpasteurized pulp at 800 MPa

Non-enzymatic browning

resulted

in almost instantaneous PME inactivation with a reNon-enzymatic browning was measured spectrophotosidual

activity

of 6.4% (Table 1). This alternative required the

metrically according to the method by Klim and Nagy (1988).

Samples (50 mL) were centrifuged at 1000 g for 15 min us- shortest processing time, but high pressures above 600 MPa

ing a tabletop centrifuge (Dynac II, Becton Dickinson, may be commercially undesirable as more expensive equipSparks, Md., U.S.A.). An aliquot (5 mL) of supernatant and 5 ment is required to continuously operate at these pressures.

mL methanol were mixed and kept on ice for 15 min. After Processing at 600 MPa or 500 MPa in combination with mild

recentrifugation at 1000 g for 15 min, absorbance was heat required longer processing times of at least 5 mins. Irwe

measured at 420 nm with a UV-2401PC spectrophotometer and Olsson (1994) explored combinations of pressure (400

and 600 MPa) and process temperature (20 to 60 C) and

(Shimadzu, Columbia, Md., U.S.A.).

their effect on the reduction of PME activity in orange juice

from different varieties. In order to achieve a substantial reColor

L (lightness), a (redness), and b (yellowness) values were duction of PME activity ( 90%) at 400 MPa, process temperdetermined directly in juice samples with a HunterLab Ul- atures of 40 or 60 C were required, depending on the variVol. 66, No. 2, 2001JOURNAL OF FOOD SCIENCE

jfsv66n2p0332-0336ms20001527.p65

Black

333

5/1/2001, 3:02 PM

333

Food Engineering and Physical Properties

Safe 620-TY (Houghton International, Valley Forge, Pa.,

U.S.A.). Houghto-Safe 620-TY contains glycol derivatives and

is used because of its anti-corrosive properties. Pressure fluid and samples in pouches or bottles were pre-chilled and

pressurization started at defined temperatures to compensate for adiabatic heating increase during pressure come-up.

Constant process temperatures were achieved by setting the

temperature of the water-jacketed pressure chamber to the

desired process temparature. Reported temperatures are actual process temperatures during hold time at reported pressure levels. Pressure, product temperature, and water-jacket

temperature were monitored and recorded in 3 s intervals

using a 21X Micrologger (Campbell Scientific Inc., Logan,

Utah, U.S.A.) connected to a computer running PC208W

datalogger support software (Campbell Scientific Inc.).

High Pressure Processing of Orange Juice . . .

Table 2Correlation coefficients of quality parameters in high-pressure processed orange juice during shelf-life study

at 4 to 37 C.

T

T

time

T x time

AA loss

Cloud loss

Browning

DE value

1.0000

time

T x time

AA loss

Cloud loss

Browning

DE value

-0.1642

1.0000

0.6439

0.4678

1.0000

0.6492

0.5130

0.9802

1.0000

0.6299

0.3077

0.7773

0.8104

1.0000

0.6032

0.5012

0.9497

0.9557

0.8163

1.0000

0.6313

0.4302

0.9951

0.9658

0.7736

0.9443

1.0000

Food Engineering and Physical Properties

ety. Whether these elevated temperatures compromise the

flavor and fresh-like taste of the orange juice needs to be examined. Treatment at 600 MPa and a process temperature of

20 C required 1 to 2 min processing time. This could be reduced to 20 s by increasing the temperature to 40 C. Under

industrial extraction conditions juice sacs are disintegrated

and fine pulp particles are found in the juice, adding to its

mouthfeel. It could be advantageous for juice products with

added pulp to heat-pasteurize the pulp before adding it back

to the juice followed by HPP. Such a process could further

reduce residual PME levels without compromising the fresh

citrus taste. As illustrated in Table 1, pulp contributed about

1/3rd of the total PME activity. Inactivation of PME in the

pulp by heat pasteurization prior to HPP reduced PME activity in the final product to 3.9%.

within a few days under refrigerated storage (see control in

Figure 1). For quality control purposes, a borderline value of

36% light transmission, measured at 650 nm and 1-cm path

length, is used as an upper limit for stable cloud in orange

juice. HPP orange juice maintained a stable cloud over a period of at least 3 mo not only in refrigerated storage at 4 C,

but also at 37 C. The extent of cloud loss increased with

storage temperature. Parish (1998b) and Goodner and others

Shelf-life study

Samples for the shelf-life study were subjected to 800 MPa

at 25 C for 1 min. Under these conditions, PME activity was

reduced to a minimum. A correlation analysis using all data

from the shelf-life study of high-pressure processed orange

juice samples revealed strong correlation between ascorbic

acid loss, development of non-enzymatic browning, DE value and the product of storage temperature and storage time

(Table 2). Correlation of these quality parameters with either

storage temperature or time only was weak. Both DE value

and non-enzymatic browning correlated strongly with ascorbic acid loss.

Cloud stability is a very important quality parameter, and Figure 2Ascorbic acid retention during storage of orin fresh unpasteurized orange juice cloud loss usually occurs ange juice processed at 800 MPa and 25 C for 1 min.

Error bars represent 1 standard deviation, n = 3.

Figure 1Cloud stability during storage of orange juice

processed at 800 MPa and 25 C for 1 min. Error bars

represent 1 standard deviation, n = 3.

Figure 3Nonenzymatic browning development during storage in orange juice processed at 800 MPa and 25 C for 1

min. Error bars represent 1 standard deviation, n = 3.

334 JOURNAL OF FOOD SCIENCEVol. 66, No. 2, 2001

jfsv66n2p0332-0336ms20001527.p65

Black

334

5/1/2001, 3:02 PM

(1998, 1999) observed comparable cloud stability in orange

juice treated at 700 MPa for 1 min and stored at 4 C for up

to 4 mo, although residual PME activity was reported to be

as high as 18% in one storage study (Goodner and others

1998). Ascorbic acid is an important vitamin in orange juice.

At the beginning of the storage period an initial drop in

ascorbic acid concentration occurred in all samples (Figure

2). This can be attributed to the fact that the juice was not

deaerated; therefore, a portion of the ascorbic acid reacted

immediately with dissolved oxygen. During further storage,

ascorbic acid concentration gradually decreased in all samples, following pseudo-zero order kinetics (Kaanane and others 1988; Kaanane 1992). This can be attributed to oxygen

diffusion through the PET bottles and anaerobic decomposition of ascorbic acid. More than 80% ascorbic acid was retained after 3 mo storage at 4 C or after 2 mo at 15 C.

Browning was most severe in samples stored at 37 C,

whereas samples stored at 4, 15, and 26 C did not brown to

an extent that would be objectionable (Figure 3). Color measurement directly in the juice samples with a HunterLab UltraScan revealed that color did not change over time except

in the samples stored at 37 C. In this case lightness (L value)

decreased, redness (a value) increased, and yellowness (b

value) decreased. This is reflected in the changes of total color differences (DE values) over time (Figure 4). Dons and

others (1996) reported no significant changes of color parameters in orange juice processed at 350 MPa for 1 min

during subsequent storage for 2 mo at 8 C. Nonenzymatic

browning in orange juice is primarily caused by degradation

of ascorbic acid, which is a precursor of the Maillard reaction. Ascorbic acid loss has been shown to correlate with the

extent of nonenzymatic browning (Kaanane and others 1988;

Kaanane 1992). Our results confirmed this, but the correlation between absorbance at 420 nm and loss of ascorbic acid

was not as good as the correlation between DE values and

ascorbic acid loss in samples stored at 37 C (Figure 5 and

Table 2). This is probably due to the fact that direct colorimetric measurements of the original juice give more accurate results than measurements of an extract after sample

preparation. The obvious lag-phase in Figure 5 can be explained by the fact that oxidation of ascorbic acid to dehydro-ascorbic acid is only the initial step in a complex Maillard reaction pathway that eventually leads to colored compounds.

Conclusion

TABILIZATION OF FRESH ORANGE JUICE BY HIGH PRESSURE

processing requires pressure levels of at least 500 MPa to

sufficiently reduce PME activity. PME inactivation can be further enhanced by combination of pressure treatment with

mild heat up to 50 C and thermal treatment of pulp prior to

HPP of juice with added pulp. HPP at 800 MPa and 25 C for

1 min and use of thermally pasteurized pulp yielded the lowest level of residual PME activity (3.9%). A shelf-life study of

juice treated under these conditions revealed that high-pressure processed orange juice retained its fresh-like quality for

several mo when stored under refrigeration. After a com-

Figure 4Color changes in orange juice during storage:

(a) yellowness (b-value), (b) total color difference (DE value).

Samples were processed at 800 MPa and 25 C for 1 min.

Error bars represent 1 standard deviation, n = 3.

Figure 5Correlation between ascorbic acid loss and total color difference (DE value) () resp. absorbance at

420 nm () in orange juice during storage at 37 C. Samples

were processed at 800 MPa and 25 C for 1 min.

Vol. 66, No. 2, 2001JOURNAL OF FOOD SCIENCE

jfsv66n2p0332-0336ms20001527.p65

Black

335

5/1/2001, 3:02 PM

335

Food Engineering and Physical Properties

High Pressure Processing of Orange Juice . . .

High Pressure Processing of Orange Juice . . .

mercially relevant period of 2 mo, cloud was stable despite

the presence of about 4% residual PME activity, color changes were minimal and ascorbic acid loss was about 15%. Higher storage temperatures compromised the juice quality substantially and would render the advantages of high pressure

processing irrelevant.

References

Food Engineering and Physical Properties

Cameron RG, Baker RA, Grohmann K. 1997. Citrus tissue extracts affect juice

cloud stability. J Food Sci 62(2):242-245.

Cameron RG, Baker RA, Grohmann K. 1998. Multiple forms of pectinmethylesterase from citrus peel and their effects on juice cloud stability. J Food Sci

63(2):253-256.

Cameron RG, Grohmann K. 1996. Purification and characterization of a thermally tolerant pectin methylesterase from a commercial Valencia fresh frozen orange juice. J Agric Food Chem 44:458-462.

Cameron RG, Neidz RP, Grohmann K. 1994. Variable heat stability for multiple

forms of pectin methylesterase from citrus tissue culture cells. J Agric Food

Chem 42:903-908.

Dons G, Ferrari G, Matteo MD. 1996. High pressure stabilization of orange juice:

evaluation of the effects of process conditions. Ital J Food Sci 2:99-106.

Goodner JK, Braddock RJ, Parish ME. 1998. Inactivation of pectinesterase in

orange and grapefruit juices by high pressure. J Agric Food Chem 46(5):19972000.

Goodner JK, Braddock RJ, Parish ME, Sims CA. 1999. Cloud stabilization of orange juice by high pressure processing. J Food Sci 64(4):699-700.

Irwe S, Olsson I. 1994. Reduction of pectinesterase activity in orange juice by

high pressure treatment. In: Singh RP and Oliveira FAR, editors. Minimal processing of foods and process optimization to an interface. Boca Raton: CRC

Press. p 35-42.

Iuchi A, Hayashi K, Tamura K, Kono T, Miyashita M, Chakraborty SK. 1996. Technique of quality control for Sudachi (Citrus sudachi Hort. ex Shirai) juice by

high pressure treatment. In: Hayashi R and Balny C, editors. High pressure

bioscience and biotechnology: Elsevier Science. p 387-390.

Kaanane A. 1992. Nonenzymatic browning of orange juice: evaluation of the

principal reaction and effect of some inhibitors [DPhil thesis]. Minneapolis:

Univ of Minnesota. 202p. Available from: University of Minnesota.

Kaanane A, Kane D, Labuza TP. 1988. Time and temperature effect on stability of

Moroccan processed orange juice during storage. J Food Sci 53(5):1470-1473, 1489.

Klim M, Nagy S. 1988. An improved method to determine nonenzymic browning

in citrus juices. J Agric Food Chem 36:1271-1274.

Linton M, McClements JMJ, Patterson MF. 1999a. Inactivation of Escherichia coli

O157:H7 in orange juice using a combination of high pressure and mild heat.

J Food Protect 62(3):277-279.

Linton M, McClements JMJ, Patterson MF. 1999b. Survival of Escherichia coli

O157:H7 during storage in pressure-treated orange juice. J Food Protect

62(9):1038-1040.

Ogawa H, Fukuhisa K, Fukumoto H. 1992. Effect of hydrostatic pressure on sterilization and preservation of citrus juice. In: Balny C, Hayashi R, Heremans K

and Masson P, editors. High Pressure and Biotechnology. France: Colloque INSERM/John Libbey Eurotext Ltd. p 269-278.

Ogawa H, Fukuhisa K, Kubo Y, Fukumoto H. 1990. Pressure inactivation of yeast,

molds, and pectinesterase in satsuma mandarin juice: effects of juice concentration, pH, and organic acids, and comparisson with heat sanitation. Agric

Biol Chem 54(5):1219-1225.

Parish ME. 1998a. High pressure inactivation of Saccharomyces cerevisiae, endogenous microflora and pectinmethylesterase in orange juice. J Food Safety

18:57-65.

Parish ME. 1998b. Orange juice quality after treatment by thermal pasteurization or isostatic high pressure. Lebensm-Wiss u-Technol 31:439-442.

Redd JB, Charles M. Hendrix J, Hendrix DL. 1986. Method 18 to Light transmission. Quality control manual for citrus processing plants. Safety Harbor, Fla.:

Intercit Inc. p 51.

Rouse AH. 1953. Distribution of pectinesterase and total pectin in component

parts of citrus fruits. Food Technol 7:360-362.

Rouse AH, Atkins CD. 1955. Pectinesterase and pectin in commercial orange

juice as determined by methods used at the Citrus Experiment Station. Bulletin of the Univ of Florida Agricultural Experiment Station, Lake Alfred, Fla.

570:1-19.

Snir R, Koehler PE, Sims KA, Wicker L. 1996. Total and thermostable pectinesterase in citrus juice. J Food Sci 61(2):379-382.

Takahashi Y, Ohta H, Yonei H, Ifuku Y. 1993. Microbicidal effect of hydrostatic

pressure on Satsuma mandarin juice. Int J Food Sci Technol 28:95-102.

Ms. 20001527

Authors are with the Dept of Food Science and Technology, The Ohio State

Univ. Direct inquiries to Thomas H. Shellhammer, Dept of Food Science

and Technology, The Ohio State Univ, 110 Parker Food Science and Technology Building, 2015 Fyffe Road, Columbus, OH 43210 (E-mail:

shellhammer.6@osu.edu).

336 JOURNAL OF FOOD SCIENCEVol. 66, No. 2, 2001

jfsv66n2p0332-0336ms20001527.p65

Black

336

5/1/2001, 3:02 PM

S-ar putea să vă placă și

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Not From Concentrate: Aseptic Storage Cooks IllustratedDocument3 paginiNot From Concentrate: Aseptic Storage Cooks IllustratedCharlesÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Development and Quality Evaluation of Pineapple BlendedDocument6 paginiDevelopment and Quality Evaluation of Pineapple BlendedJournal of Environment and Bio-SciencesÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Orange Book PDFDocument218 paginiThe Orange Book PDFtien67% (3)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Review Enzimas SucoDocument7 paginiReview Enzimas SucoCaio ToledoÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Effect On Orange Juice of Batch Pasteurization in An Improved Pilot-Scale Microwave OvenDocument5 paginiEffect On Orange Juice of Batch Pasteurization in An Improved Pilot-Scale Microwave OvenNicoÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Pulsed Electric Field TechnologyDocument6 paginiPulsed Electric Field TechnologyDavid UribeÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Zest O CorporationDocument21 paginiZest O CorporationJhamane Chan53% (15)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Studies On The Kinetic Changes of Mixed Fruit Marmalade Developed From Lemon and OrangeDocument11 paginiStudies On The Kinetic Changes of Mixed Fruit Marmalade Developed From Lemon and OrangeRahma NusandariÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Determing The Vitamin C Content in Various FoodDocument10 paginiDeterming The Vitamin C Content in Various FoodIsmaliza Ishak100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Use of Additives To Reduce Browning PDFDocument11 paginiUse of Additives To Reduce Browning PDFnhidinh97Încă nu există evaluări

- Mocktail INFOSHEETSDocument18 paginiMocktail INFOSHEETSizwarni Mohd sallehÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Freeze Concentration ReviewDocument14 paginiFreeze Concentration ReviewCamila GlinskiÎncă nu există evaluări

- Topic 1: Lab BurgerDocument7 paginiTopic 1: Lab BurgerLan Anh HoàngÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Art Biology MarzuqDocument43 paginiArt Biology MarzuqZihad ZainalÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Design and Construction of A Citrus Juice ExtractorDocument91 paginiDesign and Construction of A Citrus Juice ExtractorDamilare Oyetade67% (3)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Complaint Angelena Lewis V TropicanaDocument25 paginiComplaint Angelena Lewis V TropicanaLara PearsonÎncă nu există evaluări

- Principle of Marketing: Launching A New BrandDocument43 paginiPrinciple of Marketing: Launching A New BrandmaherbanÎncă nu există evaluări

- JBT Citrus Ps 451 enDocument12 paginiJBT Citrus Ps 451 enGuilherme CarvalhoÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Rabobank Brazilian Orange Juice Intro Tcm43-55739Document7 paginiRabobank Brazilian Orange Juice Intro Tcm43-55739Eliton Medeiros Candido de MacêdoÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Citrus 2012 PDFDocument8 paginiCitrus 2012 PDFBruce DoyaoenÎncă nu există evaluări

- Neraca Massa D3Document16 paginiNeraca Massa D3RÎncă nu există evaluări

- Enzymes in Fruit Juice ProductionDocument7 paginiEnzymes in Fruit Juice ProductionOrhan AvurÎncă nu există evaluări

- Approximate Viscosities of Some Common LiquidsDocument4 paginiApproximate Viscosities of Some Common Liquidsaaro_oraalÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Acc AssignmentDocument26 paginiAcc AssignmentPriyanka BajajÎncă nu există evaluări

- Exercise 0.3 Evaporation of Fresh Orange JuiceDocument16 paginiExercise 0.3 Evaporation of Fresh Orange JuiceAntonio MoncayoÎncă nu există evaluări

- Beginner's Guide To Homemade Haircare - (2023)Document28 paginiBeginner's Guide To Homemade Haircare - (2023)KaseyÎncă nu există evaluări

- Marketing and Export of Citrus FruitDocument12 paginiMarketing and Export of Citrus Fruitashhhhhhhh0% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Corporate Governance Practice ACMEDocument35 paginiCorporate Governance Practice ACMEShanto SaifulÎncă nu există evaluări

- Homework Probstat PreuasDocument3 paginiHomework Probstat PreuasTsabita fidinillahÎncă nu există evaluări

- Nestle Marketing Research ProjectDocument175 paginiNestle Marketing Research ProjectRizwan Ahmad100% (1)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)