Documente Academic

Documente Profesional

Documente Cultură

Shell Diala Oil D Dried: Very High Performance Electrical Oil

Încărcat de

medrayaliTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Shell Diala Oil D Dried: Very High Performance Electrical Oil

Încărcat de

medrayaliDrepturi de autor:

Formate disponibile

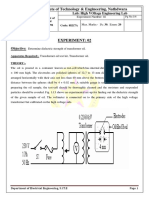

Technical Data Sheet

Shell Diala Oil D Dried

Very high performance electrical oil

Shell Diala D Dried is a non-inhibited insulating oil manufactured

from specially refined naphthenic feedstock. It offers very high

oxidation stability, very good dielectric properties and excellent

low temperature properties and has a lower water content than

required by industry norms for delivered oil quality.

Shell Diala D Dried meets both the established and new copper

corrosion tests.

the transformer, even from lowest

starting temperatures.

Applications

Transformers

Electrical insulating oil for

transformers, grid and industrial

transformers up to maximum load.

Electrical equipment

Components like rectifiers, circuit

breakers, switch-gears.

Advice on applications not covered in

this leaflet may be obtained from your

Shell Representative.

Low water content of delivered oil

Diala D dried is specially handled

to retain a high breakdown voltage

as delivered. This enables it to

be used in many applications

without further treatment.

Specification and Approvals

Performance Features and

Advantages

Shell Diala D Dried meets the

following specifications:

IEC 60296 (2003)

Table 2 Transformer Oil (U),

uninhibited

Baader oxidation test of (obsolete)

DIN 57370-1 (1978)

Excellent oxidation stability

Diala D Dried offers inherent natural

resistance to oil degradation and is

suitable for long life applications.

Very good dielectric properties

Meets the requirements of all major

specifications.

Anti corrosion properties

Shell Diala D Dried is non-corrosive

towards copper, with no need for

passivation. Diala D Dried meets all

relevant tests on copper corrosion,

namely the established DIN 51353

(Silver Strip Test) and ASTM D1275,

and also the newer tests: IEC CCD

(WG35), now draft IEC 62535 and ASTM

D1275B.

Very good low temperature properties

The naphthenic nature of the

feedstock of Diala D Dried provides

a superior low temperature

performance without the use of

additives.

Very good heat transfer characteristics

The very good fluidity of the oil

ensures proper heat transfer inside

Shell Lubricants

Page 1 of 3

Storage precautions

The critical electrical properties of

Shell Diala D Dried are easily

compromised by trace contamination

with foreign material. Typically

encountered contaminants include

moisture, particles, fibres and

surfactants. Therefore, it is

imperative that electrical insulating

oils be kept clean and dry.

It is strongly recommended that

storage containers be dedicated for

electrical service and include airtight seals. It is further

recommended that electrical

insulating oils be stored indoors in

climate-controlled environments.

Health and Safety

Guidance on Health and Safety are

available on the appropriate Material

Safety Data Sheet which can be

obtained from your Shell

representative.

Shell Diala D Dried is free of

polychlorinated biphenyls (PCB).

OCTOBER 2007

Technical Data Sheet

Do not discharge into drains, soil or

water.

Protect the environment

Take used oil to an authorized

collection point.

Typical Characteristics

Property

Units

Appearance

Specification

requirements

IEC 60296

Diala D Dried

IEC 60296

Clear, free of

solids

Complies

Method

Density at 15C

kg/m3

ISO 3675

884

Density at 20C

kg/m3

ISO 3675

<895

881

Kinematic viscosity

at 40C

mm /s

ISO 3104

12 max

8,1

Kinematic viscosity

at 20C

mm2/s

ISO 3104

25 max

17,3

Kinematic viscosity

at -30C

mm2/s

ISO 3104

1800 max

730

Flashpoint P.M.

ISO 2719

135 min

138

Pourpoint

ISO 3016

< -40

-60

Neutralisation value

mg KOH/g

IEC 62021-1

0.01 max

< 0.01

Corrosive Sulphur

Draft IEC 62535

Non-corrosive

Corrosive Sulphur

ASTM D 1275 B

Non-corrosive

Corrosive Sulphur

DIN 51353

Breakdown voltage

Untreated

After treatment

kV

Water content

(ex works)

ppm

Non-corrosive

Non-corrosive

IEC 60156

min 30

min 70

IEC 60814

Dielectric

dissipation factor

(DDF) at 90C

IEC 60247

Oxidation Stability

(164h/120C)

IEC 61125 C

>30

>70

40 max (drums and

IBC)

30 max (bulk)

<40 drums/IBC

0.005 max

0.001

<30 bulk

Total acidity

mg KOH/g

1,2 max

0.23

Sludge

%m

0,8 max

0,1

0.5 max

0,15

DDF at 90 C

Oxidation Stability

Baader (140h/110C)

DIN 51554

Neutralisation value

mg KOH/g

0.09

Sludge content

% m

0.02

0.11

Dielectric

dissipation factor

(DDF) at 90C

Shell Lubricants

Page 2 of 3

OCTOBER 2007

Technical Data Sheet

These characteristics are typical of current production.

Whilst future production will conform to Shell's specification, variations in these

characteristics may occur.

Shell Lubricants

Page 3 of 3

OCTOBER 2007

S-ar putea să vă placă și

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsDe la EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsEvaluare: 5 din 5 stele5/5 (1)

- Shell Diala BDocument2 paginiShell Diala BArnold Steven75% (4)

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityDe la EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityEvaluare: 3 din 5 stele3/5 (4)

- Lubricants For The Manufacturing IndustryDocument20 paginiLubricants For The Manufacturing IndustrynarenjiÎncă nu există evaluări

- International Standard: Norme InternationaleDocument12 paginiInternational Standard: Norme Internationaleevin34Încă nu există evaluări

- Transformer Oil Pumps-Operation Installation & Maintenance PDFDocument16 paginiTransformer Oil Pumps-Operation Installation & Maintenance PDFCT Barokah0% (1)

- Standard Operating Procedure MaintenanceDocument6 paginiStandard Operating Procedure MaintenancePADCL100% (1)

- Cryogenics Safety Manual: A Guide to Good PracticeDe la EverandCryogenics Safety Manual: A Guide to Good PracticeÎncă nu există evaluări

- En 50216-6 2002Document15 paginiEn 50216-6 2002Mahmoud ShaheenÎncă nu există evaluări

- ABB Testing of Power TransformerDocument55 paginiABB Testing of Power TransformerM Kumar Marimuthu100% (3)

- 445 - Guide - For - Transformer - Maintenance CIGRE A2 - 34 PDFDocument123 pagini445 - Guide - For - Transformer - Maintenance CIGRE A2 - 34 PDFJohnDoe100% (10)

- Modeling, Control, and Optimization of Natural Gas Processing PlantsDe la EverandModeling, Control, and Optimization of Natural Gas Processing PlantsEvaluare: 5 din 5 stele5/5 (1)

- GST001 MV-LV Transformers - Rev.03Document77 paginiGST001 MV-LV Transformers - Rev.03GLOBAL SAFE ENGENHARIA100% (1)

- Statoil Loadway EP 100 Industrial Gear OilDocument2 paginiStatoil Loadway EP 100 Industrial Gear Oilmstan11Încă nu există evaluări

- Manual Book KHV-F15Document24 paginiManual Book KHV-F15Ari100% (1)

- Oxidation Stability of Insulating FluidsDocument79 paginiOxidation Stability of Insulating FluidsJicheng PiaoÎncă nu există evaluări

- Shell Diala D OilDocument2 paginiShell Diala D OilBasim Al-AttarÎncă nu există evaluări

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesDe la EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesEvaluare: 3.5 din 5 stele3.5/5 (3)

- Gpcdoc Gtds Shell Diala s3 Zx-I (En) TdsDocument2 paginiGpcdoc Gtds Shell Diala s3 Zx-I (En) TdsSecret64Încă nu există evaluări

- 1329809804Document1 pagină1329809804muh4iminÎncă nu există evaluări

- Shell Diala Oil DX: High Performance Inhibited Insulating OilDocument1 paginăShell Diala Oil DX: High Performance Inhibited Insulating OilDilip KarkiÎncă nu există evaluări

- High performance insulating oil for transformersDocument1 paginăHigh performance insulating oil for transformersDilip KarkiÎncă nu există evaluări

- Shell Diala Oil BDocument1 paginăShell Diala Oil Bmilik bersamaÎncă nu există evaluări

- Heat Transfer OilDocument2 paginiHeat Transfer OilDony LieÎncă nu există evaluări

- Gpcdoc Sa Tds ThermiaDocument2 paginiGpcdoc Sa Tds ThermiaAbdelrahman MagdyÎncă nu există evaluări

- Technical Data Sheet for Shell Diala S2 ZX-A Insulating OilDocument2 paginiTechnical Data Sheet for Shell Diala S2 ZX-A Insulating OilJoseÎncă nu există evaluări

- Shell Diala D Insulating Oil High Performance PropertiesDocument2 paginiShell Diala D Insulating Oil High Performance PropertiesSecret64Încă nu există evaluări

- Insulating Oil for Transformers, Rheostats and Circuit BreakersDocument1 paginăInsulating Oil for Transformers, Rheostats and Circuit BreakersAbah Hafiz HadifÎncă nu există evaluări

- Shell Diala S3 ZX-IG Dried Premium Insulating Oil TDSDocument2 paginiShell Diala S3 ZX-IG Dried Premium Insulating Oil TDSAnonymous oAbjbl4HÎncă nu există evaluări

- Statoil LoadWay EP 220Document2 paginiStatoil LoadWay EP 220mstan11Încă nu există evaluări

- Product Information Navisyn De: DescriptionDocument2 paginiProduct Information Navisyn De: DescriptionGabriel NogueiraÎncă nu există evaluări

- Shell Thermia Oil B Heat Transfer Fluid Properties and ApplicationsDocument2 paginiShell Thermia Oil B Heat Transfer Fluid Properties and ApplicationsNhu Kien PhamÎncă nu există evaluări

- Disola: 15W40 Multigrade Oil For Highly Rated Diesel EnginesDocument2 paginiDisola: 15W40 Multigrade Oil For Highly Rated Diesel EnginesPedroÎncă nu există evaluări

- Diala 5f4b3840d431Document2 paginiDiala 5f4b3840d431edan28Încă nu există evaluări

- Corena S2 P 68Document3 paginiCorena S2 P 68MBA103003Încă nu există evaluări

- High Grade Electrical Insulating Oil Nytro Izar IDocument2 paginiHigh Grade Electrical Insulating Oil Nytro Izar IMichael HayesÎncă nu există evaluări

- PDS Nytro Bear ASTM EN PDFDocument2 paginiPDS Nytro Bear ASTM EN PDFP_sanchezÎncă nu există evaluări

- Reliable Insulating Oil for TransformersDocument2 paginiReliable Insulating Oil for TransformersSena DarmawanÎncă nu există evaluări

- Shell Diala S2 ZU-I Dried PDFDocument2 paginiShell Diala S2 ZU-I Dried PDFAnonymous oAbjbl4HÎncă nu există evaluări

- Oil - Shell-Diala-S2-Zui PDFDocument2 paginiOil - Shell-Diala-S2-Zui PDFkiran kumarÎncă nu există evaluări

- Shell Diala S2 ZU-I Dried PDFDocument2 paginiShell Diala S2 ZU-I Dried PDFAnonymous oAbjbl4H100% (1)

- Maximum performance insulating oil Nytro 10XNDocument2 paginiMaximum performance insulating oil Nytro 10XNusefiÎncă nu există evaluări

- Diala s3 Zui PDFDocument2 paginiDiala s3 Zui PDFDebora Septania PurbaÎncă nu există evaluări

- Nynas Y3000 10' ENG PDS PDFDocument2 paginiNynas Y3000 10' ENG PDS PDFP_sanchezÎncă nu există evaluări

- Aceite Agip IteDocument1 paginăAceite Agip Ite434lapÎncă nu există evaluări

- High Performance Multi-Purpose GreaseDocument2 paginiHigh Performance Multi-Purpose GreaseAhsan IjazÎncă nu există evaluări

- Gpcdoc Local Tds Iraq Shell Turbo T 32 (Ar-Iq) TdsDocument3 paginiGpcdoc Local Tds Iraq Shell Turbo T 32 (Ar-Iq) Tds100impianÎncă nu există evaluări

- Gpcdoc Local Tds Iraq Shell Turbo T 68 (Ar-Iq) TdsDocument2 paginiGpcdoc Local Tds Iraq Shell Turbo T 68 (Ar-Iq) TdsBar AvaitÎncă nu există evaluări

- Spesifikasi - Shell AlbidaDocument2 paginiSpesifikasi - Shell AlbidanursetoÎncă nu există evaluări

- Nynas OilDocument2 paginiNynas OilusefiÎncă nu există evaluări

- Shell Diala Product Family Brochure LowDocument4 paginiShell Diala Product Family Brochure LowAvoor KhanÎncă nu există evaluări

- Kat en DQ InchDocument14 paginiKat en DQ InchThariqÎncă nu există evaluări

- Shell Turbo Oil T 32 TDSDocument2 paginiShell Turbo Oil T 32 TDSBahim BahimanÎncă nu există evaluări

- Altis MV2 (11.12.03)Document1 paginăAltis MV2 (11.12.03)D Wahyu BawonoÎncă nu există evaluări

- Aceite Corena S4 R 46Document3 paginiAceite Corena S4 R 46aledneroÎncă nu există evaluări

- Shell Diala S3 ZX-IGDocument2 paginiShell Diala S3 ZX-IGAnonymous oAbjbl4HÎncă nu există evaluări

- High Temp EP Grease DataDocument2 paginiHigh Temp EP Grease DataRED DRAGO100% (1)

- Kat en DQ CMDocument14 paginiKat en DQ CMThariqÎncă nu există evaluări

- GPCDOC GTDS Shell Gadus S2 A320 2 (En) TDS PDFDocument2 paginiGPCDOC GTDS Shell Gadus S2 A320 2 (En) TDS PDFJako MishyÎncă nu există evaluări

- Shell Gadus S5 T460:: Shell Stamina Grease HDSDocument2 paginiShell Gadus S5 T460:: Shell Stamina Grease HDSPablo Soler SalazarÎncă nu există evaluări

- Shell Corena Oil AP Advanced Synthetic LubricantDocument2 paginiShell Corena Oil AP Advanced Synthetic LubricantGanesh AnandÎncă nu există evaluări

- Air Tool Oil s2 A 100Document2 paginiAir Tool Oil s2 A 100José Edgar Rodriguez BritoÎncă nu există evaluări

- Shell Thermia BDocument2 paginiShell Thermia Bsegunoyes100% (1)

- Spirax s2 Atf d2Document1 paginăSpirax s2 Atf d2bilalyunusÎncă nu există evaluări

- Isovoltine IiDocument1 paginăIsovoltine IilovegamingÎncă nu există evaluări

- Product Information: Valvoline™ HD Nitrite Free Coolant RTUDocument2 paginiProduct Information: Valvoline™ HD Nitrite Free Coolant RTUmcalidonio5656Încă nu există evaluări

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965De la EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Încă nu există evaluări

- Virtual CP Communications ManualDocument66 paginiVirtual CP Communications ManualmedrayaliÎncă nu există evaluări

- Electronics CatalogDocument259 paginiElectronics CatalogmedrayaliÎncă nu există evaluări

- Fujitsu MAN3xxxSCSIDocument145 paginiFujitsu MAN3xxxSCSImedrayaliÎncă nu există evaluări

- Hs 2 Man 96Document29 paginiHs 2 Man 96medrayaliÎncă nu există evaluări

- Materials System SpecificationDocument8 paginiMaterials System SpecificationMudabbir HussainÎncă nu există evaluări

- Materials System SpecificationDocument10 paginiMaterials System SpecificationMudabbir Hussain100% (1)

- Accepted ManuscriptDocument31 paginiAccepted ManuscriptCRISTIAN CAMILO MORALES SOLISÎncă nu există evaluări

- FP36Document3 paginiFP36shasailappanÎncă nu există evaluări

- PDS Nytro Libra EN PDFDocument2 paginiPDS Nytro Libra EN PDFmk116dÎncă nu există evaluări

- MEE Tanmay RautDocument18 paginiMEE Tanmay RautAkash RathodÎncă nu există evaluări

- Internal Insulation Failure of HV EquipmentDocument6 paginiInternal Insulation Failure of HV EquipmentashawishÎncă nu există evaluări

- Specs For Transformer Oil (Normal Grade)Document9 paginiSpecs For Transformer Oil (Normal Grade)Georgina SuleÎncă nu există evaluări

- NP Sto 50 Silicone Transformer Oil ClearcoDocument2 paginiNP Sto 50 Silicone Transformer Oil ClearcoAkshay MutalikÎncă nu există evaluări

- Kelman™ DGA 900: Installation ManualDocument68 paginiKelman™ DGA 900: Installation ManualHiro ItoÎncă nu există evaluări

- Transformers: Gas Insulated Transformers OverviewDocument22 paginiTransformers: Gas Insulated Transformers OverviewTech Technic100% (1)

- HydranM2 X Brochure EN 2018 03 Grid GA 1644 - R002 - A4 - HRDocument2 paginiHydranM2 X Brochure EN 2018 03 Grid GA 1644 - R002 - A4 - HRrodineicarraroÎncă nu există evaluări

- Insulating Material - FinalDocument25 paginiInsulating Material - FinalNaghul PranavÎncă nu există evaluări

- 400+ TOP ELECTRICAL Engineering Interview Questions & Answers PDFDocument1 pagină400+ TOP ELECTRICAL Engineering Interview Questions & Answers PDFZedo ZedoÎncă nu există evaluări

- B90005034 Utilities Choose FR3Document3 paginiB90005034 Utilities Choose FR3Jefferson CalderónÎncă nu există evaluări

- HV Lab Exp.2Document4 paginiHV Lab Exp.2AkshayÎncă nu există evaluări

- Transformer Radiator Components GuideDocument25 paginiTransformer Radiator Components GuideRomario Kreyder Rojas HuaynalayaÎncă nu există evaluări

- Corrosive Sulfur in Transformer Oil enDocument4 paginiCorrosive Sulfur in Transformer Oil enreza515heiÎncă nu există evaluări

- Univolt Is Formulated To Improve Performance and Extend Transformer LifeDocument2 paginiUnivolt Is Formulated To Improve Performance and Extend Transformer LifeАлександар СтевићÎncă nu există evaluări

- Transformer Oil-Article-Very NewDocument5 paginiTransformer Oil-Article-Very NewArshad AhmeedÎncă nu există evaluări