Documente Academic

Documente Profesional

Documente Cultură

5256 - Brighton Park Apts - SPECS

Încărcat de

MichaelPiscopoDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

5256 - Brighton Park Apts - SPECS

Încărcat de

MichaelPiscopoDrepturi de autor:

Formate disponibile

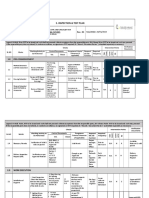

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD,

CONNECTICUT

PROJECT MANUAL

ISSUE DATE: 02-06-2015

DD REVIEW SET

KL PROJECT NO.

5256

Kenneth Linehan, Architect

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

KL PROJECT No. 5256

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CONNECTICUT

PROJECT MANUAL

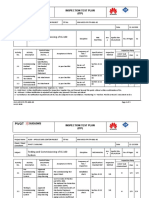

TABLE OF CONTENTS

INTRODUCTORY INFORMATION

A.

B.

COVER PAGE

TABLE OF CONTENTS

DATE

BY

02/06/15 KL

02/06/15 KL

DIVISION 00 - PROCUREMENT AND CONTRACT DOCUMENTS

003132

007200

007300

GEOTECHNICAL REPORT

GENERAL CONDITIONS OF THE CONTRACT

SUPPLEMENTARY CONDITIONS

04/21/14

02/06/15

02/06/15

PSI

KL

KL

02/06/15

02/06/15

02/06/15

02/06/15

02/06/15

02/06/15

02/06/15

02/06/15

02/06/15

02/06/15

02/06/15

02/06/15

02/06/15

02/06/15

02/06/15

KL

KL

KL

KL

KL

KL

KL

KL

KL

KL

KL

KL

KL

KL

KL

SPECIFICATIONS

DIVISION 01 - GENERAL REQUIREMENTS

011000

012100

012500

012600

012900

013100

013200

013233

013300

014000

014200

015000

016000

017300

017419

SUMMARY

ALLOWANCES

SUBSTITUTION PROCEDURES

CONTRACT MODIFICATION PROCEDURES

PAYMENT PROCEDURES

PROJECT MANAGEMENT AND COORDINATION

CONSTRUCTION PROGRESS DOCUMENTATION

PHOTOGRAPHIC DOCUMENTATION

SUBMITTAL PROCEDURES

QUALITY REQUIREMENTS

REFERENCES

TEMPORARY FACILITIES AND CONTROLS

PRODUCT REQUIREMENTS

EXECUTION

CONSTRUCTION WASTE MANAGEMENT AND DISPOSAL

TABLE OF CONTENTS

PAGE 1 OF 5

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

KL PROJECT No. 5256

017700

017823

017839

017900

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

CLOSEOUT PROCEDURES

OPERATION AND MAINTENANCE DATA

PROJECT RECORD DOCUMENTS

DEMONSTRATION AND TRAINING

DIVISION 02 EXISTING CONDITIONS

02/06/15

02/06/15

02/06/15

02/06/15

KL

KL

KL

KL

NOT USED

DIVISION 03 CONCRETE

033000

035216

035413

CAST-IN-PLACE CONCRETE

LIGHTWEIGHT CONCRETE TOPPING

GYPSUM CEMENT UNDERLAYMENT

02/06/15

02/06/15

02/06/15

MSP

MSP

KL

02/06/15

02/06/15

MSP

KL

02/06/15

02/06/15

KL

KL

02/06/15

02/06/15

02/06/15

02/06/15

02/06/15

MSP

MSP

MSP

KL

KL

02/06/15

02/06/15

02/06/15

02/06/15

02/06/15

02/06/15

02/06/15

02/06/15

02/06/15

02/06/15

02/06/15

KL

KL

KL

KL

KL

KL

KL

KL

KL

KL

KL

DIVISION 04 MASONRY

042000

047200

UNIT MASONRY

CAST STONE MASONRY

DIVISION 05 METALS

055100

055213

METAL STAIRS

PIPE AND TUBE RAILINGS

DIVISION 06 WOOD, PLASTICS AND COMPOSITES

061000

061600

061753

062013

064023

ROUGH CARPENTRY

SHEATHING

SHOP FABRICATED WOOD TRUSSES

EXTERIOR FINISH CARPENTRY

INTERIOR FINISH CARPENTRY

DIVISION 07 - THERMAL AND MOISTURE PROTECTION

071326

072100

072500

073113

074633

076200

076500

077200

078413

078446

079200

SELF-ADHERING SHEET WATERPROOFING

THERMAL INSULATION

WATER RESISTIVE BARRIER / AIR BARRIER

ASPHALT SHINGLES

VINYL SIDING, SOFFIT VENT STRIP AND SOFFIT

SHEET METAL FLASHING AND TRIM

MANUFACTURED FLASHING PANELS

ROOF SPECIALTIES

PENETRATION FIRESTOPPING

FIRE-RESISTIVE JOINT SYSTEMS

JOINT SEALANTS

TABLE OF CONTENTS

PAGE 2 OF 5

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

KL PROJECT No. 5256

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

DIVISION 08 OPENINGS

081115

081416

081620

083113

083613

085313

087100

088000

088300

HOLLOW METAL DOORS AND WOOD FRAMES

INTERIOR WOOD DOORS

MIRRORED CLOSET DOORS

ACCESS DOORS AND FRAMES

SECTIONAL DOORS

VINYL WINDOWS

DOOR HARDWARE

GLAZING

MIRRORS

02/06/15

02/06/15

08/08/11

02/06/15

02/06/15

02/06/15

02/06/15

02/06/15

02/06/15

KL

KL

KL

KL

KL

KL

KL

KL

KL

02/06/15

02/06/15

02/06/15

02/06/15

02/06/15

02/06/15

02/06/15

07/17/11

KL

KL

KL

KL

KL

KL

KL

KL

02/06/15

02/06/15

02/06/15

02/06/15

02/06/15

02/06/15

KL

KL

KL

KL

KL

KL

02/06/15

KL

02/06/15

02/06/15

KL

KL

DIVISION 09 FINISHES

092216

092900

093000

096513

096519

096816

099113

099123

NON-STRUCTURAL METAL FRAMING

GYPSUM BOARD

TILING

RESILIENT BASE AND ACCESSORIES

RESILIENT TILE AND STRIP FLOORING

SHEET CARPETING

EXTERIOR PAINTING

INTERIOR PAINTING

DIVISION 10 SPECIALTIES

101400

102801

104413

104416

105500

105610

SIGNAGE

BATH ACCESSORIES

FIRE EXTINGUISHER CABINETS

FIRE-EXTINGUISHERS

POSTAL SPECIALTIES

CLOSET SPECIALTIES

DIVISION 11 EQUIPMENT

113100

RESIDENTIAL APPLIANCES

DIVISION 12 FURNISHINGS

122113

123530

HORIZONTAL LOUVER BLINDS

RESIDENTIAL CASEWORK

DIVISION 13 - SPECIAL CONSTRUCTION

TABLE OF CONTENTS

NOT APPLICABLE

PAGE 3 OF 5

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

KL PROJECT No. 5256

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

DIVISION 14 - CONVEYING SYSTEMS

NOT APPLICABLE

DIVISION 15 through 20

NOT USED

DIVISION 21 FIRE SUPPRESSION

210517

210518

210553

211100

211200

211313

SLEEVES AND SLEEVE SEALS FOR FIRE-SUPPRESSION PIPING

ESCUTCHEONS FOR FIRE-SUPPRESSION PIPING

IDENTIFICATION FOR FIRE-SUPPRESSION PIPING AND

EQUIPMENT

FACILITY FIRE-SUPPRESSION WATER-SERVICE PIPING

FIRE SUPPRESSION STANDPIPIES

WET-PIPE SPRINKLER SYSTEMS

02-06-15

02-06-15

02-06-15

MGE

MGE

MGE

02-06-15

02-06-15

02-06-15

MGE

MGE

MGE

02-06-15

02-06-15

02-06-15

02-06-15

MGE

MGE

MGE

MGE

DIVISION 22 PLUMBING

220517

220518

220523

220529

220719

221116

221119

221316

221319

223430

224100

SLEEVES AND SLEEVE SEALS FOR PLUMBING PIPING

ESCUTCHEONS FOR PLUMBING PIPING

GENERAL DUTY VALVES FOR PLUMBING PIPING

HANGERS & SUPPORTS FOR PLUMBING, PIPING, AND

EQUIPMENT

PLUMBING PIPING INSULATION

DOMESTIC WATER PIPING

DOMESTIC WATER PIPING SPECIALTIES

SANITARY WASTE AND VENT PIPING

SANITARY WASTE PIPING SPECIALTIES

DIRECT-VENT GAS, DOMESTIC WATER HEATERS

RESIDENTIAL PLUMBING FIXTURES

02-06-15

MGE

02-06-15

MGE

02-06-15

MGE

02-06-15

MGE

02-06-15

MGE

NOT ISSUED

02-06-15

MGE

DIVISION 23 HEATING, VENTILATING AND AIR CONDITIONING (HVAC)

230513

230517

230518

230529

230593

230713

230719

232300

233113

233116

233300

233423

233713

COMMON MOTOR REQUIREMENTS FOR HVAC EQUIPMENT

SLEEVES AND SLEEVE SEALS FOR HVAC PIPING

ESCUTCHEONS FOR HVAC PIPING

HANGERS AND SUPPORTS FOR HVAC PIPING AND EQUPMENT

TESTING, ADJUSTING, AND BALANCING FOR HVAC

DUCT INSULATION

HVAC PIPING INSULATION

REFRIGERANT PIPING

METAL DUCTS

NONMETAL DUCTS

AIR DUCT ACCESSORIES

HVAC POWER VENTILATORS

DIFFUSERS, REGISTERS, AND GRILLES

TABLE OF CONTENTS

02-06-15

02-06-15

02-06-15

02-06-15

02-06-15

02-06-15

02-06-15

02-06-15

02-06-15

02-06-15

02-06-15

02-06-15

02-06-15

MGE

MGE

MGE

MGE

MGE

MGE

MGE

MGE

MGE

MGE

MGE

MGE

MGE

PAGE 4 OF 5

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

KL PROJECT No. 5256

234100

238126

238239

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

PARTICULATE AIR FILTRATION

SPLIT-SYSTEM AIR-CONDITIONERS

UNIT HEATERS

DIVISIONS 24 and 25

02-06-15

02-06-15

02-06-15

MGE

MGE

MGE

NOT USED

DIVISION 26 - ELECTRICAL

260519

260526

260533

260923

262416

262713

262726

262816

265100

265600

270528

LOW-VOLTAGE ELECT. POWER CONDUCTORS & CABLES

GROUNDING AND BONDING FOR ELECTRICAL SYSTEMS

RACEWAYS AND BOXES FOR ELECTRICAL SYSTEMS

LIGHTING CONTROL DEVICES

PANELBOARDS

ELECTRICITY METERING

WIRING DEVICES

ENCLOSED SWITCHES AND CIRCUIT BREAKERS

INTERIOR LIGHTING

EXTERIOR LIGHTING

PATHWAYS FOR COMMUNICATIONS SYSTEMS

DIVISIONS 27 and 28

02-06-15

02-06-15

02-06-15

02-06-15

02-06-15

02-06-15

02-06-15

02-06-15

02-06-15

02-06-15

02-06-15

MGE

MGE

MGE

MGE

MGE

MGE

MGE

MGE

MGE

MGE

MGE

NOT USED

DIVISION 31 EARTHWORK

313116

WDO CONTROL

DIVISIONS 32 through 49

02-06-15

FK

NOT USED

END TABLE OF CONTENTS

TABLE OF CONTENTS

PAGE 5 OF 5

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

KL PROJECT No. 5256

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

SECTION 003132 GEOTECHNICAL REPORT

PART 1 - GENERAL

1.1

SUMMARY

A.

A report of preliminary geotechnical engineering report dated November 26, 2014 has been

prepared for this Project by:

GZA Geoenvironmental, Inc.

655 Winding Brook Drive

Suite 402

Glastonbury, Connecticut, 06033

B.

A copy of the report is provided for reference with this Section.

PART 2 - PRODUCTS (Not Used)

PART 3 - EXECUTION (Not Used)

END OF SECTION 003132

GEOTECHNICAL REPORT

003132 - 1

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

KL PROJECT No. 5256

SECTION 007200 - GENERAL CONDITIONS OF THE CONTRACT

PART 1 - GENERAL

1.1

Form

A.

The American Institute of Architects Document A201 - GENERAL CONDITIONS OF

THE CONTRACT FOR CONSTRUCTION, 2007 Edition, contains the General

Conditions of the Contract. AIA Document A201 is amended by supplementary

conditions provided in Section 007300 - Supplementary Conditions herein.

B.

The General Conditions of the Contract for Construction and the Supplementary

Conditions shall be taken together and constitute the Conditions of the Contract

referenced in the Agreement.

C.

The General Conditions of the Contract for Construction and the Supplementary

Conditions are referred together in the Project Manual as the General Conditions,. No

contractual adjustments shall be due or become exigent as a result of failure on the part

of the Contractor to fully acquaint himself and all other parties to the Contract with the

General Conditions of the Contract for Construction and the Supplementary Conditions.

PART 2 - PRODUCTS

NOT USED.

PART 3 - EXECUTION

NOT USED.

END OF SECTION 007200

GENERAL CONDITIONS OF THE CONTRACT

007200 - 1

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

KL PROJECT No. 5256

SECTION 007300 - SUPPLEMENTARY CONDITIONS

PART 1 - GENERAL

Document Includes

The following supplements modify, rescind, supplement, and take precedence over the General

Conditions of the Contract for Construction, AIA Document A201, 2007 edition, referenced in

Document 007200 - General Conditions of the Contract Documents. Where a portion of the

General Conditions is modified or deleted by these Supplementary Conditions, the unaltered

portions of the General Conditions shall remain in effect.

ARTICLE 1 - GENERAL PROVISIONS

Add Section 1.1.9 as follows:

1.1.9

1.2

MISCELLANEOUS DEFINITIONS

.1

Where the words "equal", "approved equal", "equivalent", "satisfactory",

"directed", "designated", "selected", "as required", and words of similar meanings

are used, the written review, comment, acceptance, selection, or similar action of

the Architect or Owner is required.

.2

Where words "required" and words of similar meaning are used, it shall mean "as

required to properly complete the Work and as required by the Architect or

Owner", unless stated otherwise.

.3

Where the words "provide" and "perform" are used, it is understood and intended

to mean that the Contractor, at his expense, shall furnish and install the Work,

complete in place and ready for use, including furnishing of necessary labor,

materials, tools, equipment and transportation. These definitions apply the same

to future, present and past tenses, except the word "provided" may mean

"contingent upon" where such is the context.

CORRELATION AND INTENT OF THE CONTRACT DOCUMENTS

Add the following Sections 1.2.4 through 1.2.8 inclusive as follow:

1.2.4

In the Specification Sections, Part 1 General, may include Related Documents,

Summary and Definitions information contained in the Specifications. The listings

are not intended to be inclusive. It shall be the responsibility of the Contractor to

determine the full extent of Work that will be required for proper completion of the

Project. No responsibility, either direct or implied, will be assumed by either the

Architect or the Owner for omissions or duplications by the Contractor due to the

SUPPLEMENTARY CONDITIONS

007300 - 1

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

KL PROJECT No. 5256

arrangement of information in the Contract Documents. It shall be the Contractor's

responsibility to properly organize and coordinate such information to accomplish the

Work.

1.2.5

Specification Sections are written in modified brief style consistent with clarity. In

general, the words "the", "shall", "will", and "all" are not used. Where such words as

"perform", "provide", "install", "erect", "furnish", "connect", "test", or words of similar

meaning are used, it shall be understood that such words include the meaning of the

phrase "(The) Contractor shall". The requirements indicated and specified apply to all

Work of the same kind, class and type, even though the word "all" is not stated.

1.2.6

Drawings are intended to show general arrangement, design and extent of Work and are

partly diagrammatic. As such, they are not intended to be scaled for measurements or to

serve as shop drawings.

1.2.7

When reference is made in the Drawings or Specifications to industry standards, or

reference type specifications, or to another part of the Contract Documents, it shall have

the same force and effect as if the document, or portion referenced, is exactly repeated in

the place where reference is made. Refer to Section 014200 References in the

Specifications for additional requirements.

1.2.8

Whenever the Drawings or Specifications, a material, component or piece of equipment is

referred to in the singular, the reference shall be interpreted to apply to as many of such

articles, devices and equipment as are required to complete the Work.

1.5

OWNERSHIP AND USE OF DRAWINGS, SPECIFICATIONS AND OTHER

INSTRUMENTS OF SERVICE

Add Section 1.5.3 as follows:

1.5.3

The Contractor will be furnished free of charge one (1) copy of each set of Drawings and

Specifications as accepted for building permit issue by the permit authority having

jurisdiction for the purpose of construction of the Work. Additional copies may be

obtained by the Contractor from the Architect for the cost of reproduction, shipping and

handling.

ARTICLE 3 CONTRACTOR

3.2

REVIEW OF CONTRACT DOCUMENTS AND FIELD CONDITIONS BY

CONTRACTOR

Add Section 3.2.5 as follows:

SUPPLEMENTARY CONDITIONS

007300 - 2

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

KL PROJECT No. 5256

3.2.5

In order that any lack of clear definition of the Work, or conflicts in the Contract

Documents, be identified and resolved prior to the start of construction activities, the

Contractor shall submit a written report to the Architect and/or Owner within fifteen (15)

days after award of Contract by the Owner. This report shall include the following

statement:

"[INSERT Contractor's name] hereby certifies that the Drawings and Specifications for

the Project have been carefully examined and sufficient time has been provided to prepare

the Contract Sum. [INSERT Contractor's name] further warrants that to the extent that

any of the provided Contract Documents required clarification in any respect, such

clarification has been obtained from the Architect in writing and [INSERT Contractor's

name] is satisfied with such responses. It is understood that the Contract Documents

contemplate a finished Project of such character and quality as is described in or is

reasonable inferable from them. Recognizing the impossibility of producing Drawings

and Specifications with perfect accuracy, [INSERT Contractor's name] agrees that the

Contract Time and Sum for the Work includes sufficient time (including rain delays) and

cost allowances to make the Work complete and in compliance with good practice and

the design intent". Contractor claims for delay due to weather conditions will not be

considered or accepted.

3.4

LABOR AND MATERIALS

Section 3.4.1: Add the following Subparagraphs to the Section:

.1

The Contractor shall provide a list showing the name of the manufacturer

proposed to be used for each of the manufacturers or products identified in the

Contract Documents and, where applicable or required, the name of the installing

subcontractor or supplier.

.2

The Owner will promptly reply in writing to the Contractor if there are any

reasonable objections to the manufacturer or products specified. If adequate data

on any proposed manufacturer or installer is not available, the Owner may state

that action will be deferred until the Contractor provides further data. Failure to

object to a manufacturer shall not constitute a waiver of any of the requirements

of the Contract Documents, and all products furnished by the listed manufacturer

must conform to such requirements.

Section 3.4.2: Add the following Subparagraphs to the Section:

.1

After the Contract has been executed, the Owner and Architect will consider requests for

the substitution of products for those specified only under the conditions provided by

Division 01 General Requirements.

SUPPLEMENTARY CONDITIONS

007300 - 3

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

KL PROJECT No. 5256

.2

3.7

By making a request for substitutions, the Contractor:

.a

represents that the Contractor has personally investigated the proposed substitute

product and determined that it is equal or superior in all respects to that specified;

.b

represents that the Contractor will provide the same warranty for the substitution

that the Contractor would for that specified;

.c

certifies that the cost data presented is complete and includes all related costs, and

waives all claims for additional costs related to the substitution which

subsequently become apparent; and

.d

will coordinate the installation of the accepted substitute, making such changes as

may be required for the Work to be complete in all respects.

PERMITS, FEES, NOTICES AND COMPLIANCE WITH LAWS

Add the following Subparagraphs 3.7.1.1 through 3.7.1.5 to Section 3.7.1:

3.10

.1

The Owner will pay for building plan review fees, utility deposits, environmental

fees, and impact fees.

.2

The Contractor will pay for all other fees including but not limited to: Utility

connection fees, subcontractor permit fees, utility meter fees, etc.

.3

The Contractor shall include in Contract Sum all administrative costs involved in

obtaining various permits and processing other fees that are the responsibility of

the Contractor.

.4

The Contractor shall further secure and pay for all other licenses and inspections

necessary for execution of the Work.

.5

The Contractor shall obtain necessary information, apply for and deliver the

payments for all fees paid by the Owner.

CONTRACTORS CONSTRUCTION SCHEDULES

In Section 3.10.2, lines 2 and 3, change approval in one (1) location each to review.

3.11

DOCUMENTS AND SAMPLES AT THE SITE

In Section 3.11, line 3, change "approved in one (1) location to reviewed.

SUPPLEMENTARY CONDITIONS

007300 - 4

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

KL PROJECT No. 5256

In Section 3.11 change the period at the end of the paragraph to a comma and add the following:

. . . . . . , except as otherwise modified by Division 01 General Requirements.

3.12

SHOP DRAWINGS, PRODUCT DATA AND SAMPLES

In Section 3.12.5, line 3, change approved in two (2) locations to accepted.

In Section 3.12.7, line 3, change approved in one (1) location to reviewed.

In Section 3.12.8, line 1, change approved in one (1) location to accepted.

In Section 3.12.8, lines 2 and 7, change approval in one (1) location in each referenced line to

review.

In Section 3.12.8, line 4, change approval to acceptance in one (1) location.

In Section 3.12.9, line 3, change approval in one (1) location to review.

In Section 3.12.10, line 16, change approve in one (1) location to indicate no exceptions

taken.

Add Section 3.12.11 as follows:

3.12.11

3.15

Procedures for submittals are further delineated in Division 01, General

Requirements.

CLEANING UP

Add Section 3.15.3 as follows:

3.15.3

The Contractor, as a minimum requirement, and as defined by the Contract

Documents, and including but not limited to, shall wash and polish all glass,

remove all stains, paint stops, fingerprints, soil and dirt from finished surfaces,

clean and polish hardware and fixtures, wash all unpainted concrete, masonry and

tile, and leave the building broom clean.

ARTICLE 4 ARCHITECT

4.1

GENERAL

In Subparagraph 4.1.3, delete the words, "as to whom the Contractor makes no unreasonable

objection and"

SUPPLEMENTARY CONDITIONS

007300 - 5

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

KL PROJECT No. 5256

4.2 ADMINISTRATION OF THE CONTRACT

In Section 4.2.3, line 2, change known in one (1) location to observed.

4.2.4 COMMUNICATIONS FACILITATING CONTRACT ADMINISTRATION

In Section 4.2.5, line 2, change certify in one (1) location to comment on.

In Section 4.2.5, line 2, insert a period (.) after Contractor and delete the words and will issue

Certificates for Payment in such amounts.

In Section 4.2.7, line 1, change approve in one (1) location to comment.

In Section 4.2.7, line 4, change approved in two (2) locations to accepted.

In Section 4.2.7, line 10, change approval in one (1) location to acceptance or endorsement.

In Section 4.2.7, line 12, change approval in two (2) locations to acceptance.

In Section 4.2.8, line 1, delete the words Change Orders and in one (1) location.

In Section 4.2.8, line 2, change investigate in one (1) location to observe.

In Section 4.2.8, line 2, delete the words determinations and.

In Section 4.2.9, line 1, change inspections in one (1) location to observations.

In Section 4.2.9, line 4, change issue in one (1) location to review.

ARTICLE 5 SUBCONTRACTORS

5.2

AWARD OF SUBCONTRACTS AND OTHER CONTRACTS FOR PORTIONS

OF THE WORK

In Section 5.2.1, line 2, change through in one (1) location to and.

ARTICLE 6 - CONSTRUCTION BY OWNER OR BY SEPARATE CONTRACTORS

6.1

OWNERS RIGHT TO PERFORM CONSTRUCTION AND TO AWARD

SEPARATE CONTRACTS

Add Section 6.1.5 and subparagraphs as follows:

SUPPLEMENTARY CONDITIONS

007300 - 6

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

KL PROJECT No. 5256

6.1.5

The Owner reserves the right to take possession and use any completed or partially

complete portion of the building prior to completion providing such possession or use

does not interfere with the Contractor's accomplishment of the Work. Such partial

occupancy or taking possession will be based on the following:

.1

Occupancy of any portion of the Work will not constitute an acceptance of the

Work not performed in accordance with Contract Documents or relieve the

Contractor of liability to perform Work required by the Contract, but not

completed at the time of occupancy.

.2

Immediately prior to any partial occupancy, the Contractor, Owner, and Architect

shall make a thorough joint observation of the portion of the Work affected and

mutually agree upon the conditions of occupancy and status of the Work. The

Architect's evaluation shall be final in determining responsibility at the time of

observations for the conditions resulting from said occupancy. Damage to the

building caused by the Owner, his representative or occupants before Final

Acceptance will be the responsibility of the Owner.

ARTICLE 7 - CHANGES IN THE WORK

7.1

GENERAL

Add the following Subparagraph to Section 7.1.1.

7.1.1.1 Procedures and administrative requirements for changes in the work are further specified

in Division 01 General Requirements.

7.2

CHANGE ORDERS

In Section 7.2.1, line 1, replace Architect in one (1) location with Contractor.

Add Section 7.2.2 as follows:

7.2.2

Reasonable allowances for overhead and profit shall be included at the rates as negotiated

and referenced in the Agreement.

7.3

CONSTRUCTION CHANGE DIRECTIVES

In Section 7.3.8, line 2, replace confirmed in one (1) location with substantiated by the

Contractor to the acceptance of the Owner and review.

In Section 7.3.9, line 3, replace certification in one (1) location with review of the

Contractors provided application.

SUPPLEMENTARY CONDITIONS

007300 - 7

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

KL PROJECT No. 5256

In Section 7.3.9, line 4, replace certify in one (1) location with accept.

In Section 7.3.10, line 3, replace Architect in one (1) location with Contractor.

ARTICLE 8 TIME

8.2

PROGRESS AND COMPLETION

Add the following Section 8.2.4:

8.2.4

The Contractor will not be entitled to additional compensation for Work performed

outside of regular working hours, except as authorized in advance and in writing by the

Owner.

8.3

DELAYS AND EXTENSIONS OF TIME

Add the following to the end of Section 8.3.1:

Inclement weather shall not be cause to justify delay.

ARTICLE 9 - PAYMENTS AND COMPLETION

9.3

APPLICATIONS FOR PAYMENT

Add the following to the end of Section 9.3.1:

Requirements for the Application for Payment shall be as specified in Division 01 General

Requirements.

Add the following Subparagraph 9.3.1.3 to Section 9.3.1:

9.3.1.3 The first Application for Payment shall be accompanied, in writing, by the Contractor's

conditional partial waiver of lien, for the amount due. Each subsequent Application for

Payment shall be accompanied, in writing, by the Contractor's partial waiver of lien for

the current and unconditional waiver for previous payment amount due and by

unconditional partial waivers of lien from all subcontractors and supplies of materials,

equipment and services who are included in the preceding Application for Payment.

Application for Final Payment shall be accompanied by the Contractor's full waiver of

lien for the amount due and by full waivers of lien from subcontractors and suppliers of

materials, equipment and services who have not previously furnished such full waivers.

SUPPLEMENTARY CONDITIONS

007300 - 8

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

KL PROJECT No. 5256

Add the following Subparagraph 9.3.1.4 to Section 9.3.1.

9.3.1.4 Until Substantial Completion, the Owner shall pay no more than ninety (90) percent of

the amount due the Contractor on account of progress payments.

Add the following Subparagraph 9.3.1.5 to Section 9.3.1.

9.3.1.5 After the Work is substantially complete and the Architect has determined that the

Contractor's list of items to be completed or corrected is acceptable, retainage shall be

adjusted to be in proportion to the value of Work on the list, plus unsettled claims.

9.4

CERTIFICATES FOR PAYMENT

In Section 9.4, delete CERTIFICATES FOR PAYMENT and replace with REVIEW OF

CONTRACTORS APPLICATION FOR PAYMENT.

In Section 9.4.1, line 2, change a Certificate for Payment in one (1) location to an acceptance

of the Contractors Application for Payment.

In Section 9.4.1, line 4, change certification in one (1) location to acceptance.

In Section 9.4.2, line 1, change a Certificate for Payment in one (1) location to an acceptance

of the Contractors Application for Payment.

In Section 9.4.2, line 7, change a Certificate for Payment in one (1) location to an acceptance

of the Contractors Application for Payment.

In Section 9.4.2, line 8, change certified in one (1) location to accepted.

In Section 9.4.2, line 9, change a Certificate for Payment in one (1) location to an acceptance

of the Contractors Application for Payment.

In Section 9.4.2, line 10, change inspections in one (1) location to observations.

In Section 9.4.2, line 12, change made examination in one (1) location to reviewed.

9.5

DECISIONS TO WITHOLD CERTIFICATION

In Section 9.5, delete CERTIFICATION in one (1) location and replace with

ACCEPTANCE.

In Section 9.5.1, line 1, change a Certificate for Payment in one (1) location to an acceptance

of the Contractors Application for Payment.

SUPPLEMENTARY CONDITIONS

007300 - 9

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

KL PROJECT No. 5256

In Section 9.5.1, line 3, change certify in one (1) location to accept.

In Section 9.5.1, line 5, change a Certificate for Payment in one (1) location to an acceptance

of the Contractors Application for Payment.

In Section 9.5.1, line 6, change a Certificate for Payment in one (1) location to an acceptance

of the Contractors Application for Payment.

In Section 9.5.1, line 7, change a Certificate for Payment in one (1) location to an acceptance

of the Contractors Application for Payment.

In Section 9.5.2, line 1, change certification in two (2) locations to acceptance.

In Section 9.5.3, line 1, change certification in one (1) location to acceptance.

In Section 9.5.3, line 5, change Certificate for Payment in one (1) location to review of the

submitted Contractors Application for Payment.

9.6

PROGRESS PAYMENTS

In Section 9.6.1, line 1, change issued a Certificate for Payment in one (1) location to

accepted the Contractors Application for Payment.

In Section 9.6.6, line 1, change a Certificate for Payment in one (1) location to An acceptance

of the Contractors Application for Payment.

9.7

FAILURE OF PAYMENT

In Section 9.7, line 1, change a Certificate for Payment in one (1) location to An acceptance

of the Contractors Application for Payment.

In Section 9.7, line 3, change certified in one (1) location to accepted.

9.8

SUBSTANTIAL COMPLETION

In Section 9.8.3, line 1, replace make an inspection with visit the Project to observe and

In Section 9.8.3, line 2, replace inspection in one (1) location with observations.

In Section 9.8.3, line 6, replace inspection in one (1) location with site visit and observation.

In Section 9.8.4, lines 5 and 6, revise the following:

Delete the following sentence:

SUPPLEMENTARY CONDITIONS

007300 - 10

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

KL PROJECT No. 5256

Warranties required by the Contract Documents shall commence on the date of substantial

completion of the work or designated portion thereof unless otherwise provided in the Certificate

of Substantial Completion.

Replace with the following sentence:

The Contractors comprehensive 1 yr. warranty and all other warranties required or

provided by the Contract Documents shall commence on the date of the Owners written

acceptance of the work or portion thereof, unless otherwise agreed upon in writing.

9.9

PARTIAL OCCUPANCY OR USE

In Section 9.9.2, line 1, replace inspect in one (1) location with observe.

9.10

FINAL COMPLETION AND FINAL PAYMENT

In Section 9.10.1, lines 1, 2, replace inspection in one (1) location, each line, with

observation.

In Section 9.10.1, line 4, replace issue a Final Certificate for Payment in one (1) location with

review the Contractors final Application for Payment.

In Section 9.10.1, line 4, replace issue a Final Certificate for Payment stating that to the best of

the Architects knowledge with review the Contractors Final Application for Payment

considering that to the extent of the Architects knowledge, available.

In Section 9.10.1, line 5, replace inspections in one (1) location with observations.

In Section 9.10.1, line 7, replace Certificate in one (1) location with Application for

Payment.

In Section 9.10.1, line 7, replace Final Certificate for Payment in one (1) location with

acceptance of the Contractors Final Application for Payment.

Add the following sentence to Section 9.10.1:

The payment amount conveyed by the accepted Contractors final Application for Payment shall

be sufficient to increase the total payments to 100 percent of the Contract Sum, less such

amounts as the Architect shall determine for incomplete Work and unsettled claims.

SUPPLEMENTARY CONDITIONS

007300 - 11

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

KL PROJECT No. 5256

Add the following Subparagraph 9.10.2.1 to Section 9.10.2:

9.10.2.1

In addition to the above, the following requirements shall be fulfilled before

application for final payment or payment of the retained percentages is accepted and

paid: The Contractor shall deliver to the Architect (for delivery to the Owner), in a

single package, properly labeled item by item, to indicate all materials, equipment and

documents contained therein the following;

(1)

Notice by the Contractor of satisfactory completion of Work including corrections

of defective Work and acceptance of same by the Architect,

(2)

Contractor's Affidavit of Payment of Debtors and Claims; AIA Document G706

and Contractor's Affidavit of Release of Liens, AIA Document G706A, or other

forms as directed or accepted by the Owner.

(3)

Submission to the Owner of required Project Record Documents as defined in

Division 01 - General Requirements.

(4)

Completion of any required instructions and training to the Owner on operation

and maintenance of all equipment and systems.

(5)

Submission of all tools which are a permanent part of equipment installed in the

work.

(6)

Submission of all keys, construction and permanent, properly identified.

In Section 9.10.3, lines 3 and 8, replace certification in one (1) location, in each referenced

line, with review".

Add Section 9.10.6 as follows:

9.10.6 Following the issuance of final payment the Owner will record a Notice of Completion

with the governmental authorities having jurisdiction within ten (10) days following

completion and acceptance by the Owner of all work in accordance with the Contract

Documents. The Notice of Completion replaces any Certificate(s) of Substantial

Completion.

Add Section 9.11 as follows:

9.11

LIQUIDATED DAMAGES

SUPPLEMENTARY CONDITIONS

007300 - 12

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

KL PROJECT No. 5256

9.11.1 The Contractor and Contractor's surety, if any, shall be liable for and shall pay the Owner

the sums stipulated in the Agreement as liquidated damages, in lieu of actual damages,

for each calendar day of delay until Substantial Completion.

ARTICLE 10 - PROTECTION OF PERSONS AND PROPERTY

10.2

SAFETY OF PERSONS AND PROPERTY

Add the following to the end of Section 10.2.1:

. . . . .This requirement shall apply continuously and not be limited to normal working

hours.

Add the following Section 10.2.2.1 to Section 10.2.2:

10.2.2.1

The Contractor, its agents, employees, materialmen and subcontractors will perform

all work on the project in a safe and responsible manner. The Contractor shall, at its

own expense, conform to the safety policies and regulations established by the

Contractor and shall comply with all specific safety requirements promulgated by all

government authorities including without limitation the requirements of the

Occupational Safety and Health Act, and the Construction Safety Act, in effect on the

date of the Agreement and all standard and regulations which have been or shall be

promulgated by the parties or agencies which administer the Acts. The Contractor

shall comply with said requirements, standards and regulations, and require and be

directly responsible for compliance therewith on the part of its said agents,

employees, materialmen, and subcontractors; and shall directly receive, respond to,

defend, and be responsible for all citations, assessments, fines or penalties which may

be incurred by reason of its failure on the part of its agents, employees, materialmen

or subcontractors to so comply.

ARTICLE 11 - INSURANCE AND BONDS

11.1

CONTRACTORS LIABILITY INSURANCE

Add the following Section 11.1.2.1 to Section 11.1.2:

11.1.2.1

.1

The Contractor shall obtain and maintain, for the full period of the Contract, the

following minimum coverage and limits, or coverage and limits that are required by

the Owner or by law, whichever is greater:

WORKER'S COMPENSATION including Occupational Disease insurance

meeting the statutory requirements of the jurisdiction of the Project together with

a Broad Form All States Endorsement and containing Employers' Liability

insurance in an amount of at least $1,000,000.

SUPPLEMENTARY CONDITIONS

007300 - 13

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

KL PROJECT No. 5256

11.3

.2

COMPREHENSIVE GENERAL LIABILITY AND/OR UMBRELLA

LIABILITY insurance on an occurrence basis provided limits for Bodily Injury

with Personal Injury including its employees of in the amounts of at least

$1,000,000 each occurrence and $1,000,000 aggregate; Property Damage

$1,000,000 each occurrence, $1,000,000 aggregate. The policy must include the

Owner, Architect and other Project Consultants as listed in the Project Directory,

as ADDITIONAL INSUREDS and must provide Premises-Operations,

Independent Contractors, Broad Form Property Damage, Contractual Liability,

Products and Completed Operations coverages (which shall be maintained in

force for a period of two years after substantial completion of the project or for

such longer period of time as is described in the Contract Documents) and

PRIMARY to any insurance of the ADDITIONAL INSUREDS. XCU Exclusions

must be deleted when applicable to operations performed by the Contractor. A

waiver of Subrogation in favor of the Owner shall also be included. Evidence of

Insurance coverage naming the additional insureds shall be provided to the Owner

and Architect prior to proceeding with the work.

.3

COMPREHENSIVE AUTOMOBILE LIABILITY on an occurrence basis

covering all Owned, Non-Owned and Hired Vehicles for limits of liability equal

to those in (.2) above.

.4

A Certificate of Insurance on an approved form must be delivered to the Owner

and Architect and must state coverage will not be altered, canceled or allowed to

expire without thirty (30) days written notice by registered mail to the Owner.

.5

Insurance coverage of $1,000,000.00 minimum limit must be obtained from each

subcontractor and, or, supplier, if any, before permitting them on the site of the

project. Otherwise, this required protection must be included within the

Contractors insurance policies.

.6

It is understood and agreed that the insurance coverages and limits required above

shall not limit the extent of the Contractor's responsibilities and liabilities

specified within the Contract Documents or by law.

.7

It is understood and agreed authorization is hereby granted to Owner to withhold

payments to the Contractor until properly executed Certificate(s) of Insurance

evidencing insurance required herein are received by the Owner.

.8

Certificates of Insurance shall be submitted as specified in Division 00

Procurement and Contracting Requirements and Division 01 - General

Requirements.

PROPERTY INSURANCE

SUPPLEMENTARY CONDITIONS

007300 - 14

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

KL PROJECT No. 5256

Add the following to the end of Section 11.3.1.1

The Contractor shall be responsible for any damage or loss not covered under the Owner's

policy to any and all materials, supplies or equipment after delivery to the site by the Contractor

or his suppliers, whether paid for by the Owner or not, whether prior to or after installation into

the building structure. (Examples: theft, damage while handling, etc..)

11.4

PERFORMANCE BOND AND PAYMENT BOND

Add Section 11.4.3 as follows:

11.4.3 The Contractor shall deliver the required bonds to the Owner not later than three days

following the date the Agreement is entered into, or if the Work is to be commenced prior

thereto in response to a letter of intent, the Contractor shall, prior to the commencement

of the Work, submit evidence satisfactory to the Owner that such bonds will be furnished.

Add Section 11.4.4 as follows:

11.4.4 The Contractor shall require the attorney-in-fact who executes the required bonds on

behalf of the surety to affix thereto a certified and current copy of the power of attorney.

ARTICLE 12 UNCOVERING AND CORRECTION OF WORK

12.1

UNCOVERING OF WORK

In Section 12.1.1, line 3, change examination in one (1) location to observation.

In Section 12.1.2, line 1, change examine in one (1) location to observe it.

In Section 12.2.1, line 1, change rejected in one (1) location to not accepted.

ARTICLE 13 - MISCELLANEOUS PROVISIONS

13.6

INTEREST

In Section 13.6, line 1, following unpaid insert after 30 days.

ARTICLE 14 - TERMINATION OR SUSPENSION OF THE CONTRACT

14.1

TERMINATION BY CONTRACTOR

In Section 14.1.1.3, line 1, change issued a Certificate for Payment in one (1) location to

accepted the Contractors Final Application for Payment.

SUPPLEMENTARY CONDITIONS

007300 - 15

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

KL PROJECT No. 5256

In Section 14.1.1.3, line 2, change certification in one (1) location to acceptance.

In Section 14.1.1.3, line 3, change or in one (1) location to or the Contractor has not provided

required or requested supporting documents including satisfaction of requirements of the Owner

related to the Owners financing resource or Lender for the Project.

14.2

TERMINATION BY THE OWNER FOR CAUSE

In Section 14.2.2, line 1, change certification in one (1) location to acceptance.

In Section 14.2.4, line 5, change certified in one (1) location to accepted.

ARTICLE 15 CLAIMS AND DISPUTES

15.1

CLAIMS

15.1.3 CONTINUING CONTRACT PERFORMANCE

In Section 15.1.3, line 3, change prepare in one (1) location to review.

In Section 15.1.3, line 3, change issue in one (1) location to review.

In Section 15.1.3, line 4, change Certificates for Payment in one (1) location to the

Contractors Application for Payment.

15.2

INITIAL DECISION

In Section 15.2.2, line 3, change reject in one (1) location to not accept.

In Section 15.2.2, line 3, change approve in one (1) location to accept.

In Section 15.2.4, line 5, change reject or approve in one (1) location to accept or not accept.

In Section 15.2.5, line 1, change approving or rejecting in one (1) location to accepting or not

accepting.

END OF SECTION 007300

SUPPLEMENTARY CONDITIONS

007300 - 16

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

KL PROJECT No. 5256

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

SECTION 011000 - SUMMARY

PART 1 - GENERAL

1.1

RELATED DOCUMENTS

A.

1.2

Drawings and general provisions of the Contract, including General and Supplementary

Conditions and other Division 01 Specification Sections, apply to this Section.

SUMMARY

A.

Section includes:

1.

2.

3.

4.

B.

Related Section:

1.

1.3

Project information.

Work covered by Contract Documents.

Access to site.

Specification and drawing conventions.

Division 01 Section "Temporary Facilities and Controls" for limitations and procedures

governing temporary use of Owner's facilities.

PROJECT INFORMATION

A.

Project Identification: The Arbors at Brighton Park

1.

B.

Project Location: On Woodland Avenue between the intersections of Old Road and

Castlewood Drive in Bloomfield, CT.

Owner: Brighton Park Apartments, LLC or assigns

c/o Rohdie Group, LLC

52 Vanderbilt Avenue, Suite 2007

New York, NY 10017

1.

C.

Owner's Representative: Marc Weil

Architect: Kenneth Linehan, Architect

c/o Fugleberg Koch, PLLC.

2555 Temple Trail

SUMMARY

011000 - 1

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

KL PROJECT No. 5256

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

Winter Park, FL. 32789

(407) 629-0595 phone

1. Architects Representative: Kenneth Linehan, Architect.

D.

Other Owner Consultants: The Owner has retained the following design professionals who

have prepared designated portions of the Contract Documents:

1.

Civil Engineering and Site Improvements

F. A. Hesketh & Associates, Inc.

6 Creamery Brook

East Granby, CT 06026

Contact:

E.

1.4

Guy Hesketh, PE

Contractor: TBD

WORK COVERED BY CONTRACT DOCUMENTS

A.

The Work of the Project is defined by the Construction Documents and consists of the

following:

New construction of one hundred thirty (130) rental apartment units of several types distributed among four (4) residential buildings of three (3) types. One (1) of the residential

building types will be of a two (2) floor configuration.. The other two (2) residential

building types will be of a three (3) story configuration as established by the Owners program and including a Clubhouse amenity building, a Mail Kiosk and a Trash Compactor

Enclosure. The Clubhouse amenity building will include two (2) dwelling units. The Project site is comprised of approximately 14 (14) acres located on Woodland Avenue between the intersections of Old Road and Castlewood Drive in Bloomfield, Connecticut.

B.

Type of Contract

1.

SUMMARY

Project will be constructed as defined by the Construction Documents issued separately.

011000 - 2

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

KL PROJECT No. 5256

1.5

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

ACCESS TO SITE

A.

General: Contractor shall have limited use of Project site for construction operations as

indicated on Drawings by the Contract limits and as indicated by requirements of this Section.

B.

Use of Site: Limit use of Project site to within the Contract limits indicated. Do not disturb

portions of Project site beyond areas in which the Work is indicated.

1.

1.6

Limits: Confine construction operations to Contract limits defined by Owner.

COORDINATION WITH OCCUPANTS

A.

Owner Limited Occupancy of Completed Areas of Construction: Owner reserves the right to

occupy completed building and related site improvement areas following the issuance of a

Certificate of Occupancy by the authorities having jurisdiction, and prior to Final Completion of

the Work, provided such occupancy does not interfere with completion of the Work. Such

occupancy shall not constitute final acceptance of the total Work.

1.

2.

3.

1.7

Obtain a Certificate of Occupancy from authorities having jurisdiction before limited

Owner occupancy.

Before limited Owner occupancy, mechanical and electrical systems shall be fully

operational, and required tests and inspections shall be successfully completed. On

occupancy, Owner will operate and maintain mechanical and electrical systems serving

occupied portions of Work.

On occupancy, Owner will assume responsibility for maintenance and custodial service

for occupied portions of Work.

WORK RESTRICTIONS

A.

Work Restrictions, General: Comply with restrictions on construction operations.

1.

Comply with limitations on use of public streets and other requirements of authorities

having jurisdiction.

B.

On-Site Work Hours: Limit work in the existing building to normal business working hours of

8:00 a.m. to 5:00 p.m., Monday through Friday, except as otherwise indicated or to hours

stipulated by Owner Contractor Agreement and as acceptable to the authorities having

jurisdiction.

C.

Existing Utility Interruptions: Do not interrupt utilities serving facilities occupied by Owner or

others unless permitted under the following conditions and then only after providing temporary

utility services according to requirements indicated:

1.

2.

SUMMARY

Notify Owner not less than two (2) days in advance of proposed utility interruptions.

Obtain Owner's written permission before proceeding with utility interruptions.

011000 - 3

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

KL PROJECT No. 5256

D.

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

Noise, Vibration, and Odors: Coordinate operations that may result in high levels of noise and

vibration, odors, or other disruption to Owner occupancy with Owner.

1.

2.

Notify Owner not less than two (2) days in advance of proposed disruptive operations.

Obtain Owner's written permission before proceeding with disruptive operations.

E.

Nonsmoking Building: Smoking is not permitted within the building or within 25 feet (8 m) of

entrances, operable windows, or outdoor air intakes.

F.

Controlled Substances: Use of controlled substances on the Project site is not permitted.

1.8

SPECIFICATION AND DRAWING CONVENTIONS

A.

Specification Content: The Specifications use certain conventions for the style of language and

the intended meaning of certain terms, words, and phrases when used in particular situations.

These conventions are as follows:

1.

2.

Imperative mood and streamlined language are generally used in the Specifications. The

words "shall," "shall be," or "shall comply with," depending on the context, are implied

where a colon (:) is used within a sentence or phrase.

Specification requirements are to be performed by Contractor unless specifically stated

otherwise.

B.

Division 01 General Requirements: Requirements of Sections in Division 01 apply to the Work

of all Sections in the Specifications.

C.

Drawing Coordination: Requirements for materials and products identified on the Drawings are

described in detail in the Specifications. One or more of the following are used on the

Drawings to identify materials and products:

1.

2.

Terminology: Materials and products are identified by the typical generic terms used in

the individual Specifications Sections.

Abbreviations: Materials and products are identified by abbreviations scheduled on

Drawings.

PART 2 - PRODUCTS (Not Used)

PART 3 - EXECUTION (Not Used)

END OF SECTION 011000

SUMMARY

011000 - 4

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

KL PROJECT No. 5256

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

SECTION 012100 - ALLOWANCES

PART 1 - GENERAL

1.1

RELATED DOCUMENTS

A.

1.2

Drawings and general provisions of the Contract, including General and Supplementary

Conditions and other Division 01 Specification Sections, apply to this Section.

SUMMARY

A.

Section includes administrative and procedural requirements governing allowances.

1.

B.

Types of allowances include the following:

1.

2.

3.

4.

C.

1.3

Certain items may be specified in the Contract Documents by allowances. Allowances

have been established in lieu of additional requirements and to defer selection of actual

materials and equipment to a later date when direction will be provided to the Contractor.

If necessary, additional requirements will be issued by Change Order.

Lump-sum allowances.

Quantity allowances.

Contingency allowances.

Testing and inspecting allowances.

Related Sections:

1.

Division 01 Section "Quality Requirements" for procedures governing the use of

allowances for testing and inspecting.

2.

Divisions 02 through 49 Sections for items of Work covered by allowances.

SELECTION AND PURCHASE

A.

At the earliest practical date after award of the Contract, advise Architect of the date when final

selection and purchase of each product or system described by an allowance must be completed

to avoid delaying the Work.

B.

At Architect's or Owners request, obtain proposals for each allowance for use in making final

selections. Include recommendations that are relevant to performing the Work.

C.

Purchase products and systems selected by Architect or Owner from the designated supplier.

1.4

SUBMITTALS

A.

Submit proposals for purchase of products or systems included in allowances, in the form

specified for Change Orders.

ALLOWANCES

012100 - 1

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

KL PROJECT No. 5256

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

B.

Submit invoices or delivery slips to show actual quantities of materials delivered to the site for

use in fulfillment of each allowance.

C.

Submit time sheets and other documentation to show labor time and cost for installation of

allowance items that include installation as part of the allowance.

D.

Coordinate and process submittals for allowance items in same manner as for other portions of

the Work.

1.5

COORDINATION

A.

1.6

Coordinate allowance items with other portions of the Work. Furnish templates as required to

coordinate installation.

LUMP-SUM ALLOWANCES

A.

Allowance shall include cost to Contractor of specific products and materials selected by

Architect, or Owner, under allowance and shall include taxes, freight, and delivery to Project

site.

B.

Unless otherwise indicated, Contractor's costs for receiving and handling at Project site, labor,

installation, overhead and profit, and similar costs related to products and materials selected by

Architect, or Owner, under allowance shall be included as part of the Contract Sum and not part

of the allowance.

C.

Unused Materials: Return unused materials purchased under an allowance to manufacturer or

supplier for credit to Owner, after installation has been completed and accepted.

1.

1.7

If requested by Architect, or Owner, retain and prepare unused material for storage by

Owner. Deliver unused material to Owner's storage space as directed.

ADJUSTMENT OF ALLOWANCES

A.

Allowance Adjustment: To adjust allowance amounts, prepare a Change Order proposal based

on the difference between purchase amount and the allowance, multiplied by final measurement

of work-in-place where applicable. If applicable, include reasonable allowances for cutting

losses, tolerances, mixing wastes, normal product imperfections, and similar margins.

1.

2.

B.

Include installation costs in purchase amount only where indicated as part of the

allowance.

If requested, prepare explanation and documentation to substantiate distribution of

overhead costs and other margins claimed.

Submit claims for increased costs because of a change in scope or nature of the allowance

described in the Contract Documents, whether for the purchase order amount or Contractor's

handling, labor, installation, overhead, and profit.

ALLOWANCES

012100 - 2

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

KL PROJECT No. 5256

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

PART 2 - PRODUCTS (Not Used)

PART 3 - EXECUTION

3.1

EXAMINATION

A.

3.2

Examine products covered by an allowance promptly on delivery for damage or defects. Return

damaged or defective products to manufacturer for replacement.

PREPARATION

A.

3.3

Coordinate materials and their installation for each allowance with related materials and

installations to ensure that each allowance item is completely integrated and interfaced with

related work.

SCHEDULE OF ALLOWANCES

A.

Allowances are applicable as listed by a Schedule of Allowances provided within the

Owner/Contractor Agreement in the absence of a Schedule of Allowances provided within the

Project Manual, Division 01 of the Contract Documents.

END OF SECTION 012100

ALLOWANCES

012100 - 3

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

KL PROJECT No. 5256

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

SECTION 012500 - SUBSTITUTION PROCEDURES

PART 1 - GENERAL

1.1

RELATED DOCUMENTS

A.

1.2

Drawings and general provisions of the Contract, including General and Supplementary

Conditions and other Division 01 Specification Sections, apply to this Section.

SUMMARY

A.

Section includes administrative and procedural requirements for substitutions.

B.

Related Sections:

1.

Division 01 Section "Product Requirements" for requirements for submitting comparable

product submittals for products by listed manufacturers.

2.

Divisions 02 through 49 Sections for specific requirements and limitations for

substitutions.

1.3

DEFINITIONS

A.

Substitutions: Changes in products, materials, equipment, and methods of construction from

those required by the Contract Documents and proposed by Contractor.

1.

2.

1.4

Substitutions for Cause: Changes proposed by Contractor that are required due to

changed Project conditions, such as unavailability of product, regulatory changes, or

unavailability of required warranty terms.

Substitutions for Convenience: Changes for convenience are not allowed.

SUBMITTALS

A.

Substitution Requests: Submit three copies of each request for consideration. Identify product

or fabrication or installation method to be replaced. Include Specification Section number and

title and Drawing numbers and titles.

1.

2.

Substitution Request Form: Use form acceptable to Architect.

Documentation: Show compliance with requirements for substitutions and the following,

as applicable:

a.

b.

Statement indicating why specified product or fabrication or installation cannot be

provided.

Coordination information, including a list of changes or modifications needed to

other parts of the Work and to construction performed by Owner and separate

contractors, that will be necessary to accommodate proposed substitution.

SUBSTITUTION PROCEDURES

012500 - 1

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

KL PROJECT No. 5256

c.

d.

e.

f.

g.

h.

i.

j.

k.

l.

m.

n.

3.

Detailed comparison of significant qualities of proposed substitution with those of

the Work specified. Include annotated copy of applicable specification section.

Significant qualities may include attributes such as performance, weight, size,

durability, visual effect, sustainable design characteristics, warranties, and specific

features and requirements indicated. Indicate deviations, if any, from the Work

specified.

Product Data, including drawings and descriptions of products and fabrication and

installation procedures.

Samples, where applicable or requested.

Certificates and qualification data, where applicable or requested.

List of similar installations for completed projects with project names and

addresses and names and addresses of architects and owners.

Material test reports from a qualified testing agency indicating and interpreting test

results for compliance with requirements indicated.

Research reports evidencing compliance with building code and regulations in

effect for Project, from an evaluation organization acceptable to the authorities

having jurisdiction.

Detailed comparison of Contractor's construction schedule using proposed

substitution with products specified for the Work, including effect on the overall

Contract Time. If specified product or method of construction cannot be provided

within the Contract Time, include letter from manufacturer, on manufacturer's

letterhead, stating date of receipt of purchase order, lack of availability, or delays

in delivery. Identify use of available float, if any, in schedule comparison.

Cost information, including a proposal of change, if any, in the Contract Sum.

Documentation of Owner acceptance of the proposed substitution.

Contractor's certification that proposed substitution complies with requirements in

the Contract Documents except as indicated in substitution request, is compatible

with related materials, and is appropriate for applications indicated.

Contractor's waiver of rights to additional payment or time that may subsequently

become necessary because of failure of proposed substitution to produce indicated

results.

Architect's Action: If necessary, Architect will request additional information or

documentation for evaluation within seven (7) days of receipt of a request for

substitution. Architect will notify Contractor of acceptance or rejection of proposed

substitution within fourteen (14) days of receipt of request, or seven (7) days of receipt of

additional information or documentation, whichever is later, unless Architect is unable to

accept the substitution as presented.

a.

b.

1.5

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

Forms of Acceptance:

Construction Change Directive, or Architect's

Supplemental Instructions for minor changes in the Work.

Use product specified if Architect does not issue a decision on use of a proposed

substitution within time allocated.

QUALITY ASSURANCE

A.

Compatibility of Substitutions:

Investigate and document compatibility of proposed

substitution with related products and materials. Engage qualified testing agency to perform

compatibility tests recommended by manufacturers.

SUBSTITUTION PROCEDURES

012500 - 2

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

KL PROJECT No. 5256

1.6

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

PROCEDURES

A.

Coordination: Modify or adjust affected work as necessary to integrate work of the accepted

substitutions.

PART 2 - PRODUCTS

2.1

SUBSTITUTIONS

A.

Substitutions for Cause: Submit requests for substitution immediately upon discovery of need

for change, but not later than ten (10) days prior to time required for preparation and review of

related submittals.

1.

Conditions: Architect will consider Contractor's request for substitution when the

following conditions are satisfied. If the following conditions are not satisfied, Architect

will return requests without action, except to record noncompliance with these

requirements:

a.

b.

c.

d.

e.

f.

g.

h.

i.

Requested substitution is consistent with the Contract Documents and will produce

indicated results.

Substitution request is fully documented and properly submitted.

Requested substitution will not adversely affect Contractor's construction schedule.

Requested substitution has received necessary approvals of authorities having

jurisdiction.

Requested substitution is compatible with other portions of the Work.

Requested substitution has been coordinated with other portions of the Work.

Requested substitution provides specified warranty.

If requested substitution involves more than one contractor, requested substitution

has been coordinated with other portions of the Work, is uniform and consistent, is

compatible with other products, and is acceptable to all contractors involved.

Owner has directed Architect to review Contractors request for substitution.

PART 3 - EXECUTION (Not Used)

END OF SECTION 012500

SUBSTITUTION PROCEDURES

012500 - 3

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

KL PROJECT No. 5256

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

SECTION 012600 - CONTRACT MODIFICATION PROCEDURES

PART 1 - GENERAL

1.1

RELATED DOCUMENTS

A.

1.2

Drawings and general provisions of the Contract, including General and Supplementary

Conditions and other Division 01 Specification Sections, apply to this Section.

SUMMARY

A.

Section includes administrative and procedural requirements for handling and processing

Contract modifications.

B.

Related Sections:

1.

1.3

Division 01 Section "Product Requirements" for administrative procedures for handling

requests for substitutions made after Contract award.

MINOR CHANGES IN THE WORK

A.

1.4

Architect will issue supplemental instructions authorizing minor changes in the Work, not

involving adjustment to the Contract Sum or the Contract Time, on AIA Document G710,

"Architect's Supplemental Instructions" or on an alternate form accepted by Architect or

directed by Owner.

PROPOSAL REQUESTS

A.

Owner-Initiated Proposal Requests: Architect will issue a detailed description of proposed

changes in the Work that may require adjustment to the Contract Sum or the Contract Time. If

necessary, the description will include supplemental or revised Drawings and Specifications.

1.

2.

Proposal Requests issued by Architect are not instructions either to stop work in progress

or to execute the proposed change.

Within time specified in Proposal Request or fourteen (14) days, when not otherwise

specified, after receipt of Proposal Request, submit a quotation estimating cost

adjustments to the Contract Sum and the Contract Time necessary to execute the change.

a.

b.

c.

Include a list of quantities of products required or eliminated and unit costs, with

total amount of purchases and credits to be made. If requested, furnish survey data

to substantiate quantities.

Indicate applicable taxes, delivery charges, equipment rental, and amounts of trade

discounts.

Include costs of labor and supervision directly attributable to the change.

CONTRACT MODIFICATION PROCEDURES

012600 - 1

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

KL PROJECT No. 5256

d.

e.

B.

Include an updated Contractor's construction schedule that indicates the effect of

the change, including, but not limited to, changes in activity duration, start and

finish times, and activity relationship. Use available total float before requesting

an extension of the Contract Time.

Quotation Form: Use form acceptable to Architect and Owner.

Contractor-Initiated Proposals: If latent or changed conditions require modifications to the

Contract, Contractor may initiate a claim by submitting a request for a change to Architect and

Owner concurrently.

1.

2.

3.

4.

5.

6.

7.

1.5

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

Include a statement outlining reasons for the change and the effect of the change on the

Work. Provide a complete description of the proposed change. Indicate the effect of the

proposed change on the Contract Sum and the Contract Time.

Include a list of quantities of products required or eliminated and unit costs, with total

amount of purchases and credits to be made. If requested, furnish survey data to

substantiate quantities.

Indicate applicable taxes, delivery charges, equipment rental, and amounts of trade

discounts.

Include costs of labor and supervision directly attributable to the change.

Include an updated Contractor's construction schedule that indicates the effect of the

change, including, but not limited to, changes in activity duration, start and finish times,

and activity relationship. Use available total float before requesting an extension of the

Contract Time. Clearly indicate amount of available float used.

Comply with requirements in Division 01 Section "Substitution Procedures" if the

proposed change requires substitution of one product or system for product or system

specified.

Proposal Request Form: Use form acceptable to Architect and Owner.

ADMINISTRATIVE CHANGE ORDERS

A.

1.6

Alternate Adjustment: Refer to Division 01 Section "Alternates" for administrative procedures

for preparation of Change Order Proposal for adjusting the Contract Sum and schedule to reflect

alternates accepted after the establishment of the Contract Sum and Schedule.

CHANGE ORDER PROCEDURES

A.

1.7

On Owner's approval of a Proposal Request, Contractor will issue a Change Order for review

and signature by Owner and Architect on AIA Document G 701.

CONSTRUCTION CHANGE DIRECTIVE

A.

Construction Change Directive: Architect may issue a Construction Change Directive on

AIA Document G714. Construction Change Directive instructs Contractor to proceed with a

change in the Work.

CONTRACT MODIFICATION PROCEDURES

012600 - 2

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

KL PROJECT No. 5256

1.

B.

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

Construction Change Directive contains a complete description of change in the Work. It

also designates method to be followed to determine change in the Contract Sum or the

Contract Time and implementation prerequisite requirements as may be applicable.

Documentation: Maintain detailed records on a time and material basis of work required by the

Construction Change Directive.

1.

After completion of change, submit an itemized account and supporting data necessary to

substantiate cost and time adjustments to the Contract as directed by the Construction

Change Directive requirements in the format of a Proposed Change Order.

PART 2 - PRODUCTS (Not Used)

PART 3 - EXECUTION (Not Used)

END OF SECTION 012600

CONTRACT MODIFICATION PROCEDURES

012600 - 3

THE ARBORS @ BRIGHTON PARK

BLOOMFIELD, CT

KL PROJECT No. 5256

ISSUE DATE: FEBRUARY 6, 2015

DD REVIEW SET

SECTION 012900 - PAYMENT PROCEDURES

PART 1 - GENERAL

1.1

RELATED DOCUMENTS

A.

1.2

Drawings and general provisions of the Contract, including General and Supplementary

Conditions and other Division 01 Specification Sections, apply to this Section.

SUMMARY

A.

This Section specifies administrative and procedural requirements necessary to prepare and

process Applications for Payment.

B.

Related Sections:

1.

2.

3.

4.

1.3

Division 01 Section "Allowances" for procedural requirements governing the handling

and processing of allowances.

Division 01 Section "Contract Modification Procedures" for administrative procedures

for handling changes to the Contract.

Division 01 Section "Construction Progress Documentation" for administrative

requirements governing the preparation and submittal of the Contractor's construction

schedule.

Division 01 Section "Submittal Procedures" for administrative requirements governing

the preparation and submittal of the submittal schedule.

DEFINITIONS

A.

1.4

Schedule of Values: A statement furnished by Contractor allocating portions of the Contract

Sum to various portions of the Work and used as the basis for reviewing Contractor's

Applications for Payment.

SCHEDULE OF VALUES

A.