Documente Academic

Documente Profesional

Documente Cultură

Application of Predictive Control To A Batch Reactor Visualmesa

Încărcat de

Mohd Hisyamuddin Mohd AminudinTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Application of Predictive Control To A Batch Reactor Visualmesa

Încărcat de

Mohd Hisyamuddin Mohd AminudinDrepturi de autor:

Formate disponibile

Application of Predictive Control to A Batch Reactor

APPLICATION OF PREDICTIVE CONTROL

TO A BATCH REACTOR

Diego Ruiz Massa, Carlos Ruiz Garca

Soteica Europe, S.L. ; Pau Riera 2, 2 2; E-08940 Cornell (Barcelona) Spain

Tel/Fax: +34 93 375 3503; http://www.soteica.com

E-mails: diego.ruiz@soteica.com ; carlos.ruiz@soteica.com

Jacques Papon, Stephane Guesneux

Adersa; 10, rue de la Croix Martre : F-91873 - Palaiseau cedex France

Tel : +33 (0)1 60 13 53 53, Fax: +33 (0) 1 69200563, http://www.adersa.com

E-mails: jacques.papon@adersa.com ; stephane.guesneux@adersa.com

Ana Isabel Sanz Mendez

Repsol Qumica S.A.; Paseo de la Castellana 278-280, E-28046 Madrid Spain

E-mail : aisanzm@repsolypf.com

Raquel Lucio Lpez

Repsol Qumica S.A.; C.I. Tarragona, La Pobla de Mafumet, E-43080 Tarragona Spain

E-mail : rluciol@repsolypf.com

ERTC Computing 2003, Milan, Italy

Page 1 of 12

Repsol / Soteica / Adersa

Application of Predictive Control to A Batch Reactor

Abstract

The REPSOL company had in mind the improvement of the control on one of their

chemical reactors. A feasibility study for the implementation of an Advanced Control

technique (Predictive Control for temperature control for chemical Reactors - PCR) for a

batch reactor for Polyols production has been performed. The proposed technique PCR is

based on a dynamic model of the unit which makes the prediction of the process variables

behaviour.

That behaviour is specified in terms of closed loop time response through a desired future

trajectory. The control system shows a substantial improvement in the reactor temperature

controllability and a notorious elimination of the competition between the cooling and

heating actuators. The improvement is partially explained by the distinction made by the

model and the control modules between the heating and the cooling dynamic effects which

are usually quite different. Among the origins of the benefits obtained by such a model

based predictive control, energy savings come from a smaller consumption of utilities, a

higher availability of the unit comes from less activated valves are non negligible aspects.

But the better handling of the temperature profile provides more significant improvements

on quality stability and on batch duration.

ERTC Computing 2003, Milan, Italy

Page 2 of 12

Repsol / Soteica / Adersa

Application of Predictive Control to A Batch Reactor

1. Introduction

Repsol Qumica operates a large petrochemical complex in Tarragona (Spain). The

principles governing their projects at production plants are:

The use of its own technology

Maximum concern for the environment

The inclusion of cutting edge technologies, to make plants safer and more

automatic

Maximum energy integration

Downstream integration, obtaining high added-value products

Repsol Qumica had in mind the improvement of the control on one of their chemical

reactors. A feasibility study for the implementation of an Advanced Control technique

(Predictive Control for temperature control for chemical Reactors - PCR) for a batch

reactor for Polyols production has been performed.

PCR covers the gap between conventional Proportional-Integrative-Derivative (PID)

controllers and large Model Based Predictive Control (MBPC) applications. PCR is

especially focused to solve control problems where PID shows poor performance and

Multivariable MBPC is not necessary. PCR can be applied also on other units such as heat

exchangers, furnaces and distillation columns. All of them can present common control

problems such as integrative, with time delays, non-linearity, strongly dependent on the

working conditions. PCR will make possible for the producer to push the process on its

limits thanks to PCR control performance.

The methodology relies on a model of the process to be controlled. The estimated model,

describing the relationships between the manipulated variables (actions) and the

temperatures to be controlled, makes possible the prediction of the behaviour of these

temperatures and the computation of the actions to be applied to the unit.

The difficulty in controlling the temperature is due to several factors:

The link between the actuators and the temperatures is integrative with time

delays

ERTC Computing 2003, Milan, Italy

Page 3 of 12

Repsol / Soteica / Adersa

Application of Predictive Control to A Batch Reactor

The heating and cooling actions affect reactor temperature with very

different dynamics; which limits the performances of the usual split range

control.

Nonlinearities in the manipulated variable, which requires a specific

controller

In this work, the results of the performed feasibility study for the implementation of PCR

for a batch reactor for Polyols production are summarized. After a brief description of the

process, the objectives of the work are explained. Then, the project steps and their results

are shown. Finally, the conclusions are commented.

2. Brief Process Description

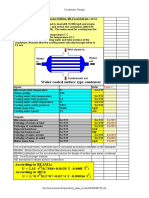

Figure 1 shows a simplified scheme of the unit for polyols production.

FCI

F

FC

PC

PC

PI

P

Reactants

PI

P

Water

TI

Tr

TC2

TC

T

PC

To Vacuum

System

TI4

PI

P

LI

L

Reactor

LI

TC

T

TC1

Secondary

loop

Heat

Exchanger

TI5

TC3

TI

T

TC

Tr

Primary loop

Water

FI

FI

Fr

CV

TI

Tr

TI6

HV

Steam

Figure 1. Simplified scheme of the batch unit for polyols production

ERTC Computing 2003, Milan, Italy

Page 4 of 12

Repsol / Soteica / Adersa

Application of Predictive Control to A Batch Reactor

TC1: Product temperature in the reactor

TC2: Product temperature at heat exchanger output, in the primary loop

TC3: Water temperature at heat exchanger input, in the secondary loop

TI4: Water temperature at heat exchanger output, in the secondary loop

TI5: Product temperature at heat exchanger input, in the primary loop

TI6: Fresh feed cooling water temperature

HV: Steam valve

CV: Cooling water valve

In order to control reaction temperature, cooling is performed by the heat exchanger which

utilizes recirculated cooling water. On the other hand, heating is performed by steam,

through a serpentine inside the reactor.

3. Objectives

The main objective is to improve reactor temperature control. By this way, a greater

efficiency is obtained by:

An improvement of quality by a better temperature stability

An increase of production through shorter batch duration

A higher availability of the plant by less activated valves

A decrease of marginal costs through smaller consumption of utilities

4. Project steps and Results

Project steps for a PCR implementation are the following:

1. Process analysis & specifications

2. Experiments

3. Modelling / Identification

4. Simulator

ERTC Computing 2003, Milan, Italy

Page 5 of 12

Repsol / Soteica / Adersa

Application of Predictive Control to A Batch Reactor

5. Controller design

6. Closed loop testing (simulation)

7. Implementation of the validated controller

8. Tests on site: dead load & production

9. Training of users

In this study, steps 1. through 6. are presented. Project steps 7. to 9. are currently being

implemented.

4.1. Process analysis and specifications

Data collection of several complete batch operation (where the selected grade was

produced) has been done. All the relevant signals around the reactor with a 5 secs sampling

period, have been collected. This information has included all the process variables, valve

outputs and setpoints.

Manipulated variables are steam and water valves. Disturbances are reactants flowrates and

fresh feed water temperature.

4.2. Experiments

A plant test is designed to provide the necessary information for the identification of the

models corresponding to the slave controller (primary loop temperature control).

The plant test is applied on a reactor without any reaction: the product inside the tank is a

dead load (non active).

The identification of the reactant effect (master controller) is performed from a set of

recorded regular batches, without any test signals.

Before starting to apply the step test, the process is stabilised around a value. When the

process is in such a stable situation, the test signals are applied separately on the heating

part and on the cooling part. Each of them is defined, at least, by three square waves with

different amplitude and duration. The tests are done at two different reactor levels.

Figure 2 shows the reactor temperature profile during the tests, corresponding to the

cooling steps.

ERTC Computing 2003, Milan, Italy

Page 6 of 12

Repsol / Soteica / Adersa

Application of Predictive Control to A Batch Reactor

100

140

90

120

TC1

80

TC2

100

70

60

80

50

TI4

60

TC3

40

30

40

CV

20

20

10

0

15:26:00

0

15:33:12

15:40:24

15:47:36

15:54:48

16:02:00

16:09:12

16:16:24

16:23:36

Time

Figure 2. Step tests: Response to cold valve square waves

4.3. Modeling / Identification

According to experimental data and process scheme, the following models are identified:

Identification of TC3 from TI4, TI6 and Cold valve (CV) position

Identification of TI4 from TC3 and TC1

Identification of TC2 from TC3 and TC1

Identification of TC1 from TC2 (at two levels)

Identification of TC1 from Hot valve (HV) position (at two levels)

Identification of TC2 from Reactants addition

Identification of TC1 from Reactants addition

ERTC Computing 2003, Milan, Italy

Page 7 of 12

Repsol / Soteica / Adersa

Application of Predictive Control to A Batch Reactor

Figure 3 shows the results of the identification of TC2 from TC3 and TC1. First plot shows

that the measured and modeled values are overwritten. The second plot corresponds to the

Prediction Error (P.E.) and allows to observe the differences.

TC2

C

TC3

C

TC1

C

(seconds)

Figure 3. Identification of TC2 from TC1 and TC3

ERTC Computing 2003, Milan, Italy

Page 8 of 12

Repsol / Soteica / Adersa

Application of Predictive Control to A Batch Reactor

4.4. Simulator

Once built, comparing the behaviour of each block separetly validates the simulator. In the

real process, each loop is updated with the measurements at each PCR controller

execution.

4.5. Controller design

According to the process structure, reactor temperature (TC1) is controlled directly by the

hot valve (steam) for heating and through TC2, TC3 and the cold valve for cooling.

Figure 4 shows the general structure of the designed PCR controller. It is composed by the

heating section, cooling section and the split range (SR) block.

Heating section contains the Block H which corresponds to a enhaced first order controller

with pure time delay, combined with feedforward controllers. Block H determines the HV

set point having as input reactor temperature setpoint and some disturbance measurements

(OE and TC2 signals).

Cooling section contains blocks C, R2 and R3 which correspond to enhaced first order

controllers with pure time delay, combined with feedforward controllers. Block C

determines the TC2 setpoint having as input reactor temperature setpoint and some

disturbance measurements (OE and HV position signals). Block R2 determines TC3

setpoint while R3 determines the Cold valve position setpoint, having as input TC2

setpoint and the disturbance of fresh water temperature.

Each block has as a tuning parameter the closed loop time response (CLTR).

4.6. Closed loop testing (simulation)

By using collected data the PCR performance has been tested by simulation. Figure 5

shows the profiles of key variables during a batch.

It can be observed that the cold valve is opened smoothly during all the reaction stage and

hot valve is closed.

ERTC Computing 2003, Milan, Italy

Page 9 of 12

Repsol / Soteica / Adersa

Application of Predictive Control to A Batch Reactor

CONTROL STRUCTURE

H

SR

HVsp

HV

CV

TC1sp

R2

R3

TC3sp

TC2sp

CVsp

Figure 4. Reactor temperature control structure

Reactants

flowrates

Kg

Kg/h

FC3

FC1

FC2

C

Temperatures

profiles during

reaction using PCR

TC1

TC2

TI4

TC3

CV & HV

%

Valve

positions

CV

HV

Time (seconds)

Figure 5. Closed loop testing results

ERTC Computing 2003, Milan, Italy

Page 10 of 12

Repsol / Soteica / Adersa

Application of Predictive Control to A Batch Reactor

Conclusions

Reactor temperature control by using PCR avoids the competition between the cooling and

heating loops. Therefore extreme temperatures do not appear and energy consumption is

minor.

Operating conditions are reproduced better for the different batches, due to the decrease of

reaction temperature variability (uniform quality).

Total batch duration is reduced due to the increase in the speed of addition of reactants.

Such increase is now possible because the deviations in temperatures have been notably

reduced. On the other hand, cold valve has a margin to give the necessary cooling.

An increase in process availability has been identified and a decrease in maintenance costs,

due to minor control valve use.

It is important to note the PCR shows an easier tuning because its tuning parameters have

physical meaning (the Closed Loop Time response), minimizing the necessary time to

adjust it.

The control technique is suited for the process equipment (heating and cooling system) so

it is not necessary too much work to adjust the parameters for all the recipes that run at the

same reactor.

At the time of preparing this paper, the final implementation project steps are being

executed.

References

Model Predictive Controller Goes To Work In Chemical Plant, Control

Engineering Europe, October 1, 2000

Predictive Functional Control (PFC) Applied to an Unstable System. An Industrial

Application, Carlos Ruiz, Marta S. Basualdo, Aldo Molina, L. Jimenez, Benjamin

Parisse and Jacques Richalet, Computer Aided Chemical Engineering, Volume 9, R.

Gani and S. B. Jorgensen (Eds.), Ed. Elsevier, pp. 731-736, 2001.

Control Predictivo de Nivel Con Retardo. Aplicacin a Un Caso Industrial. Carlos

Ruiz, Aldo Molina y Daro Lpez, Ingeniera Qumica, n 381, Julio (2001).

ERTC Computing 2003, Milan, Italy

Page 11 of 12

Repsol / Soteica / Adersa

Application of Predictive Control to A Batch Reactor

Model-Based Predictive Control Comes To The Factory Floor, Control

Engineering Europe, February 1, 2001

Control Predictivo de Nivel de una Columna de Destilacin: Una Aplicacin

Industrial, Carlos Ruiz, Marta S. Basualdo, Aldo Molina, Daro Lpez, Benjamin

Parisse y Jacques Richalet, XVII Simposio Nacional de Control Automtico

(AADECA), Buenos Aires, Argentina, September 2000.

Richalet J.; Pratique de la Commande Prdicitve. Editorial Herms. Paris - France

(1993).

Richalet J.; Pratique de lIdentification. Editorial Herms. Paris - France (1998).

ERTC Computing 2003, Milan, Italy

Page 12 of 12

Repsol / Soteica / Adersa

S-ar putea să vă placă și

- Gd4 Guidance Uncertainty enDocument45 paginiGd4 Guidance Uncertainty enMohd Hisyamuddin Mohd AminudinÎncă nu există evaluări

- Service Engineer EMODocument2 paginiService Engineer EMOMohd Hisyamuddin Mohd AminudinÎncă nu există evaluări

- SpectableBlinds Catalog SingleBlindsSpacersDocument10 paginiSpectableBlinds Catalog SingleBlindsSpacersMohd Hisyamuddin Mohd AminudinÎncă nu există evaluări

- Gantt Chart Dp1 Sept14 Jan15Document1 paginăGantt Chart Dp1 Sept14 Jan15Mohd Hisyamuddin Mohd AminudinÎncă nu există evaluări

- Aspen Repot Lab 4Document8 paginiAspen Repot Lab 4Mohd Hisyamuddin Mohd AminudinÎncă nu există evaluări

- Unit 9Document11 paginiUnit 9Mohd Hisyamuddin Mohd AminudinÎncă nu există evaluări

- General Operating Procedures: Exp/Gas AbsorptionDocument4 paginiGeneral Operating Procedures: Exp/Gas AbsorptionMohd Hisyamuddin Mohd AminudinÎncă nu există evaluări

- Mini Project (CHE421) : Assignment OutcomeDocument2 paginiMini Project (CHE421) : Assignment OutcomeMohd Hisyamuddin Mohd AminudinÎncă nu există evaluări

- Sustainable Growth With Resil IenceDocument31 paginiSustainable Growth With Resil IenceMohd Hisyamuddin Mohd AminudinÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- CCW - Common Cooling System ProblemsDocument59 paginiCCW - Common Cooling System Problemszerocool86Încă nu există evaluări

- Ansi IndexDocument2 paginiAnsi IndexhalloihrÎncă nu există evaluări

- Instruction Manual: Portable Spot GunDocument15 paginiInstruction Manual: Portable Spot GunMustafa SabryÎncă nu există evaluări

- ASHRAE 2011 Liquid Cooling WhitepaperDocument28 paginiASHRAE 2011 Liquid Cooling WhitepaperOsmo KuusistoÎncă nu există evaluări

- DC220 Catalogue 4th EditionDocument70 paginiDC220 Catalogue 4th EditionMuchammatAlvinurÎncă nu există evaluări

- Changzhou RATTM MOTOR Co.,Ltd: RTM100-30-24Z/3.0 220V User InstructionsDocument10 paginiChangzhou RATTM MOTOR Co.,Ltd: RTM100-30-24Z/3.0 220V User InstructionsrusbogdanclaudiuÎncă nu există evaluări

- An Instruction Manual: HTSR Series BlowersDocument10 paginiAn Instruction Manual: HTSR Series Blowersjmra12Încă nu există evaluări

- DSM 1510002 SP 20 - V1.0Document28 paginiDSM 1510002 SP 20 - V1.0Kalaivani Arunachalam100% (2)

- TORCH CUTTING Datasheet GEGA Bloom Billet Torch Cutting MAIL enDocument12 paginiTORCH CUTTING Datasheet GEGA Bloom Billet Torch Cutting MAIL enFahrgerusteÎncă nu există evaluări

- Study of Water CoolersDocument4 paginiStudy of Water Coolers01parth0% (1)

- S 110 1224 0901S - 1 - 0001Document27 paginiS 110 1224 0901S - 1 - 0001duongtuongÎncă nu există evaluări

- Manual VXTD 202 303Document83 paginiManual VXTD 202 303Juan José MeroÎncă nu există evaluări

- Rittal Enclosure and Process CoolingDocument98 paginiRittal Enclosure and Process CoolingVadivelu DhanakotiÎncă nu există evaluări

- Service Manual: Screw Compressor CSDDocument146 paginiService Manual: Screw Compressor CSDmina riad100% (1)

- Uis ReportDocument41 paginiUis ReportVikas SandhuÎncă nu există evaluări

- LURECDocument22 paginiLURECHavyTHaÎncă nu există evaluări

- Unit Notes PDFDocument29 paginiUnit Notes PDFPrashant UbarhandeÎncă nu există evaluări

- Cylinder Head, Exhaust Valve, ChainDocument11 paginiCylinder Head, Exhaust Valve, ChainAnakin Skywalker100% (1)

- Manitowoc Ice Machine S-Model Awr HB Mii en 8014793-WebDocument292 paginiManitowoc Ice Machine S-Model Awr HB Mii en 8014793-Webdan themanÎncă nu există evaluări

- Ebara GS ContentsDocument26 paginiEbara GS ContentsSinggih MechanicÎncă nu există evaluări

- Challendger MT 655BDocument500 paginiChallendger MT 655BAlexÎncă nu există evaluări

- A4-P 1.0 enDocument207 paginiA4-P 1.0 enAtiq Ur RehmanÎncă nu există evaluări

- GARDNER DENVER Part List EBQ99MDocument75 paginiGARDNER DENVER Part List EBQ99MReinaldo Jacobs100% (1)

- Operation Manual-54624838.2002 - M90-160 GBDocument37 paginiOperation Manual-54624838.2002 - M90-160 GBPopovici Alexandru50% (2)

- VME MinogaDocument199 paginiVME MinogaFakhri DzulfiqarÎncă nu există evaluări

- Condenser DesignDocument2 paginiCondenser DesignRahul ChandrawarÎncă nu există evaluări

- ASHRAE Standards For Cooling TowersDocument51 paginiASHRAE Standards For Cooling TowersAaron M. WardÎncă nu există evaluări

- UMA WDPA06AGDD4 - 3000cfmsDocument9 paginiUMA WDPA06AGDD4 - 3000cfmsAlfredooCarpioÎncă nu există evaluări

- Lauda Cooler WK - 500Document27 paginiLauda Cooler WK - 500psteÎncă nu există evaluări

- Hydronic d5wsDocument27 paginiHydronic d5wsHorváthVargaLászlóÎncă nu există evaluări