Documente Academic

Documente Profesional

Documente Cultură

Cables

Încărcat de

srigirisetty208Descriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Cables

Încărcat de

srigirisetty208Drepturi de autor:

Formate disponibile

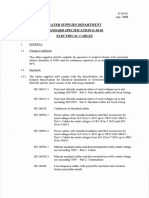

CABLES

1.0

Sl.No

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

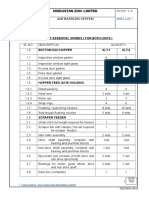

2.0

Sl.No.

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

10.0

11.0

12.0

3.0

650V/1100V, AL, PVC, Armoured, Multicore cables.(as per CCI catalogue)

CABLE SIZE IN

MM2

2CX4

3CX2.5

3CX4

3CX6

3CX10

3CX16

3CX25

3CX50

3CX70

3CX95

3CX120

3CX150

3CX185

3CX240

3CX300

3CX400

3.5CX25

3.5CX35

3.5CX50

3.5CX70

3.5CX95

3.5CX120

3.5CX150

3.5CX185

3.5CX240

3.5CX300

3.5CX400

3.5CX500

4CX1.5

4CX2.5

4CX4

4CX6

4CX10

4CX16

4CX25

4CX35

4CX50

CURRENT RATING IN AMPS

IN GROUND

IN AIR

32

21

28

35

46

60

76

110

135

165

185

210

235

275

305

335

76

92

110

135

165

185

210

235

275

305

335

355

16

21

28

35

46

60

76

92

110

27

18

23

30

40

51

70

105

130

155

180

205

240

280

315

375

70

86

105

130

155

180

205

240

280

315

375

405

13

18

23

30

40

51

70

86

105

CURRENT RATING AFTER

DERATING IN AMPS

IN GROUND IN AIR

X

X 0.69

O.75

22.08

20.25

14.49

13.50

19.32

17.25

24.15

22.50

31.74

30.00

41.40

38.25

52.44

52.50

75.90

78.75

93.15

97.50

113.85

116.25

127.65

135

144.90

153.75

162.15

180

189.75

210

210.45

236.25

231.15

281.25

52.44

52.50

63.48

64.50

75.90

78.75

93.15

97.50

113.85

116.25

127.66

135

144.90

153.75

162.15

180

189.75

210

210.45

236.25

231.15

281.25

245

303.75

11.04

9.75

14.49

13.50

19.32

17.25

24.15

22.50

31.74

30

41.40

38.25

52.44

52.50

63.48

64.50

75.90

78.75

IMPEDANCE

IN OHMS/ KM

O.D

mm

in

8.90

14.50

8.90

5.54

3.7

2.3

1.44

0.775

0.538

0.394

0.316

0.262

0.215

0.171

0.146

0.125

1.443

1.044

0.776

0.539

0.394

0.317

0.264

0.217

0.174

0.1495

0.129

0.1145

21.70

14.50

8.90

5.54

3.701

2.302

1.443

1.044

0.775

17.50

17.00

18.00

19.50

21.50

23.50

23.50

29.50

33

37

39

43

47

54

60

66

26

27

31

34

39

42

47

52

58

65

72

82

16

17.50

19

20.50

21.50

25.50

26

28.50

33

HV cables (as per CCI catalogue)

Cable

size

3Cx25

3Cx35

3Cx50

3Cx70

3Cx95

3Cx120

3Cx150

3Cx185

3Cx240

3Cx300

3Cx400

3Cx500

O.D

Z/KM

COST/KM

O.D

Z/KM

COST/KM

O.D

Z/KM

COST/KM

Current

rating in

Amps

Gnd

Air

40

43

46

50

54

59

62

66

72

78

89

97

1.545

1.117

0.830

0.579

0.423

0.341

0.283

0.232

0.186

0.159

0.136

0.118

6,14,200

7,06,200

7,75,000

8,61,800

9,76,300

10,82,600

11,58,400

14,35,700

16,15,200

18,61,400

22,53,600

-

44

47

50

54

58

63

66

70

76

81

90

97

1.546

1.118

0.831

0.580

0.425

0.342

0.285

0.234

0.188

0.161

0.136

0.118

7,15,300

7,84,100

8,61,800

9,95,800

11,06,300

12,51,700

13,53,000

15,95,400

17,94,100

20,66,900

25,05,400

-

54

57

6063

68

72

75

79

85

92

99

106

1.547

1.119

0.853

0.582

0.428

0.345

0.288

0.238

0.193

0.166

0.142

0.124

9,94,300

11,09,500

11,94,600

13,17,800

14,89,000

16,46,900

18,21,600

20,41,700

24,06,400

26,86,900

32,55,800

-

93

110

130

160

190

215

240

270

315

355

405

455

3.8/6.6kV(E), A2XCEFY

Voltage grade

6.35/11kV(E), A2XCEFY

Cable codes: (as per IS:7098& IS:1554)

A

2X

W

Aluminium conductor

XLPE insulation

Steel round wire armour

11/11kV(UE), A2XCEFY

100

120

145

180

220

255

285

330

385

440

510

590

Short

circuit

rating

for 1

second

(kA)

2.35

3.29

4.70

6.58

8.93

11.30

14.10

17.40

22.60

28.20

37.60

47

4.0

Wa

F

Fa

WW

FF

Non magnetic round wire armour

Steel strip armour

Non magnetic strip armour

Double steel round wire armour

Double steel strip armour

Note:

No code for conductor is required when the conductor material is copper.

IS:5831(PVC insulation and sheath)

5.0

Type A insulation

Type-B insulation

Type-C insulation

Type ST-1 sheath

Type ST-2 sheath

Maximum temperature of 70C for cables up to and including

3.3/3.3kV.

Maximum temperature of 70C for cables above 3.3/3.3kV.

HR insulation for a maximum temperature of 85C for cables

up to and including 1100V.

General purpose sheath for a maximum temperature of 70C

Heat resisting sheath for a maximum temperature of 90C

IS:8130(Conductors for insulated electric cables)

Class-2 conductors

Class 5 & 6 conductors -

AL/CU conductor, solid up to 1.5mm2.

AL solid/stranded from 2.5mm2 to 10mm2

CU solid or stranded from 2.5mm2 to 6mm2

AL/CU stranded : CU > 10mm2 ; AL > 16mm2

Flexible cables

Grade-0

Grade-H2

Grade H4

Tensile strength up to and including 100N/mm 2

100 up to and including 150N/mm2

>150N/mm2

Class-1 conductors

Note:

6.0

For solid & welding cable conductors ; use grade 0

For conductors of area up to 10mm2; use H2 or H4 grade.

For remaining conductors, use 0 or H2 or H4.

Area of cross section,

IF ( in amps) x

75 for AL PVC cables

t (in seconds)

Where

(as per design guide)

94

for

AL

XLPE

112 for CU PVC

144 for CU XLPE

cables.

cables.

cables.

7.0

TCE-M4-208-01(R6): Cables

a)

Conductor:

Aluminium

Stranded,

Copper

Annealed,

grade H4 & Class-2

stranded & Class-2

b)

PVC insulated HV power cables shall be insulated with extruded PVC compound

type-A for cables with rated voltage up to and including 3.3/3.3kV and extruded PVC

compound type-B for cables with rated voltage above 3.3/3.3kV, provided with

extruded inner sheath of PVC compound type ST-1 and shall have extruded outer

sheath of black PVC compound type ST-1. All cables of 11kV voltage class shall be

provided with both conductor and insulation screening(shielding).

Conductor

screening shall be extruded semi conducting compound and insulation screening

shall be as per applicable standard.

c)

1100V grade, PVC insulated power cables shall be insulated with extruded PVC

compound type-A, provided with inner sheath(which shall be of extruded type when

specified only) and outer sheath of extruded black PVC compound type ST-1.

d)

1100V grade, PVC insulated control cables shall be insulated with extruded PVC

compound type-A, provided with inner sheath(which shall be of extruded type when

specified only) and outer sheath of extruded black PVC compound type ST-1.

e)

HV, XLPE insulated power cables: The conductors shall be screened by extruded

semi conducting compound and XLPE insulated. The cores shall be screened by

extruded semi conducting compound in combination with non magnetic metallic

tape(copper tape preferred). The inner sheath over laid up cores and outer sheath

over the armour shall be extruded black PVC compound type ST-2.

f)

1100V grade, XLPE insulated power and control cables shall be extruded XLPE

insulated. The inner sheath over laid up cores and outer sheath over the armour shall

be extruded black PVC compound type ST-2.

g)

Tele communication cables:

Insulation

Conductor

Solid tinned and annealed copper.

PVC insulation type-A.

Twisting

The insulated cables shall be twisted together to form twisted pairs or

quads. These shall be stranded in concentric layers to form the cable core. The

cable thus formed shall be tightly lapped with outer wrapping tapes. The interstices of

insulated cable core shall be completely filled with viscose compound.

Overall screening

With 0.075mm aluminium tape or 0.013mm melinex tape,

overlap not less than 30%.

Other details A suitable non-magnetic ripcord shall be longitudinally under the

sheath. The armouring shall be of galvanized steel wires or galvanized single steel

strip. The inner PVC sheath shall be of type-A. The outer PVC sheath shall be of

type ST-1.

h)

Special requirements for FRLS/FS cables :

i)

Oxygen index: The critical index value shall be minimum 29 when tested at

27 2C as per ASTM-D-2863 and the temperature index value shall be

minimum 250C at oxygen index of 21 when tested as per NES 715.

ii)

Flammability : The cables shall pass test under fire conditions as per

IS:10810 Part-53. Cables shall also pass tests as per IS:10810 Part-61 &

Part- 62. FS cables in addition to the above tests shall also pass tests as per

IEC:331.

iii)

Smoke generation:

The cables shall satisfy the tests conducted to

evaluate the percentage obstruction by smoke in an optical system placed in

the path of the smoke. The maximum smoke density rating shall not be more

than 60% when tested as per ASTM-D-2843.

iv)

Acid gas generation: The hydrochloric acid generation when tested as per

IEC 754-1 shall be less than 20% by weight.

v)

Resistance to ultra violet radiation: This test shall be carried out as per

DIN 53387. The retention values of tensile strength and ultimate elongation

after the tests shall be minimum 60% of tensile strength and ultimate

elongation before test.

vi)

Tests for water absorption: Outer sheath shall be subjected to tests for

water absorption as per IS: 10810.

S-ar putea să vă placă și

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDe la Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsEvaluare: 4 din 5 stele4/5 (1)

- Rewinding GeneratorsDocument4 paginiRewinding GeneratorsSherehan ShawkatÎncă nu există evaluări

- XLPE Cable 33KV - Rev 2 PDFDocument12 paginiXLPE Cable 33KV - Rev 2 PDFRatul ChakrabortyÎncă nu există evaluări

- HT Cable RFQ Specifications PDFDocument7 paginiHT Cable RFQ Specifications PDFAshil ThomasÎncă nu există evaluări

- Three Core Cables To VDE 0276Document15 paginiThree Core Cables To VDE 0276A. HassanÎncă nu există evaluări

- Chapter 20: Technical Specification For Xlpe Cable With TerminationDocument46 paginiChapter 20: Technical Specification For Xlpe Cable With TerminationSristi MitraÎncă nu există evaluări

- 4.17 - Powerhouse - Powerhouse CraneDocument3 pagini4.17 - Powerhouse - Powerhouse Cranesrigirisetty208Încă nu există evaluări

- Pilot Cable Specs FewaDocument13 paginiPilot Cable Specs Fewabharat_22nandulaÎncă nu există evaluări

- Arial Bunch ConductorDocument10 paginiArial Bunch Conductorbbakari2000Încă nu există evaluări

- 33kV Cable Sizing CalcDocument9 pagini33kV Cable Sizing Calcsrigirisetty208Încă nu există evaluări

- 18.1-1996 Aerial Bundled ConductorsDocument11 pagini18.1-1996 Aerial Bundled ConductorsnilushkaaÎncă nu există evaluări

- Care and Maintenance of CFB Boilers Refractory FailureDocument6 paginiCare and Maintenance of CFB Boilers Refractory FailureAnonymous a19X9GHZÎncă nu există evaluări

- HFE0508 ChenakinDocument7 paginiHFE0508 ChenakinmarkessÎncă nu există evaluări

- 497 Airfield LightingDocument4 pagini497 Airfield LightingmolgarÎncă nu există evaluări

- SCH 3A.12 Special Tools &tacklesDocument3 paginiSCH 3A.12 Special Tools &tacklessrigirisetty208Încă nu există evaluări

- XLPE Power Cable 11 & 33 KVDocument9 paginiXLPE Power Cable 11 & 33 KVArjun M KumarÎncă nu există evaluări

- 06-POWER AND CONTROL CABLE - Rev5 PDFDocument14 pagini06-POWER AND CONTROL CABLE - Rev5 PDFSanjay RoutÎncă nu există evaluări

- 15kv Phelps DodgeDocument4 pagini15kv Phelps DodgeJuan E Torres M100% (1)

- OPGW Specifications: GeneralDocument18 paginiOPGW Specifications: GeneralMubashir HussainÎncă nu există evaluări

- Tech - Spec.-Aerial Bunched Cable-XLPE Insulated H.T. Cable.Document6 paginiTech - Spec.-Aerial Bunched Cable-XLPE Insulated H.T. Cable.Bilal AhmadÎncă nu există evaluări

- Speed Control of Stepper MotorDocument63 paginiSpeed Control of Stepper MotorMohammad Ismail Hossain (Sujohn)100% (4)

- FEWA LV Cable SpecsDocument46 paginiFEWA LV Cable Specsjtwani100% (2)

- NKT 12-42kv GB BsDocument54 paginiNKT 12-42kv GB BsvhgiaoÎncă nu există evaluări

- Technical Specification For 33 KV Aerial Bunched Cable - 2Document7 paginiTechnical Specification For 33 KV Aerial Bunched Cable - 2BijuÎncă nu există evaluări

- Equipment Supply by BidderDocument6 paginiEquipment Supply by Biddersrigirisetty208100% (2)

- Specification - 11KV 300 SQ - MM XLPE CableDocument2 paginiSpecification - 11KV 300 SQ - MM XLPE CableAsaf Khader AliÎncă nu există evaluări

- Cap Ngam 240mm2 Cach Dien Xlpe Hay EprDocument7 paginiCap Ngam 240mm2 Cach Dien Xlpe Hay EprMinh VienÎncă nu există evaluări

- Spec 11kV 3 Core CablesDocument5 paginiSpec 11kV 3 Core CablessasikalaÎncă nu există evaluări

- TECHNICAL SPECIFICATION - INSTRUMENT & CONTROL CABLE-Hyundai Engineering - WP-1 LINE Project - LSAG 25NOV2022Document9 paginiTECHNICAL SPECIFICATION - INSTRUMENT & CONTROL CABLE-Hyundai Engineering - WP-1 LINE Project - LSAG 25NOV2022nnÎncă nu există evaluări

- Appendix C - Specification For 33kV Cable (v2) PDFDocument15 paginiAppendix C - Specification For 33kV Cable (v2) PDFOGBONNAYA MARTINSÎncă nu există evaluări

- Technical Specification - LV Control Cable - WP4Document10 paginiTechnical Specification - LV Control Cable - WP4nnÎncă nu există evaluări

- Cable Technical Specifications - MV CableDocument4 paginiCable Technical Specifications - MV CableapranaguptaÎncă nu există evaluări

- Section-6-Control - Power CablesDocument12 paginiSection-6-Control - Power Cablesthumula.rameshÎncă nu există evaluări

- 15 Sec Technical Rev 0Document13 pagini15 Sec Technical Rev 0mohanksebÎncă nu există evaluări

- 33kv Cables SpecsDocument20 pagini33kv Cables SpecsMohamed WahidÎncă nu există evaluări

- LT Cable AnnexureDocument4 paginiLT Cable Annexureqwertyui123321Încă nu există evaluări

- Cable Selection Guide Gtc020212Document4 paginiCable Selection Guide Gtc020212MEGA_ONEÎncă nu există evaluări

- LV Power Cable Specification - 06.11.2009Document10 paginiLV Power Cable Specification - 06.11.2009ErAkashAryanÎncă nu există evaluări

- Spec 315 MV 105 PowerGuard-XL 35KVDocument2 paginiSpec 315 MV 105 PowerGuard-XL 35KVSarah PinkÎncă nu există evaluări

- Technical Information-Cables PDFDocument5 paginiTechnical Information-Cables PDFAlvin Smith100% (1)

- Tza123 en 1 1Document8 paginiTza123 en 1 1Ahmed AdelÎncă nu există evaluări

- 05 Interface C ConnectorsDocument31 pagini05 Interface C ConnectorsjjcanoolivaresÎncă nu există evaluări

- Is 7098 Part I 1998Document17 paginiIs 7098 Part I 1998Sanjeev DhariwalÎncă nu există evaluări

- TS-OPGW 1.4 9feb2017Document18 paginiTS-OPGW 1.4 9feb2017asim204Încă nu există evaluări

- Single Core Cables To VDE 0276Document11 paginiSingle Core Cables To VDE 0276rose chenÎncă nu există evaluări

- FIER RESISTANT 2-Hour Fire Rated Cables PDFDocument4 paginiFIER RESISTANT 2-Hour Fire Rated Cables PDFJairo WilchesÎncă nu există evaluări

- Cable SizesDocument2 paginiCable SizesBassem MostafaÎncă nu există evaluări

- DEWA 1513403-R0 22kV 11kV XLPE Cables PDFDocument11 paginiDEWA 1513403-R0 22kV 11kV XLPE Cables PDFHashimAmrÎncă nu există evaluări

- IEC 60708 SummaryDocument6 paginiIEC 60708 SummaryAdnan Khan0% (1)

- Cable Selection Guide: Gai-Tronics®Document4 paginiCable Selection Guide: Gai-Tronics®Vicente HdezÎncă nu există evaluări

- TECHNICAL SPECIFICATION - LV CONTROL CABLE - Hyundai Engineering - WP-1 LINE Project - LSAG 25NOV2022Document9 paginiTECHNICAL SPECIFICATION - LV CONTROL CABLE - Hyundai Engineering - WP-1 LINE Project - LSAG 25NOV2022nnÎncă nu există evaluări

- JIS F 0414 Shipbuilding - Internal Wiring and Piping of Engine Control ConsoleDocument4 paginiJIS F 0414 Shipbuilding - Internal Wiring and Piping of Engine Control ConsoleSopon SrirattanapiboonÎncă nu există evaluări

- 5 CablesDocument4 pagini5 CablesAlfredo Balcazar MayÎncă nu există evaluări

- EPR Insulated EVA Sheathed Copper Cable NPCIL SpecificationDocument23 paginiEPR Insulated EVA Sheathed Copper Cable NPCIL SpecificationVarun ThakurÎncă nu există evaluări

- 150619110614e31-33-132-220kv Xlpe Cable Spec 12042019 PDFDocument81 pagini150619110614e31-33-132-220kv Xlpe Cable Spec 12042019 PDFعريب صالح الروسانÎncă nu există evaluări

- Rdso SpecificationDocument36 paginiRdso SpecificationShivangi BhardwajÎncă nu există evaluări

- MC-HL MVDocument2 paginiMC-HL MVElectrificationÎncă nu există evaluări

- Water Supplies Department Standard Specification E-30-01 Electrical CablesDocument8 paginiWater Supplies Department Standard Specification E-30-01 Electrical CablesJaggu JrzÎncă nu există evaluări

- 3m qtII 5623kDocument4 pagini3m qtII 5623kcerachuckÎncă nu există evaluări

- C& I CablesDocument8 paginiC& I Cablessethu1091Încă nu există evaluări

- Kerpen Leoni Catalogo EspanolDocument4 paginiKerpen Leoni Catalogo EspanolOsiros LunaÎncă nu există evaluări

- 33 KV Cable Transmission Line Technical SpesificationDocument10 pagini33 KV Cable Transmission Line Technical SpesificationNima dawa SherpaÎncă nu există evaluări

- Single Core Cables To IEC 60502Document12 paginiSingle Core Cables To IEC 60502rose chen100% (1)

- En Erg ExDocument16 paginiEn Erg ExAhmed H. HassanÎncă nu există evaluări

- Technical Specification For 3C XPLE CableDocument9 paginiTechnical Specification For 3C XPLE Cableramana3339Încă nu există evaluări

- Nuhas BrochureDocument71 paginiNuhas BrochuremealysrÎncă nu există evaluări

- NB O&M Brochure 01sept2020Document10 paginiNB O&M Brochure 01sept2020srigirisetty208Încă nu există evaluări

- 4.19 - Instrumentation and ControlDocument2 pagini4.19 - Instrumentation and Controlsrigirisetty208Încă nu există evaluări

- 5C1. Coal Ash Generation Process and Application FieldsDocument2 pagini5C1. Coal Ash Generation Process and Application Fieldssrigirisetty208Încă nu există evaluări

- 4.10 - Desilting Basin - Flushing Sluice Gate and HydraulicDocument4 pagini4.10 - Desilting Basin - Flushing Sluice Gate and Hydraulicsrigirisetty208Încă nu există evaluări

- Revised Fire Detection & Alarm System DBR-Arar-02!06!05Document12 paginiRevised Fire Detection & Alarm System DBR-Arar-02!06!05srigirisetty208Încă nu există evaluări

- Boiler Tube Failures Due To Improper CommissioningDocument21 paginiBoiler Tube Failures Due To Improper CommissioningDhandapani ManoharanÎncă nu există evaluări

- 4.13 - Penstock Intake - Trashrack and Cleaning MachineDocument2 pagini4.13 - Penstock Intake - Trashrack and Cleaning Machinesrigirisetty208Încă nu există evaluări

- 4.11 - Bypass Channel - Automatic GateDocument1 pagină4.11 - Bypass Channel - Automatic Gatesrigirisetty208Încă nu există evaluări

- 4.10 - Desilting Basin - Flushing Sluice Gate and HydraulicDocument4 pagini4.10 - Desilting Basin - Flushing Sluice Gate and Hydraulicsrigirisetty208Încă nu există evaluări

- 4.2 - Dam and Spillway - Radial Gates and Hydraulic HoistDocument3 pagini4.2 - Dam and Spillway - Radial Gates and Hydraulic Hoistsrigirisetty208Încă nu există evaluări

- 4.2 - Dam and Spillway - Radial Gates and Hydraulic HoistDocument3 pagini4.2 - Dam and Spillway - Radial Gates and Hydraulic Hoistsrigirisetty208Încă nu există evaluări

- 4.15 - Penstock Intake - Stoplog and Gantry CraneDocument2 pagini4.15 - Penstock Intake - Stoplog and Gantry Cranesrigirisetty208Încă nu există evaluări

- HZL Crane EssentialsparesDocument2 paginiHZL Crane Essentialsparessrigirisetty208Încă nu există evaluări

- SCH 3A.17 Q.a.assessmentDocument1 paginăSCH 3A.17 Q.a.assessmentsrigirisetty208Încă nu există evaluări

- HZL Ahs EssentialsparesDocument8 paginiHZL Ahs Essentialsparessrigirisetty208Încă nu există evaluări

- 4.5 - Dam and Spillway - ElevatorDocument2 pagini4.5 - Dam and Spillway - Elevatorsrigirisetty208Încă nu există evaluări

- HZL Chs EssentialsparesDocument6 paginiHZL Chs Essentialsparessrigirisetty208Încă nu există evaluări

- Schedule-3A/16 Proposed Quality Assurance ArrangementsDocument1 paginăSchedule-3A/16 Proposed Quality Assurance Arrangementssrigirisetty208Încă nu există evaluări

- The Details Will Be Submitted Later Stage: Schedule-3A/15 Contractors Construction EquipmentDocument2 paginiThe Details Will Be Submitted Later Stage: Schedule-3A/15 Contractors Construction Equipmentsrigirisetty208Încă nu există evaluări

- SCH 3A.9 Places of Mfg.Document1 paginăSCH 3A.9 Places of Mfg.srigirisetty208Încă nu există evaluări

- BFP Drawings PDFDocument42 paginiBFP Drawings PDFsrigirisetty208Încă nu există evaluări

- BFP DrawingsDocument42 paginiBFP Drawingssrigirisetty208Încă nu există evaluări

- SCH 3A.11 SparesDocument3 paginiSCH 3A.11 Sparessrigirisetty208Încă nu există evaluări

- Sch-3A 14-Perfor GuartDocument5 paginiSch-3A 14-Perfor Guartsrigirisetty208Încă nu există evaluări

- Guaranteed DataDocument2 paginiGuaranteed Datasrigirisetty208Încă nu există evaluări

- Product Data Sheet: Circuit Breaker Compact Nsx630H, 70 Ka at 415 Vac, Micrologic 2.3 Trip Unit 630 A, 3 Poles 3DDocument3 paginiProduct Data Sheet: Circuit Breaker Compact Nsx630H, 70 Ka at 415 Vac, Micrologic 2.3 Trip Unit 630 A, 3 Poles 3Dmahmoud yahyaÎncă nu există evaluări

- 08 PSC-12 Power SupplyDocument12 pagini08 PSC-12 Power SupplyHemant ParmarÎncă nu există evaluări

- 20KVA Hipulse D - SIMHADRI POWER LTD.Document36 pagini20KVA Hipulse D - SIMHADRI POWER LTD.seil iexÎncă nu există evaluări

- Zoomer's Toy Robotic Dog - Shadow PDFDocument16 paginiZoomer's Toy Robotic Dog - Shadow PDFBill N.Încă nu există evaluări

- Stereophile 1971 72 WinterDocument36 paginiStereophile 1971 72 WinterNatiÎncă nu există evaluări

- Sheet of Chapter (3) : PlottingDocument5 paginiSheet of Chapter (3) : PlottingAhmad Ash SharkawiÎncă nu există evaluări

- Bi CMOSDocument1 paginăBi CMOSJunaid IkramÎncă nu există evaluări

- Instruction Manual: Multiple Shot Reclosing Relay BE1-79MDocument74 paginiInstruction Manual: Multiple Shot Reclosing Relay BE1-79Mbaosyle9201Încă nu există evaluări

- Velammal Engineering College, Chennai-600066 Electronics and Communication Engineering Ut I Question Bank Unit I Part ADocument3 paginiVelammal Engineering College, Chennai-600066 Electronics and Communication Engineering Ut I Question Bank Unit I Part Asubramanian subramanianÎncă nu există evaluări

- 7PG15 TR Catalogue SheetDocument28 pagini7PG15 TR Catalogue SheetajayraamÎncă nu există evaluări

- 2 Marks With Answers Collection 1Document19 pagini2 Marks With Answers Collection 1Guna PriyaÎncă nu există evaluări

- Motor Driven Throttle Valve (MDK) Technical Service BulletinDocument3 paginiMotor Driven Throttle Valve (MDK) Technical Service Bulletinsinbadfun0% (1)

- ASIC List For Garden LightsDocument1 paginăASIC List For Garden LightsAnirudhÎncă nu există evaluări

- An 7517Document8 paginiAn 7517Anonymous 3mJfZEÎncă nu există evaluări

- An Inexpensive Digital Gradient Controller For HPLCDocument1 paginăAn Inexpensive Digital Gradient Controller For HPLCCamilo LaraÎncă nu există evaluări

- Radar Motion Detector For Automatic DoorsDocument4 paginiRadar Motion Detector For Automatic DoorsIndustrial DoorsÎncă nu există evaluări

- STREETLIGHT IP Family Data SheetDocument7 paginiSTREETLIGHT IP Family Data Sheeting_dumitracheÎncă nu există evaluări

- Correlation Between Dislocations and Leakage Current of P-N Diodes On A Free-Standing Gan SubstrateDocument5 paginiCorrelation Between Dislocations and Leakage Current of P-N Diodes On A Free-Standing Gan SubstrateAna-Maria DucuÎncă nu există evaluări

- NEC CHAPTER 3 QUIZ With AnswersDocument20 paginiNEC CHAPTER 3 QUIZ With AnswersAbdul RaheemÎncă nu există evaluări

- Mg90k502 Service Guide Frame FDocument228 paginiMg90k502 Service Guide Frame FAdson GomesÎncă nu există evaluări

- Astm B910 B910M 07Document2 paginiAstm B910 B910M 07gestordecomprasÎncă nu există evaluări

- Electrical Skill StandardsDocument34 paginiElectrical Skill StandardsYang LiuÎncă nu există evaluări

- Error Messages 4.1 Brief DescriptionDocument10 paginiError Messages 4.1 Brief DescriptionRuben DuranÎncă nu există evaluări

- Сервизно ръководство AUX (E - series - 18000-24000Btu) PDFDocument47 paginiСервизно ръководство AUX (E - series - 18000-24000Btu) PDFVeselin AngelovÎncă nu există evaluări

- BCT 11Document16 paginiBCT 11Jesu RajÎncă nu există evaluări

- Epcu Fault CodesDocument33 paginiEpcu Fault Codesqureshihakeem2005Încă nu există evaluări

- 20m VfoDocument1 pagină20m VfoDavidÎncă nu există evaluări