Documente Academic

Documente Profesional

Documente Cultură

Belt Feeder Calc. Pns Line 1

Încărcat de

Waris La Joi WakatobiDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Belt Feeder Calc. Pns Line 1

Încărcat de

Waris La Joi WakatobiDrepturi de autor:

Formate disponibile

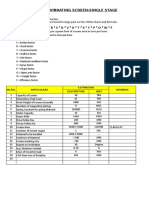

Project

Client

Location

Unit

:

:

:

:

Assesment Jhon lin Group

PT. Pandu Nusantara Sakti (PNS)

Line 1

Belt Feeder

BELT FEEDER CALCULATION

1. PROFILE BELT FEEDER

Hh

Wh

Lh

L

Cc

TOP VIEW

1. MODEL

SIDE

2. INPUT DATA

Material Type

Bulk Density

Surchage Angle

Angle Repose

Lump Size

Belt Width

Belt Feeder Length

Lifting

Friction Coefficient Coal-steel

7 ROM

Coal, Bituminous

()

()

()

600

(B)

(Cc)

(H)

(C)

1400

850

20

37

12

7

9,1

0,79

0,65

kg/m

Deg.

Deg.

mm

mm

m

m

3. BELT and Idler Data

Belt Width

Belt Type

Rating

Carcass Weight

Carcass Gauge

Top Cover Gauge

Bottom Cover Gauge

Belt Weight

Carry Idler spacing

Carry Idler Weight

Unitary Carry Idler Weight

Return Idler spacing

Return Idler Weight

Unitary Return Idler Weight

Total Unitary Weight

Length of the Belt Conveyor

Material Loading on Belt

Length of Surcharge material

(B)

RMBT

Md

dGk

TGk

BGk

(Mb )

(Sc)

(Mc)

(Wc)

(Sr)

(Mr)

(Wr)

(M)

(Cc)

(Wh)

(Lh)

1400

FABRIC - EP / 23

315 / 3

31

mm

N/mm

3,75

kg/m^2

2,7

5

2

16,98

300

25

83

1,1

35

32

132,13

9,1

933

1800

mm

mm

mm

kg/m

mm

kg

kg/m

m

kg

kg/m

kg/m

m

mm

mm

5,25 kg/m

8,3804 m^2

3,35216 m^2

4. SPEED AND CAPACITY OF BELT FEEDER

Actual Ratio Drive Unit

Driver Teeth

Driven Teeth

Angular Speed of Drive Unit

Controlling Gate

Actual Angular Speed

Belt Speed

Actual Capacity

Mass Material

5.

BELT FEEDER LOAD

Numerical co-efficient, being a

function of Conveyor length

Conveyor inclination

Artificial co-efficient of friction

Total primary resistance

Slope Resistance

Resistance beyond feed zone

Resistance at Loading Material

Resistance bulk and belt

Resistance Internal Bulk

Total Seconcadary Resistance

Length of wall Palte

Throughing Factor

Co-efficient of friction idler and belt

Co-efficient of friction belt-belt cleaner

Tilting angle

Drag resistance

Resistance between Skirt Plate-material

Internal Belt Cleaner

External Belt Cleaner

Area Contact belt cleaner-Belt

Pressure Between Belt-Belt Cleaner

Resistance between Belt-Belt Cleaner

Volume of the surcharge material

Volume of unload Material

Specific Weight of Material

Internal Friction on Bulk

Shearing Resistance Vertical Load

Special main Resistance

6. POWER AND BELT TENSIONS

Effective Tension On Belt

Belt Power

Power loss due to drive pulley

Absorbed power at gear box output

Gearbox Efficiency

Required power at motor shaft

Actual Drive in Use

(i)

(Z1)

(Z2)

(n)

(h)

(n1)

(v)

(C)

(Mg)

350

20

15

31

1485

7

35,93

0,752

752,161

0,2458

(n)

()

(f)

(FH)

(FN)

(Fa)

(Fska)

(Fb)

(Fw)

(Fs)

(L)

(Ci)

(0)

(1)

(i)

(Fi)

(Fsk)

(bi)

(be)

(Ai)

(P)

(Fbc)

(Vfs)

(Vu)

(Q)

(1)

(TQ)

(Fsp)

5

0,03

398,49

1,905

208,934

547,319

100

315

1171,25

3900

0,4

0,35

0,65

0

0

5178,83

0

0

0

0

0

1,08

0,69

1,50

0,75

11077,90

16256,73

(Te)

(Pb)

(Pl)

(Pa)

()

17826,48

13,41

0,21

13,62

94,00

14,5

15

(Ptotal)

(PActual)

rpm

mm

rpm

m/s

t/h

m/s

350

Deg.

N

N

N

N

N

N

N

mm

deg

N

N

m

N/m

N

m

m

Ton

Assuming

N

N

N

kW

kW

kW

%

kW

Kw

230

Pulley Surface type

Coefficient of friction

Take-up Type

Wrap angel

Tension on tight side

Tension on slack side

Belt sag

Minimum Tension

Tail Tension

length of Take-up Pulley from Head

Lift of Take-up Pulley from Head

Take-up Tension

Belt Selection

Maximum Belt Running Tension = (T1)/B

Belt Selection -----> FABRIC - EP / 315 / 3

Running Tension / Rating.

7. PULLEY DIAMETER SELECTION

Recommended Min. Pulley Diameter

- Drive Pulley Diameter

- Tail Pulley Diameter

Assuming Mass of Pulley

- Head Pulley Mass

- Tail Pulley Mass

8. DRIVE PULLEY SHAFT DESIGN

Dia. Shaft at Coupling

Weight of Head Pulley

Horizontal Force

Vertical Force

Resultant Force

Pulley Bearing Center

arm Length

Bending Moment

Torque

Combined Shock and Fatique Factor (Bending)

Combined Shock and Fatique Factor (Torsion)

Equivalent Torque

Allowable Shear Stress

Case:1 Based on Equivalent torque

Shaft Diameter at Hub

Case:2 Based on Linear deflection.

Pulley Bearing Center

Max Deflection

Allowable Deflection

Shaft Diameter Required at Hub.

(T1)

(T2)

(S)

(Tmin)

(Tt)

(L1)

(H1)

(Ttu)

(Tmax)

Rubber Lagging Pulley

0,4

Manual

180

27501,79

9675,31

0,02

316,89

9557,89

0

0

9675,3

19,64

31

63%

1,65

Deg.

N

N

N

N

m

m

N/mm

N/mm

Ok, but check the Accel. & drift condition

(DTr1)

(DTr2)

400

315

mm

mm

(Mh)

(Mt)

490

450

kg

kg

(Dc)

(Whp)

(Fhh)

(Fhv)

(Fhr)

(Lbc)

(al)

(MB)

(MT)

(Kb)

(Kt)

(Teq)

(fs)

120

4806,9

33801,1

-4752,6

34133,60642

2

0,225

3840,03

1929,15

2

1,5

8207,1

45

mm

N

N

N

N

m

m

N.m

N.m

N.m

MPa

(Dh)

97,57

mm

(Lbc)

2

1200

0,00167

102,82

mts

mm

68,23

mm

(a)

(Dr)

Case:3 Based on Equivalent torque at coupling end.

Shaft Diameter at Hub

(Dc)

Assuming

Assuming

9. TAIL PULLEY SHAFT DESIGN

Weight of Head Pulley

Horizontal Force

Vertical Force

Resultant Force

Bending Moment

Allowable Bending Stress

(Wtp)

(Fth)

(Ftv)

(Ftr)

(MtB)

(fb)

6376,5

19115,78

6376,5

20151,25

2267,02

90

N

N

N

N

N.m

MPa

Case:1 Based on Bending moment.

Shaft diameter required at hub

(Dth1)

80,06

mm

Case:2 Based on Linear deflection

Shaft diameter reqd. at hub

(Dth2)

90,13

mm

S-ar putea să vă placă și

- BELT FEEDER Preliminary Dimension IngDocument29 paginiBELT FEEDER Preliminary Dimension Ingshani5573100% (1)

- Belt Feeder Calculation CEMADocument7 paginiBelt Feeder Calculation CEMANAITIK100% (4)

- Apron Feeder Power Calculations PDFDocument4 paginiApron Feeder Power Calculations PDFtuba25% (4)

- Conveyor design parameters for slag ash materialDocument33 paginiConveyor design parameters for slag ash materialMustafa AkbarÎncă nu există evaluări

- Sidewinder ManualDocument162 paginiSidewinder Manualoscarjofk0% (1)

- Analisis Drag Scrapper Chain Feeder (FB01 & FB02) EPIDocument10 paginiAnalisis Drag Scrapper Chain Feeder (FB01 & FB02) EPIWaris La Joi WakatobiÎncă nu există evaluări

- Belt Catalog #2 Bridge StoneDocument55 paginiBelt Catalog #2 Bridge Stonetinyfalse100% (3)

- Chapter 13 D1 CEMA Bucket Elevator HP and CalculationsDocument4 paginiChapter 13 D1 CEMA Bucket Elevator HP and Calculationshafidh naufaldiÎncă nu există evaluări

- BELT CONVEYOR - Discharge TrajectoryDocument1 paginăBELT CONVEYOR - Discharge TrajectoryEslam FaroukÎncă nu există evaluări

- BELT CONVEYOR - Discharge TrajectoryDocument3 paginiBELT CONVEYOR - Discharge TrajectorySergio Diaz DuarteÎncă nu există evaluări

- Belt Conveyor CalculationDocument8 paginiBelt Conveyor CalculationFarrahxviiiÎncă nu există evaluări

- Transfer Chute Design ManualDocument4 paginiTransfer Chute Design ManualluiasnadradeÎncă nu există evaluări

- Manual Helix Delta t6Document309 paginiManual Helix Delta t6Ricardo Garay Reinoso100% (2)

- Bucket Elevator Excel Calculations Bucket Elevator ApplicationsDocument22 paginiBucket Elevator Excel Calculations Bucket Elevator ApplicationsThaigroup CementÎncă nu există evaluări

- Sidewinder Manual (001-155)Document150 paginiSidewinder Manual (001-155)NighWolfÎncă nu există evaluări

- Apron Feeder 7Document1 paginăApron Feeder 7cumpio425428100% (1)

- Telescopic ChuteDocument2 paginiTelescopic Chutebiswajit sabuiÎncă nu există evaluări

- Rubber Belt Conveyor Calculations (ISO 5048: 1989 E) : BC 2304 NDDocument8 paginiRubber Belt Conveyor Calculations (ISO 5048: 1989 E) : BC 2304 NDmah moudÎncă nu există evaluări

- Travelling Trippers PDFDocument4 paginiTravelling Trippers PDFPinakesh GhoshÎncă nu există evaluări

- FeederDocument13 paginiFeedernileshÎncă nu există evaluări

- Belt Conveyor Pulley Design - Why The FailuresDocument16 paginiBelt Conveyor Pulley Design - Why The FailuresenrimauryÎncă nu există evaluări

- Belt Conveyor Take Up DesignDocument4 paginiBelt Conveyor Take Up DesignKroya HunÎncă nu există evaluări

- Belt ConveyorDocument3 paginiBelt ConveyorJawed AnsariÎncă nu există evaluări

- Bucket Elevators for Powder and Granular MaterialsDocument20 paginiBucket Elevators for Powder and Granular MaterialsCORDOVA DAVILA HECTOR ALONSOÎncă nu există evaluări

- Apron FeederDocument2 paginiApron FeederRaji Suri100% (1)

- Pipe ConveyorDocument4 paginiPipe ConveyorDIBYENDU MONDALÎncă nu există evaluări

- Chute Calculation ExampleDocument1 paginăChute Calculation ExampleBimal DeyÎncă nu există evaluări

- Cema 576Document9 paginiCema 576Edwin MariacaÎncă nu există evaluări

- Chain Conveyor Design Calculation for 400 TPH Drag ConveyorDocument3 paginiChain Conveyor Design Calculation for 400 TPH Drag Conveyorsudip giriÎncă nu există evaluări

- Sturt Air ClassifierDocument6 paginiSturt Air ClassifierHenry Vladimir VianchaÎncă nu există evaluări

- 10 Drag Conveyor Section VIIDocument11 pagini10 Drag Conveyor Section VIIBUDAPESÎncă nu există evaluări

- Belt Feeder Properly DesignedDocument2 paginiBelt Feeder Properly DesignedCarlos Ediver Arias Restrepo100% (1)

- Calculation CEMA 5 - Parte1Document5 paginiCalculation CEMA 5 - Parte1Angel AlvarezÎncă nu există evaluări

- Belt Conveyor PowerDocument10 paginiBelt Conveyor PowerRyukiÎncă nu există evaluări

- Conveyor Pulley DesignDocument2 paginiConveyor Pulley DesignZoebair100% (1)

- Travelling Tripper CalculationDocument5 paginiTravelling Tripper CalculationHarshGupta100% (1)

- AUMUND Belt Bucket Elevator Overcomes Coarse Material ChallengesDocument53 paginiAUMUND Belt Bucket Elevator Overcomes Coarse Material Challengesnathaniel villanueva100% (1)

- Vibrating ScreensDocument3 paginiVibrating ScreensvinodsnÎncă nu există evaluări

- Belt Conveyor Belt Feeder Design ProgramDocument147 paginiBelt Conveyor Belt Feeder Design Programmanoj983@gmail.com100% (1)

- Mulani I G (2005) - Belt Feeder Design and Hooper Bin Silo-OCR3Document455 paginiMulani I G (2005) - Belt Feeder Design and Hooper Bin Silo-OCR3Carlos Gallardo LagosÎncă nu există evaluări

- 7155 - 5 Apron Conveyors Apron FeedersDocument5 pagini7155 - 5 Apron Conveyors Apron FeedersMann GurpreetÎncă nu există evaluări

- Apron FeederDocument12 paginiApron FeederMidDeL'OrmeÎncă nu există evaluări

- Sidewinder ManualDocument245 paginiSidewinder ManualkukstrongÎncă nu există evaluări

- Chute Calculation ExampleDocument1 paginăChute Calculation ExampleRené Mella CidÎncă nu există evaluări

- Calculation CEMA 5 - Parte3Document5 paginiCalculation CEMA 5 - Parte3Angel AlvarezÎncă nu există evaluări

- Yokohama Conveyor BeltsDocument87 paginiYokohama Conveyor BeltsU Thaung Myint100% (12)

- ChuteDesignFormulas Paper43Document11 paginiChuteDesignFormulas Paper43Martin LarochelleÎncă nu există evaluări

- Bearing Centre and Face Width in Conveyor PulleyDocument8 paginiBearing Centre and Face Width in Conveyor PulleyPrashant MishraÎncă nu există evaluări

- Screw ConveyorDocument4 paginiScrew ConveyorRaji SuriÎncă nu există evaluări

- Metso Apron Feeder Application Data SheetDocument2 paginiMetso Apron Feeder Application Data SheetAnonymous 8t0V9SÎncă nu există evaluări

- Advances in Mechanical Conveyor Design for Bulk Materials HandlingDocument27 paginiAdvances in Mechanical Conveyor Design for Bulk Materials HandlingJakes100% (1)

- Rex High Performance Chain Bucket Elevator ManualDocument170 paginiRex High Performance Chain Bucket Elevator ManualJohnÎncă nu există evaluări

- C 107 - Pulley Catalog - 04 2014Document46 paginiC 107 - Pulley Catalog - 04 2014kawula alit100% (1)

- Motor Selection CalculatorDocument5 paginiMotor Selection Calculatorjay100% (5)

- Extra Credit 6.6Document7 paginiExtra Credit 6.69thwonder10Încă nu există evaluări

- PT. Bangun Arta Hutama Drum Winch CalculationDocument3 paginiPT. Bangun Arta Hutama Drum Winch CalculationWaris La Joi WakatobiÎncă nu există evaluări

- 8.12.01.03 - Technical Data CH890Document8 pagini8.12.01.03 - Technical Data CH890gytoman100% (1)

- Brake CalcDocument4 paginiBrake CalcYash ShahÎncă nu există evaluări

- Length (FT) Width (FT) Thickness (FT) Structure Description: F1 F2 F3 F4 F5Document44 paginiLength (FT) Width (FT) Thickness (FT) Structure Description: F1 F2 F3 F4 F5FoisulAlamÎncă nu există evaluări

- Komatsu ®: Model Komatsu WA900-3E0 Komatsu WA1200-6 Caterpillar 993 K (T4) GeneralDocument4 paginiKomatsu ®: Model Komatsu WA900-3E0 Komatsu WA1200-6 Caterpillar 993 K (T4) GeneralGaming BebasÎncă nu există evaluări

- Technical Data Hino 700 ProfiaDocument5 paginiTechnical Data Hino 700 ProfiaWaris La Joi WakatobiÎncă nu există evaluări

- RENOLD CHAIN DOUBLE PITCH SPROCKET DESIGN SPECIFICATIONSDocument1 paginăRENOLD CHAIN DOUBLE PITCH SPROCKET DESIGN SPECIFICATIONSWaris La Joi Wakatobi0% (1)

- Pulley Weight Calc PDFDocument9 paginiPulley Weight Calc PDFWaris La Joi WakatobiÎncă nu există evaluări

- Recommended Lubricants for Gear UnitsDocument9 paginiRecommended Lubricants for Gear UnitsWaris La Joi WakatobiÎncă nu există evaluări

- ELPEX Flexible CouplingDocument24 paginiELPEX Flexible CouplingWaris La Joi WakatobiÎncă nu există evaluări

- Calc - Vibrating Screen Single Deck NPK1Document5 paginiCalc - Vibrating Screen Single Deck NPK1Waris La Joi WakatobiÎncă nu există evaluări

- Operating Instructions: BA K295 EN 06.97Document45 paginiOperating Instructions: BA K295 EN 06.97Waris La Joi WakatobiÎncă nu există evaluări

- Recommended Lubricants for Gear UnitsDocument9 paginiRecommended Lubricants for Gear UnitsWaris La Joi WakatobiÎncă nu există evaluări

- Operating Instructions: BA G298 EN 08.98Document39 paginiOperating Instructions: BA G298 EN 08.98Waris La Joi WakatobiÎncă nu există evaluări

- 8702en PDFDocument32 pagini8702en PDFWaris La Joi WakatobiÎncă nu există evaluări

- Flender GearboxDocument47 paginiFlender GearboxWaris La Joi Wakatobi100% (2)

- RUPEX Coupling RWNDocument26 paginiRUPEX Coupling RWNWaris La Joi WakatobiÎncă nu există evaluări

- Measuring Bulk Coal Friction on Wear PlatesDocument8 paginiMeasuring Bulk Coal Friction on Wear PlatesWaris La Joi WakatobiÎncă nu există evaluări

- N-EUPEX CouplingDocument24 paginiN-EUPEX CouplingWaris La Joi WakatobiÎncă nu există evaluări

- ZAPEX CouplingDocument22 paginiZAPEX CouplingWaris La Joi WakatobiÎncă nu există evaluări

- Editor User's ManualDocument60 paginiEditor User's ManualWaris La Joi WakatobiÎncă nu există evaluări

- Flexible N-EUPEXDocument22 paginiFlexible N-EUPEXWaris La Joi WakatobiÎncă nu există evaluări

- Gear CouplingDocument36 paginiGear CouplingWaris La Joi WakatobiÎncă nu există evaluări

- Analisis Drag Scrapper Chain Feeder (FB01 & FB02) EPIDocument10 paginiAnalisis Drag Scrapper Chain Feeder (FB01 & FB02) EPIWaris La Joi WakatobiÎncă nu există evaluări

- 8703en PDFDocument35 pagini8703en PDFWaris La Joi WakatobiÎncă nu există evaluări

- SdeDocument10 paginiSderefiiiÎncă nu există evaluări

- Arpex CouplingDocument38 paginiArpex CouplingWaris La Joi WakatobiÎncă nu există evaluări

- Power LV CopperDocument52 paginiPower LV CopperBeny Indrawan SÎncă nu există evaluări

- Lsis Is7 Simple Usermanual PDFDocument255 paginiLsis Is7 Simple Usermanual PDFMichael DavenportÎncă nu există evaluări

- UNCTAD Review of Maritime Transport 2017 2017 10Document130 paginiUNCTAD Review of Maritime Transport 2017 2017 10Mehmet AliÎncă nu există evaluări

- PARAMAX NEW Copy Rev2Document281 paginiPARAMAX NEW Copy Rev2Waris La Joi WakatobiÎncă nu există evaluări

- Survey of Cargo Handling ResearchDocument95 paginiSurvey of Cargo Handling ResearchWaris La Joi WakatobiÎncă nu există evaluări

- AlldocumentsDocument8 paginiAlldocumentsWaris La Joi WakatobiÎncă nu există evaluări

- Editor User's ManualDocument60 paginiEditor User's ManualWaris La Joi WakatobiÎncă nu există evaluări

- DPO 6 0 Enterprise ManualDocument63 paginiDPO 6 0 Enterprise ManualWaris La Joi WakatobiÎncă nu există evaluări

- Plate Mill ProcessDocument2 paginiPlate Mill ProcessVinay RajputÎncă nu există evaluări

- Tutorial 5Document6 paginiTutorial 5Mohammad Asri ChristopherÎncă nu există evaluări

- Modified Asphalt Binders: Need of Present PavementsDocument85 paginiModified Asphalt Binders: Need of Present PavementsPalika ChopraÎncă nu există evaluări

- Full Length Test 1 Paper Civil Ki GoliDocument45 paginiFull Length Test 1 Paper Civil Ki GoliPankaj BadiwalÎncă nu există evaluări

- DestrebutionDocument4 paginiDestrebutionYosef AbebeÎncă nu există evaluări

- Mccauley Constant Speed Propellers: Threaded Series Threadless Series Retention Nut Split Retainer RingDocument10 paginiMccauley Constant Speed Propellers: Threaded Series Threadless Series Retention Nut Split Retainer Ringcam cotÎncă nu există evaluări

- Modes of Heat Transfer: O Q (Gate, Ies, Ias)Document7 paginiModes of Heat Transfer: O Q (Gate, Ies, Ias)ankitÎncă nu există evaluări

- Bolt Tightening TorqueDocument10 paginiBolt Tightening Torquekb7401100% (1)

- Cup 04 HSP Uk Web PDFDocument2 paginiCup 04 HSP Uk Web PDFcasda73Încă nu există evaluări

- Solutions of 8 Online Physics BrawlDocument47 paginiSolutions of 8 Online Physics BrawlDino SelimovicÎncă nu există evaluări

- Daenyx LOGODocument6 paginiDaenyx LOGOamarÎncă nu există evaluări

- B&J Fuel InjectionDocument24 paginiB&J Fuel InjectionZeeshan Ahmad100% (1)

- Z22 DoubleSuctionAxiallysplitSingleStageCentrifugalPump60HzUS E10118 USDocument2 paginiZ22 DoubleSuctionAxiallysplitSingleStageCentrifugalPump60HzUS E10118 USediÎncă nu există evaluări

- Grundfos Catalogue Industry and Water UtilityDocument542 paginiGrundfos Catalogue Industry and Water UtilityAdina Mariana Costache100% (7)

- Investigation of building collapse in AbujaDocument15 paginiInvestigation of building collapse in AbujaEmeso OjoÎncă nu există evaluări

- ExercisesDocument13 paginiExercisesAhmed Magdy BeshrÎncă nu există evaluări

- Mcdonnell & Miller Service Parts CatalogDocument76 paginiMcdonnell & Miller Service Parts Catalogkamran shahÎncă nu există evaluări

- CG AlternatorsDocument23 paginiCG AlternatorsHitesh Shinde100% (2)

- Tutorial 2 - Physical OperationsDocument2 paginiTutorial 2 - Physical OperationsnasuhaÎncă nu există evaluări

- Directional Controls: Solenoid Operated Directional Control ValvesDocument16 paginiDirectional Controls: Solenoid Operated Directional Control Valvesreincidentesk8Încă nu există evaluări

- Alli 15Document2 paginiAlli 15Robson belchiorÎncă nu există evaluări

- Machine Design Lesson on Buckling of Slender ColumnsDocument10 paginiMachine Design Lesson on Buckling of Slender ColumnsCarl JavierÎncă nu există evaluări

- Valve Vault Connection 2Document50 paginiValve Vault Connection 2Joel LacbayoÎncă nu există evaluări

- Engineering Mechanics Statics 14th Edition Ebook PDFDocument61 paginiEngineering Mechanics Statics 14th Edition Ebook PDFdebra.glisson665100% (42)

- Manual CBR 600fDocument446 paginiManual CBR 600fJavi erÎncă nu există evaluări

- Innovex Lead Seal Casing Patch March2022a-1Document10 paginiInnovex Lead Seal Casing Patch March2022a-1Christian MatteoÎncă nu există evaluări

- Demolition Robot (Brokk 500) (Brochure) - 1Document2 paginiDemolition Robot (Brokk 500) (Brochure) - 1Julius GatchalianÎncă nu există evaluări

- As (One Touch)Document105 paginiAs (One Touch)carlos223344Încă nu există evaluări

- Wire Rope Inspection Checklist FormDocument1 paginăWire Rope Inspection Checklist FormРашад ИбрагимовÎncă nu există evaluări

- Dynapac f1800w En-20220822.134322Document2 paginiDynapac f1800w En-20220822.134322Fredrik ÅkessonÎncă nu există evaluări