Documente Academic

Documente Profesional

Documente Cultură

Anex G From EN 4 1 2

Încărcat de

Ela DonTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Anex G From EN 4 1 2

Încărcat de

Ela DonDrepturi de autor:

Formate disponibile

Page 95

Draft prEN1994-1-2:2003

Annex G

[informative]

Balanced summation model for the calculation of the fire resistance

of composite columns with partially encased steel sections, for

bending around the weak axis, exposed to fire all around the column

according to the standard temperature-time curve .

b

Z

ef

u1

bc,fi

h

h w,fi

u2

b c,fi

ew

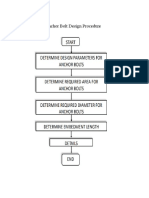

Figure G.1: Reduced cross-section for structural fire design

G.1 Introduction

(1) This calculation model is based on the principles and rules given in 4.3.5.1, but has been developed

only for bending around the axis Z such as:

N fi ,Rd ,z = z N fi , pl ,Rd

(G.1)

(2) For the calculation of the design value of the plastic resistance to axial compression

the effective flexural stiffness

N fi , pl ,Rd and of

( EI ) fi ,eff ,z in the fire situation, the cross-section is divided into four

components:

-

the flanges of the steel profile;

the web of the steel profile;

the concrete contained by the steel profile and

the reinforcing bars.

(3) Each component may be evaluated on the basis of a reduced characteristic strength, a reduced

modulus of elasticity and a reduced cross-section in function of the standard fire resistance R30, R60,

R90 or R120.

(4) The design value of the plastic resistance to axial compression and the effective flexural stiffness of

the cross-section may be obtained, according to (4) and (5) of 4.3.5.1, by a balanced summation of the

corresponding values of the four components.

Page 96

Draft prEN1994-1-2:2003

(5) Strength and deformation properties of steel and concrete at elevated temperatures complies with the

corresponding principles and rules of 3.1 and 3.2.

G.2 Flanges of the steel profile

(1) The average flange temperature may be determined from:

f ,t = o ,t + k t ( Am V )

(G.2)

where:

is the duration in minutes of the fire exposure

Am V is the section factor in m-1, with Am = 2 (h + b) in [m] and V = h b in [m]

o ,t

is a temperature in C given in Table G.1

kt

is an empirical coefficient given in Table G.1.

Table G.1

Standard Fire Resistance

R30

R60

R90

R120

(2) On behalf of the temperature

= f ,t

o ,t

kt

[C]

[mC]

550

680

805

900

9,65

9,55

6,15

4,65

the corresponding maximum stress level and the modulus of

elasticity are determined from:

f ay , f ,t = f ay , f k y ,

and

Ea , f ,t = Ea , f k E ,

with

(G.3)

k y , and k E , following Table 3.2 of 3.2.1

(G.4)

(3) The design value of the plastic resistance to axial compression and the flexural stiffness of the two

flanges of the steel profile in the fire situation are determined from:

N fi , pl ,Rd , f = 2 (b e f f ay , f ,t ) M , fi ,a and

( EI ) fi , f ,z = Ea , f ,t e f b 3

(G.5)

(G.6)

G.3 Web of the steel profile

(1) The part of the web with the height

hw , fi and starting at the inner edge of the flange may be neglected

(see Figure G.1). This part is determined from:

hw , fi = 0 ,5 (h 2e f ) 1 1 - 0,16 (H t h ) where H t is given in Table G.2.

(G.7)

Page 97

Draft prEN1994-1-2:2003

Table G.2

Standard Fire Resistance

H t [mm]

R 30

R 60

R 90

R 120

350

770

1100

1250

(2) The maximum stress level is obtained from:

f ay ,w ,t = f ay ,w 1 - (0,16H t h )

(G.8)

(3) The design value of the plastic resistance to axial compression and the flexural stiffness of the web of

the steel profile in the fire situation are determined from:

N fi , pl ,Rd ,w = ew (h 2e f 2hw , fi ) f ay ,w,t

( EI ) fi ,w ,z = Ea ,w (h 2e f 2hw , fi ) ew3

M , fi ,a

(G.9)

(G.10)

12

G.4 Concrete

(1) An exterior layer of concrete with a thickness

G.1). The thickness

bc , fi may be neglected in the calculation (see

Figure

-1

bc , fi is given in Table G.3, with Am V , the section factor in m of the entire

composite cross-section.

Table G.3

Standard Fire Resistance

bc , fi [mm]

R30

4,0

R60

15,0

R90

0,5 ( Am

V ) + 22,5

R120

2,0 ( Am

V ) + 24,0

(2) The average temperature in concrete

c ,t

is given in Table G.4 in function of the section factor

Am V of the entire composite cross-section and for the standard fire resistance classes.

Table G.4

R30

R60

c ,t

Am V

[m ]

[C]

4

23

46

-

136

300

400

-

Am V

-1

R90

c ,t

Am V

[m ]

[C]

4

9

21

50

-

214

300

400

600

-

-1

R120

c ,t

Am V

[m ]

[C]

[m ]

[C]

4

6

13

33

54

-

256

300

400

600

800

-

4

5

9

23

38

41

43

265

300

400

600

800

900

1000

-1

-1

c ,t

Page 98

Draft prEN1994-1-2:2003

(3) On behalf of the temperature

= c ,t the secant modulus of concrete is obtained from:

Ec ,sec, = f c , cu , = f c k c , cu , with k c , and cu , following Table 3.3 of 3.2.2

(G.11)

(4) The design value of the plastic resistance to axial compression and the flexural stiffness of the

concrete in the fire situation are determined from:

N fi , pl ,Rd ,c = 0 ,86 {((h 2e f 2bc , fi )(b ew 2bc , fi )) As } f c , M , fi ,c

(G.12)

where As is the cross-section of the reinforcing bars, and 0,86 is a calibration factor.

(EI )

fi , c , z

where

= Ec , sec,

[{(h 2e 2b ) ((b 2b

f

c , fi

c , fi

) e ) 12} I

3

s ,z

(G.13)

I s ,z is the second moment of area of the reinforcing bars related to the central axis Z of the

composite cross-section.

G.5 Reinforcing bars

(1) The reduction factor

k y ,t of the yield point and the reduction factor k E ,t of the modulus of elasticity

of the reinforcing bars, are defined in function of the standard fire resistance and the geometrical average

u of the axis distances of the reinforcement to the outer borders of the concrete (see Tables G.5 and

G.6).

Table G.5: Reduction factor ky,t for the yield point fsy of the reinforcing bars

u[mm]

40

45

50

55

60

R60

0,789

0,883

0,976

R90

0,314

0,434

0,572

0,696

0,822

R120

0,170

0,223

0,288

0,367

0,436

Standard

Fire Resistance

R30

Table G.6: Reduction factor kE,t for the modulus of elasticity Es of the reinforcing bars

u[mm]

40

45

50

55

60

0,830

0,865

0,888

0,914

0,935

R60

0,604

0,647

0,689

0,729

0,763

R90

0,193

0,283

0,406

0,522

0,619

R120

0,110

0,128

0,173

0,233

0,285

Standard

Fire Resistance

R30

(2) The geometrical average u of the axis distances

u1 and u 2 is obtained from:

u = u1 u 2

(G.14)

where:

u1

u2

is the axis distance from the outer reinforcing bar to the inner flange edge

[mm]

is the axis distance from the outer reinforcing bar to the concrete surface

[mm]

Page 99

Draft prEN1994-1-2:2003

If

(u1 - u2 ) > 10 mm, then u =

u 2 (u 2 + 10 ) ,

or

(u2 - u1 ) > 10 mm, then u =

u1 (u1 + 10 ) .

Note:

(3) The design value of the plastic resistance to axial compression and the flexural stiffness of the

reinforcing bars in the fire situation are obtained from:

N fi , pl ,Rd ,s = As k y ,t f sy M , fi ,s

(G.15)

(EI ) fi ,s ,z = k E ,t

(G.16)

E s I s ,z

G.6 Calculation of the axial buckling load at elevated temperatures

(1) According to (4) of G.1, the design value of the plastic resistance to axial compression and the

effective flexural stiffness of the cross-section in the fire situation are determined from:

N fi , pl ,Rd = N fi , pl ,Rd , f + N fi , pl ,Rd ,w + N fi , pl ,Rd ,c + N fi , pl ,Rd ,s

(G.17)

(EI ) fi ,eff ,z = f , (EI ) fi , f ,z + w , (EI ) fi ,w ,z + c , (EI ) fi ,c ,z + s , (EI ) fi ,s ,z

(G.18)

where

i, is

a reduction coefficient depending on the effect of thermal stresses. The values of

i,

are

given in Table G.7.

Table G.7

Standard Fire Resistance

f,

w,

c,

s,

R30

1,0

1,0

0,8

1,0

R60

0,9

1,0

0,8

0,9

R90

0,8

1,0

0,8

0,8

R120

1,0

1,0

0,8

1,0

(2) The Euler buckling load or elastic critical load follows by:

N fi ,cr ,z = (EI ) fi ,eff ,z

l 2

(G.19)

where:

l is the buckling length of the column in the fire situation.

(3) The non-dimensional slenderness ratio is obtained from:

= N fi, pl,R N fi,cr,z

(G.20)

where:

N fi , pl ,R is the value of N fi , pl ,Rd according to (1) when the factors M , fi ,a , M , fi ,c and M , fi ,s are taken

as 1,0.

Page 100

Draft prEN1994-1-2:2003

(4) Using and the buckling curve c of EN 1993-1-1, the reduction coefficient

the design axial buckling load in the fire situation is obtained from:

z may be calculated and

N fi ,Rd ,z = z N fi , pl ,Rd

(G.21)

(5) Limitations of the method of this Annex are given as follows for the different standard fire resistance

classes:

R30:

R60:

b and h 230 mm

for

230 mm b < 300 mm or h/b > 3

for

b 300 mm and h/b 3

l 13,5b

l 10b

l 13,5b

b 300 mm and h 300 mm

R90

and

R120

for h / b > 3

l 10b

for h / b 3

l 13,5b

(6) The design values of the resistance of members in axial compression or the design axial buckling

loads N fi ,Rd ,z are shown in Figures G.2 and G.3 in function of the buckling length l for the profile series

HEA and the material grades S355 of the steel profile, C40/50 of the concrete, S500 of the reinforcing

bars and for the different standard fire resistance classes R60, R90 and R120.

These design graphs are based on the partial material safety factors

M , fi ,a = M , fi ,s = M , fi ,c = 1,0 .

G.7 Eccentricity of loading

(1) For a column submitted to a load with an eccentricity , the design buckling load

N fi ,Rd , may be

obtained from:

N fi ,Rd , = N fi ,Rd (N Rd , N Rd )

(G.22)

where:

N Rd and N Rd , represent the axial buckling load and the buckling load in case of an eccentric load

calculated according to EN 1994-1-1, for normal temperature design.

(2) The application point of the eccentric load remains inside the composite cross-section of the column.

S-ar putea să vă placă și

- Extracts From Ec3 For Students 2012Document6 paginiExtracts From Ec3 For Students 2012Alexandru MarincuÎncă nu există evaluări

- P 5.0.1 Loading Condition For Columns: 5.0 Analysis of ColumnDocument6 paginiP 5.0.1 Loading Condition For Columns: 5.0 Analysis of Columnanimesh91Încă nu există evaluări

- Steldeck Slab DesignDocument18 paginiSteldeck Slab DesignJason Ubaub CellonaÎncă nu există evaluări

- Towerwind Analysis - Anchoragebolt - Base PlateDocument14 paginiTowerwind Analysis - Anchoragebolt - Base PlateJoy lauriaÎncă nu există evaluări

- Flange Leakage Test As Per Asme Boiler & Pressure Vessel CodeDocument12 paginiFlange Leakage Test As Per Asme Boiler & Pressure Vessel CoderssambhiÎncă nu există evaluări

- Sensitivity Analysis of Fire Resistance of A Composite Floor SlabDocument10 paginiSensitivity Analysis of Fire Resistance of A Composite Floor SlabKevin R. FabreagÎncă nu există evaluări

- Glulam Curved Beam Design To EC5Document6 paginiGlulam Curved Beam Design To EC5Burak Kırcal100% (1)

- EC3EXT200102 Steel Reference in EC3Document6 paginiEC3EXT200102 Steel Reference in EC3mileÎncă nu există evaluări

- 5 Asme Viii A-24 Clamp ConnectionDocument6 pagini5 Asme Viii A-24 Clamp ConnectionpastylÎncă nu există evaluări

- Calculo de Brida Segun ASMEDocument29 paginiCalculo de Brida Segun ASMEakarcz6731Încă nu există evaluări

- EC2 Bending With or Without Axial ForceDocument11 paginiEC2 Bending With or Without Axial ForceselinaÎncă nu există evaluări

- 5 Asmeviii A-24 Clamp ConnectionDocument6 pagini5 Asmeviii A-24 Clamp ConnectionpastylÎncă nu există evaluări

- Assemblage Poteau-Semelle IsoléeDocument11 paginiAssemblage Poteau-Semelle IsoléeFrancklinMeunierM'ondoÎncă nu există evaluări

- Fixed Column BaseDocument3 paginiFixed Column BasemontavarÎncă nu există evaluări

- Design of BeamDocument17 paginiDesign of Beamravikiran226100% (1)

- Kamal Handa Vindber KningarDocument7 paginiKamal Handa Vindber Kningarpedlopes01Încă nu există evaluări

- Assume A Plate Girder of The Following Properties: Span of Beam (L)Document10 paginiAssume A Plate Girder of The Following Properties: Span of Beam (L)D SRINIVASÎncă nu există evaluări

- تصميم الكمرات بطريقة ultimate PDFDocument42 paginiتصميم الكمرات بطريقة ultimate PDFqaisalkurdyÎncă nu există evaluări

- Compression MemberDocument45 paginiCompression MemberSatyasapath RoyÎncă nu există evaluări

- 1.stress and Strain PDFDocument33 pagini1.stress and Strain PDFharshdeepÎncă nu există evaluări

- Suggested Approach Based On ACI Code For Maximum Bending Capacity of Singly and Doubly Reinforced Concrete Beam SectionsDocument12 paginiSuggested Approach Based On ACI Code For Maximum Bending Capacity of Singly and Doubly Reinforced Concrete Beam SectionsRatul RanjanÎncă nu există evaluări

- 1 3Document2 pagini1 3kelvito09Încă nu există evaluări

- Ec3 Kolon HesabıDocument5 paginiEc3 Kolon HesabınaimalimliÎncă nu există evaluări

- End-Plate - Beam To Beam Connection Design 3Document8 paginiEnd-Plate - Beam To Beam Connection Design 3gianniorlatiÎncă nu există evaluări

- Design Aid For Triangular Bracket Plates Using AISC SpecificationsDocument10 paginiDesign Aid For Triangular Bracket Plates Using AISC Specificationsmaroco1098100% (7)

- Structural Design of Pergola With Airfoil LouversDocument8 paginiStructural Design of Pergola With Airfoil LouversSudhakar Krishnamurthy100% (1)

- Design of Anchorage Length EC2Document4 paginiDesign of Anchorage Length EC2ECC100% (2)

- AZ024 Lecture 3 (Rev (1) A)Document12 paginiAZ024 Lecture 3 (Rev (1) A)Tong Kin Lun100% (4)

- CB01 AXIS 27-K Change 800x800Document11 paginiCB01 AXIS 27-K Change 800x800Reab SimanthÎncă nu există evaluări

- Toaz - Info Merge PRDocument81 paginiToaz - Info Merge PRMildred CanopinÎncă nu există evaluări

- Structural Design of Steelwork Web BearingDocument18 paginiStructural Design of Steelwork Web BearingJacob GrechÎncă nu există evaluări

- Steel Beam DesignDocument26 paginiSteel Beam DesignWazini D. Izani100% (1)

- Example - Buckling Resistance of A Pinned Column With Intermediate RestraintsDocument5 paginiExample - Buckling Resistance of A Pinned Column With Intermediate RestraintsAndreea NanÎncă nu există evaluări

- Section 13 PDFDocument17 paginiSection 13 PDFherrerafaridÎncă nu există evaluări

- Homework #5:: Material-Property Relations & Yield/Failure CriterionDocument1 paginăHomework #5:: Material-Property Relations & Yield/Failure CriterionPranjal SinghÎncă nu există evaluări

- Curva de Tensión-Deformación de IngenieríaDocument16 paginiCurva de Tensión-Deformación de Ingenieríamaikol cantorÎncă nu există evaluări

- Second Class /materials Engineering Department: TorsionDocument5 paginiSecond Class /materials Engineering Department: TorsionYzhel LopezÎncă nu există evaluări

- Steel Column DesignDocument10 paginiSteel Column DesignWazini D. IzaniÎncă nu există evaluări

- Calculation For Sight Glass FlangeDocument4 paginiCalculation For Sight Glass FlangeOmil Rastogi0% (2)

- Cold Formed BendingDocument8 paginiCold Formed BendinggeorgeispasoiuÎncă nu există evaluări

- Cantilever Curtain WallDocument18 paginiCantilever Curtain WallkingdbmÎncă nu există evaluări

- Column Design With Base Plate and Stiffeners PDFDocument7 paginiColumn Design With Base Plate and Stiffeners PDFAhmed AlmayaliÎncă nu există evaluări

- Column Steel DesignDocument37 paginiColumn Steel DesignIlya Joohari100% (1)

- Summary of Equations and Tables - En1992-2 Eurocode 2 - Design of Concrete Structures 2C Part 2 - Concrete BridgesDocument21 paginiSummary of Equations and Tables - En1992-2 Eurocode 2 - Design of Concrete Structures 2C Part 2 - Concrete BridgesgoawaynowÎncă nu există evaluări

- Circular Hollow Concrete ColumnDocument3 paginiCircular Hollow Concrete ColumnUttam Kumar GhoshÎncă nu există evaluări

- BlindDocument3 paginiBlindSajal KulshresthaÎncă nu există evaluări

- Pile Cap Design - ColumnsDocument6 paginiPile Cap Design - Columnssssmou100% (1)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsDe la EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsÎncă nu există evaluări

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsDe la EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsÎncă nu există evaluări

- Mechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingDe la EverandMechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingÎncă nu există evaluări

- Pressure Vessel and Stacks Field Repair ManualDe la EverandPressure Vessel and Stacks Field Repair ManualEvaluare: 4 din 5 stele4/5 (4)

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationDe la EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationÎncă nu există evaluări

- Dynamic Damage and FragmentationDe la EverandDynamic Damage and FragmentationDavid Edward LambertÎncă nu există evaluări

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysDe la EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysÎncă nu există evaluări

- Examples of Balancing Method - Four-Run and Least-Squares Influence CoefficientsDocument44 paginiExamples of Balancing Method - Four-Run and Least-Squares Influence CoefficientsNguyen Anh TuÎncă nu există evaluări

- Linux NFS and Automounter Administration (Craig Hunt Linux Library)Document0 paginiLinux NFS and Automounter Administration (Craig Hunt Linux Library)Bryan BowmanÎncă nu există evaluări

- Put Call ParityDocument37 paginiPut Call ParityVaidyanathan Ravichandran100% (1)

- Yang Learning Face Age CVPR 2018 PaperDocument9 paginiYang Learning Face Age CVPR 2018 Paperandr234ibateraÎncă nu există evaluări

- Case StudyDocument4 paginiCase Studyadil rangoonÎncă nu există evaluări

- Mohamad Fakhari Mehrjardi - 1Document18 paginiMohamad Fakhari Mehrjardi - 1Hilmi SanusiÎncă nu există evaluări

- Leading The Industry In: Solar Microinverter TechnologyDocument2 paginiLeading The Industry In: Solar Microinverter TechnologydukegaloÎncă nu există evaluări

- Epson L6170 Wi-Fi Duplex All-in-One Ink Tank Printer With ADFDocument3 paginiEpson L6170 Wi-Fi Duplex All-in-One Ink Tank Printer With ADFCarl DonaireÎncă nu există evaluări

- CH 12 Review Solutions PDFDocument11 paginiCH 12 Review Solutions PDFOyinkansola OsiboduÎncă nu există evaluări

- Plate - 3 (FLOT)Document2 paginiPlate - 3 (FLOT)patrick dgÎncă nu există evaluări

- Ce2202 - Mechanics of FluidsDocument3 paginiCe2202 - Mechanics of FluidsPrashant GaradÎncă nu există evaluări

- Caterpillar Product Line 13Document7 paginiCaterpillar Product Line 13GenneraalÎncă nu există evaluări

- Gantt ChartDocument4 paginiGantt ChartSyed FaridÎncă nu există evaluări

- ORC - Airbag SystemDocument13 paginiORC - Airbag SystemGarikoitz FranciscoeneÎncă nu există evaluări

- W.R. Klemm (Auth.) - Atoms of Mind - The - Ghost in The Machine - Materializes-Springer Netherlands (2011)Document371 paginiW.R. Klemm (Auth.) - Atoms of Mind - The - Ghost in The Machine - Materializes-Springer Netherlands (2011)El equipo de Genesis ProjectÎncă nu există evaluări

- Lexium 23 Plus - BCH0802O12A1CDocument4 paginiLexium 23 Plus - BCH0802O12A1Cagungch100% (1)

- (Frankel 1962) The Production Function in Allocation and GrowthDocument29 pagini(Frankel 1962) The Production Function in Allocation and GrowthT-roy Taylor100% (1)

- Numerical ModelDocument61 paginiNumerical ModelAlbert AguileraÎncă nu există evaluări

- Substations - Part 1 - Procedural: DisclaimerDocument44 paginiSubstations - Part 1 - Procedural: DisclaimerSergio Henrique F. CArniettoÎncă nu există evaluări

- PB152 - CJ60 GongDocument2 paginiPB152 - CJ60 GongJibjab7Încă nu există evaluări

- Chapter 1: Coding Decoding: Important Note: It Is Good To Avoid Pre-Defined Coding Rule To Write A Coded MessageDocument7 paginiChapter 1: Coding Decoding: Important Note: It Is Good To Avoid Pre-Defined Coding Rule To Write A Coded MessageUmamÎncă nu există evaluări

- Ant CabDocument93 paginiAnt CabZubair MinhasÎncă nu există evaluări

- Newvhdl Syllabus (It&Cse)Document2 paginiNewvhdl Syllabus (It&Cse)Mude Kishore NaikÎncă nu există evaluări

- InfoDocument18 paginiInfoKaran Verm'aÎncă nu există evaluări

- Numbers (0, 1, 2, 3,... ) Are Defined To Be Natural Numbers, Including Zero, That Does Not ContainDocument9 paginiNumbers (0, 1, 2, 3,... ) Are Defined To Be Natural Numbers, Including Zero, That Does Not ContainRomela EspedidoÎncă nu există evaluări

- Research and Development at The BENSON Test RigDocument20 paginiResearch and Development at The BENSON Test RigsbktceÎncă nu există evaluări

- Avh-X8550bt Operating Manual Eng-Esp-PorDocument7 paginiAvh-X8550bt Operating Manual Eng-Esp-PorRannie IsonÎncă nu există evaluări

- Os ND06Document3 paginiOs ND06kevinbtechÎncă nu există evaluări

- Ruby On Rails 3 Cheat SheetDocument7 paginiRuby On Rails 3 Cheat SheetJarosław MedwidÎncă nu există evaluări

- 19 04 20 p2 PDFDocument32 pagini19 04 20 p2 PDFGovind SajuÎncă nu există evaluări