Documente Academic

Documente Profesional

Documente Cultură

MS For Spatterdash (Nitobond)

Încărcat de

Gary LoTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

MS For Spatterdash (Nitobond)

Încărcat de

Gary LoDrepturi de autor:

Formate disponibile

METHOD STATEMENT FOR

LATE APPLIED SPATTERDASH

Effective Date

09/07/2013

MST/A/001

Document No.

Issue No.

:

Revision No.

:

Page:

CONSTRUCTION OF LOWER NGAU TAU KOK

REDEVELOPMENT PH 2 & 6, DEMOLITION AND

MINOR WORKS AT TUNG TAU ESTATE

REDEVELOPMENT PHASE 8 AND ALTERATION AND

ADDITION WORKS AT HOMANTIN ESTATE

(CONTRACT NO. 20120141)

METHOD STATEMENT FOR

LATE APPLIED SPATTERDASH

Prepared by: Rosemary Leung

Reviewed by: Alex Chan

Contractor: Gammon

Signature

Contractor: Gammon

Signature

Reviewed by: Raymond

Wong

Contractor: Gammon

Signature

Name:

Post: AQCC

Date: 09 (dd)/ 07 (mm)/2013

Name:

Post: QCM

Date: 09 (dd)/ 07 (mm)/2013

Name:

Post: QE

Date: 09 (dd)/ 07 (mm)/2013

Reviewed by: Dickson Li

Contractor: Gammon

Signature

Reviewed by:

Contractor: Gammon

Signature

Approved by: CL Chow

Contractor: Gammon

Signature

Name:

Post: Safety Officer

Date: 09 (dd)/ 07 (mm)/2013

Name:

Post: TWC

Date: 09 (dd)/ 07 (mm)/2013

Name:

Post: Site Agent

Date: 09 (dd)/ 07 (mm)/2013

METHOD STATEMENT FOR

LATE APPLIED SPATTERDASH

Effective Date

09/07/2013

MST/A/001

Document No.

Issue No.

:

Revision No.

:

1 of 17

Page:

CONTENT

1.

Introduction

2.

Sequence and Method of Works

2.1

Surface Preparation

2.2

Application of Spatterdash

3.

Quality Control

4.

Safety Concern

5.

Environmental Protection

Appendix

A

Standard Method Statement from Supplier (As reference document to

show compliance with suppliers recommended method)

Material Safety Data Sheet of Bonding Agent for Spatterdash

Risk Assessment & Hazard identification

Field Control Sheet

METHOD STATEMENT FOR

LATE APPLIED SPATTERDASH

Effective Date

09/07/2013

MST/A/001

Document No.

Issue No.

:

Revision No.

:

2 of 17

Page:

1.

Introduction

This submission covers the method statement of spatterdash for vertical concrete

surface and soffits, where plastering or rendering will be received.

2. Sequence and Method of Works

2.1.

Surface Preparation

The concrete surface shall be cleaned of all loose, dust or deleterious materials,

especially from oils or other contaminants likely to affect the bond. The

application shall be thoroughly wetted and saturated but shall have no standing

water on the surface.

2.2.

Application of spatterdash

Spatterdash shall be applied to vertical concrete surface and soffits after the

surface is fully cured.

Spatterdash shall be consist of (1:2) cement: coarse sand with a bonding agent

(please refer to material submission ref: LNTK2&TT8&HMT/FIN/007) , Nitobond

SBR, and keep well stirred by both hand mix or machine mix. The mixture shall be

applied by dashing it on the previously dampened background by a hand scoop or

a trowel to give a complete coverage with a rough texture, as per specification

FIN1.W210.5 as below:

1) Uncovered areas do not exceed 0.01m2

2) Spacing between strokes is less than 50mm

3) Uncovered area at wall edges is less than 50mm

After hardening and curing, use high pressure water jet to clean off dust and

loose particles before applying subsequent finishing coat.

3. Quality Control

To ensure the works are completed up to the standard, the working method and

acceptance criteria shall be communicated to relevant supervision staff,

subcontractors and workers.

Following pre-checking of completed works by supervision staff to confirm

compliance, an inspection form shall be submitted to CMs representative for

arranging joint inspection of works.

METHOD STATEMENT FOR

LATE APPLIED SPATTERDASH

Effective Date

09/07/2013

MST/A/001

Document No.

Issue No.

:

Revision No.

:

Page:

Test Procedure for spatterdash as per specification FIN1.W240.5 as below:

1) Carry out joint inspection with CMs representative to minimum 10% of

spatterdash

3 of 17

2) After hardening and curing, check the adhesion of the spatterdash coat by

brushing with a stiff wire brush

3) Where spatterdash is easily removed, completely remove loosened

spatterdash. Re-apply and re-inspect after 7 days.

4) Subsequent works will not be started on any affected area until re-inspection

is to CMs satisfaction.

4. Safety Concern

All works at high level will be performed on the temporary working platform,

which should be checked and approved by competent person bi-weekly. Form 5

signed by competent person should be posted on the temporary working platform

at all time.

Workers working at high level shall wear safety harness at all time with lanyard

connected to supports fixed to independent lifeline. To prevent falling of hand

tools, toe boards would be fixed to working platform.

Risk Assessment, Hazard Identification & Field Control Sheet:

- Please refer to Appendix C & D

5. Environmental Assessment

Close supervision will be carried out through the spatterdash in order to minimize

any adverse impacts to the surrounding environment. All cement bags shall be

covered with tarpaulin sheet to prevent inhalation of cement powder. Chemical

containers will be labelled as per attached Material Safety Data Sheet (MSDS).

METHOD STATEMENT FOR

LATE APPLIED SPATTERDASH

Effective Date

09/07/2013

MST/A/001

Document No.

Issue No.

:

Revision No.

:

Page:

Appendix A

Standard Method Statement from Supplier

4 of 17

METHOD STATEMENT FOR

LATE APPLIED SPATTERDASH

Effective Date

09/07/2013

MST/A/001

Document No.

Issue No.

:

Revision No.

:

Page:

METHOD STATEMENT FOR

LATE APPLIED SPATTERDASH

Effective Date

09/07/2013

MST/A/001

Document No.

Issue No.

:

Revision No.

:

Page:

METHOD STATEMENT FOR

LATE APPLIED SPATTERDASH

Effective Date

09/07/2013

MST/A/001

Document No.

Issue No.

:

Revision No.

:

Page:

METHOD STATEMENT FOR

LATE APPLIED SPATTERDASH

Effective Date

09/07/2013

MST/A/001

Document No.

Issue No.

:

Revision No.

:

Page:

METHOD STATEMENT FOR

LATE APPLIED SPATTERDASH

Effective Date

09/07/2013

MST/A/001

Document No.

Issue No.

:

Revision No.

:

9 of 17

Page:

Appendix B

Material Safety Data Sheet of Bonding Agent for Spatterdash

METHOD STATEMENT FOR

LATE APPLIED SPATTERDASH

Effective Date

09/07/2013

MST/A/001

Document No.

Issue No.

:

Revision No.

:

Page:

METHOD STATEMENT FOR

LATE APPLIED SPATTERDASH

Effective Date

09/07/2013

MST/A/001

Document No.

Issue No.

:

Revision No.

:

Page:

METHOD STATEMENT FOR

LATE APPLIED SPATTERDASH

Effective Date

09/07/2013

MST/A/001

Document No.

Issue No.

:

Revision No.

:

Page:

METHOD STATEMENT FOR

LATE APPLIED SPATTERDASH

Effective Date

09/07/2013

MST/A/001

Document No.

Issue No.

:

Revision No.

:

Page:

METHOD STATEMENT FOR

LATE APPLIED SPATTERDASH

Effective Date

09/07/2013

MST/A/001

Document No.

Issue No.

:

Revision No.

:

Page:

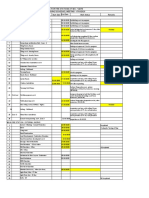

Appendix C

Risk Assessment & Hazard identification

14 of 17

METHOD STATEMENT FOR

LATE APPLIED SPATTERDASH

Effective Date

09/07/2013

MST/A/001

Document No.

Issue No.

:

Revision No.

:

15 of 17

Page:

Risk Assessment & Hazard Idntification

Works Related Projects/Department: J3299 Victoria Park Swimming Pool

Complex

Type of Activity Operation: Spatterdash

METHOD STATEMENT FOR

LATE APPLIED SPATTERDASH

Effective Date

09/07/2013

MST/A/001

Document No.

Issue No.

:

Revision No.

:

16 of 17

Page:

Appendix D

Field Control Sheet

LNTK 2&6

METHOD STATEMENT FOR

LATE APPLIED SPATTERDASH

Effective Date

09/07/2013

MST/A/001

Document No.

Issue No.

:

Revision No.

:

Page:

Lower Ngan Tau

Kok

S-ar putea să vă placă și

- MS For Wet TradeDocument11 paginiMS For Wet TradeGary LoÎncă nu există evaluări

- Method of Statement MarinaDocument8 paginiMethod of Statement MarinaMohammed AshrafÎncă nu există evaluări

- Method Statement For Installation of Fan Coil UnitDocument4 paginiMethod Statement For Installation of Fan Coil UnitGary LoÎncă nu există evaluări

- Technical Information For Typical Stretch CeilingsDocument2 paginiTechnical Information For Typical Stretch Ceilingseromax1Încă nu există evaluări

- PAL - Construction GuidelinesDocument28 paginiPAL - Construction GuidelinesCarew Mohammed AbayomiÎncă nu există evaluări

- Method Statement For In-Situ Pull Off Test On MarbleDocument15 paginiMethod Statement For In-Situ Pull Off Test On MarbleGary Lo67% (3)

- Cash Flow EngDocument1 paginăCash Flow EngFaizalFendiÎncă nu există evaluări

- BeamDocument6 paginiBeamFouad Hassan100% (1)

- Brick ConquasDocument17 paginiBrick ConquasIs EastÎncă nu există evaluări

- Malaysia Boleh!: Reference Calculation Output Staircase (Supported by Beams)Document6 paginiMalaysia Boleh!: Reference Calculation Output Staircase (Supported by Beams)Chung May LynnÎncă nu există evaluări

- METHODOLOGY EE-Hanger Support InstallationDocument4 paginiMETHODOLOGY EE-Hanger Support Installationjerrick raulÎncă nu există evaluări

- Method Statement For Chipping and Grouting For All EDI System in PH2Document6 paginiMethod Statement For Chipping and Grouting For All EDI System in PH2vinodhyperÎncă nu există evaluări

- Quality Management System for Construction ProjectsDocument1 paginăQuality Management System for Construction ProjectsmaddumasooriyaÎncă nu există evaluări

- Concrete Surface Treatments - 2Document4 paginiConcrete Surface Treatments - 2derma_irmawanÎncă nu există evaluări

- Minimizing Color Variations in Troweled ConcreteDocument1 paginăMinimizing Color Variations in Troweled ConcretepipiÎncă nu există evaluări

- Sika Top Seal 107 MSDocument3 paginiSika Top Seal 107 MSTan TounÎncă nu există evaluări

- Method Statement For Construction of Drainage and Manholes (Rev. A)Document53 paginiMethod Statement For Construction of Drainage and Manholes (Rev. A)Gary LoÎncă nu există evaluări

- Expansion Joint Cover Catalogue 43Document72 paginiExpansion Joint Cover Catalogue 43Jacky LeongÎncă nu există evaluări

- Stretch Ceiling System Newmat Uk Midlands LTDDocument24 paginiStretch Ceiling System Newmat Uk Midlands LTDNewmatUKÎncă nu există evaluări

- Brushbond FLXIII Provides Tough WaterproofingDocument2 paginiBrushbond FLXIII Provides Tough WaterproofingTori SmallÎncă nu există evaluări

- 2020.04.14 Esah 3.1 PDFDocument130 pagini2020.04.14 Esah 3.1 PDFShahril ShahibullahÎncă nu există evaluări

- Method Statement For Concrete Blockwall ErectionDocument21 paginiMethod Statement For Concrete Blockwall ErectionGary LoÎncă nu există evaluări

- Method Statement: Interiors Sources Decor LLCDocument10 paginiMethod Statement: Interiors Sources Decor LLCaayasirÎncă nu există evaluări

- Method Statement For AAC Block Masonry: Material RequiredDocument2 paginiMethod Statement For AAC Block Masonry: Material RequiredEyutt HghghÎncă nu există evaluări

- Remove Bathroom Suite Method StatementDocument2 paginiRemove Bathroom Suite Method StatementUbah ChigozieÎncă nu există evaluări

- Screenshot 2020-08-24 at 2.42.43 PM PDFDocument2 paginiScreenshot 2020-08-24 at 2.42.43 PM PDFCody WongÎncă nu există evaluări

- Method Statement For Painting Works: ProjectDocument9 paginiMethod Statement For Painting Works: Projectfaizan khan100% (1)

- Progress Report No. 2-Dhangadhi PDFDocument6 paginiProgress Report No. 2-Dhangadhi PDFIrah IrakihdaÎncă nu există evaluări

- Renderoc TGDocument4 paginiRenderoc TGBalasubramanian Ananth100% (1)

- Concrete Coring Method StatementDocument1 paginăConcrete Coring Method StatementAnonymous kWfNFbÎncă nu există evaluări

- Epoxy Painting Method GuideDocument3 paginiEpoxy Painting Method GuideKaram MoatasemÎncă nu există evaluări

- Carpet Floorring-Method StatementDocument6 paginiCarpet Floorring-Method StatementAli Bouchakor0% (1)

- Density Values and Measurements for Common Building MaterialsDocument26 paginiDensity Values and Measurements for Common Building MaterialssutanuprojectsÎncă nu există evaluări

- O&M Manual - Beach Villa FormattedDocument32 paginiO&M Manual - Beach Villa Formattedlinga2014Încă nu există evaluări

- Polyurea Waterproofingitp-1 PDFDocument3 paginiPolyurea Waterproofingitp-1 PDFgops1963Încă nu există evaluări

- Precase Concrete Pipes (Mac, 16)Document4 paginiPrecase Concrete Pipes (Mac, 16)KpChuaÎncă nu există evaluări

- Trakhees Mandatory InspectionsDocument2 paginiTrakhees Mandatory InspectionsGhayas JawedÎncă nu există evaluări

- Method Statement For Coring WorkDocument6 paginiMethod Statement For Coring Workadeniyi abiolaÎncă nu există evaluări

- Method Statement for Relocating Floor TrapsDocument1 paginăMethod Statement for Relocating Floor TrapsAnonymous wTTx1LÎncă nu există evaluări

- Method Statement For Exposed ColumnsDocument12 paginiMethod Statement For Exposed ColumnsdeviesrigatiÎncă nu există evaluări

- Method Statement& Risk Assesment For Demolition WorksDocument5 paginiMethod Statement& Risk Assesment For Demolition Workschandanprakash30Încă nu există evaluări

- Method Statement - Roof VentilatorDocument7 paginiMethod Statement - Roof VentilatorJuwe Pkdo100% (1)

- Methods of Landscaping and Lighting WorksDocument6 paginiMethods of Landscaping and Lighting WorksFibin HaneefaÎncă nu există evaluări

- Ed 000 CST WMS 0021Document9 paginiEd 000 CST WMS 0021Fitriansyah Adi Putra IrwanÎncă nu există evaluări

- Method Statement GeneralDocument21 paginiMethod Statement GeneralSaibal Saha67% (3)

- Site Works Scheduel Meeting - 17/10/2020: Epic For Fire Stations at Mic - 143/18Document2 paginiSite Works Scheduel Meeting - 17/10/2020: Epic For Fire Stations at Mic - 143/18HariKumar PÎncă nu există evaluări

- Method Statement FencDocument5 paginiMethod Statement FencKhairul Adli Mohd RaniÎncă nu există evaluări

- Renderoc FC (1) Fairing Coat PDFDocument4 paginiRenderoc FC (1) Fairing Coat PDFPrashant MankarÎncă nu există evaluări

- Blockwork Method StatementDocument33 paginiBlockwork Method Statementscarlett3232100% (2)

- RC PilesDocument4 paginiRC Pileshasif21Încă nu există evaluări

- Ms Conc Block Masonry 01Document3 paginiMs Conc Block Masonry 01Engr Muhammad SohailÎncă nu există evaluări

- 010-MS For Grouting PDFDocument33 pagini010-MS For Grouting PDFKöksal PatanÎncă nu există evaluări

- 013-MS For Mass Concrete Works PDFDocument26 pagini013-MS For Mass Concrete Works PDFKöksal Patan100% (1)

- G SM PPLT Pip 805Document12 paginiG SM PPLT Pip 805rokan123Încă nu există evaluări

- MS For Windows - Louvres InstallationDocument9 paginiMS For Windows - Louvres InstallationGary LoÎncă nu există evaluări

- GRP ProcedureDocument42 paginiGRP Proceduremansih45775% (4)

- Inspection Summary - V-1000CDocument6 paginiInspection Summary - V-1000CSyed Shiraz AliÎncă nu există evaluări

- Field Engineer's Guide to Sewerage ProjectsDocument40 paginiField Engineer's Guide to Sewerage ProjectsSyed AliÎncă nu există evaluări

- Field Joint Coating A01Document8 paginiField Joint Coating A01Toreson OfuafoÎncă nu există evaluări

- 012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFDocument16 pagini012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFKöksal Patan91% (11)

- Astm F1292-2004Document25 paginiAstm F1292-2004Gary Lo100% (3)

- Astm C603Document2 paginiAstm C603Gary Lo100% (1)

- Typical SectionDocument1 paginăTypical SectionGary LoÎncă nu există evaluări

- BD List of Approved Foundation SystemDocument2 paginiBD List of Approved Foundation SystemGary LoÎncă nu există evaluări

- Method Statement For Excavating Additional 3m Deep Trial Pits (2013!08!13)Document16 paginiMethod Statement For Excavating Additional 3m Deep Trial Pits (2013!08!13)Gary Lo0% (2)

- Method Statement For Decommiss - 1102 CSF POC CS 000197Document20 paginiMethod Statement For Decommiss - 1102 CSF POC CS 000197Gary LoÎncă nu există evaluări

- 1102 W Hik SWL Q08 395aDocument1 pagină1102 W Hik SWL Q08 395aGary LoÎncă nu există evaluări

- Kobelco Rk250-7 SpecDocument4 paginiKobelco Rk250-7 SpecVictor Abel Prieto Pizarro100% (4)

- Method Statement For Eredtion - 1102 ERFC CM (SCLC) CS 000126Document3 paginiMethod Statement For Eredtion - 1102 ERFC CM (SCLC) CS 000126Gary LoÎncă nu există evaluări

- Haul RoadDocument8 paginiHaul RoadGary LoÎncă nu există evaluări

- 1102 W Hik SWL C10 301aDocument1 pagină1102 W Hik SWL C10 301aGary LoÎncă nu există evaluări

- 1102 W Hik SWL C10 301aDocument1 pagină1102 W Hik SWL C10 301aGary LoÎncă nu există evaluări

- Method Statement For Demolition & Modification Works at Existing Retaining Wall RW5Document47 paginiMethod Statement For Demolition & Modification Works at Existing Retaining Wall RW5Gary Lo75% (4)

- 1102 W Hik SWL Q08 395aDocument1 pagină1102 W Hik SWL Q08 395aGary LoÎncă nu există evaluări

- Location Plan: East RailDocument1 paginăLocation Plan: East RailGary LoÎncă nu există evaluări

- APP129Document10 paginiAPP129Gary LoÎncă nu există evaluări

- Method Statement of Pre Bored - 1102-ERFC-CM (SCLC) - FDN-000291Document3 paginiMethod Statement of Pre Bored - 1102-ERFC-CM (SCLC) - FDN-000291Gary LoÎncă nu există evaluări

- Zaxis 75Document2 paginiZaxis 75Gary Lo100% (1)

- Tree LayoutDocument1 paginăTree LayoutGary LoÎncă nu există evaluări

- Central Data Bank List For FixingDocument49 paginiCentral Data Bank List For FixingGary LoÎncă nu există evaluări

- Appendix - A Details of Temporary OHL Mast, Back-Tie Brackets & Protective FenceDocument6 paginiAppendix - A Details of Temporary OHL Mast, Back-Tie Brackets & Protective FenceGary LoÎncă nu există evaluări

- Instrumentation Installation Summary for Slope FR65Document1 paginăInstrumentation Installation Summary for Slope FR65Gary LoÎncă nu există evaluări

- RA-003-Risk Assessment For Installation of Temporary OHL Masts & Back-TiesDocument5 paginiRA-003-Risk Assessment For Installation of Temporary OHL Masts & Back-TiesGary LoÎncă nu există evaluări

- Details of TM3Document1 paginăDetails of TM3Gary LoÎncă nu există evaluări

- Instrumentation Installation Summary for Slope FR65Document1 paginăInstrumentation Installation Summary for Slope FR65Gary LoÎncă nu există evaluări

- Short Term Program - Pit by Pit (7sw-D-fr65)Document3 paginiShort Term Program - Pit by Pit (7sw-D-fr65)Gary LoÎncă nu există evaluări

- Instrumentation Installation Summary for Slope FR65Document1 paginăInstrumentation Installation Summary for Slope FR65Gary LoÎncă nu există evaluări

- URS Hong Kong LTD: Shatin To Central LinkDocument1 paginăURS Hong Kong LTD: Shatin To Central LinkGary LoÎncă nu există evaluări

- Method Statement For Excavating Additional 3m Deep Trial Pits (2013!08!13)Document16 paginiMethod Statement For Excavating Additional 3m Deep Trial Pits (2013!08!13)Gary Lo0% (2)

- Short Term Program For Temporary OHL Mast & Back TieDocument1 paginăShort Term Program For Temporary OHL Mast & Back TieGary LoÎncă nu există evaluări