Documente Academic

Documente Profesional

Documente Cultură

Araldite Epoxy Adhesive - 2

Încărcat de

SatyamEngDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Araldite Epoxy Adhesive - 2

Încărcat de

SatyamEngDrepturi de autor:

Formate disponibile

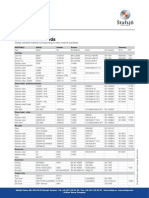

Lap shear strength versus heat ageing

Cure:16 hours/40C

Test: at 23C, 50% rh

As-made value

Adhesives and Tooling

20C / 5 years

Structural Adhesives

80C / 60 days

80C / 5 years

120C / 60 days

N/mm

10

15

20

25

30

AralditeAW106/HV953U

Two component epoxy paste adhesive

35

Lap shear strength versus tropical weathering (40/92, DIN 50015; typical average values)

Cure:16 hours/40C Lap shear strength was determined after immersion for 90 days at 23C in media shown.

Key properties

Tough and resiliant

As-made value

Good resistance to dynamic loading

After 30 days

Bonds a wide variety of materials in common use

After 60 days

After 90 days

N/mm

High shear and peel strength

Description

0

10

15

20

25

Araldite AW106/HV953U is a multipurpose, two component, room temperature curing, paste adhesive of high

strength and toughness.

30

It is suitable for bonding a wide variety of metals, ceramics, glass, rubber, rigid plastics and most other materials

in common use. It is a versatile adhesive for the craftsman as well as most industrial applications.

Fatigue test on simple lap joints (DIN 53285)

Cure: 20 minutes/100C Mean static lap shear strength: 16.3N/mm2

No. of load cycles to joint failure

Fluctuating load as % of static shear strength

30

20

15

Product data

105 - 106

106 - 107

> 107

AW106

HV953U

Colour (visual)

neutral

pale yellow

pale yellow

Specific gravity

ca. 1.15

ca. 0.95

ca. 1.05

Viscosity (Pas)

30-50

20-35

30-45

100 minutes

3 years

3 years

Pot Life (100 gm at 25C)

Storage

Araldite 2011/A and Araldite 2011/B may be stored for up to 3 years at room temperature provided the

Shelf life (2-40C)

mixed

components are stored in sealed containers. The expiry date is indicated on the label.

Handling

precautions

Processing

Caution

Pretreatment

Vantico products are generally quite harmless to handle provided that certain precautions normally taken when handling chemicals

The strength and durability of a bonded joint are dependant on proper treatment of the surfaces to be bonded.

are observed. The uncured materials must not, for instance, be allowed to come into contact with foodstuffs or food utensils, and

At the very least, joint surfaces should be cleaned with a good degreasing agent such as acetone,

measures should be taken to prevent the uncured materials from coming in contact with the skin, since people with particularly

trichloroethylene or proprietary degreasing agent in order to remove all traces of oil, grease and dirt.

sensitive skin may be affected. The wearing of impervious rubber or plastic gloves will normally be necessary; likewise the use of eye

Alcohol, gasoline (petrol) or paint thinners should never be used.

protection. The skin should be thoroughly cleansed at the end of each working period by washing with soap and warm water. The

The strongest and most durable joints are obtained by either mechanically abrading or chemically etching

use of solvents is to be avoided. Disposable paper - not cloth towels - should be used to dry the skin. Adequate ventilation of the

(pickling) the degreased surfaces. Abrading should be followed by a second degreasing treatment

working area is recommended. These precautions are described in greater detail in Vantico publication No. 24264/3/e Hygienic

Mix ratio

Parts by weight

Parts by volume

Araldite AW106

100

100

Araldite HV953U

80

100

precautions for handling plastics products of Vantico and in the Vantico Material Safety Data sheets for the individual products.

These publications are available on request and should be referred to for fuller information.

Resin and hardener should be blended until they form a homogeneous mix.

Resin and hardener are also available in cartridges incorporating mixers and can be applied as ready-to-use

adhesive with the aid of the tool recommended by Huntsman.

Vantico

Adhesives and Tooling

Duxford, Cambridge

England CB2 4QA

All recommendations for the use of our products, whether given by us in writing, verbally, or to be implied from the results of tests

carried out by us, are based on the current state of our knowledge. Notwithstanding any such recommendations the Buyer shall

remain responsible for satisfying himself that the products as supplied by us are suitable for his intended process or purpose. Since

we cannot control the application, use or processing of the products, we cannot accept responsibility therefor. The Buyer shall

ensure that the intended use of the products will not infringe any third partys intellectual property rights. We warrant that our

products are free from defects in accordance with and subject to our general conditions of supply.

Application of adhesive

The resin/hardener mix is applied with a spatula, to the pretreated and dry joint surfaces.

A layer of adhesive 0.05 to 0.10 mm thick will normally impart the greatest lap shear strength to the joint.

The joint components should be assembled and clamped as soon as the adhesive has been applied. An even

Vantico, 2000

Araldite is a registered trademark of Vantico AG, Basel Switzerland.

contact pressure throughout the joint area will ensure optimum cure.

Tel:+44(0)1223832121

Fax:+44(0) 1223 493322

www.vantico.com

August 2000

Publication No. A 230 e GB

Page 4 of 4

August 2000

Publication No. A 230 e GB

Page 1 of 4

Mechanical processing

Lap shear strength versus temperature (ISO 4587) (typical average values)

Specialist firms have developed metering, mixing and spreading equipment that enables the bulk processing of

Cure: (a) = 7 days /23C; (b) = 24 hours/23C + 30 minutes/80C

adhesive.

N/mm

40

Vantico will be pleased to advise customers on the choice of equipment for their particular needs.

Equipment maintenance

All tools should be cleaned with hot water and soap before adhesives residues have had time to cure. The

30

removal of cured residues is a difficult and time-consuming operation.

If solvents such as acetone are used for cleaning, operatives should take the appropriate precautions and, in

20

a

addition, avoid skin and eye contact.

10

Times to minimum shear strength

Temperature

Cure time to reach

LSS > 1N/mm

Cure time to reach

LSS > 10N/mm2

10

15

23

40

60

100

hours

24

12

minutes

30

hours

36

18

10

minutes

45

0

-60

-40

-20

Roller peel test (ISO 4578)

20

Cured 16 hours/40C

40

60

80

100

5 N/mm

Glass transition temperature Cure: 16 hours at 40C

ca. 45C

LSS = Lap shear strength.

Electrolytic corrosion (DIN 53489) (cure 16hrs at 40C or 20 mins at 100C)

Typical cured

properties

Unless otherwise stated, the figures given below were all determined by testing standard specimens made by

Test: 4 days in a conditioning chamber in 40/92 climate as specified by DIN 50015

lap-jointing 170 x 25 x 1.5 mm strips of aluminium alloy. The joint area was 12.5 x 25 mm in each case.

Rating according to specified standard

The figures were determined with typical production batches using standard testing methods. They are

Minimum dielectric strength at 50 Hz, 24C (VSM 77170)

provided solely as technical information and do not constitute a product specification.

Mix ratio

Instantaneous value

100:80 pbw

25-27 kV/mm

A -A/B 1,2

Water vapour permeability (NF 41001) (38C, 90% rh)

Average lap shear strengths of typical metal-to-metal joints (ISO 4587)

Cure: 5 days/23C

16g/m2/24 hours

Test on a 1mm thick film

Cured for 16 hours at 40C and tested at 23C

1-minute value

22-24 kV/mm

Water absorption (ISO 62-80)

Pretreatment - Sand blasting

Aluminium

24 hours at 23C

0.8%

30 mins at 100C

1.3%

Thermal conductivitiy (ISO 8894/90)

Steel 37/11

Cure: 20 minutes/100C

Test: At 23C

0.22W/mK

Shear modulus (DIN 53445)

Stainless steel V4A

-50C

Cure: 16 hours/40C

1.5GPa

Galvanised steel

0C

Copper

50C

0.2GPa

100C

7MPa

1.2GPa

Brass

N/mm

10

15

20

25

30

30 days

Average lap shear strengths of typical plastic-to-plastic joints (ISO 4587)

Cured for 16 hours at 23C and tested at 23C

60 days

90 days

Cure: 16 hour/40C

As-made value

Pretreatment - Lightly abrade and alcohol degrease.

IMS

SMC

Gasoline (petrol)

ABS

Ethyl acetate

Polycarbonate

Acetic acid, 10%

PVC

Xylene

Polyamide(nylon6)

Lubricating oil

N/mm

Degraded

Paraffin

10

Water at 23C

Water at 60C

Water at 90C

N/mm

August 2000

Publication No. A 230 e GB

Page 2 of 4

August 2000

Publication No. A 230 e GB

10

15

20

25

30

Page 3 of 4

Mechanical processing

Lap shear strength versus temperature (ISO 4587) (typical average values)

Specialist firms have developed metering, mixing and spreading equipment that enables the bulk processing of

Cure: (a) = 7 days /23C; (b) = 24 hours/23C + 30 minutes/80C

adhesive.

N/mm

40

Vantico will be pleased to advise customers on the choice of equipment for their particular needs.

Equipment maintenance

All tools should be cleaned with hot water and soap before adhesives residues have had time to cure. The

30

removal of cured residues is a difficult and time-consuming operation.

If solvents such as acetone are used for cleaning, operatives should take the appropriate precautions and, in

20

a

addition, avoid skin and eye contact.

10

Times to minimum shear strength

Temperature

Cure time to reach

LSS > 1N/mm

Cure time to reach

LSS > 10N/mm2

10

15

23

40

60

100

hours

24

12

minutes

30

hours

36

18

10

minutes

45

0

-60

-40

-20

Roller peel test (ISO 4578)

20

Cured 16 hours/40C

40

60

80

100

5 N/mm

Glass transition temperature Cure: 16 hours at 40C

ca. 45C

LSS = Lap shear strength.

Electrolytic corrosion (DIN 53489) (cure 16hrs at 40C or 20 mins at 100C)

Typical cured

properties

Unless otherwise stated, the figures given below were all determined by testing standard specimens made by

Test: 4 days in a conditioning chamber in 40/92 climate as specified by DIN 50015

lap-jointing 170 x 25 x 1.5 mm strips of aluminium alloy. The joint area was 12.5 x 25 mm in each case.

Rating according to specified standard

The figures were determined with typical production batches using standard testing methods. They are

Minimum dielectric strength at 50 Hz, 24C (VSM 77170)

provided solely as technical information and do not constitute a product specification.

Mix ratio

Instantaneous value

100:80 pbw

25-27 kV/mm

A -A/B 1,2

Water vapour permeability (NF 41001) (38C, 90% rh)

Average lap shear strengths of typical metal-to-metal joints (ISO 4587)

Cure: 5 days/23C

16g/m2/24 hours

Test on a 1mm thick film

Cured for 16 hours at 40C and tested at 23C

1-minute value

22-24 kV/mm

Water absorption (ISO 62-80)

Pretreatment - Sand blasting

Aluminium

24 hours at 23C

0.8%

30 mins at 100C

1.3%

Thermal conductivitiy (ISO 8894/90)

Steel 37/11

Cure: 20 minutes/100C

Test: At 23C

0.22W/mK

Shear modulus (DIN 53445)

Stainless steel V4A

-50C

Cure: 16 hours/40C

1.5GPa

Galvanised steel

0C

Copper

50C

0.2GPa

100C

7MPa

1.2GPa

Brass

N/mm

10

15

20

25

30

30 days

Average lap shear strengths of typical plastic-to-plastic joints (ISO 4587)

Cured for 16 hours at 23C and tested at 23C

60 days

90 days

Cure: 16 hour/40C

As-made value

Pretreatment - Lightly abrade and alcohol degrease.

IMS

SMC

Gasoline (petrol)

ABS

Ethyl acetate

Polycarbonate

Acetic acid, 10%

PVC

Xylene

Polyamide(nylon6)

Lubricating oil

N/mm

Degraded

Paraffin

10

Water at 23C

Water at 60C

Water at 90C

N/mm

August 2000

Publication No. A 230 e GB

Page 2 of 4

August 2000

Publication No. A 230 e GB

10

15

20

25

30

Page 3 of 4

Lap shear strength versus heat ageing

Cure:16 hours/40C

Test: at 23C, 50% rh

Adhesives and Tooling

As-made value

Structural Adhesives

20C / 5 years

80C / 60 days

80C / 5 years

120C / 60 days

N/mm

10

15

20

25

30

Araldite 2011 (AW 106/HV 953U)

Two component epoxy paste adhesive

35

Lap shear strength versus tropical weathering (40/92, DIN 50015; typical average values)

Cure:16 hours/40C Lap shear strength was determined after immersion for 90 days at 23C in media shown.

Key properties

Tough and resiliant

As-made value

Good resistance to dynamic loading

After 30 days

Bonds a wide variety of materials in common use

After 60 days

After 90 days

N/mm

High shear and peel strength

Description

0

10

15

20

25

Araldite 2011 is a multipurpose, two component, room temperature curing, paste adhesive of high strength and

toughness.

30

It is suitable for bonding a wide variety of metals, ceramics, glass, rubber, rigid plastics and most other materials

in common use. It is a versatile adhesive for the craftsman as well as most industrial applications.

Fatigue test on simple lap joints (DIN 53285)

Cure: 20 minutes/100C Mean static lap shear strength: 16.3N/mm2

No. of load cycles to joint failure

Fluctuating load as % of static shear strength

Product data

105 - 106

106 - 107

> 107

30

20

15

2011/A

2011/B

2011 (mixed)

Colour (visual)

neutral

pale yellow

pale yellow

Specific gravity

ca. 1.15

ca. 0.95

ca. 1.05

Viscosity (Pas)

30-50

20-35

30-45

100 minutes

3 years

3 years

Pot Life (100 gm at 25C)

Storage

Araldite AW106 and Araldite HV953U may be stored for up to 3 years at room temperature provided the

Shelf life (2-40C)

components are stored in sealed containers. The expiry date is indicated on the label.

Handling

precautions

Processing

Caution

Pretreatment

Araldite products are generally quite harmless to handle provided that certain precautions normally taken when handling chemicals

The strength and durability of a bonded joint are dependant on proper treatment of the surfaces to be bonded.

are observed. The uncured materials must not, for instance, be allowed to come into contact with foodstuffs or food utensils, and

At the very least, joint surfaces should be cleaned with a good degreasing agent such as acetone,

measures should be taken to prevent the uncured materials from coming in contact with the skin, since people with particularly

trichloroethylene or proprietary degreasing agent in order to remove all traces of oil, grease and dirt.

sensitive skin may be affected. The wearing of impervious rubber or plastic gloves will normally be necessary; likewise the use of eye

Alcohol, gasoline (petrol) or paint thinners should never be used.

protection. The skin should be thoroughly cleansed at the end of each working period by washing with soap and warm water. The

The strongest and most durable joints are obtained by either mechanically abrading or chemically etching

use of solvents is to be avoided. Disposable paper - not cloth towels - should be used to dry the skin. Adequate ventilation of the

(pickling) the degreased surfaces. Abrading should be followed by a second degreasing treatment

working area is recommended. These precautions are described in greater detail in Araldite publication No. 24264/3/ e Hygienic

Mix ratio

Parts by weight

Parts by volume

Araldite 2011/A

100

100

Araldite 2011/B

80

100

precautions for handling plastics products of Araldite and in the Araldite Material Safety Data sheets for the individual products.

These publications are available on request and should be referred to for fuller information.

Resin and hardener should be blended until they form a homogeneous mix.

Resin and hardener are also available in cartridges incorporating mixers and can be applied as ready-to-use

adhesive with the aid of the tool recommended by Vantico.

Araldite

All recommendations for the use of our products, whether given by us in writing, verbally, or to be implied from the results of tests

carried out by us, are based on the current state of our knowledge. Notwithstanding any such recommendations the Buyer shall

remain responsible for satisfying himself that the products as supplied by us are suitable for his intended process or purpose. Since

we cannot control the application, use or processing of the products, we cannot accept responsibility therefor. The Buyer shall

ensure that the intended use of the products will not infringe any third partys intellectual property rights. We warrant that our

products are free from defects in accordance with and subject to our general conditions of supply.

Application of adhesive

The resin/hardener mix is applied with a spatula, to the pretreated and dry joint surfaces.

A layer of adhesive 0.05 to 0.10 mm thick will normally impart the greatest lap shear strength to the joint.

The joint components should be assembled and clamped as soon as the adhesive has been applied. An even

Huntsman Advanced Materials

(Switzerland) GmbH

Klybeckstrasse 200

4057 Basel

Switzerland

Tel: +41 (0)61 966 33 33

Fax: +41 (0)61 966 35 19

www.huntsman.com/advanced_materials

August 2000

Publication No. A 230 e GB

contact pressure throughout the joint area will ensure optimum cure.

[Araldite 2011] is a registered trademark of Huntsman Corporation or an affiliate thereof.

Copyright 2007 Huntsman Corporation or an affiliate thereof. All rights reserved.

Page 4 of 4

August 2000

Publication No. A 230 e GB

Page 1 of 4

S-ar putea să vă placă și

- Determining Abrasion Resistance of Inks and Coatings On Substrates Using Dry or Wet Abrasive MediumDocument3 paginiDetermining Abrasion Resistance of Inks and Coatings On Substrates Using Dry or Wet Abrasive MediumwerrteÎncă nu există evaluări

- D 2574 - 97 Rdi1nzqtukveDocument4 paginiD 2574 - 97 Rdi1nzqtukveGuritno GustiantoÎncă nu există evaluări

- Trim Material Valve PlugDocument4 paginiTrim Material Valve Plugalexmontell100% (1)

- D4940 15 (Reapproved 2020) REDDocument3 paginiD4940 15 (Reapproved 2020) REDcarlos_k1555alejo100% (1)

- Sikaproof Membrane: Safety Data SheetDocument6 paginiSikaproof Membrane: Safety Data SheetSamuel CastilloÎncă nu există evaluări

- Design storage vessels and pressure equipmentDocument53 paginiDesign storage vessels and pressure equipmenthugo100% (2)

- Guidebook-1 Load Effects On StructuresDocument218 paginiGuidebook-1 Load Effects On Structuresaskro100% (4)

- Penguard Special: Technical Data SheetDocument5 paginiPenguard Special: Technical Data SheetajuhaseenÎncă nu există evaluări

- D2094-00 (2014) Standard Practice For Preparation of Bar and Rod Specimens For Adhesion TestsDocument4 paginiD2094-00 (2014) Standard Practice For Preparation of Bar and Rod Specimens For Adhesion Testsjose flores100% (1)

- 3 6077 RTVDocument2 pagini3 6077 RTVgkretroÎncă nu există evaluări

- Polymer Lab ManualDocument48 paginiPolymer Lab ManualShaukat AliÎncă nu există evaluări

- ASTM D 3023 - 98 Determination of Resistance of Factory-Applied Coatings On Wood Products To Stains and ReagentsDocument2 paginiASTM D 3023 - 98 Determination of Resistance of Factory-Applied Coatings On Wood Products To Stains and Reagentsalin2005Încă nu există evaluări

- Certificate of Analysis: National Institute of Standards & TechnologyDocument3 paginiCertificate of Analysis: National Institute of Standards & Technologylehdruk7100Încă nu există evaluări

- Astm E1558.24503Document13 paginiAstm E1558.24503Juan Shevchenko100% (1)

- Polythionic Acid Stress Corrosion CrackingDocument3 paginiPolythionic Acid Stress Corrosion Crackingvajidqc100% (1)

- Astm D-4214Document4 paginiAstm D-4214Ahmad RoyaniÎncă nu există evaluări

- D1414-22 9.02 Standard Test Methods For Rubber O-RingsDocument24 paginiD1414-22 9.02 Standard Test Methods For Rubber O-RingsHamidreza AraghianÎncă nu există evaluări

- Asme SB466Document9 paginiAsme SB466Stéphane LevasseurÎncă nu există evaluări

- Sspc-Pa2 PDFDocument13 paginiSspc-Pa2 PDFEdgarDavidDiazCamposÎncă nu există evaluări

- Cathodic Disbonding TesterDocument1 paginăCathodic Disbonding TesterfelavinÎncă nu există evaluări

- Astm d3330Document2 paginiAstm d3330Asep Achmad RamdhaniÎncă nu există evaluări

- Beginners Guide To CorrosionDocument10 paginiBeginners Guide To Corrosionshamu081Încă nu există evaluări

- Evaluate paint film cure with solvent rub testDocument3 paginiEvaluate paint film cure with solvent rub testNisa_nisheÎncă nu există evaluări

- Hi - Temp 900Document5 paginiHi - Temp 900bhavesh solankiÎncă nu există evaluări

- SUBJECT: Corrossion Problems Associated With Stainless Steel 4-1Document11 paginiSUBJECT: Corrossion Problems Associated With Stainless Steel 4-1Mufleh IdrisÎncă nu există evaluări

- Galvosil 15680 Data SheetDocument2 paginiGalvosil 15680 Data Sheetn00b1810Încă nu există evaluări

- Protective Coating and Lining Work For Power Generation FacilitiesDocument2 paginiProtective Coating and Lining Work For Power Generation FacilitiesLuizao CabeloÎncă nu există evaluări

- DC 781 Acetoxy SealantDocument3 paginiDC 781 Acetoxy SealantL.S.Încă nu există evaluări

- Astm D 3310 - 00Document2 paginiAstm D 3310 - 00phaindika100% (1)

- ASTM-3574-11 Flexible Cellular Materials-Slab, Bonded, and Molded Urethane FoamDocument29 paginiASTM-3574-11 Flexible Cellular Materials-Slab, Bonded, and Molded Urethane FoamheobukonÎncă nu există evaluări

- F 941 - 99 - RJK0MQ - PDFDocument3 paginiF 941 - 99 - RJK0MQ - PDFRománBarciaVazquezÎncă nu există evaluări

- ASTM D3299 Tanques Fabricados em Fibra de VidroDocument17 paginiASTM D3299 Tanques Fabricados em Fibra de VidroAugusto André100% (1)

- Data Sheet Proguard CN 200 A.SDocument3 paginiData Sheet Proguard CN 200 A.SAlexir Thatayaone NdovieÎncă nu există evaluări

- ASTM D4708 - 12 Purchased VersionDocument3 paginiASTM D4708 - 12 Purchased VersionnishanthÎncă nu există evaluări

- ASTM D 714 - 87 r00Document6 paginiASTM D 714 - 87 r00Abi PutraÎncă nu există evaluări

- Astm D6670-2018Document21 paginiAstm D6670-2018damaso taracenaÎncă nu există evaluări

- Aircraft and Support Equipment Polyurethane Coating SpecificationDocument24 paginiAircraft and Support Equipment Polyurethane Coating SpecificationmurphygtÎncă nu există evaluări

- Astm 4752Document8 paginiAstm 4752Martin ManriqueÎncă nu există evaluări

- Fenomastic Hygiene Emulsion SilkDocument4 paginiFenomastic Hygiene Emulsion Silkمحمد عزتÎncă nu există evaluări

- Preparation of Surfaces of Plastics Prior To Adhesive BondingDocument3 paginiPreparation of Surfaces of Plastics Prior To Adhesive BondingShaker QaidiÎncă nu există evaluări

- 11.03 Iso-6272-1-2011Document9 pagini11.03 Iso-6272-1-2011hoanvuÎncă nu există evaluări

- Auramix 350: High Performance PCE Based Super Plasti-Cizing Admixture - Retarding TypeDocument2 paginiAuramix 350: High Performance PCE Based Super Plasti-Cizing Admixture - Retarding TypeVipin Kumar Parashar100% (1)

- Section13 Spark TestingDocument3 paginiSection13 Spark TestingGustavoÎncă nu există evaluări

- Mar Resistance of Organic Coatings: Standard Test Method ForDocument3 paginiMar Resistance of Organic Coatings: Standard Test Method Formit uotÎncă nu există evaluări

- PTFEDocument1 paginăPTFEIkhsan LyÎncă nu există evaluări

- SSPC Guide 16 PDFDocument15 paginiSSPC Guide 16 PDFkishorekumar.animu100% (1)

- SP 18 Thoro Spot & Sweep 12-30-20Document7 paginiSP 18 Thoro Spot & Sweep 12-30-20Donzt Dontz FaujiÎncă nu există evaluări

- 68 25 Haze Gard I PDFDocument6 pagini68 25 Haze Gard I PDFshubhendra mishraaÎncă nu există evaluări

- A498Document13 paginiA498rgi178Încă nu există evaluări

- As NZS 1580.481.1.10-1998 Paints and Related Materials - Methods of Test Coatings - Exposed To Weathering - DDocument2 paginiAs NZS 1580.481.1.10-1998 Paints and Related Materials - Methods of Test Coatings - Exposed To Weathering - DSAI Global - APAC100% (1)

- NABL Assessor Training Course IntroDocument4 paginiNABL Assessor Training Course IntroRaghu Nagar100% (1)

- Din 50018 Sulfur Dioxide Corrosion TestDocument3 paginiDin 50018 Sulfur Dioxide Corrosion TestJoao Pedro Rendeiro Correia de SousaÎncă nu există evaluări

- Astm D4228 05R17Document3 paginiAstm D4228 05R17Johana Rivadeneira100% (1)

- Astm D3330-D3330M - 04 2010 PDFDocument6 paginiAstm D3330-D3330M - 04 2010 PDFdamaso taracenaÎncă nu există evaluări

- Hempadur Avantguard 750 1736g - Product DatasheetDocument2 paginiHempadur Avantguard 750 1736g - Product DatasheetWisnu Wardhana0% (1)

- SES Amercoat Dimetcote 9Document4 paginiSES Amercoat Dimetcote 9kamalkashÎncă nu există evaluări

- Paint For SteelDocument11 paginiPaint For SteelSaud PathiranaÎncă nu există evaluări

- Nondestructive Measurement of Dry Film Thickness of Applied Organic Coatings Using An Ultrasonic GageDocument4 paginiNondestructive Measurement of Dry Film Thickness of Applied Organic Coatings Using An Ultrasonic GageAdrian OrtizÎncă nu există evaluări

- Corrosion Failures: Theory, Case Studies, and SolutionsDe la EverandCorrosion Failures: Theory, Case Studies, and SolutionsÎncă nu există evaluări

- Industrial radiography A Complete Guide - 2019 EditionDe la EverandIndustrial radiography A Complete Guide - 2019 EditionÎncă nu există evaluări

- Painting Inspector: Passbooks Study GuideDe la EverandPainting Inspector: Passbooks Study GuideÎncă nu există evaluări

- Fittech Brochure Companion Flanges and FittingsDocument16 paginiFittech Brochure Companion Flanges and FittingsSatyamEngÎncă nu există evaluări

- Material Selection GuideDocument0 paginiMaterial Selection GuidebbmokshÎncă nu există evaluări

- Welding Rod For c5 & f5 - Er 80s-b6Document1 paginăWelding Rod For c5 & f5 - Er 80s-b6SatyamEngÎncă nu există evaluări

- Stainless Steel Grade Comparision System Diagram of Stainless Steel - Corrosion &heat Resistance Strength, Machinability WiseDocument1 paginăStainless Steel Grade Comparision System Diagram of Stainless Steel - Corrosion &heat Resistance Strength, Machinability WiseSatyamEngÎncă nu există evaluări

- Adjustable Floating ReamersDocument1 paginăAdjustable Floating ReamersSatyamEngÎncă nu există evaluări

- Conversion Factors, Pressure Conversion, Pressure Equivalents, Unit of Vaccum, Unit of FlowDocument3 paginiConversion Factors, Pressure Conversion, Pressure Equivalents, Unit of Vaccum, Unit of FlowSatyamEngÎncă nu există evaluări

- Tank Linings Resistance GuideDocument7 paginiTank Linings Resistance Guideenrico100% (1)

- Equivalencia de MaterialesDocument1 paginăEquivalencia de MaterialesHelden Jasmani100% (1)

- TorcUP Rebirth Bolting IndustryDocument4 paginiTorcUP Rebirth Bolting IndustrySatyamEngÎncă nu există evaluări

- GEE ElectrodeDocument17 paginiGEE ElectrodeSatyamEngÎncă nu există evaluări

- Cast Iron Pressure Temperature RatingDocument1 paginăCast Iron Pressure Temperature RatingSatyamEngÎncă nu există evaluări

- 3M Abrasives - Catalogue For AutoComponents PDFDocument48 pagini3M Abrasives - Catalogue For AutoComponents PDFSatyamEngÎncă nu există evaluări

- Asco Direct Acting Solenoid Valve - 320Document6 paginiAsco Direct Acting Solenoid Valve - 320SatyamEng100% (1)

- Parker O-Ring Material Guide-2008Document72 paginiParker O-Ring Material Guide-2008Ian Pillay50% (2)

- MechIndia Burnishing ToolsDocument4 paginiMechIndia Burnishing ToolsSatyamEngÎncă nu există evaluări

- Weartech Electrode Stellite Cobalt NickleDocument1 paginăWeartech Electrode Stellite Cobalt NickleSatyamEngÎncă nu există evaluări

- Surface Roughness Tester Page 1Document1 paginăSurface Roughness Tester Page 1SatyamEngÎncă nu există evaluări

- ENERPAC 00682GB - LPwrenchDocument4 paginiENERPAC 00682GB - LPwrenchSatyamEngÎncă nu există evaluări

- Enerpac NC E324Document1 paginăEnerpac NC E324SatyamEngÎncă nu există evaluări

- Equivalent Materials Grade DIN ASTM BS GOSTDocument4 paginiEquivalent Materials Grade DIN ASTM BS GOSTSatyamEngÎncă nu există evaluări

- Hindstan Nylons - Ptfe CatalogueDocument11 paginiHindstan Nylons - Ptfe CatalogueSatyamEngÎncă nu există evaluări

- Tank Linings Resistance GuideDocument7 paginiTank Linings Resistance Guideenrico100% (1)

- Enerpac NC E324Document1 paginăEnerpac NC E324SatyamEngÎncă nu există evaluări

- Material standards cross reference guideDocument2 paginiMaterial standards cross reference guideSatyamEng80% (5)

- Enerpac HXD - E324Document2 paginiEnerpac HXD - E324SatyamEngÎncă nu există evaluări

- Material Conversion TableDocument5 paginiMaterial Conversion TableMilin DesaiÎncă nu există evaluări

- Casting Grade Wise Welding Electrode Grade and MakeDocument1 paginăCasting Grade Wise Welding Electrode Grade and MakeSatyamEngÎncă nu există evaluări

- TorcUP Rebirth Bolting IndustryDocument4 paginiTorcUP Rebirth Bolting IndustrySatyamEngÎncă nu există evaluări

- Conversion Factors, Pressure Conversion, Pressure Equivalents, Unit of Vaccum, Unit of FlowDocument3 paginiConversion Factors, Pressure Conversion, Pressure Equivalents, Unit of Vaccum, Unit of FlowSatyamEngÎncă nu există evaluări

- Ac 25-307-1Document10 paginiAc 25-307-1Candace FrankÎncă nu există evaluări

- Construction Project AssignmentDocument61 paginiConstruction Project AssignmentJashimkolyeÎncă nu există evaluări

- WWW - Universityquestions.in: Department of Civil Subject Code: Ce6015 Year: Iv Subject Name: Tall Buildings Sem: ViiiDocument11 paginiWWW - Universityquestions.in: Department of Civil Subject Code: Ce6015 Year: Iv Subject Name: Tall Buildings Sem: ViiisrieeÎncă nu există evaluări

- Ijert Ijert: Analysis & Design of Fire Damage StructureDocument6 paginiIjert Ijert: Analysis & Design of Fire Damage StructureAmar WadoodÎncă nu există evaluări

- Structural Design Data MatrixDocument1 paginăStructural Design Data MatrixselinaÎncă nu există evaluări

- S 000 1310 0001 - 1 - 0010Document47 paginiS 000 1310 0001 - 1 - 0010mikedavd1Încă nu există evaluări

- ASCE 7 load combinations and load factorsDocument7 paginiASCE 7 load combinations and load factorsTake NoriÎncă nu există evaluări

- Master Thesis Report Ivar BoomDocument320 paginiMaster Thesis Report Ivar BoomNuno Telmo LopesÎncă nu există evaluări

- Design Forces For Shaft Supports of Elevated Water TanksDocument10 paginiDesign Forces For Shaft Supports of Elevated Water TanksIrfan MughalÎncă nu există evaluări

- Building Drifts in ETABSDocument16 paginiBuilding Drifts in ETABSJaime Manalili Landingin100% (1)

- Assessment of Existing Structures Using Cyclic Load TestingDocument7 paginiAssessment of Existing Structures Using Cyclic Load TestingProfessor Dr. Nabeel Al-Bayati-Consultant EngineerÎncă nu există evaluări

- Cipl MJB 1+055.734 DGN 001Document206 paginiCipl MJB 1+055.734 DGN 001rao shoaibÎncă nu există evaluări

- Improving The Safety of Steel BridgesDocument183 paginiImproving The Safety of Steel BridgescarloarchivioÎncă nu există evaluări

- Piperack PresentationDocument23 paginiPiperack PresentationOmar AlkubaiciÎncă nu există evaluări

- DSL Car InspectionDocument78 paginiDSL Car InspectionJanardan RamekarÎncă nu există evaluări

- Stresses in Rigid PavementsDocument84 paginiStresses in Rigid PavementsCharl de Reuck100% (1)

- 153 WuDocument13 pagini153 WuMarino DugaroÎncă nu există evaluări

- Engineered System Failure AnalysisDocument68 paginiEngineered System Failure AnalysisAdimasu AyeleÎncă nu există evaluări

- ZPurlinR1 OdsDocument21 paginiZPurlinR1 OdsRamachandra SahuÎncă nu există evaluări

- Iso 834 1975Document11 paginiIso 834 1975amadeumfldantasÎncă nu există evaluări

- Seismic Design of Steel StructuresDocument55 paginiSeismic Design of Steel StructuresAndrea LitzÎncă nu există evaluări

- Cascade Failure Analysis of Transmision Line TowerDocument114 paginiCascade Failure Analysis of Transmision Line Towertanujaayer100% (1)

- Nonrepetitive static plate load test procedureDocument10 paginiNonrepetitive static plate load test procedurecenkunal100% (2)

- Wind Design Standard For Edge Systems Used With Low Slope Roofing SystemsDocument27 paginiWind Design Standard For Edge Systems Used With Low Slope Roofing SystemsAl-Ibnu Mas'udÎncă nu există evaluări

- Analysis and Design of Multi Storied Building by Using Etabs SoftwareDocument5 paginiAnalysis and Design of Multi Storied Building by Using Etabs SoftwareAnonymous jiV5nJÎncă nu există evaluări

- CIGA-NG180100021-CGSA1-CX4019-000046-Elevated Water Tank Steel Structural Stand Design ReportDocument13 paginiCIGA-NG180100021-CGSA1-CX4019-000046-Elevated Water Tank Steel Structural Stand Design ReportMathias OnosemuodeÎncă nu există evaluări

- (DR Naik) RCC 1 UpdatedDocument229 pagini(DR Naik) RCC 1 UpdatedMohammad AliÎncă nu există evaluări