Documente Academic

Documente Profesional

Documente Cultură

Brochure e

Încărcat de

Francois-Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Brochure e

Încărcat de

Francois-Drepturi de autor:

Formate disponibile

Lightweight Solutions in Concrete

lightweight

biaxial strength

long span

time saving

no beams

sustainable

cost effective

flexible layouts

its in the air

its in the air

The company group Cobiax Technologies, with Headquarters in Zug, Switzerland and its European subsidiaries, formerly known as BubbleDeck, founded

in 1997 has become the specialist of lightweight biaxial flat slabs in reinforced concrete.

The latest development, the cobiax lightweight flat slab, (patent pending) with its modular and flexible features, improves application of the techno- logy

and also economy.

Add value to your building and your construction process by using cobiax lightweight flat slab instead of traditional concrete solid slab and other lightweight slabs. Introducing the technology early in the design process yields the most benefits.

The Idea:

How does a bird fly?

Cobiax flat slab

Between upper and lower reinforcement rebar cages

with hollow plastic spheres of recycled polyethylene

An essential feature to being able to fly is in the struc- displace concrete that has no structural benefit. The

ture of its bones. Birds bones have evolved to a high- result is a floor that weighs up to 35% less than an

ly efficient structure. A hard shell and struts formed equivalent solid floor. This can lead to substantial

by multiple cavities, appropriately located give the savings in weight and materials on the building as a

bone a stability equivalent to solid bones. The result whole. When integrated into the whole structural

is efficient structure that has less mass and requires frame solution Cobiax delivers many benefits and

fewer resources to lift. Its in the air. A bird flies.

saves money.

Design principles:

Remove the non working dead load, maintain biaxial

strength. In concrete, realise a hard shell with struts

through the use of appropriately located cavities formed by hollow spheres.

Value chain of Cobiax

Break into a new dimension of structural options. You can realise a multitude of improvements to building

concepts and sustainability.

Substantially improved

lifecycle costs and ecology

Yields

Added value

Benefits

Flexible layouts

Open plan,

wide spans without

beams

Economy

Up to 50% weight

reduction, savings

in materials and

transport, reduction

in CO2 emissions

Ecology

A biaxial design

assures

all benefits

of a solid slab

Time

saving

Increased

usage and easy

change of use

performance

Biaxial

Longer Span no beams

Weight savings - fewer supports

high earthquake resistance

Your benefit - the optimum use of cobiax Big5

Retrofit, change of use

Big5

Reduction in

construction time

Actual benefit in % savings when compared to solid flat slab

Concrete in floors

32 %

Floor reinforcing steel

20 %

Concrete in foundation

20 %

Columns

40 %

Beams and Joists

Deck construction time

100 %

35 %

Passiro Meran, BD Italy

Larger grids, half the columns, no beams or joists

Frankfort Niederrad, BD Germany

Additional level of car park, 1,150 m2

Additional space

Cobiax

Designed with beams

Frankfort Niederrad, BD Germany

performance

Change of use - Only possible through considerable weight reduction

ROOF

TERRACE

Red: Existing

Blue: New Build

Steigerwald Gerolzhofen, BD Germany

Cobiax Big5 optimises 34000 m2 slab surface

Mainova Frankfort, Germany

Sandbanks Poole/Dorset, BD UK

Bridging long spans without beams, carrying large load with slim

columns because of cobiax system.

Travel Europe Stans, BD Austria

options

In modular, flexible production options

Cage Module

cobiax CBCM

Linked Cage Module

cobiax CBLM

Semi-Precast

cobiax CBSP

Precast Element

cobiax CBPE

The delivery options can suit the construction requirements.

The cage module and linked cage modul are suitable for in situ applications with traditional formwork as well as for delivery to industrial production facilities. The semi-precast and precast modules are for delivery to site where the benefits of speed of construction

and economy of equipment requiremensts can be realised.

Concrete quantity [m3/m2]

cobiax versus solid flat slab

Spans [m] with the same imposed load and concrete volume

0.5

d = deck thickness

dia.= sphere diameter

0.4

d 58.0 cm / dia. 45.0 cm

d 52.0 cm / dia. 40.5 cm

d 45.0 cm / dia. 36.0 cm

0.3

d 40.0 cm / dia. 31.5 cm

d 34.0 cm / dia. 27.0 cm

0.2

d 28.0 cm / dia. 22.5 cm

d 23.0 cm / dia. 18.0 cm

0.1

10

11

12

13

14

15

16

17

18

Spans [m] with the same slab thickness

d = deck thickness

dia. = sphere diameter

22

20

A d 23.0 cm / dia. 18.0 cm

Loads [kN/m2]

18

16

B d 40.0 cm / dia. 31.5 cm

14

12

C d 58.0 cm / dia. 45.0 cm

10

8

6

4

2

4

Post tensioning

10

11

12

13

14

15

16

17

18

19

20

21

Installation guide

Cobiax can be adapted to any layout. The

arrangement of the spheres and the size and

shape of the panel are determined by the

project requirements. Cobiax can be used

with other building techniques such as post

tensioning and composite structures.

Concrete grade and bulk density can be specified to suit the project requirements.

Interfaces and installation details are similar

to traditional concrete details.

economic and sustainable

The overall evaluation of buildings with cobiax flat slabs leads to decisive yield for the owner.

Energy saving

Reduction of transport

CO2 reduction by saving on concrete

Spheres in recycled HDPE

Thermal mass

Earthquake resistance

Faade surface

Fire safety

Shoring props

Columns

Beams

Installation

Removal

Environmental aspects

Alternative use

Flexibility of layout

Usage

Construction time

Load-bearing walls

Concrete and Steel

Foundation

Economic savings potential

Tamping

Type of building

Detached house

Apartment Building

Multi-storey car park

Retail / Industrial

Administration / School / Museum

Hospital / Hotel

Office and high-rise building

Tunnel building

The resource effectiveness leads to R.I.O. Innovation Award 2003

Cobiax reduces cost but at the same time makes a major contribution to the environment in concrete where

its most important. Cement manufacture is the largest single producer of CO2 emissions worldwide. Cement

manufacture is responsible for around 7% of CO2 emission.

Current goals for sustainable development and reduction of CO2 can be effectively met by using cobiax.

Cobiax is ideally suited for initial use but also offers flexibility for reuse

Long span flat deck layouts provide design flexibility for initial use as well as flexibility for change to suit future use. By comparison solid deck is restricted by too much deflection. Till now longer spans could only be achieved with post tensioning or the use of beams. This has been associated with high design and construction costs.

The cobiax lightweight flat slab is a less expensive alternative to achieve deflection criteria in long span applications. Cobiax also permits more flexibility for the use of the building both in the horizontal as well as the

vertical.

Space is an

irreplaceable

resource!

rice

P

s

e

l

a

S

Rent

Space

asure

e

m

o

t

e

d

a

M

flat slab technology

Performance of the Cobiax Group:

Frame Contractors for cobiax lightweight concrete slabs

- Added value consulting for owners, architects, engineers and construction companies

- Design and detailing of the deck structure

- Just-in-time delivery of cobiax modules

Technology consulting and sales of cobiax range

International marketing services and licensing business

Quality management System cobiax QLL 06/2004

Lightweight flat slab technology development

Most benefit is realised when the cobiax technology is incorporated in the

design at an early stage. Cobiax assists

designers to achieve greatest return on

the use of the product.

With this assistance engineers can independently calculate the floor stress analysis incorporating the advantages of

using cobiax technology. Cobiax is a

solutions driven product. Cobiax can

assist the client throughout the project

process to achieve superior buildings

using the most up to date construction

techniques.

Cobiax Your partner

cobiax your partner

HEADQUARTERS:

Switzerland & Cobiax Technologies AG

International Postfach 140

Oberallmendstrasse 20A

CH-6301 Zug

Phone +41 41 767 00 00

Fax +41 41 767 00 09

info@cobiax.com

www.cobiax.com

United Kingdom Cobiax Technologies Ltd

Studio 4

The Cooperage

91 Brick Lane

GB-London E1 6QL

Phone +44 20 7877 8575

Fax +44 20 7375 2759

info.uk@cobiax.com

www.cobiax.com

Germany Cobiax Technologies GmbH

Heidelberger Strasse 6-8

D-64283 Darmstadt

Phone +49 6151 918 16 00

Fax +49 6151 918 16 22

info.germany@cobiax.com

www.cobiax.com

Austria Cobiax Technologies GmbH

Rotenturmstrasse 27/5

A-1010 Wien

CB 11/04 Cobiax Trade Mark is registered and patent pending. All rights reserved.

Phone +43 1 533 75 82

Fax +43 1 533 26 03

flexible layouts

info.austria@cobiax.com

www.cobiax.com

Italy Cobiax Technologies s.r.l.

Via Julius Durst 6/B

I-39042 Bressanone

Phone +39 0472 83 04 04

Fax +39 0472 20 74 26

info.italy@cobiax.com

www.cobiax.com

its in the air

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Samtech 200 Epoxy Grout: Three Component Rapid Cure High Strength Epoxy GroutDocument3 paginiSamtech 200 Epoxy Grout: Three Component Rapid Cure High Strength Epoxy GroutFrancois-Încă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Masterflow 410 PCDocument3 paginiMasterflow 410 PCFrancois-Încă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Standard Grout PDFDocument3 paginiStandard Grout PDFFrancois-Încă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Ferroflow 939: Iron Fortified Shrinkage Compensated GroutDocument2 paginiFerroflow 939: Iron Fortified Shrinkage Compensated GroutFrancois-Încă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- FlowcableDocument4 paginiFlowcableFrancois-Încă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- MEYCO MP320 Questions & Answers PDFDocument12 paginiMEYCO MP320 Questions & Answers PDFFrancois-Încă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Ferromortar 707: Iron Fortified Non-Shrink Grout For Dry-Pack To Pourable InstallationDocument2 paginiFerromortar 707: Iron Fortified Non-Shrink Grout For Dry-Pack To Pourable InstallationFrancois-Încă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Meyco FIB 500 PDFDocument2 paginiMeyco FIB 500 PDFFrancois-Încă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Masterflow 400: High Strength, Free Flowing Epoxy GroutDocument2 paginiMasterflow 400: High Strength, Free Flowing Epoxy GroutFrancois-Încă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Meyco MP308 PDFDocument3 paginiMeyco MP308 PDFFrancois-Încă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- MEYCO MP 367 Foam PDFDocument2 paginiMEYCO MP 367 Foam PDFFrancois-Încă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Meyco MP 357 GS PDFDocument2 paginiMeyco MP 357 GS PDFFrancois-Încă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Meyco MP302 PDFDocument3 paginiMeyco MP302 PDFFrancois-Încă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Meyco Fix Lube 1 PDFDocument2 paginiMeyco Fix Lube 1 PDFFrancois-Încă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- MEYCO MP 364 Flex PDFDocument2 paginiMEYCO MP 364 Flex PDFFrancois-Încă nu există evaluări

- Method Statement - Masterseal 345 REV D PDFDocument17 paginiMethod Statement - Masterseal 345 REV D PDFFrancois-Încă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Meyco MP 301 PDFDocument2 paginiMeyco MP 301 PDFFrancois-Încă nu există evaluări

- Primer SC PDFDocument3 paginiPrimer SC PDFFrancois-Încă nu există evaluări

- RheoFIT 761 PDFDocument2 paginiRheoFIT 761 PDFFrancois-Încă nu există evaluări

- Rheocrete 222+: Organic Corrosion Inhibiting AdmixtureDocument3 paginiRheocrete 222+: Organic Corrosion Inhibiting AdmixtureFrancois-Încă nu există evaluări

- Protectosil CIT PDFDocument3 paginiProtectosil CIT PDFFrancois-Încă nu există evaluări

- Pozzolith 390N PDFDocument2 paginiPozzolith 390N PDFFrancois-Încă nu există evaluări

- Meyco MP355 1K - TDS - 07 - PDFDocument2 paginiMeyco MP355 1K - TDS - 07 - PDFFrancois-Încă nu există evaluări

- Meyco FIB 600 PDFDocument2 paginiMeyco FIB 600 PDFFrancois-Încă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Pozzolith 555: Non-Chloride Accelerating AdmixtureDocument3 paginiPozzolith 555: Non-Chloride Accelerating AdmixtureFrancois-Încă nu există evaluări

- Primer TC PDFDocument3 paginiPrimer TC PDFFrancois-Încă nu există evaluări

- Pozzolith CRP4+: High Performance Retarding Plasticiser For ConcreteDocument2 paginiPozzolith CRP4+: High Performance Retarding Plasticiser For ConcreteFrancois-Încă nu există evaluări

- Pozzolith 600R PDFDocument2 paginiPozzolith 600R PDFFrancois-Încă nu există evaluări

- Pozzolith LD20: Water-Reducing, Plasticiser / Retarder For ConcreteDocument2 paginiPozzolith LD20: Water-Reducing, Plasticiser / Retarder For ConcreteFrancois-Încă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Rheofinish 303: High Performance Chemical and Physical Mould Release Agents DescriptionDocument1 paginăRheofinish 303: High Performance Chemical and Physical Mould Release Agents DescriptionFrancois-Încă nu există evaluări

- Fiscal Deficit UPSCDocument3 paginiFiscal Deficit UPSCSubbareddyÎncă nu există evaluări

- DX210WDocument13 paginiDX210WScanner Camiones CáceresÎncă nu există evaluări

- RM AllowanceDocument2 paginiRM AllowancekapsicumadÎncă nu există evaluări

- Bahasa Inggris IIDocument15 paginiBahasa Inggris IIMuhammad Hasby AsshiddiqyÎncă nu există evaluări

- Strategic Planning For The Oil and Gas IDocument17 paginiStrategic Planning For The Oil and Gas ISR Rao50% (2)

- BCG Executive Perspectives CEOs DilemmaDocument30 paginiBCG Executive Perspectives CEOs DilemmaageÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- VENDOR TBE RESPONSE OF HELIMESH FROM HELITECNICA (Update 11-2)Document1 paginăVENDOR TBE RESPONSE OF HELIMESH FROM HELITECNICA (Update 11-2)Riandi HartartoÎncă nu există evaluări

- Buku Petunjuk Tata Cara Berlalu Lintas Highwaycode Di IndonesiaDocument17 paginiBuku Petunjuk Tata Cara Berlalu Lintas Highwaycode Di IndonesiadianÎncă nu există evaluări

- Request BADACODocument1 paginăRequest BADACOJoseph HernandezÎncă nu există evaluări

- 2023 DPWH Standard List of Pay Items Volume II DO 6 s2023Document103 pagini2023 DPWH Standard List of Pay Items Volume II DO 6 s2023Alaiza Mae Gumba100% (1)

- Jay Chou Medley (周杰伦小提琴串烧) Arranged by XJ ViolinDocument2 paginiJay Chou Medley (周杰伦小提琴串烧) Arranged by XJ ViolinAsh Zaiver OdavarÎncă nu există evaluări

- BNI Mobile Banking: Histori TransaksiDocument1 paginăBNI Mobile Banking: Histori TransaksiWebi SuprayogiÎncă nu există evaluări

- © 2015 Mcgraw-Hill Education Garrison, Noreen, Brewer, Cheng & YuenDocument62 pagini© 2015 Mcgraw-Hill Education Garrison, Noreen, Brewer, Cheng & YuenHIỀN LÊ THỊÎncă nu există evaluări

- Pune HNIDocument9 paginiPune HNIAvik Sarkar0% (1)

- Financial Astrology by Mahendra SharmaDocument9 paginiFinancial Astrology by Mahendra SharmaMahendra Prophecy33% (3)

- Modified Jominy Test For Determining The Critical Cooling Rate For Intercritically Annealed Dual Phase SteelsDocument18 paginiModified Jominy Test For Determining The Critical Cooling Rate For Intercritically Annealed Dual Phase Steelsbmcpitt0% (1)

- Patent Trolling in IndiaDocument3 paginiPatent Trolling in IndiaM VridhiÎncă nu există evaluări

- Trade Confirmation: Pt. Danareksa SekuritasDocument1 paginăTrade Confirmation: Pt. Danareksa SekuritashendricÎncă nu există evaluări

- GST Rate-: Type of Vehicle GST Rate Compensation Cess Total Tax PayableDocument3 paginiGST Rate-: Type of Vehicle GST Rate Compensation Cess Total Tax PayableAryanÎncă nu există evaluări

- Pandit Automotive Pvt. Ltd.Document6 paginiPandit Automotive Pvt. Ltd.JudicialÎncă nu există evaluări

- Oil Opportunities in SudanDocument16 paginiOil Opportunities in SudanEssam Eldin Metwally AhmedÎncă nu există evaluări

- Latihan Soal PT CahayaDocument20 paginiLatihan Soal PT CahayaAisyah Sakinah PutriÎncă nu există evaluări

- HPAS Prelims 2019 Test Series Free Mock Test PDFDocument39 paginiHPAS Prelims 2019 Test Series Free Mock Test PDFAditya ThakurÎncă nu există evaluări

- Accra Resilience Strategy DocumentDocument63 paginiAccra Resilience Strategy DocumentKweku Zurek100% (1)

- Indian Contract ActDocument8 paginiIndian Contract ActManish SinghÎncă nu există evaluări

- Ethical Game MonetizationDocument4 paginiEthical Game MonetizationCasandra EdwardsÎncă nu există evaluări

- PDC Yanque FinalDocument106 paginiPDC Yanque FinalNilo Cruz Cuentas100% (3)

- Globalization #1 PDFDocument2 paginiGlobalization #1 PDFSuzette Hermoso100% (4)

- Top Form 10 KM 2014 ResultsDocument60 paginiTop Form 10 KM 2014 ResultsabstickleÎncă nu există evaluări

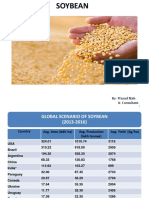

- Soybean Scenario - LaturDocument18 paginiSoybean Scenario - LaturPrasad NaleÎncă nu există evaluări

- The Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterDe la EverandThe Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterEvaluare: 4 din 5 stele4/5 (467)

- How to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingDe la EverandHow to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingEvaluare: 4.5 din 5 stele4.5/5 (847)

- Clean Mama's Guide to a Healthy Home: The Simple, Room-by-Room Plan for a Natural HomeDe la EverandClean Mama's Guide to a Healthy Home: The Simple, Room-by-Room Plan for a Natural HomeEvaluare: 5 din 5 stele5/5 (2)

- Simplified Organization: Learn to Love What Must Be DoneDe la EverandSimplified Organization: Learn to Love What Must Be DoneÎncă nu există evaluări

- Process Plant Equipment: Operation, Control, and ReliabilityDe la EverandProcess Plant Equipment: Operation, Control, and ReliabilityEvaluare: 5 din 5 stele5/5 (1)

- Summary of Goodbye, Things: The New Japanese Minimalism by Fumio SasakiDe la EverandSummary of Goodbye, Things: The New Japanese Minimalism by Fumio SasakiEvaluare: 4.5 din 5 stele4.5/5 (5)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresDe la EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresEvaluare: 1 din 5 stele1/5 (2)

- The Martha Manual: How to Do (Almost) EverythingDe la EverandThe Martha Manual: How to Do (Almost) EverythingEvaluare: 4 din 5 stele4/5 (11)