Documente Academic

Documente Profesional

Documente Cultură

Pad-Eye Main

Încărcat de

Pradeep ChitluriTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Pad-Eye Main

Încărcat de

Pradeep ChitluriDrepturi de autor:

Formate disponibile

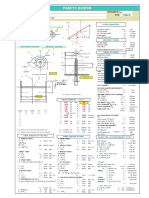

PAD EYE ATTACHED TO LCB

pg 1 of 8

Design of Pad-Eye

Load:

Static Sling Load:

S 182.3 tonnef 1787.75 kN

Dynamic Amplification Factor

DAF 1.62

Dynamic Load

P S DAF 2896.16 kN

Sling Angle with horizontal

90deg

Sling angle with horizontal in

out of plane of pad-eye

0deg

Sling Properties:

Sling Type Used: KTL - 6.6in Hand Spliced

d sling 6.6 in

Sling Dia

Shackle Properties:

Shackle Type: CROSBY G2160 - 200t

Load Capacity

Pshackle 200tonnef

Inside Length of Shackle

C 18.90 in 48.006 cm

Jaw width

A 5.91 in 15.011 cm

Pin Diameter

d pin 4.12 in 10.465 cm

Pad-Eye Dimensions

Yield Stress of Pad-Eye Plates

Fy 355MPa

Minimum diameter of hole required:

d holemin

max d pin 4mm 1.03 d pin

max d pin 2mm 1.03 d pin

if d pin 50mm

108.648 mm

otherwise

Maximum diameter of hole permitted

d holemax min d pin 6mm d pin 1.06 110.648 mm

Diameter of Hole

d hole 109mm

Minimum Radius of Pad-Eye Main Plate required:

Rmin max 1.5 d hole d hole 3in 185.2 mm

PAD EYE ATTACHED TO LCB

pg 2 of 8

Radius of Main Plate

R 200mm

Thickness of Main Plate

tm 50mm

tc 0.5 tm 25 mm

Maximum of thickness of cheek plate permitted

Radius of Cheek Plate-1

rc1 150mm

Radius of Cheek Plate-2

rc2 100mm

Thickness of cheek plate-1

tc1 30mm

Thickness of cheek plate-2

tc2 10mm

Pad_Eye Dimensions Check

Pad-Eye thickness to jaw width ratio

"O.K" if

tm 2. tc1 2tc2

A

0.8

"O.K"

"Not O.K" otherwise

Shackle Inside Length Clearance

d hole

Clength C R

d sling 166.92 mm

"O.K" if Clength 6mm "O.K"

"Clash" otherwise

Minimum clearance recommended to avoid sling ovalisation:

1.25 d sling 25mm 234.55 mm

Shackle Inside Width Clearance

Cwidth A tm 2tc1 2tc2 20.114 mm

"O.K" if Cwidth 5mm "O.K"

"Not O.K" otherwise

PAD EYE ATTACHED TO LCB

pg 3 of 8

Shackle Derating

If pad-eye thickness is less than 0.8 times the jaw width the shackle has to be derated

as below:

0

0.8

0.5

1.0

Derating factor, f1

f1

1.0 if

tm 2. tc1 2tc2

linterp x y

0.8

tm 2. tc1 2tc2

A

otherwise

If lateral loads acting on pad-eye the shackle capacity has to be derated as below:

0

x 45

90

Derating factor

1.0

y 0.7

0.5

f2 linterp( x y ) 1

Shackle capacity check after derating

"O.K" if f1 f2 Pshackle S "O.K"

"Not O.K" otherwise

PAD EYE ATTACHED TO LCB

pg 4 of 8

Pad Eye Strength Check

Pv P sin( ) 2896.16 kN

Vertical Sling Force

Horizontal Sling Force Inplane of Pad-eye

Pinplane P cos( ) cos( ) 0 kN

Horizontal Sling Force out ofplane of Pad-eye

Pout_plane max P sin( ) cos( ) 0.05 P 144.81 kN

Shear stress at section -

Area 2 R

Shear Stress

d hole

2

tm rc1

2tc1 26010.00 mm

2

2

d hole

P

shear

111.348 MPa

Area

Allowable Shear Stress

shearallow 0.40 Fy 142 MPa

shear

UCshear

0.784

shearallow

Tear stress at section -

Area

2 R d hole tm 2 rc1 d hole 2tc1 26010.00 mm

Tear Stress

P

tear

111.348 MPa

Area

Allowable Tear Stress

tearallow 0.45 Fy 159.75 MPa

tear

UCtear

0.697

tearallow

Tensile Stress at section -

2

Area 2 R tm 20000 mm

PAD EYE ATTACHED TO LCB

pg 5 of 8

Tensile Stress

Area

144.808 MPa

Allowable Tensile Stress allow 0.6 Fy 213 MPa

UCten

0.68

allow

Bearing Stress at Pad-Eye-Pin Contact

Conventional:

Areabearing

d hole

Bearing Stress

2

tm 2 tc1 2 tc2 14838.79 mm

P

bear

195.175 MPa

Areabearing

Allowable Bearing Stress

bearallow 0.9 Fy 319.5 MPa

bear

UCbear

0.611

bearallow

Hertz's Formula:

d hole d pin

Kd

2.621 m

d hole d pin

Load per unit length p

Hertz Stress fH 0.591

Allowable Hertz Stress

P

tm 2 tc1 2 tc2

pE

Kd

22278.14

kN

m

770.562 MPa

fHallow 2.5 Fy 887.5 MPa

fH

UChertz

0.868

fHallow

Weld check between pad-eye plate and cheek plates:

Cheek plate 1 to Pad-eye main plate

Load carried by cheek plate 1

Weld length

p c1

P tc1 tc2

tm 2tc1 2tc2

891.126 kN

wc1 2 rc1 0.942 m

PAD EYE ATTACHED TO LCB

pg 6 of 8

weldallow 0.3 70ksi 144.79 MPa

Allowable stress of E70xx weld

weld thickness required

twc1

p c1

9.237 mm

0.707 wc1 weldallow

Cheek plate 2 to cheek plate 1

Load carried by cheek plate 2

p c2

P tc2

tm 2tc1 2tc2

222.781 kN

wc2 2 rc2 0.628 m

Weld length

Allowable stress of E70xx weld

weldallow 0.3 70ksi 144.79 MPa

weld thickness required

twc1

p c2

3.464 mm

0.707 wc2 weldallow

Stress Check at Pad-Eye base

e 325mm

Vertical distance between center of pad-eye hole to base

Bending Moments:

In Plane bending moment

Out of plane bending moment

14

M IP Pinplane e 5.763 10

kN m

M OP Pout_plane e 47.063 kN m

Section Properties

a = dimension parallel to X - axis

b = dimension parallel to Y- Axis

Y - CG of element from X = 0

Z - CG of element from Y = 0

Section Depth parallel to X

d x 300mm

Section Depth parallel to Y

d y 500mm

PAD EYE ATTACHED TO LCB

pg 7 of 8

50

150

150

0

a 0 mm

0

0

150

150

i 1 9

500

25

25

0

b 0 mm

0

0

25

25

Area a b

i

Cross sectional area

250

59.5

59.5

0

Y 0 mm

0

0

440.5

440.5

100

100

0

Z 0 mm

0

0

100

100

Area 40000 mm

a b

AY Area Y

i

AYY AY Y

Ixxown

12

ai bi

Iyyown

3

AZ Area Z

i

COG from X = 0 y

AZZ AZ Z

i

AY

250 mm

12

COG from Y = 0 z

Area

Moment of Inertia about X-XIxx

Ixxown AYY

Moment of Inertia about Y-Y Iyy

Iyyown AZZ

Ixx

AY AY

Area

AZ AZ

Area

3

3

Section modulus about X-X Zxx

4.264 10 cm

max y d y y

Section modulus about Y-Y

Zyy

Iyy

max z d x z

611.111 cm

AZ

0 mm

Area

5

4

1.066 10 cm

4

4

1.833 10 cm

PAD EYE ATTACHED TO LCB

pg 8 of 8

Stress Calculations

Axial Stress

Pv

fa

72.404 MPa

A

M IP

14

fbx

1.352 10

MPa

Zxx

In Plane bending stress

Out of Plane bending stress

M OP

fby

77.011 MPa

Zyy

UCaxial

UCbx

UCby

fa

0.6 Fy

fbx

0.66 Fy

fby

0.66 Fy

0.34

0

0.329

UCcombined UCaxial UCbx UCby 0.669

Combined Shear Stress

fv

2

2

Pinplane Pout_plane

A

3.62 MPa

UCv

fv

0.4 Fy

0.025

Von Mises Stress

fx fa fbx 72.404 MPa

fy fby

fv fv

fvm

2

2

2

fx fy 3fv fx fy 75.077 MPa

UCvm

fvm

0.7 Fy

0.302

S-ar putea să vă placă și

- Lifting PadeyeDocument16 paginiLifting PadeyeLưu XuânÎncă nu există evaluări

- 2L5x3x1/2LLBB: #N/A #N/A #N/ADocument1 pagină2L5x3x1/2LLBB: #N/A #N/A #N/ARaza AidanÎncă nu există evaluări

- CEN TOOL - Standard Padeyes - V4-Rollup Padeye SheaveDocument5 paginiCEN TOOL - Standard Padeyes - V4-Rollup Padeye SheaveLaurentiu TeacaÎncă nu există evaluări

- Input Rev. NO: L + (c1 + c2) TWDocument6 paginiInput Rev. NO: L + (c1 + c2) TWMudasir MughalÎncă nu există evaluări

- Pad Eye New ReleaseDocument10 paginiPad Eye New ReleaseRaza AidanÎncă nu există evaluări

- SWI PadeyeDocument11 paginiSWI PadeyeFian ArdiyanaÎncă nu există evaluări

- Lifting Lug AnalysisDocument3 paginiLifting Lug Analysisராபர்ட் ஆன்றோ ரெனி67% (3)

- Padeye 7Document24 paginiPadeye 7Ramesh SelvarajÎncă nu există evaluări

- Pad Eye Design CalculationDocument7 paginiPad Eye Design CalculationLưu Xuân0% (1)

- Padeye DolphinDocument38 paginiPadeye DolphinMuhammad FadelÎncă nu există evaluări

- Padeye Calculation LatestDocument10 paginiPadeye Calculation LatestPavan RayÎncă nu există evaluări

- Round Bar Suppot Plate Design CalculationDocument3 paginiRound Bar Suppot Plate Design CalculationinnovativekarthiÎncă nu există evaluări

- Padeye - 01Document9 paginiPadeye - 01ramÎncă nu există evaluări

- Section Properties: Design of Padeye As Per Aisc 360-2005Document5 paginiSection Properties: Design of Padeye As Per Aisc 360-2005Fadil WimalaÎncă nu există evaluări

- Padeye .5MT CHKDocument12 paginiPadeye .5MT CHKDhanraj VasanthÎncă nu există evaluări

- Padeye8t (Without Cheek Plate)Document2 paginiPadeye8t (Without Cheek Plate)Mohd Khir Johari100% (1)

- Pad Eye StrengthDocument3 paginiPad Eye Strengthhyoung65Încă nu există evaluări

- Calculation PadeyeDocument6 paginiCalculation PadeyeAddy Sumoharjo ST100% (1)

- Seafastening Calculations Transit ModifiedDocument380 paginiSeafastening Calculations Transit ModifiedUtkarsh RamayanÎncă nu există evaluări

- DNV 2.7-3 Pad Eye Calculations For 15k Debris CatcherDocument2 paginiDNV 2.7-3 Pad Eye Calculations For 15k Debris CatcherDhanraj VasanthÎncă nu există evaluări

- LiftingLug TrunnionDocument22 paginiLiftingLug Trunnionrichardchiam100% (2)

- Star Plate Design With Sector Tubular MODIFIEDDocument14 paginiStar Plate Design With Sector Tubular MODIFIEDparvej0% (1)

- Padeye PATIDocument43 paginiPadeye PATIbayu_23RÎncă nu există evaluări

- Calculation Sheet: Padeye Calculations LoadsDocument14 paginiCalculation Sheet: Padeye Calculations Loadsandi_nu0% (1)

- Horizontal Lifting LugDocument1 paginăHorizontal Lifting LugTushar MangratiÎncă nu există evaluări

- Design of Lifting LugsDocument3 paginiDesign of Lifting LugsSaravan KumarÎncă nu există evaluări

- Lifting Lug CalculationsDocument6 paginiLifting Lug CalculationsYash RamiÎncă nu există evaluări

- Padeye Design: Project: Prepared By: Client: Date: 14-May-20 CaseDocument7 paginiPadeye Design: Project: Prepared By: Client: Date: 14-May-20 CaseFian ArdiyanaÎncă nu există evaluări

- 17 TonsDocument8 pagini17 TonsFernando Humberto100% (1)

- Padeye CheckDocument12 paginiPadeye CheckBen100% (1)

- 8 Padeye - Spreadsheet Check1Document4 pagini8 Padeye - Spreadsheet Check1oluomo1Încă nu există evaluări

- H0a C03al A1Document2 paginiH0a C03al A1iw2fualÎncă nu există evaluări

- 17 TonsDocument8 pagini17 Tonsabuzahrau100% (3)

- Padeye DesignDocument2 paginiPadeye DesignChiedu Okondu100% (1)

- LGS Seafastening Design - Revision 3Document2 paginiLGS Seafastening Design - Revision 3ksangeeth2000Încă nu există evaluări

- 17 Padeye - Spreadsheet Rev ADocument12 pagini17 Padeye - Spreadsheet Rev Aoluomo1Încă nu există evaluări

- Padeye CalculationDocument6 paginiPadeye CalculationKarun DasÎncă nu există evaluări

- LIFTING LUG Weld Check KGDocument4 paginiLIFTING LUG Weld Check KGjoerijiÎncă nu există evaluări

- Lifting Lug CalculationDocument5 paginiLifting Lug CalculationEm Mar100% (2)

- Padeye Check SttandardDocument36 paginiPadeye Check SttandardRiandi HartartoÎncă nu există evaluări

- Lifting Analysis Report - Mahadi KurniawanDocument31 paginiLifting Analysis Report - Mahadi KurniawanDian SasÎncă nu există evaluări

- Lifting Analysis GuideDocument3 paginiLifting Analysis GuideNwosu Augustine100% (1)

- Sample Section Modulas CalculationDocument18 paginiSample Section Modulas CalculationShamik ChowdhuryÎncă nu există evaluări

- Padeye Design CheekDocument3 paginiPadeye Design CheekBolarinwa89% (9)

- C4.tension Member Compatibility ModeDocument45 paginiC4.tension Member Compatibility ModejojomarbunÎncă nu există evaluări

- 321 Chapter 5 Splice DesignDocument91 pagini321 Chapter 5 Splice DesignHemant Ramesh NarkarÎncă nu există evaluări

- Design of Base PlateDocument14 paginiDesign of Base Plateruel galutanÎncă nu există evaluări

- Mathcad - Bolt Loading VDI M39 01Document10 paginiMathcad - Bolt Loading VDI M39 01Pete SwiftÎncă nu există evaluări

- TorsionDocument27 paginiTorsioncriscab12345Încă nu există evaluări

- Deep Beam TypicalDocument6 paginiDeep Beam TypicalArpit SinghÎncă nu există evaluări

- Mechanics of Materials Chap 08-02Document22 paginiMechanics of Materials Chap 08-02Melissa LaraÎncă nu există evaluări

- Skirt Support Analysis TransportDocument5 paginiSkirt Support Analysis TransportHunnymijie NorÎncă nu există evaluări

- M2-CV-RC-D-005 (R1)Document22 paginiM2-CV-RC-D-005 (R1)ksshashidharÎncă nu există evaluări

- IS 456 Fig 4: y S T Req. T Prov. T 2 2Document23 paginiIS 456 Fig 4: y S T Req. T Prov. T 2 2Rahul Aggarwal100% (1)

- IS 456 Fig 4: y S T Req. T Prov. T 2 2Document8 paginiIS 456 Fig 4: y S T Req. T Prov. T 2 2Rahul AggarwalÎncă nu există evaluări

- Column SpliceDocument6 paginiColumn SplicedudoodooÎncă nu există evaluări

- Design As Per Is-456Document23 paginiDesign As Per Is-456ALOK THAKURÎncă nu există evaluări

- Is 456 2000Document22 paginiIs 456 2000Sourav Chandra100% (1)

- Mathcad - Analysis of The ModuleDocument11 paginiMathcad - Analysis of The ModulePradeep ChitluriÎncă nu există evaluări

- Spectral Fatigue Analysis Flow ChartDocument1 paginăSpectral Fatigue Analysis Flow ChartPradeep ChitluriÎncă nu există evaluări

- HB RopeDocument104 paginiHB Ropemuhammad-ahmed-salman-2537Încă nu există evaluări

- Mathcad - Pipe Gusset PlateDocument4 paginiMathcad - Pipe Gusset PlatePradeep ChitluriÎncă nu există evaluări

- PneumaticTire - HS 810 561Document707 paginiPneumaticTire - HS 810 561Scott KimbroughÎncă nu există evaluări

- Practical Cost Saving Ideas For The Design Professionals - WeldingDocument2 paginiPractical Cost Saving Ideas For The Design Professionals - WeldingPradeep ChitluriÎncă nu există evaluări

- Mathcad - Laydown Area Deck PlateDocument3 paginiMathcad - Laydown Area Deck PlatePradeep ChitluriÎncă nu există evaluări

- WasteDocument3 paginiWastePradeep ChitluriÎncă nu există evaluări

- Fatigue Analysis (Compatibility Mode)Document80 paginiFatigue Analysis (Compatibility Mode)Pradeep Chitluri100% (1)

- Wind Loads Calculation BS6399Document3 paginiWind Loads Calculation BS6399jeddij100% (1)

- Mathcad - AB DesignDocument5 paginiMathcad - AB Designrmartinson8Încă nu există evaluări

- Motion CalcDocument4 paginiMotion CalcPradeep ChitluriÎncă nu există evaluări

- Composite Design Column Against FireDocument41 paginiComposite Design Column Against FirePradeep ChitluriÎncă nu există evaluări

- SACS TrainingDocument105 paginiSACS TrainingAli Zaidi75% (8)

- Deck Plate Timoshenko TheoreyDocument4 paginiDeck Plate Timoshenko TheoreyPradeep ChitluriÎncă nu există evaluări

- Fatigue Analyses of Offshore StructuresDocument64 paginiFatigue Analyses of Offshore Structuresgeeawhiz55100% (4)

- U S Steel Tubular Products Standard and Line Pipe PDFDocument102 paginiU S Steel Tubular Products Standard and Line Pipe PDFarmando0212-1Încă nu există evaluări

- Modelling in SACS BasicDocument26 paginiModelling in SACS BasicPradeep ChitluriÎncă nu există evaluări

- 1 Deterministic Fatigue Analysis (Compatibility Mode)Document27 pagini1 Deterministic Fatigue Analysis (Compatibility Mode)Pradeep Chitluri100% (2)

- Indian Concrete CodeDocument25 paginiIndian Concrete CodePiv0terÎncă nu există evaluări

- Theories of Failure - Combined & Direct StressesDocument36 paginiTheories of Failure - Combined & Direct StressesPradeep ChitluriÎncă nu există evaluări

- Hilbert EngDocument6 paginiHilbert EngRaphaelÎncă nu există evaluări

- Math-3 SyllabusDocument19 paginiMath-3 SyllabusPrecious Ann CostorioÎncă nu există evaluări

- Greenberg 2011Document22 paginiGreenberg 2011a4662352Încă nu există evaluări

- Pearson Geometry Two Semester Pacing CalendarDocument37 paginiPearson Geometry Two Semester Pacing Calendarapi-232815344Încă nu există evaluări

- SIEMENS - Ingenieria Mecanica 2012 08 - CENITEC 1Document141 paginiSIEMENS - Ingenieria Mecanica 2012 08 - CENITEC 1Nestor IglesiasÎncă nu există evaluări

- Plane and Solid GeometryDocument38 paginiPlane and Solid GeometryMichael FigueroaÎncă nu există evaluări

- Test 4Document6 paginiTest 4sheanÎncă nu există evaluări

- Mathematical System NewDocument68 paginiMathematical System NewAsiel Rie Raytana100% (1)

- Grade 9 Advanced Geometry Algebra 1 Course PlanDocument7 paginiGrade 9 Advanced Geometry Algebra 1 Course Planritu jalanÎncă nu există evaluări

- Relativity EssayDocument15 paginiRelativity EssayQuinto BeatleÎncă nu există evaluări

- Geometry TopicsDocument4 paginiGeometry TopicsRejieÎncă nu există evaluări

- Lines and Angles 2Document21 paginiLines and Angles 2Pratik LahotiÎncă nu există evaluări

- Summative Assessment QuestionsDocument9 paginiSummative Assessment Questionsapi-384616765Încă nu există evaluări

- SM GM Akcd L009Document3 paginiSM GM Akcd L009kimflewÎncă nu există evaluări

- Chapter 3 Lines and CirclesDocument10 paginiChapter 3 Lines and CirclesSong KimÎncă nu există evaluări

- Pair of Lines Second Degree General EquationDocument29 paginiPair of Lines Second Degree General EquationGautam100% (1)

- Om DiamondDocument48 paginiOm DiamondAbraham JyothimonÎncă nu există evaluări

- A Demonstration Lesson PlanDocument9 paginiA Demonstration Lesson PlanSylvia Estoesta100% (1)

- ReflnDocument20 paginiReflnDaniel Boenfie100% (1)

- College GeometryDocument27 paginiCollege GeometryRichard BuettnerÎncă nu există evaluări

- 3D GeometryDocument31 pagini3D GeometryavsÎncă nu există evaluări

- Perpendicular and Parallel Lines Worksheet 1Document8 paginiPerpendicular and Parallel Lines Worksheet 1eelaine kohÎncă nu există evaluări

- MS Answer Key - CK-12 Basic Geometry Concepts (Revised)Document158 paginiMS Answer Key - CK-12 Basic Geometry Concepts (Revised)adar100% (1)

- DLL Math Grade7 Quarter3 Week3Document5 paginiDLL Math Grade7 Quarter3 Week3Leizel SamsonÎncă nu există evaluări

- Exercises On Vectors Geometry in Space - IDocument9 paginiExercises On Vectors Geometry in Space - IAiko Rowyena Constantino CruzÎncă nu există evaluări

- Geometry Section 3 3Document10 paginiGeometry Section 3 3api-262621710Încă nu există evaluări

- Chapter04 PDFDocument15 paginiChapter04 PDFKumari Ujwala SinhaÎncă nu există evaluări

- Lesson PlanDocument7 paginiLesson PlanGlory Jane LuzaraÎncă nu există evaluări

- ParLine Proof PDFDocument3 paginiParLine Proof PDFanjumrajgoliÎncă nu există evaluări