Documente Academic

Documente Profesional

Documente Cultură

Skid Calc

Încărcat de

Ryan FadhliTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Skid Calc

Încărcat de

Ryan FadhliDrepturi de autor:

Formate disponibile

SKID CALCULATION SHEET

Customer

Contract No.

Project

Item

Tag No

:

:

:

:

:

MEDCO E&P INDONESIA

0

KONENG GAS STATION

PIPING PLAN FUEL GAS SYSTEM

KNG-MBF-113 & KNG-MAJ-112A/B

Revision

Date

Prepared by

Checked by

Approved by

:

:

:

:

:

0

###

NV

FL

PJN

Reference : Pressure Vessel Handbook, Eugene F. Megyesy

Material

WF 8" x 4"

SA-36

1.

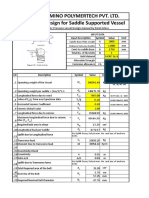

CENTER OF GRAVITY (COG) FOR ALL PIPE SPOOL

a. SECTION I (GAS SCRUBBER & PIPING)

COG

WEIGHT

b. SECTION II (FUEL GAS A FILTER & PIPING)

COG

COG

1.930 m

500.000 Kg

2.100 m

1.450 m

WEIGHT

c. SECTION III (FUEL GAS B & PIPING)

0.762 m

=

X

350.000 Kg

2.900 m

1.200 m

WEIGHT

340.000 Kg

X TOTAL x W TOTAL

2102.000 Kg.m

Y TOTAL x W TOTAL

1880.500 Kg.m

WEIGHT TOTAL

1190.000 Kg

COG

1.766 M

1.580 M

SKID CALCULATION SHEET

Customer

Contract No.

Project

Item

Tag No

:

:

:

:

:

MEDCO E&P INDONESIA

0

KONENG GAS STATION

PIPING PLAN FUEL GAS SYSTEM

KNG-MBF-113 & KNG-MAJ-112A/B

Revision

Date

Prepared by

Checked by

Approved by

:

:

:

:

:

0

###

NV

FL

PJN

1,1 CENTER OF GRAVITY (COG) FRAME SKID DETAIL

WEIGHT

COG

800 KG

1.800 M

1.350 M

1,2 CENTER OF GRAVITY (COG) FOR PACKAGE

ALL PIPE SPOOL

SKID DETAIL

WEIGHT TOTAL

COG

W.X

2102.000

KG.M

W.Y

1880.500

KG.M

W.X

1440.000

KG.M

W.X TOTAL

3542.000

KG.M

W.Y

1080.000

KG.M

W.Y TOTAL

2960.500

KG.M

1990.000

KG

4458.8 lbs

1.780

1779.9 MM

70.075 inch

1.488

1487.7 MM

58.570 inch

SKID CALCULATION SHEET

Customer

Contract No.

Project

Item

Tag No

:

:

:

:

:

MEDCO E&P INDONESIA

0

KONENG GAS STATION

PIPING PLAN FUEL GAS SYSTEM

KNG-MBF-113 & KNG-MAJ-112A/B

Revision

Date

Prepared by

Checked by

Approved by

:

:

:

:

:

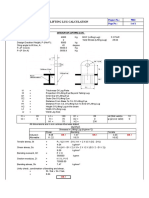

Structural analysis for lifting condition

Length of Structural Members

L1

432.0

mm

17.01

in

L2

1,860.0

mm

73.23

in

L4

3,632.0

mm

142.99

in

L5

2,667.0

mm

105.00

in

4458.834

lbs

1990.000

kg.

1860.000

mm

73.23

in

1347.899

mm

53.07

in

512.101

mm

20.16

in

2.1 Along x - axis

F

L2

a

b

Lp1

a = x - L1

b = L2 - a

The maximum bending moment of the skid is equal to either the maximum bending moment at x-axis M m1

or the maximum bending moment at y-axis Mm2, whichever is the greater.

M m 1=

Maximum bending moment along x - axis :

F.a.b

L2

65,146

in-lbs

2.2 Along y - axis

F

b

L4

4,458.83

lbs

L4

142.992

in

3,632.00

mm

58.570

in

1,487.69

mm

84.422

in

2,144.31

mm

a= y

b = L2 a

0

###

NV

FL

PJN

SKID CALCULATION SHEET

Customer

Contract No.

Project

Item

Tag No

:

:

:

:

:

MEDCO E&P INDONESIA

0

KONENG GAS STATION

PIPING PLAN FUEL GAS SYSTEM

KNG-MBF-113

b = L a & KNG-MAJ-112A/B

:

:

:

:

:

154,185

in-lbs

154,185

in-lbs

M m 2=

Maximum bending moment at y - axis :

F.a.b

L2

Mmax.

Therefore, maximum bending moment of skid at lifting condition :

Revision

Date

Prepared by

Checked by

Approved by

Bending stress and deflection of skid in lifting condition

WF 300x150x6.5x9 mm

Skid material

SA-36

Number of parallel beams

t

h

Yield stress

N

Sy

36,000

psi

Allowablel bending stress

Sa

24,000

psi

1.43

in3

200

mm

7.874

in.

Minimum required section modulus

Z MIN =

M max

Sy N

s

Beam Dimensions :

h = d - 2s

Moment of Inertia

Ix=

80

mm

3.150

in.

7.5

mm

0.295

in.

90

mm

3.543

in.

11.3

mm

0.445

in.

160

mm

6.299

in.

76.496

in4

19.430

in3

2.90E+07

psi

7.440

2,645.14

psi

Sb

<

Sa

OK

[ bd 3 h 3 ( bt ) ]

12

[ bd 3 h3 ( bt ) ]

Z x=

(6 d )

Section Moduluis

Modulus of Elasticity

A =bd[ h ( bt ) ]

Area

Bending Stress of Skid in Lifting Condition

S b=

4

M max

Z x N

sq.in.

Deflection of skid in lifting condition.

F

a

X - axis

b

R1

R2

4,458.83

lbs.

L = L2

73.23

in.

a = x-L1

53.07

in.

b = L2 - a

20.16

in.

0.04

in.

L4

Maximum allowable deflection

( L2 b2 )

Fb

Da =

3 EI x L

3

Dd=

Fa 2 b 2

3 EI x L

0

###

NV

FL

PJN

SKID CALCULATION SHEET

Customer

Contract No.

Project

Item

Tag No

:

:

:

:

:

MEDCO E&P INDONESIA

0

KONENG GAS STATION

PIPING PLAN FUEL GAS SYSTEM

KNG-MBF-113 & KNG-MAJ-112A/B

2 2

Dd=

Actual deflection of skid in lifting condition

Revision

Date

Prepared by

Checked by

Approved by

Fa b

3 EI x L

:

:

:

:

:

0.01

in.

<

Da

OK

L = L2

73.23

in.

a=y

58.57

in.

b=L-a

14.66

in.

0.029

in.

0.007

in.

<

Da

OK

Dd

0

###

NV

FL

PJN

F

a

b

Y - axis

R1

R2

L2

Maximum allowable deflection

( L2 b2 )

Fb

Da =

3 EI x L

3

Actual deflection of skid in lifting condition

Dd=

Fa 2 b 2

3 EI x L

Dd

Design of Lifting Lug.

Material

SA 36

Minimum yield strength of material (Sy)

=

36,000

psi.

14,400

psi.

Allowable Shear Stress (Sa)

S a =0 . 4S y

Weight of piping + structural support + weight of equipment

4,458.83

Number of lugs

4.00

Load Factor

2.00

Thickness of lifting lug, selected

1.00

in.

2,229.42

lbs.

Vertical Load

Pv =

Angle between Sling Load and Vertical Load

Sling Load

Ps =

Pv

lbs.

cos

Use the greater value of Ps

W F

N

lbs.

15

35

40

45

2,308.06

2,721.62

2,910.30

3,152.87

Ps

For 4459 lbs load, select from Table on page 119 of Pressure Vessel Handbook :

3,152.87

lbs.

SKID CALCULATION SHEET

Customer

Contract No.

Project

Item

Tag No

:

:

:

:

:

MEDCO E&P INDONESIA

0

KONENG GAS STATION

PIPING PLAN FUEL GAS SYSTEM

KNG-MBF-113 & KNG-MAJ-112A/B

Revision

Date

Prepared by

Checked by

Approved by

:

:

:

:

:

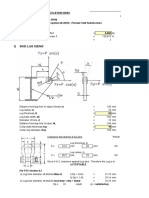

Shackle Pin Diameter for a load of 6375 lbs.

0.875

in.

Lug Hole Diameter

1.000

in.

Lug Radius (designed)

1.500

in.

0.11

in.

lbs.

Required Thickness of Lug

Ps

t r=

2 S y R

D

2

Selected thickness is more than adequate !

5.1 Strength of Fillet Weld of Lifting Lug.

Allowable Concentrated Axial Load Pa = Ps

Pa

3,152.87

Length of Weld

Aw

8.00

in.

9.60

kips/in2

Allowable Load on Weld

Load on Fillet Weld

W=

Pa F

A w10 3

Fillet Weld Leg Dimension

w=

W

f

0.788

kips/lin.in

0.082

in.

0.300

in.

fillet weld

Use fillet weld leg

5.2 Check for Bearing Stress.

Allowable Bearing Stress

S b =0 . 9S y

32,400

psi.

Ps

3,152.87

lbs.

Length of Pin Contact l = lug thickness t

1.000

in.

Shackle pin diameter

0.875

in.

PS

ld

3,603

psi.

SbP

<

Sb

OK

Sling Load

Bearing stress in the lug

S bP=

5.3 Check for Shear Stress.

Allowable Shear Stress

S S =0 . 4S y

14,400.00

psi.

Ps

3,152.87

lbs.

Lug Radius

1.500

in.

Lug Hole Diameter

1.000

in.

1,576

psi.

<

SS

OK

Sling Load

Shear Stress in Lug

S SP =

PS

2 t R

2)

SSP

0

###

NV

FL

PJN

SKID CALCULATION SHEET

Customer

Contract No.

Project

Item

Tag No

:

:

:

:

:

MEDCO E&P INDONESIA

0

KONENG GAS STATION

PIPING PLAN FUEL GAS SYSTEM

KNG-MBF-113 & KNG-MAJ-112A/B

Revision

Date

Prepared by

Checked by

Approved by

:

:

:

:

:

5.4 Check for Bending Stress.

Lifting Lug Dimensions

Bending Load

Allowable Bending Stress

Maximum Bending Moment

in.

b

c

in.

5.500

in.

1.00

in.

Pb =5 PS F

315.29

lbs.

S B=0 .66S y

23,760.00

psi.

M B max =Pb a

1,261.15

in-lb.

2.90E+07

psi.

0.67

in4

1.33

in3

945.86

<

SB

OK

0.0111

in.

0.000348

in.

Modulus of Elasticity

E

3

Moment of Inertia

Section Modulus

Bending Stress

bh

12

2

bh

Z=

6

M B max

S BP=

Z

I=

SBP

5.5 Deflection of Lug in Lifting Condition.

Maximum Allowable Deflection

(per STAAD pro 2004 manual)

a=

a

360

3

Deflection of Lug in Lifting Condition

Pb a

L=

3 EI

0

###

NV

FL

PJN

SKID CALCULATION SHEET

Customer

Contract No.

Project

Item

Tag No

:

:

:

:

:

MEDCO E&P INDONESIA

0

KONENG GAS STATION

PIPING PLAN FUEL GAS SYSTEM

KNG-MBF-113 & KNG-MAJ-112A/B

Revision

Date

Prepared by

Checked by

Approved by

L

<

:

:

:

:

:

OK

0

###

NV

FL

PJN

S-ar putea să vă placă și

- Saddle CalculationDocument7 paginiSaddle CalculationMichael HaiseÎncă nu există evaluări

- Grade Slab ACI-150thkDocument7 paginiGrade Slab ACI-150thkMUTHUKKUMARAM100% (1)

- CalculationDocument15 paginiCalculationTohid Karimi67% (3)

- Beam Shear TabDocument13 paginiBeam Shear TabGautam SharmaÎncă nu există evaluări

- Line Stop Welded To Shoe CalculationDocument4 paginiLine Stop Welded To Shoe CalculationpipestressÎncă nu există evaluări

- Lug Design (XLS)Document4 paginiLug Design (XLS)Bhartendu Patni100% (1)

- Lifting LugDocument24 paginiLifting LugMas Arman Tewo100% (6)

- Skid Lifting and Skid Design As Per ASCE PDFDocument183 paginiSkid Lifting and Skid Design As Per ASCE PDFTeju Ashu100% (1)

- Saddle DesignDocument6 paginiSaddle DesignPankajDhobleÎncă nu există evaluări

- Skid Structure Calculation Rev.a - MBD - APPROVEDDocument45 paginiSkid Structure Calculation Rev.a - MBD - APPROVEDnamasral100% (6)

- Lifting Beam CalculationDocument2 paginiLifting Beam Calculationராபர்ட் ஆன்றோ ரெனி100% (4)

- Pump+Turbine - Foundation Design SpreadsheetDocument26 paginiPump+Turbine - Foundation Design Spreadsheetnpwal88% (8)

- Design of Conical Storage TankDocument17 paginiDesign of Conical Storage TankvijaypatelnewtonÎncă nu există evaluări

- Design Calculation For Column Skirt SupportDocument5 paginiDesign Calculation For Column Skirt SupportRitesh VishambhariÎncă nu există evaluări

- Skid Lifting Lug DesignDocument3 paginiSkid Lifting Lug Designmahhor82_635643838Încă nu există evaluări

- Pad Eye New ReleaseDocument10 paginiPad Eye New ReleaseRaza AidanÎncă nu există evaluări

- Lifting Lug DesignDocument27 paginiLifting Lug Designmramico100% (1)

- XXX-XXXX-XXX - Details of Completion Skid Structural Calculation ReportDocument33 paginiXXX-XXXX-XXX - Details of Completion Skid Structural Calculation Reportsridhar100% (1)

- Mathcad - Control Room - Depth 3mDocument14 paginiMathcad - Control Room - Depth 3mJuli NirwantoÎncă nu există evaluări

- Strength Calculation of Skid For Indirect HeaterDocument19 paginiStrength Calculation of Skid For Indirect HeaterDIANTORO100% (1)

- Structure Skid Frame ReportDocument25 paginiStructure Skid Frame ReportNama PejaÎncă nu există evaluări

- Design of Tail LugDocument34 paginiDesign of Tail LugPrajwal Shetty100% (1)

- Mathcad - Spreader Beam Design Calculations As Per DNV 5th VerDocument29 paginiMathcad - Spreader Beam Design Calculations As Per DNV 5th VerAbderraoufAffes100% (3)

- Engineering Fundamentals of The Internal Combustion Engine - Willard W. PulkrabekDocument425 paginiEngineering Fundamentals of The Internal Combustion Engine - Willard W. Pulkrabekmi2jaca100% (2)

- Design Calculation R1 PDFDocument14 paginiDesign Calculation R1 PDFJagankumarÎncă nu există evaluări

- Anchor Bolt Calc.Document1 paginăAnchor Bolt Calc.nishant131100% (1)

- Boiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFDocument4 paginiBoiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFAlexandru AsmarandeiÎncă nu există evaluări

- Lifting Lug - Skid - 2018.07.16Document4 paginiLifting Lug - Skid - 2018.07.16RaghÎncă nu există evaluări

- Lifting Lug DesignDocument7 paginiLifting Lug DesignadammzjinÎncă nu există evaluări

- Calculation Lifting LugDocument4 paginiCalculation Lifting Lugelang purbayaÎncă nu există evaluări

- Saddle AnalysisDocument17 paginiSaddle AnalysisPEJU0007Încă nu există evaluări

- Tailing Lug - 173004-05Document1 paginăTailing Lug - 173004-05shazan100% (1)

- Lifting Lug Cal PDFDocument1 paginăLifting Lug Cal PDFveeru2906Încă nu există evaluări

- T208 Bored Pile Design - XLSXDocument3 paginiT208 Bored Pile Design - XLSXerikaren85Încă nu există evaluări

- Report Rectangular Tank - REV 0 - 28.11.12Document26 paginiReport Rectangular Tank - REV 0 - 28.11.12JijinJohn100% (1)

- Lug Design R4, ASME BTH-1Document4 paginiLug Design R4, ASME BTH-1chuckhsu1248Încă nu există evaluări

- Simply Support Beam. Centre LoadDocument7 paginiSimply Support Beam. Centre LoadjhsompuraÎncă nu există evaluări

- Flat Plate - Roark & YoungDocument15 paginiFlat Plate - Roark & YoungPrasad Pingle0% (1)

- 44.lifting Lug With Collar CalculationDocument44 pagini44.lifting Lug With Collar CalculationAnonymous AyDvqg100% (1)

- Client Comment Response - DG FoundationDocument7 paginiClient Comment Response - DG FoundationAnnelzÎncă nu există evaluări

- Design of Flanges - Loose Hub Type 2010Document58 paginiDesign of Flanges - Loose Hub Type 2010bakellyÎncă nu există evaluări

- Design Calculation LiftingDocument19 paginiDesign Calculation LiftingAbu Al Sayyid100% (1)

- SSF Skid Analysis & Design - Doc Rev ADocument19 paginiSSF Skid Analysis & Design - Doc Rev AsridharÎncă nu există evaluări

- Lifting Lug DesignDocument18 paginiLifting Lug DesignRui Salvador0% (1)

- Tailing LugDocument12 paginiTailing LuguvarajmecheriÎncă nu există evaluări

- Spreader Bar Plus Free BodyDocument17 paginiSpreader Bar Plus Free BodyMichael HaiseÎncă nu există evaluări

- 28 Roark Flat PlatesDocument4 pagini28 Roark Flat PlatesJorge Silva100% (1)

- Weldstrength Calc ProgDocument10 paginiWeldstrength Calc ProgSajal KulshresthaÎncă nu există evaluări

- Lifting LugDocument7 paginiLifting LugSajal KulshresthaÎncă nu există evaluări

- BlindDocument3 paginiBlindSajal KulshresthaÎncă nu există evaluări

- Design of Foundation For Highway Signs Under Good Soil ConditionsDocument43 paginiDesign of Foundation For Highway Signs Under Good Soil ConditionsKuang Ngang EÎncă nu există evaluări

- Mathcad - Spreader Bar FinalDocument4 paginiMathcad - Spreader Bar FinalOkondu Chiedu100% (3)

- Structural TrunnionDocument4 paginiStructural TrunnionecsalomÎncă nu există evaluări

- Lifting LugsDocument2 paginiLifting LugsAdi Cahyoko82% (11)

- Three Saddle Supports For Horizontal VesselDocument7 paginiThree Saddle Supports For Horizontal VesselhuangjlÎncă nu există evaluări

- Concrete DesignDocument169 paginiConcrete DesignabuzahrauÎncă nu există evaluări

- Support Leg DesignDocument4 paginiSupport Leg DesignDeepika0% (2)

- Design and Verification of Lifting LugsDocument3 paginiDesign and Verification of Lifting LugsFabio Okamoto100% (1)

- FM-Approval Standard For Deluge and Pre-Action Sprinkler SystemDocument68 paginiFM-Approval Standard For Deluge and Pre-Action Sprinkler Systemngockhoaps100% (1)

- Lifting Trunnion AnalysisDocument1 paginăLifting Trunnion Analysisprajwal86Încă nu există evaluări

- Determination of Maximum Span Between Pipe Support Using Bending Stress TheoryDocument4 paginiDetermination of Maximum Span Between Pipe Support Using Bending Stress TheoryMannattil Krishna KumarÎncă nu există evaluări

- Fe Report of Base SkidDocument16 paginiFe Report of Base SkidpawanÎncă nu există evaluări

- N2XRY 3 X (1.5-300) MM 0.6/1 KVDocument1 paginăN2XRY 3 X (1.5-300) MM 0.6/1 KVRyan FadhliÎncă nu există evaluări

- API 6D - E24 PADocument5 paginiAPI 6D - E24 PAsaulogarciaÎncă nu există evaluări

- Qpedia Apr09 Basic Principles of Wind Tunnel Design9Document3 paginiQpedia Apr09 Basic Principles of Wind Tunnel Design9Ryan FadhliÎncă nu există evaluări

- TurbulenceDocument69 paginiTurbulenceRegis NgenziÎncă nu există evaluări