Documente Academic

Documente Profesional

Documente Cultură

Brazil 2014ugm Torpedo Anchor in Seabed PDF

Încărcat de

islamDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Brazil 2014ugm Torpedo Anchor in Seabed PDF

Încărcat de

islamDrepturi de autor:

Formate disponibile

FEM Modelling of the Torpedo Anchor

Penetration in the Seabed

Pedro Henrique Epichin Cheroto

www.esss.com.br

Topics

PAGE 2

General Idea

Motivation

Overview

Geometry

Material

Meshing

Solution

Results

Final Remarks

www.esss.com.br

Torpedo Anchor General Idea

PAGE 3

What is a Torpedo Anchor?

What is its use?

www.esss.com.br

Torpedo Anchor Motivation

PAGE 4

Torpedo Anchor modelling in Ansys

Goal: correctly predict the anchor pull-out capacity

The soil displacement during the

penetration causes an increased stress

and pore pressure on the regions near

the anchor, resulting in a reduced pullout resistance. Subsequent soil

reconsolidation will provide a recovery

of the pull-out capacity.

Today we focuse on the

stationary solution, were the

pore pressure field is

consolidated. Pore pressure

relaxed to stationary condition

result in larges effective stress

in the soil and the largest pull

out capacity.

The pullout resistance is mostly

caused by the shear strength in the

soil-anchor interface which is greatly

affected by the reconsolidation time

after the installation.

We do not model the

interface capacity. The

anchor pull-out capacity

is limited by the soil

material limits.

www.esss.com.br

Torpedo Anchor Overview

PAGE 5

Analysis Overview

Model Based on paper from Sturm H. and Andresen L (2010)

Automated model in Ansys APDL to generate the geometry, mesh,

contacts, loads and solution config.

Model with ineherent Ansys material models for soil - drucker

prager.

Model with multiPlas materials for soil

Tresca

Mohr Coulomb

www.esss.com.br

Torpedo Anchor Geometry

PAGE 6

Geometry

Axissimetric Model

Small gap between axissimetric axis and geometry, to prevent

mesh distortion problems, based on assumption of Cudmani and

Sturm (2006)

www.esss.com.br

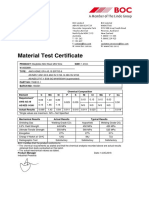

Torpedo Anchor Material

PAGE 7

Material

The material model used for the soil in this case is Tresca, from the

multiPlas material library

A region with reduced stiffness was created to simulate an infinite

domain, based on a proposal from Burd and Houslby (1990)

The torpedo anchor was modelled with as a rigid line

Region with reduced

stiffness.

Torpedo

anchor

modelled as

rigid line.

www.esss.com.br

Torpedo Anchor Meshing

PAGE 8

Meshing

Initially mapped mesh, with rezoning after initial penetration

www.esss.com.br

Torpedo Anchor Solution

PAGE 9

Solution

Quasistatic solution, with many substeps for stability and accuracy

Rezoning to solve convergence issues

Large strains create large mesh distortions

www.esss.com.br

Torpedo Anchor Results

PAGE 10

Results

With mises and tresca failure: Radial stress results comparison.

Similar contours.

Radial Stress contours in

Abaqus model

Radial Stress Contours in Ansys

www.esss.com.br

Torpedo Anchor Results

PAGE 11

Results

With mises and tresca failure: Normalised Stress Components.

Very similar results, with small differences near the torpedo anchor

interface with the soil.

Normalised Stress Components Abaqus

Normalised Stress Components - Ansys

www.esss.com.br

Torpedo Anchor Results

PAGE 12

Results

With mises and tresca failure: Residual stresses and Strains.

Same behavior on both models, the stresses on the near wall region

after the installation of the anchor are higher on Ansys models

Strain at midheight of the anchor and Radial above the

anchor, after installation - Abaqus

Strain at midheight of the anchor and Radial above the

anchor, after installation - Ansys

www.esss.com.br

Torpedo Anchor Results

PAGE 13

Results

With mises and tresca failure: Normalized stress results over time

at depth 5.8m, 0.3 meters away from the anchor

Again, very similar results, with slightly different values after the anchor

insertion.

Normalized stresses during penetration Abaqus

Normalized stresses during penetration - Ansys

www.esss.com.br

Torpedo Anchor Results

PAGE 14

Additional remarks

Although the mohr-coulomb and drucker prager material models

can be used to model more realistic materials, on this particular

case, experimental data would be required to define the material

parameters.

The normalized results of ansys and abaqus are almost the same,

but the paper used does not give the exact material parameters, so

the actual results will differ.

The results from simulations using Tresca and Mises failure were

almost the same. For that reason, the images in this report are

from only one of the simulations the one using tresca failure

criteria.

www.esss.com.br

References

PAGE 15

Cudmani, R. and H. Sturm (2006).An investigation of the tip

resistance in granular and soft soils during static, alternating

and dynamic penetration. In H. Gonin, A. Holeyman, and F.

Rocher-Lacoste (Eds.), TransVib 2006: International

Symposium on vibratory pile driving and deep soil compaction,

pp. 221231.

Burd, H. and G. Houlsby (1990). Finite Element Analysis of two

Cylindrical Expansion Problems involving nearly Incompressible

Material Behaviour. International Journal for Numerical and

Analytical Methods in Geomechanics 14(5), 351366.

Sturm, H. and Andresen, L. (2010). Large deformation analysis

of the installation of Dynamic Anchor. Numerical Methods in

Geotechnical Engineering Benz & Nordal (eds) 2010 Taylor &

Francis Group

www.esss.com.br

S-ar putea să vă placă și

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Lab 8 Teknologi ElektrikDocument9 paginiLab 8 Teknologi ElektrikAten RamÎncă nu există evaluări

- Magnetism Guided NotesDocument14 paginiMagnetism Guided Notesdericksonj32Încă nu există evaluări

- CHEM31.1 ATQ3 SantosDocument2 paginiCHEM31.1 ATQ3 SantosClaire SantosÎncă nu există evaluări

- Outline Physical Geography For CssDocument35 paginiOutline Physical Geography For CssUsman Shahid JuttÎncă nu există evaluări

- Construction and Building Materials: Ngoc Hieu Dinh, Hai Van Tran, Kyoung-Kyu ChoiDocument14 paginiConstruction and Building Materials: Ngoc Hieu Dinh, Hai Van Tran, Kyoung-Kyu ChoiArindam SarkarÎncă nu există evaluări

- Webinar Series: Applying Rules and Standards When Analysing Structural DesignDocument47 paginiWebinar Series: Applying Rules and Standards When Analysing Structural DesignPaulo MoreiraÎncă nu există evaluări

- Turbine DeatailDocument17 paginiTurbine DeatailShambhu MehtaÎncă nu există evaluări

- Prosper IntroductionDocument17 paginiProsper Introductionashraff09Încă nu există evaluări

- Solar DesalinationDocument41 paginiSolar DesalinationRahul TripathiÎncă nu există evaluări

- Unsteady Flow Visualisation T Akes The Heat Out of Hot SpotsDocument2 paginiUnsteady Flow Visualisation T Akes The Heat Out of Hot SpotsDeepak Chachra100% (1)

- Wire Certificate 706B12!1!180301Document1 paginăWire Certificate 706B12!1!180301mehdiÎncă nu există evaluări

- Mee2161 Fluid Mechanics - 2021Document99 paginiMee2161 Fluid Mechanics - 2021dany rwagatareÎncă nu există evaluări

- DWDM Mux PDFDocument7 paginiDWDM Mux PDFChavez CheloÎncă nu există evaluări

- Physics ProjectDocument16 paginiPhysics ProjectSukalpo BanerjeeÎncă nu există evaluări

- Service Manual Aquantia-R32-Pro-Bibloc-Wall-Mounted-EngDocument114 paginiService Manual Aquantia-R32-Pro-Bibloc-Wall-Mounted-EngGuido Berra0% (1)

- Investigation Seismic Behaviour of Hollow-Core SlaDocument9 paginiInvestigation Seismic Behaviour of Hollow-Core SlaVitor BrancoÎncă nu există evaluări

- Practice Problems For Advanced Vibrations: April 2019Document36 paginiPractice Problems For Advanced Vibrations: April 2019Animesh ChandraÎncă nu există evaluări

- Waves and TidesDocument13 paginiWaves and TidesDiana Morales100% (1)

- Problems in A-Level PhysicsDocument201 paginiProblems in A-Level Physicsweews97% (36)

- Spraytech Ed - 2 Air AtomizingDocument20 paginiSpraytech Ed - 2 Air AtomizingsatishÎncă nu există evaluări

- Two Storey Residential BuildingDocument52 paginiTwo Storey Residential BuildingMaiko Laine CarbonelÎncă nu există evaluări

- SN04Document4 paginiSN04Cherascu LiviuÎncă nu există evaluări

- Jet Engine Operation and Malfunctions Basic Familiarization For Flight Crews-2Document37 paginiJet Engine Operation and Malfunctions Basic Familiarization For Flight Crews-2Natalia ClavijoÎncă nu există evaluări

- MD Problem Set 2Document2 paginiMD Problem Set 2Cllyan ReyesÎncă nu există evaluări

- Measuring Rates of ReactionDocument3 paginiMeasuring Rates of Reactionbob turnerÎncă nu există evaluări

- Chapter 6Document67 paginiChapter 6dodaÎncă nu există evaluări

- Troubleshooting and Mitigating Gels in Polyethylene Film ProductsDocument24 paginiTroubleshooting and Mitigating Gels in Polyethylene Film ProductsTHEREZA TORRES BLANCASÎncă nu există evaluări

- CE 420 CEM 402 Study Guide - Structural TheoryDocument5 paginiCE 420 CEM 402 Study Guide - Structural TheoryKaryl Briant FloresÎncă nu există evaluări

- Relacion de Normas DVS PDFDocument8 paginiRelacion de Normas DVS PDFNeto Paucar ChancaÎncă nu există evaluări

- Cross Section Area in MM: Enter The THK-T in MM Enter The Deg-DDocument7 paginiCross Section Area in MM: Enter The THK-T in MM Enter The Deg-DAnas MaliyekkalÎncă nu există evaluări